Abstract

Iron hydroxide supported onto porous diatomite (D-Fe) is a low-cost material with potential to remove arsenic from contaminated water due to its affinity for the arsenate ion. This affinity was tested under varying conditions of pH, contact time, iron content in D-Fe and the presence of competitive ions, silicate and phosphate. Batch and column experiments were conducted to derive adsorption isotherms and breakthrough behaviours (50 μg L−1) for an initial concentration of 1,000 μg L−1. Maximum capacity at pH 4 and 17 % iron was 18.12–40.82 mg of arsenic/g of D-Fe and at pH 4 and 10 % iron was 18.48–29.07 mg of arsenic/g of D-Fe. Adsorption decreased in the presence of phosphate and silicate ions. The difference in column adsorption behaviour between 10 % and 17 % iron was very pronounced, outweighing the impact of all other measured parameters. There was insufficient evidence of a correlation between iron content and arsenic content in isotherm experiments, suggesting that ion exchange is a negligible process occurring in arsenate adsorption using D-Fe nor is there co-precipitation of arsenate by rising iron content of the solute above saturation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Arsenic’s high toxicity and its widespread environmental occurrence have been recognised as a cause for worldwide public health concern. For example in Bangladesh and India alone, it is estimated that up to 150 million people are exposed to arsenic-contaminated groundwater. Much attention has been given to establishing exposure limits as well as techniques that allow for its better monitoring and control. The World Health Organization (WHO) has set a provisional guideline value for arsenic in drinking water of 10 μg L−1. Many countries have accordingly lowered their drinking water limits in response to increasing recognition of groundwater arsenic problems (WHO 2008; Melamed 2005; Smedley and Kinniburgh 2002).

Methods to reduce arsenic in water supplies have focussed on well-established properties such as arsenic’s high adsorption affinity for metal oxides and hydroxides. This can be a natural process that mitigates against major toxicity problems in the environment and is therefore a basis for many adsorption-based removal technologies (Henke 2009).

In adsorption processes, ions are attracted when the surface of the solid substrate (adsorbent) is of an opposite charge and adsorption is low when the surface is neutral or has the same charge. When physical rather than chemical adsorption occurs, such adsorption is driven by non-selective competition between ions of similar charge that bind (electrostatic-coulumbic, electro-kinetic or van der Waal forces) to the surface charge of the solid. This attraction is very strongly pH dependent. The point of zero charge (PZC) or iso-electric point is used to measure the ability of a given surface to attract ions. Thus at pH of PZC, an equal number of positively and negatively charged surface sites exist, and below and above this pH the surface becomes positively or negatively charged. (Crittenden and Thomas 1998; Everett 1998; Inglethorpe et al. 1999; Asano et al. 2007).

Arsenate anions predominate in oxygenated water with a pH range from 2 to 14. Therefore electrostatic attraction of anionic arsenate is favoured onto positively charged surfaces. Arsenite is not likely to be found in ionic form and is the predominant species under reducing conditions, thus being less likely to be adsorbed onto metal oxy-hydroxides (Goldberg and Johnston 2001).

Adsorption behaviour can be accurately modelled through the use of an isotherm which is a way to interpret and fit specific observations into general adsorption data without providing information on the adsorption mechanism. Freundlich and Langmuir equations are the most used and best explained models both being variants of the mass action law, either simplifications, or with added electrostatic terms (Everett 1998; Asano et al. 2007).

There are many factors to be considered when choosing the best technology for treating contaminated water including not only effective removal from a quantitative/technological viewpoint but also a method that suits specific socioeconomic and geo-demographic conditions, and as such the best solutions commonly are a combination of methods. For example, an effective and commonly used material for removal of organic pollutants by adsorption is activated carbon, but its use may be precluded by its relative expense. (Ruthven 1984; Baruth 2005; Garelick et al. 2009).

A readily available and cheap material that may be effective in removing arsenic is modified diatomite. Raw diatomite is formed from fossilised remains of diatoms, a common type of phytoplankton and it is an abundant mineral whose main constituent is silicon dioxide followed by aluminium oxide and iron oxide. Previous studies using calcined, raw and modified (iron and manganese-coated) diatomite have reported the removal of arsenic from contaminated water to a maximum absorption of approximately 60 mg/g adsorbent, corresponding to over 300 mg/g expressed as milligramme As per gramme Mn or Fe (Table 1). By coating diatomite with iron the pH of PZC is increased, reported values of raw diatomite are around 6 and for diatomite coated with iron, hydrous ferric oxide and granular ferric oxides the pH of ZPC is 8 (Kosmulski 2009; Chang et al. 2009).

