Abstract

Complexing agents are extensively applied in many fields of industry. They are used to provide effective controlling trace metal ions in cleaning industries, textile, pulp and paper production, water treatment, agriculture, food industries, etc. Recently, the low biodegradability of these ligands and their accumulation in the environment has become a cause for concern. Therefore, replacement of ethylenediaminetetraacetic acid and diethylenetriaminepentaacetic acid by more environmentally friendly chelating agents is highly desirable. So far, these acids and their salts have been applied as components of household chemistry, cosmetics, modern microelement fertilizers and agrochemicals. This paper reviews the sorption of heavy metal ions such as Cu(II), Zn(II), Cd(II) and Pb(II) in the presence of the above-mentioned complexing agents on commercially available anion exchangers of different matrix. The obtained sorption results were fitted using the Langmuir and Freundlich sorption isotherm models. The kinetic data were also analysed using the Lagergren, Ho and McKay sorption kinetic equations. The studies were carried out considering the effects of such important parameters as phase contact time, initial concentration, pH and temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Aminopolycarboxylates (APCA) have been used since the end of the 1940s as effective complexing agents in various branches of industry. For example EDTA (ethylenediaminetetraacetic acid), NTA (nitrilotriacetic acid) and DTPA (diethylene-triaminepentaacetic acid), among others, can be used in industrial cleaning, household detergents and cosmetics, in pulp and paper, nuclear, photographic, pharmaceuticals, textile, leather and rubber industries.

Forming stable complexes with metal ions, they can mobilize contaminating metal ions adsorbed in sediments, solubilize radioactive metal ions and increase their environmental mobility, contribute to water eutrophication as they contain nitrogen that could be available to aquatic microbiota and redissolve calcium and iron phosphates, releasing phosphorous and as ligand–metal complexes may significantly increase the bioavailability of extremely dangerous heavy metals, for example the Cu(II)-EDTA and Cd(II)-EDTA complexes are more toxic than the respective free metals. Another important argument for abandoning traditional complexones is the lack of their biodegradability. It has been reported that the biodegradability of aminopolycarboxylic group complexing agents depends on the character as well as the number of substituents and nitrogen atoms in the molecule. Thus tetra-(EDTA) or penta-(DTPA) substituted derivatives with two or more tertiary nitrogen atoms and carboxymethyl groups are highly stable and are reported to be photodegradable only as their Fe(III) complexes.

However, new complexing agents introduced at the end of the twentieth century are an important alternative for the sparingly biodegradable chelates used so far mainly in such fields as detergents, modern liquid microelement fertilizers and agrochemicals. In this group, the following complexing agents should be mentioned: IDS (N-(1,2-dicarboxyethyl)-D,L-aspartic acid (iminodisuccinic acid), DS (polyaspartic acid), EDDS (N,N′-ethylenediaminedisuccinic acid), GLDA (N,N-bis(carboxylmethyl)-L-glutamic acid) and MGDA (methylglycinediacetic acid). All of these are readily biodegradable, although in the case of IDS or EDDS, the biodegradability depends significantly on the isomeric form of the compound (Knepper 2003; Nowack 2007).

In 1997/1998, iminodisuccinic acid (IDS) was introduced by Bayer AG (now Lanxess) as Baypure CX 100 (Brochure of Baypure CX 100; Kołodyńska 2011). Its production is based on the reaction of maleic anhydride with ammonia and sodium hydroxide. The isomeric mixture of IDS consists of 25 % [S,S], 25 % [R,R] and 50 % [R,S] forms (Cokesa et al. 2004a; Vasilev et al. 1996, 1998). After 7 days, it was found that 80 % of IDS underwent biodegradation. IDS is also characterized by excellent calcium binding properties, stability over a wide pH range, good complexation of heavy metal ions and low environmental impact due to low toxicity and good biodegradability (Cokesa et al. 2004a, b).

In 2005, the Polish company ADOB, in cooperation with Bayer AG, developed a process to produce readily biodegradable chelates (IDHA-brand) that are applied as foliar sprays in agriculture and horticulture, in soil applications as well as hydroponics and fertigation (Brochure of ADOB 2012).

EDDS (N,N′-ethylenediaminedisuccinic acid) is a structural isomer of EDTA (Schowanek et al. 1997; Kołodyńska 2011). EDDS exists in the form of four isomers: S,S- (25 %), R,R- (25 %) and S,R- (50 %). The S,S-isomer of EDDS produced by some bacteria and fungi (Nishikiori et al. 1984; Takahashi et al. 1999) is easily biodegradable, in contrast to the R,R- and S,R-isomers (Takahashi et al. 1997; Luo et al. 2011). Biodegradation of EDDS complexes strongly depends on the type of metal and is not related to the stability constant of the chelate complex (Vandevivere et al. 2001a, b).

From the late 1990s, many investigations have examined the suitability of EDDS as a substitute for EDTA for many purposes, not only in laundry detergents where it is used at a low level (<1 %) but also in cosmetics, pulp and paper, photographic industries as well as in purification of contaminated soils and phytoremediation (Jones and Williams 2002; Brochure of Enviomet™ 2009; Wu et al. 2004).

GLDA (tetrasodium of N,N-bis(carboxymethyl) glutamic acid) also known as Dissolvine GL-38 was introduced on the commercial scale by AkzoNobel Functional Chemicals (Kołodyńska 2011). Its production is based on the flavour enhancer monosodium glutamate (MSG) from fermentation of readily available corn sugars (Seetz 2007; Seetz and Stanitzek 2008). GLDA is characterized by good solubility over a wide range of pH. Over 60 % of the L-GLDA degrades within 28 days. It should be mentioned that Dissolvine GL-38 consists only of the L-form because the D-form is not biodegradable. Due to its thermal stability, GLDA is used in boilers water treatment systems to reduce the effect of hard water (Brochure of Dissolvine GL-38, 2007). Siegert (2008) found that the new generation complexing agents such as GLDA, IDS or EDDS can boost the effect of preservatives such as phenoxyethanol/ethylhexylglycerin (Euxyl PE 9010). GLDA has also further potential uses in the production of micronutrient fertilizers (Borowiec and Hoffmann 2005; Borowiec et al. 2007). The structural formulae of the above complexing agents as well as some traditional ones are presented in Fig. 1.

The structural formula of the aminopolycarboxylic acids: EDTA ethylenediaminetetraacetic acid, NTA nitrilotrioacetic acid, EDDS N,N′-ethylenediaminedisuccinic acid, IDS N-(1,2-dicarboxyethyl)-D,L-aspartic acid, iminodisuccinic acid, DS polyaspartic acid, GLDA N,N-bis(carboxylmethyl)-L-glutamic acid, MGDA methylglycinediacetic acid, HEIDA hydroxyethyliminodiacetic acid

The great progress observed in the field of complexing agents (Fig. 2) is the result, among others, of legislative changes. In September 2002, the European Commission adopted a regulation proposal for detergents and their ingredients such as EDTA, non-biodegradable surfactants, alkylphenolethoxylates (APEO) or chlorine-based bleach. Therefore, the following proposals for substitution were made: polyacrylate should be replaced by polyaspartates (such as Baypure DS 100), citrate by iminodisuccinate (Baypure CX 100) and phosphonate by iminodisuccinate (Baypure CX 100; Environmental Risk Assessment of Complexing Agents 2001).

To remove heavy metal ions, many physical and chemical methods including such common ones as chemical precipitation, coagulation, filtration, ion exchange, membrane processes and adsorption can be applied. Adsorption methods based on complexing agents together with ion exchangers give new prospects for removal of heavy metal ions.

To understand the metal ion removal, it is important to know the metal ion–ligand interactions. The complexation can be regarded as the equilibrium reaction between the ligand and the metal ions:

where M is the metal ion (e − pair acceptor), m is the charge of M, L is the ligand (e − pair donor) and n is the charge of ligand.

According to the principle of mass action, the activities of M, L and ML are as follows:

where K ML is the equilibrium constant (also denoted as the stability constant). In the case when pH should be taken into account, the conditional stability constant K cond can be defined as:

were K cond is the conditional stability constant, K is the stability constant (equals KML), αHL is the coefficient of ligand protonation and αM is the coefficient of side reactions competing with the ligand for the metal ions (formation of metal hydroxides, effects of buffers and forming of MLH or MLOH species).

It should be remarked that the amount of free L n− increases with the increasing pH value. The single steps of protonation are described by the equilibrium constants K 1, K 2,.. , K n and αHL can be defined as:

whereas αM can be expressed as:

where s is the factor which determines if species n exists (s = 1) or not (s = 0) and K I and K II are the equilibrium constants for insoluble metal hydroxides formation.