Competing ions can affect arsenic adsorption. Silicate and more pronouncedly phosphate are similar to arsenate ions in structure and solubility and have been shown to be major competitors in arsenate adsorption (Chang et al. 2009).

Previous investigations into the sorption of arsenate by media adsorbents, more specifically iron-coated substrates, such as diatomite, have modelled, characterised or investigated the sorption capacities and kinetics without examining in depth the mechanism underpinning such adsorption. This paper considers one mechanism suggested by pioneering studies on arsenic sorption by diatomite made by Inglethorpe in 1999 where ion exchange was presumed to be involved (Inglethorpe et al. 1999; Aragon and Thompson 2005; Chen et al. 2007).

The work presented here provides further evidence on the adsorption of arsenic onto iron-modified diatomite under different conditions and considers in more detail breakthrough behaviour using isotherm and column experiments. This paper offers further evidence on the effect of the strongest competing ions and provides further tools for an optimal selection of process parameters namely pH, contact time and iron content in the modified media.

Materials and methods

All bottles, glassware and columns were washed with alkaline laboratory detergent (Fisher Scientific, UK), allowed to soak overnight in 10 % HNO3 solution, triple rinsed with deionised water (Purite, 18.2 MΩ) and allowed to air dry. All experiments were undertaken at ambient temperature (22–26 °C).

Media preparation

The diatomite material used in this study originated from Aktyubinsk, Kazakhstan. It was treated with HCL in a previous experiment (Bakr 2010). Diatomite was crushed in a mortar and then oven-dried at 105 °C prior to weighing. The modification of diatomite with iron (hereafter referred to as D-Fe) was carried out as described elsewhere (Winchester et al. 2001). Briefly, diatomite was mixed in a solution containing two different amounts of ferric chloride (0.9 M) to achieve two contrasting levels of coating and the mixture was left to sit overnight while stirring. Then equimolar amounts of sodium hydroxide (2.14 M) were slowly added until the mixture reached pH 9 to precipitate iron hydroxide into the complex. The iron-coated diatomite was then washed with deionised water and filtered using qualitative filter paper. The D-Fe was dried at 105 °C overnight then ground and sieved using standard laboratory test sieves to obtain a particle size range of 75 to 250 μm.

Media characterisation

The D-Fe was characterized by density determination and by scanning electron microscopy (SEM) using a Cambridge stereoscan 240 scanning electron microscope. Microwave acid digestion (Method EPA 3051A, 2007) followed by ICP-OES (Thermo-Scientific iCap 6500 ICP) analysis determined the iron concentration and the efficiency/capacity of the iron coating process as well as the arsenic content.

Arsenic and iron analysis

Arsenic (V) was prepared using sodium arsenate Na2HAsO4.7H2O (Sigma-Aldrich UK, laboratory reagent grade) diluted in deionised water. The pH was tested and adjusted as required using buffer solutions: potassium hydrogen phthalate (Fisher Scientific) and potassium carbonate/potassium tetraborate/potassium hydroxide/disodium EDTA dihydrate (Fisher Scientific).

All samples were collected in 25 mL glass vials and analysed within 24 h. Total arsenic and iron were measured using ICP-OES. Calibration curves (10, 100, 500, 750, 1,000 and 10,000 μg L−1) were prepared for iron and arsenic. The method detection limits were 46 and 59 μg L−1 for arsenic and iron, respectively.

Isotherm experiments

Adsorption of arsenic using raw diatomite has been studied in the past and is considered to be insignificant (Inglethorpe et al. 1999; Wu et al. 2005), see Table 1. Thus, only iron-coated diatomite was used in this study. For the isotherm experiments, pseudo equilibrium time was set at 48 h. Previous kinetic studies found that the rate of change was minimal after 12 h and equilibrium was reached after 24 h and therefore the 48-h period chosen was considered appropriately conservative (Bakr 2010).

Freundlich and Langmuir isotherms were calculated by two experimental methods:

-

1.