The conditional stability constant gives a relationship between the concentrations of the solvated complex formed (ML), the concentration of the unreacted metal (M) and the concentration of the unreacted cleaning agent (L). Figure 3 shows the comparison of the conditional stability constant values of some complexes of metals with EDTA and EDDS, IDS and GLDA. It was also found that these constants pass for all metal complexes through a maximum as a function of the pH value (Treichel et al. 2011).

Only a few examples of the application of ion exchange for removal of heavy metal ions and/or chelating ligands and anion exchangers have been published. One of the first papers by Nelson et al. (1960) dealt with the separation of alkaline earth and Mn(II), Co(II), Ni(II) and Zn(II) ions in the presence of EDTA on the anion exchanger Dowex 1 × 4 in the EDTA form. For some years, complexones were also used for the determination of, among others, Cu(II), Zn(II), Cd(II), Ni(II) and Co(II) in solution and metallurgical wastes as well as in studies of complexation reactions and determination of stability constants of complexones (Hering and Morel 1990).

The pioneer papers by Dyczyński dealt with the application of EDTA and DCTA to the separation of microquantities of rare earth elements (Dybczyński 1964; Wódkiewicz and Dybczyński 1968). Non-monotonic affinity series were used by Hubicka and Hubicki (1992) for separation of chosen pairs of rare earth element complexes with NTA, HEDTA and IMDA in the macro-microcomponent system. The studies of the application of such complexing agents as EDTA, NTA and citric acid in heavy metal ions removal were begun by Bolto, Dudzińska, Clifford or Juang (Dudzinska and Clifford 1991/1992; Juang and Shiau 1998). The authors showed the superiority of the polyacrylate anion exchangers over polystyrene ones. Moreover, the works of Juang and co-workers prove that Cu(II) removal is possible in the presence of EDTA and formaldehyde (Juang et al. 2005). Additionally, in a paper (Juang et al. 2003) on the removal of Co(II), Ni(II), Mn(II) and Sr(II) ions from the solutions containing EDTA, NTA and citric acid, it was shown that the process is affected not only by pH solutions but also by the kind of complexing agent and the molar complexing agent–metal ion ratio. Therefore, the polyacrylic anion exchangers were also used for the removal of Cu(II) with IDA, NTA and EDTA (Hubicki and Jakowicz 2003; Juang et al. 2006).

In this paper, the optimization of the removal of Cu(II), Zn(II), Cd(II) and Pb(II) from waters and waste waters using the ion exchange method and the possibility of applying a new generation of biodegradable complexing agents is presented. For this study, the complexing agents IDS, EDDS and GLDA were selected. As anion exchangers, Lewatit MonoPlus M 800 and Ionac SR7 were chosen. It should also be mentioned that these compounds are not well known and the existing literature on the subject is not systematic and is usually connected with specific needs. Therefore such investigations are of considerable importance.

Experimental

Materials and anion exchangers

In the investigations, polystyrene anion exchangers produced by Lanxess (Lewatit MonoPlus M 800) and Sybron Chemical Inc. (Ionac SR7) were used. The resins were selected by their good sorption properties. In the case of Ionac SR7, its high selectivity toward nitrate ions (three times higher the selectivity for nitrates of any commercially available anion exchangers) was taken into account. Prior to the use, the resin was washed with 1 M NaOH and 1 M HCl as well as with distilled water several time to remove organic and inorganic impurities from its synthesis and finally air dried. The physicochemical properties and short specification of these anion exchangers are presented in Table 1.

The solutions of Cu(II), Zn(II), Cd(II) and Pb(II) complexes with IDS, EDDS and GLDA were prepared by mixing the appropriate metal salts with Baypure CX100 (Lanxess), Enviomet C140 (Innospec) and Dissolvine GL-38 (Akzo Nobel) solutions. The pH values of the obtained solutions were as follows: for IDS complexes—Cu(II) 6.7, Zn 6.5, Cd 6.9 and Pb(II) 7.5; for EDDS complexes—Cu(II) 4.2, Zn(II) 4.5, Cd(II) 5.1 and Pb(II) 4.7; and for GLDA complexes—Cu(II) 8.7, Zn(II) 9.0, Cd(II) 9.3, and Pb(II) 9.3

Sorption kinetics studies

Sorption was carried out by the static method. The effects of some important parameters such as phase contact time, initial concentration, pH and temperature on these systems were studied. Ion exchanger (0.2 g) and 20 ml of a suitable solution containing Cu(II), Zn(II), Cd(II) and Pb(II) complexes with IDS, EDDS and GLDA and also the same systems with the addition of accompanying ions, i.e. Cl−, NO3 − and SO4 2−, were put into 100 ml conical flasks tightly closed with a silicone stopper. Then they were placed in a mechanical shaker for a definite time with a constant shaking rate and vibration amplitude. After a fixed time (1, 3, 5, 10, 15, 20, 30, 60 and 120 min), heavy metal ions were determined by the atomic absorption spectrometry (AAS). All experiments were made in triplicate and the results were taken as the average value.