Fixed amount of adsorbate (arsenic V), varying amount of adsorbent (D-Fe)

Screw-top polyethylene batch reactors (50 mL) were filled with 45 mL of 10 mgL−1 arsenic (V) solution of pH 4, 7 and 10, containing a varying amount of D-Fe (10 % and 17 %) (0.001, 0.01, 0.1, 0.5 and 1 g). The batch reactors were mixed in an orbital shaker (IKA KS-130) for 48 h. After equilibrium, the reactors were centrifuged for 4.5 min at 4,400 rpm. The supernatant was taken to 25-mL glass vials to measure arsenic and iron content. A control experiment, without the addition of D-Fe, was performed for each condition.

-

2.

Fixed amount of adsorbent (D-Fe), varying amount of adsorbate (arsenic V)

The procedure followed the previous conditions but using 45 mL of different arsenic (V) solutions (0.5, 1, 2, 5, 10 mg L−1) at pH 4 and 7 and two sets of fixed amount (0.01 and 0.045 g) of D-Fe (10 % and 17 %).

Effect of competitive ions

The effect of the presence of phosphate and silicate was investigated as follows: 50 mL screw top polyethylene batch reactors were filled with:

-

Forty-five millilitre of solution containing 10 mg L−1 of arsenic (V) and 10 mg L−1 of phosphate (as trisodium orthophosphate dodecahydrated, Na3PO4.12H2O, Sigma Aldrich) for the phosphate effect or

-

Forty-five millilitre of solution containing 10 mg L−1 of arsenic (V) and 10 mg L−1 of silicate (as sodium silicate, 2SiO2:Na2O, Fisher Scientific) for the silicate effect

A control experiment was performed for each condition with no competitive ions added. A fixed amount of D-Fe (17 %) (0.1 g) was added to the reactors. The same procedure was followed as with the isotherm experiments. The concentration of the competing ions used was not intended to be representative of environmental waters but to provide concentrations of a similar order of magnitude to the arsenic being tested and thus provide a high level of competitive ions, since preliminary experiments using low concentrations of the competing ions did not adversely impact arsenic adsorption.

Rapid small-scale column test experiments

The rapid small-scale column test (RSSCT) consisted of 6 mL polypropylene solid phase extraction tubes (Supelco), fitted with 20 μm pore polyethylene frits, glass wool, 10 mL syringe pistons (used as caps and connectors) and two-stop PVC tubing. The column set-up is shown in Fig. 1.

Columns were packed with 1.5 and 2.5 g D-Fe with different iron contents. The D-Fe was submerged in deionised water for at least 1 h prior to column loading and the complex was packed wet to avoid air entrapment. A D-Fe particle size of 0.1625 mm was used, yielding a ratio of column inner diameter to adsorbent particle diameter of 13/0.1625 = 80, (a minimum of 50 is recommended) which in theory may suppress wall and channelling effects (Crittenden et al.1986). Arsenic (V) solution of 1 mg L−1 (pH 4 and pH 7) was pumped in down-flow mode using a peristaltic pump. The terms used in the RSSCT calculations are summarised in Table 2.

Ion exchange experiments

In order to investigate ion exchange as a mechanism in arsenic adsorption using D-Fe, as well as co-precipitation of arsenic by raising iron content of the solute above saturation, the association between iron and arsenic concentrations were determined by undertaking correlation analysis from the column experiments.

Statistical methods

Statistical analyses were undertaken using Minitab® v.15. Correlation coefficients were calculated using Pearson's correlation coefficients and simple regression, least squares method. Analyses of differences were undertaken using two-sample t tests and one-way analysis of variance. Normality and equal variance assumptions as appropriate were tested in all experiments.

The data for breakthrough curves were transformed using base 10 logarithms to standardise it using a simple linear regression and obtain the best model. The model with highest correlation coefficient (at least 80 %) was fitted in the regression equations. Models were compared via analyses of difference of the standard errors and confidence intervals of the regression coefficients obtained.

Results and discussion

Characterisation

The composition of the raw and HCl-treated diatomite used in this study is presented in Table 3 and has been previously discussed (Mohamedbakr and Burkitbaev 2009). The amount of iron coating achieved in this study was 9.6 % (w/w; SE = 0.12, n = 2, hereafter referred to as 10 % D-Fe) and 16.6 % (w/w; SE = 0.28, n = 3, hereafter referred to as 17 % D-Fe) and is therefore clearly substantially different from raw and HCl-treated diatomite.

The apparent density of the bulk dry 10 % D-Fe and 17 % D-Fe was 0.54 and 0.74 g mL−1, respectively. Similar apparent densities of D-Fe have been reported in some studies and led to buoyancy effects, necessitating the use of more complex differential batch reactors to overcome these. The permeability of the batch of D-Fe used in this study was high enough to prevent buoyancy effects and the use of batch reactors was therefore not necessary in this study (Jang et al. 2006; USEPA 2009).

SEM observations of exhausted D-Fe are presented in Fig. 2a and b. It can be observed that the porous structure is almost completely covered. This is in contrast to a previous study which remarked that the porous structure of diatomite was clear and not obstructed by iron after the same iron coating process used in this study. The authors measured the specific surface area using energy dispersive spectrometry finding it to be similar before and after the coating process (Wu et al. 2005).

The coating results are congruent with previous experiments that found 17.9 % iron in their intended 25 % D-Fe which suggest that this is the approximate maximum iron content that diatomite can support by the same coating process (Wu et al. 2005). Different coating methods have been described elsewhere, achieving more effective iron coating, and associated superior arsenic adsorption capacities. Some authors have described the use of “an incipient wetness impregnation” method to incorporate nanoscale hydrous ferric hydroxide using a vortex mixer, claiming to be inexpensive and simple to perform, reaching up to 37.0 % w/w of iron coating onto diatomite (Jang et al. 2006). In other studies the use of ferrous sulphate, potassium permanganate and manganese chloride have been proposed for coating diatomite with iron as well as manganese. Adding another metal such as manganese may also allow coverage of sites with different characteristics that iron cannot interact with (Chang et al. 2009). However, the currently limited number of studies using these novel methods precludes comparison and the focus of the currently reported work was to achieve substantial simple incorporation of iron into diatomite in order to study the adsorption mechanism rather than comparing coating methods or the influence of other metals.

Isotherms

Modelling of the isotherm experimental data showed that the Freundlich isotherm was better correlated with the empirical observations than the Langmuir isotherm. The Freundlich constants were calculated and are summarised in Table 4 where consistently high coefficients of determination can be observed. In addition, examples of Freundlich and Langmuir isotherms are shown in Fig. 3a and b, respectively.

Some conditions stated in Table 4 were considered non-optimal as reflected in the low correlation coefficients and experiments were repeated with optimised conditions. However, results having high correlation coefficients (>0.9) show that maximum arsenic adsorption capacity found in this study was for pH 4, 17 % iron (18.12–40.82) mgAs/g adsorbent, followed by pH 4, 10 % iron (18.48–29.07) mgAs/g adsorbent, pH 7, 17 % iron (11.44–22.37) mgAs/g and finally pH 7, 10 % (5.93–8.40) mgAs/g adsorbent [Table 4].

The use of surface complexation models has often displaced the use of Freundlich, Langmuir and mass action equilibrium models since conventional models do not correlate well. However, surface complexation models incorporate more complex terms, equations and interpretation of results. The application of Freundlich and Langmuir models in the present study generates high correlation coefficients. Therefore, in an attempt to balance the complexity versus the reliability of the results, the choice of either Freundlich or Langmuir models for the adsorption of arsenic using D-Fe is appropriate. Although on average, the data were slightly better fitted by the Freundlich model, the Langmuir model also gave satisfactory fits and importantly, incorporates a constant not present in the Freundlich model, which can directly predict the adsorption capacity, a parameter of relevance to this study. A summary of similar batch experiments is presented in Table 5 where other isotherm results are compared along with other experimental conditions used where it can also be seen that the Langmuir model is the most commonly employed. In the currently reported study, the achieved capacities are higher than previously reported for modified diatomite, comparable to char carbon but somewhat lower than modified orange residue.

Competitive ion effects

As previously found in isotherm experiments, arsenate removal was more effective at pH 4. Experiments on the impact of competing ions showed a minimal effect of phosphate and silicate on arsenic adsorption at pH 4 (Fig. 4). At pH 7, there was a reduction of 35.0 % in the adsorption capacity in the presence of phosphate ions and a reduction of 14.0 % in the presence of silicate ions. At pH 10, there was a 10.0 % reduction in the presence of silicate ions and an 8.8 % reduction in the presence of phosphate ions.

Other authors have reported a similar negative effect of silicate and phosphate. It is claimed that these ions compete with arsenic for similar adsorption sites, but their effects on arsenic adsorption are slightly different.

Generally, silicate and phosphate have low solubility in natural waters with common forms of phosphate such as apatite minerals being largely insoluble. The solubility of the specific form used in the study was 190 g/L at 20 °C. Only the sodium, potassium and ammonium salts of phosphate are soluble in water in normal conditions, and these salts are not abundant in natural waters. Nevertheless, soluble phosphate may reach natural waters via anthropogenic input in detergents and agricultural runoff, causing adverse effects through eutrophication and by potentially limiting the efficiency of arsenic adsorption at pH around 7. Although silicate is not commonly found in natural waters it can be found in reclaimed water that can be subject to arsenic removal treatments.

Phosphate is similar in structure and therefore competes for similar sites to arsenate without altering the surface characteristics. In addition to this, silicate forms monomers and dimers that are negatively charged thus reducing the pH of ZPC of the surface and creating exclusion of arsenate ions. This silicate coating over the iron coating occurs in minutes and can form silicate polymers in a matter of hours (Smith and Edwards 2005).

Silicate in solution is found as silicic acid H4SiO4 or as H3SiO4 −. There is a bigger dissociation of silicic acid as the pH increases thus increasing the relative concentration of silicate in solution (Frankenberg 2002). This may be the reason for the behaviour observed in Fig. 5 where at pH 10 neither arsenate nor phosphate are effectively adsorbed, but the relative abundance of silicate makes competition stronger than phosphate. At pH 4 there is also maximal adsorption of arsenate because there is an increasing electrostatic attraction with a decrease in pH related to the ZPC of the Fe-D complex (PZC ≈ 8); this makes competition with phosphate negligible as the two are readily adsorbed at this pH. Due to the negligible dissociation of silicate at this pH, its competition with arsenic is also low under these conditions.

Thus an assessment of the concentration of such ions before large-scale arsenic treatment is carried out is recommended since this would better inform the choice of the best removal strategy (Chang et al. 2009; Su 2001; Zhang et al. 2007; Henke 2009).

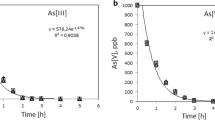

Rapid small-scale column test experiments

Fifteen columns were operated using two different pH solutions: 4 and 7. These pH solutions were combined with different iron contents in D-Fe (10 % and 17 %) and different flow rates (using different tubing diameter). A total of 132.03 L of pH 7 solution and 115.83 L of pH 4 solution were used in the experiments.

Breakthrough (BT) point was calculated by taking the volume (expressed as number of bed volumes) of water treated at the intersection with a curve that is 5 % of the initial normalised concentration (50 μg L−1). BT point occurred at less than 45 bed volumes for all the experiments at 10 % iron. The BT points calculated for all the experiments, at different empty bed contact time (EBCT) [see Table 2], pH and iron content are shown in Table 6. Figure 5 illustrates the breakthrough behaviour at pH 7 and 17 % iron in the Fe-D complex, where the cut-off point for breakthrough is illustrated with a dotted line 0.05 (5 %) where a wide range (400–2,800) of bed volumes (BV) is associated with breakthrough.

Some columns were operated with on–off pump cycles as suggested by Westerhoff et al. (2008) and also to allow continuous effluent sampling at 2-h intervals. An example of this configuration is shown in Fig. 5 (1.507, 17 %, pH 7). In all columns operated in this way, removal of arsenate after the shutdown period was higher than when the column was running, followed by rapid reduction in adsorption capacity. This was expected according to the intra-particle diffusion theory where arsenate adsorption may have been facilitated first by diffusion through the stagnant film, then diffusion along the media surface (external and internal surfaces) or into the internal pore spaces, and finally by adsorption at specific binding sites (Westerhoff et al. 2008).

In order to test for quality control of the test systems to include satisfactory handling of the test columns, a regression analysis was undertaken on the effect of EBCT on arsenic removal at pH 7 and 4 using 17 % D-Fe. As expected, a good fit was obtained (r 2 = 0.65, p = 0.018) at pH 7. However, at pH 4 the fit was poor (r 2 = 0.083, p = 0.58) which suggests that some maldistribution of flow may have occurred in this instance, thus reducing the contact area between adsorbate and adsorbent (Aragon and Thompson 2005; Winchester et al. 2001). It was therefore important to check BV values and correlations with their EBCT as a quality assurance as shown in Table 6. It is also possible for some maldistribution of flow to explain some of the larger than expected BV values at pH 7 for small changes in EBCT (Table 6).

The ratio of column inner diameter to adsorbent particle diameter was kept above 50, to avoid channelling and wall effects, but diatomite being a very soft material can be compressed easily by the action of the solution flow causing excessive pressure build-up. Therefore a ratio closer to 50 is recommended. By diminishing this ratio, there is also a risk of decreasing adsorption capacity as it has been shown that smaller particle sizes increase this capacity (Bakr 2010). Therefore, optimisation between good flow and minimal particle size is recommended before undertaking adsorption studies.

Very strong evidence (p < 0.0001) was found for the impact of iron content on arsenic removal (at constant pH and EBCT). However, there was insufficient evidence of difference in the regression coefficients of the impact of pH for four different comparisons (17 % D-Fe and similar EBCT [pH 7 17 % 1.268 vs. pH 4 17 % 1.293] [pH 7 17 % 2.634 vs. pH 4 17 % 2.565] [pH 7 17 % 4.127 vs. pH 4 17 % 4.258]) and for 10 % D-Fe pH 7 vs. pH 4 with 1.393 EBCT with these comparisons having p = 0.85, 0.83, 0.24 and 0.16, respectively.

Indeed, the overriding influence of iron content is exemplified in Fig. 6 where BT curves obtained for all the experiments are shown and where the effect of iron content can be clearly visualised by the presence of two predominant groupings associated with iron content irrespective of other experimental parameters.

High arsenic (V) adsorption capacities and breakthrough bed volumes for commercial and low-cost modified adsorbents have been reported in batch (Table 5) and RSSCT experiments (Table 7) where adsorption capacities and efficiencies are compared with this study’s findings. Generally, however, comparisons between reported capacities are difficult to make due to the variability in experimental parameters utilised, such as initial arsenic concentration, type of water (e.g. groundwater, drinking water, industrial water, acid mine drainage), pH of the water, adsorbent dose, temperature, contact time, modification method, pHPZC of the adsorbent and surface area among others (Mohan and Pittman 2007; Westerhoff et al. 2008; Aragon and Thompson 2005). The best adsorption in column experiments was at 2.467 EBCT, pH 4 and 17 % iron with BT point of 3045 at target concentration of 50 μg L−1 and initial concentration of 1,000 μg L−1. The adsorption at 5.811 EBCT, pH 7 and 17 % iron was very similar with BT point of 2,886. The difference between BT for the same conditions and different iron percentage was as high as 1,195 bed volumes.

Differences in column behaviour due to iron content were clearly evident. Despite the fact that in the isotherm results derived from batch experiments, pH 4 solutions yielded bigger adsorption capacities, this behaviour was not observed in the column experiments. The reason for this behaviour is unclear and warrants further investigation.

This study has shown that altering the pH of the solution alone does not yield a better performance in column processes and that the iron content clearly has a stronger impact on performance. The method used in this study to incorporate iron into diatomite is thought to have reached its maximum capacity, although it is recognised that alternative methods have been described claiming iron coatings reaching up to 37 % w/w (Jang et al. 2006; Chang et al. 2009). Given the iron-associated performance shown in this study, consideration of alternative methods of iron coating to achieve superior arsenic adsorption capacities is warranted.

Such approaches are based on using a small particle size of the modifier (iron nanoparticles). Other approaches may incorporate more than one metal oxide and hydroxide to pore sites that iron is not capable of attaching using, for example manganese, aluminium, titanium and perhaps cobalt and nickel. Mohan and Pittman (2007) provide a comprehensive review on low-cost adsorbents for arsenic, some of them modified using several metals.

Ion exchange tests

There was insufficient evidence to establish a correlation between iron content in the column effluent vs. arsenic content in the same effluent (r 2 = 0.06, n = 49) suggesting that ion exchange or any other relationship is negligible in arsenate removal using D-Fe. Although ion exchange does not mean that arsenate anion exchanges with iron oxide or iron, this study demonstrates that iron is the most important parameter affecting arsenic adsorption, therefore it is the only ion released that is worth investigating because no analogue of arsenic exists in the chemical composition of diatomite (e.g. phosphate).

The D-Fe was considered to be exhausted when the concentration of As in the effluent reached 85 % (850 μg L−1) of the initial concentration (1,000 μg L−1). A mean of 0.88 % w/w of arsenic, or 8.83 mgAs(V)/g of D-Fe (17 %) (SE = 0.08, n = 6) was found in the exhausted D-Fe. This is only a fraction of the theoretical adsorption capacity, and this is the reason why at full scale, operations are conducted with more than one column in series or parallel configurations.

It was also found that the iron content in the exhausted D-Fe was 172.8 mg of Fe per gramme of D-Fe or 17.3 % w/w (SE = 0.19, n = 6). Importantly, this suggests good stability of the iron coating on diatomite pores.

The formation of inner spheres could be an important mechanism in arsenic adsorption, in which case the amount of iron in diatomite and therefore the formation of bidentate–binuclear bridging complexes between arsenate and iron oxy-hydroxide would play a more important role than electrostatic attraction caused by changes in pH which is consistent with our reported findings.

In contrast, if the formation of outer spheres was predominant, electrostatic interactions would be more important and therefore pH would be expected to have greater influence. If this was indeed the major mechanism the amount of iron in diatomite would not exert such a large influence on arsenate adsorption before (column experiments) and after (isotherm experiments) equilibrium (Everett 1998) as we observed.

Conclusions

Arsenate adsorption was tested using D-Fe having 10 % and 17 % of iron impregnation and modelled by Freundlich and Langmuir isotherms to have a maximum capacity at pH 4 and 17 % iron of 18.12–40.82 mg of arsenic per gramme of D-Fe followed by adsorption at pH 4 and 10 % 18.48–29.07 mg of arsenic per gramme of D-Fe. There was insufficient evidence of a correlation between iron and arsenic content in the isotherm experiments suggesting that the presence of soluble iron is independent of any process involving arsenic removal (e.g. ion exchange, co-precipitation, chemical adsorption).

A more detailed investigation on the BT behaviour showed that although a correlation between EBCT vs. BT for pH 7 was expected and established but it was not possible to establish one for pH 4. The difference in the behaviour of the columns due to iron content was evident and was far more important than any other measured parameter including pH of the solution. Breakthrough point was found at 3,045 bed volumes for optimal conditions of pH 4 and 17 % iron, using initial arsenic (V) concentration of 1,000 μg L−1.

Evidence on the effect of phosphate and silicate on arsenate adsorption was gathered. Capacities decreased from 77 % to 63 % in the presence of silicate and from 77 % to 42 % in the presence of phosphate at pH 7. In practice, full-scale adsorption columns are strongly affected by natural water components, therefore further studies using natural water containing arsenic are recommended.

The incorporation of iron into the diatomite matrix increased the performance in both batch and column experiments. In order to enhance the potential of low-cost diatomite-based adsorbents to remediate arsenic contaminated water, it is recommended that further studies are carried out to optimize methods of coating these adsorbents with iron and other metal oxides.

References

Aragon A, Thompson B (2005) Rapid small-scale column testing for arsenic adsorption media. Arsenic Water Technology Partnerships

Asano T, Burton FL, Leverenz HL, Tsuchihashi R, Tchobanoglous G (2007) Water reuse: issues, technologies, and applications. Metcalf & Eddy Inc, McGraw-Hill, New York

Bakr MH (2010) Diatomite: its characterisation, modifications and applications. Asian J Mater Sci 2(3):121–136

Baruth E (2005) Water treatment plant design. McGraw-Hill, New York

Chang F, Qu J, Lui H, Lui R, Zhao X (2009) Fe-Mn binary oxide incorporated into diatomite as an adsorbent for arsenite removal: preparation and evaluation. J Colloid Interf Sci 338:353–358

Chen W, Parette R, Zou J, Cannon FS, Dempsey BA (2007) Arsenic removal by iron-modified activated carbon. Water Res 41:1851–1858

Crittenden B, Thomas WJ (1998) Adsorption technology and design. Elsevier Inc

Crittenden J, Berrigan J, Hand D (1986) Design of rapid small-scale adsorption tests for a constant diffusivity. J Water Pollut Control Fed 58:312–319

Everett AJ (1998) Adsorption of metals by geomedia. Academic Press, London

Frankenberg WT (2002) Environmental chemistry of arsenic. Marcel Dekker Inc, New York

Garelick H, Jones H, Dybowska A, Valsami-Jones E (2009) Arsenic pollution sources. Rev Environ Contam Toxicol 97:17–60

Ghimire KN, Inoue K, Yamaguchi HY, Makino K, Miyajima T (2003) Adsorptive separation of arsenate and arsenite anions from aqueous medium by using orange waste. Water Res 37:4945–4953

Goldberg S, Johnston C (2001) Mechanisms of arsenic adsorption on amorphous oxides evaluated using macroscopic measurements, vibrational spectroscopy, and surface complexation modelling. J Colloid Interf Sci 234:204–216

Henke KR (2009) Arsenic. Environmental chemistry, health threats and waste treatment. Wiley, Chichester

Hue NT, Cam, BD, Nam, LTH (2008) Removal of arsenic and manganese in underground water by manganese dioxide and diatomites mineral ores. WEPA International Forum on Water Environmental Governance in Asia 23–24 October 2008. Putrajaya, Malaysia

Inglethorpe SD, Whitbread-Abrutat P, Metcalfe R (1999) Overseas geology services technical report WC/99/20: an investigation of the sorption of arsenic by Diatomite. Natural Environment Research Council, UK

Jang M, Min S-H, Kim T-H, Jae KP (2006) Removal of arsenite and arsenate using hydrous ferric oxide incorporated into naturally occurring porous diatomite. Environ Sci Technol 40:1636–1643

Kosmulski M (2009) pH-dependent surface charging and points of zero charge. IV. Update. J Colloid Interf Sci 337:439–448

Melamed D (2005) Monitoring arsenic in the environment: a review of science and technologies with the potential for field measurements. Anal Chim Acta 532:1–13

Mohamedbakr H, Burkitbaev M (2009) Elaboration and characterization of natural diatomite in Aktyubinsk/Kazakhstan. The Open Mineralogy Journal 3:12–16

Mohan D, Pittman CU (2007) Arsenic removal from water/wastewater using adsorbents. A critical review. J Haz Mat 142:1–53

Ruthven DM (1984) Principles of adsorption and adsorption processes. Wiley, New York

Smedley P, Kinniburgh D (2002) A review of the source, behaviour and distribution of arsenic in natural waters. Appl Geochem 17:517–568

Smith SD, Edwards M (2005) The influence of silica and calcium on arsenate sorption. J Water Supply: Res Technol Aqua 54:201–211

Su CP (2001) Arsenate and arsenite removal by zerovalent iron: effects of phosphate, silicate, carbonate, borate, sulfate, chromate, molybdate, and nitrate, relative to chloride. Environ Sci Technol 35:4562–4568

USEPA (2009) Arsenic removal from drinking water by adsorptive media U.S. EPA Demonstration Project at Wellman, TX Final Performance Evaluation Report: EPA/600/R-09/145

Westerhoff PK, Benn TM, Chen AS, Wang L, Cumming L (2008) Assessing arsenic removal by metal (hydr)oxide adsorptive media using rapid small scale column tests, USEPA

WHO (2008) Guidelines for drinking-water quality: incorporating 1st and 2nd addenda, vol 1, 3rd edn. WHO, Geneva

Winchester EL, Berry RC, McMullin MJ (2001) Patent no. 6,200,482 B1. USA

Wu C, Wang Y, Lin T, Tsao H, Chen P (2005) Removal of arsenic from wastewater using surface modified diatomite. J Chin Inst Environ Eng 15:255–261

Zhang G, Qu J, Liu H, Liu R, Wu R (2007) Preparation and evaluation of a novel Fe-Mn binary oxide adsorbent for effective arsenite removal. Water Res 41:1921–1928

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Pantoja, M.L., Jones, H., Garelick, H. et al. The removal of arsenate from water using iron-modified diatomite (D-Fe): isotherm and column experiments. Environ Sci Pollut Res 21, 495–506 (2014). https://doi.org/10.1007/s11356-013-1891-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-013-1891-7