The amounts of metal ions adsorbed at time t (q t , mg g−1) were calculated from the mass balance equation:

where c 0 is the initial concentration of metal ion, mg L−3; c t is the concentration of metal ion at time t, mg dm−3; V is the volume of the solution, L −3; m is the mass of hybrid ion exchanger, g.

Sorption isotherms

The adsorption isotherms of the above-mentioned metal complexes for the anion exchangers Lewatit MonoPlus M 800 and Ionac SR 7 were determined by shaking 0.2 g of ion exchanger and 20 ml of the suitable solution containing Cu(II), Zn(II), Cd(II) and Pb(II) complexes with IDS, EDDS and GLDA in 100 ml flasks. The process took place at the concentration rate of 1 × 10−3–2.5 × 10−2 M and a constant pH value 6.5 for IDS complexes, 6.0 for EDDS complexes and 9.0 for GLDA complexes for 24 h. After shaking, the content was filtered off and metal ions were determined in the raffinate as in the case of sorption kinetics studies.

The equilibrium data have been analysed using the Langmuir and Freundlich isotherms and the characteristic parameters for each isotherm have been determined. The linear form of the Langmuir model (Langmuir 1916) can be expressed as:

where c e is the equilibrium concentration of metal ions (mg L−1), q e is the amount of the metal ions adsorbed on the hybrid sorbent (mg g−1), q 0 and K L are the Langmuir constants related to the adsorption capacity (mg g−1) and the equilibrium constant (L g−1), respectively.

The adsorption equilibrium data was also applied to the Freundlich model (Freundlich 1906) given below:

where K F and n are the Freundlich constants related to the adsorption capacity and the adsorption intensity, respectively.

The pseudo first order model (PFO) was expressed as (Blanchard et al. 1984):

where q t is the amount of metal ions adsorbed on the hybrid sorbents at time t and k 1 is the rate constant (min−1). The rate constant, k 1 was obtained from the slope of linear plots of log(q e − q t ) against t.

The adsorption data was also analysed in terms of the pseudo second order mechanism (PSO) as described by Ho and McKay (1998):

and the initial rate of adsorption h is:

where k 2 is the rate constant of PS-order adsorption (g mg min−1) and h is the initial rate of adsorption (mg g min−1).

The constants q e, h and k 2 can be determined from the plots of t/q t against t.

The laboratory shaker Elpin type 357 (Elpin-Plus, Poland) was used for shaking. The pH values were measured with a PHM 84 pH meter (Radiometer, Denmark) with the glass REF 451 and calomel pHG 201-8 electrodes. The accuracy of the pH meter is ±0.01 pH units. The concentrations of heavy metals were measured with the AAS spectrometer SpectrAA 240FZ (Varian, Australia).

Results

The sorption capacity of heavy metals is influenced by many factors, including the properties of metal ions such as their radius and valence, their concentration in aqueous solution, experimental conditions (pH, temperature, phase contact time, interfering ions presence and initial concentration of metal and complexing agent).

One of the most important parameters is pH. As follows from the distribution diagrams of IDS, EDDS and GLDA known from the literature data (Kołodyńska 2009, 2010; Crouch et al. 2001), the existing species can be denoted as H4L, H3L−, H2L2−, HL3− and L4−. At very low pH (acidic medium), the protonated forms (H4L) are predominant. In contrast, at high pH (basic medium), fully deprotonated forms (L4−) predominate. As the pH values change from low to high, other forms predominate in certain pH values.

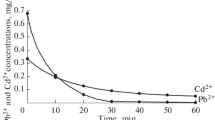

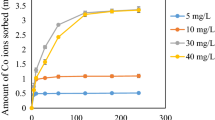

Therefore, in Fig. 4, the adsorption and kinetic characteristics of the monodisperse polystyrene strongly basic anion exchanger Lewatit MonoPlus M 800 and Lewatit SR-7 towards Cu(II) and Cd(II) complexes with IDS, EDDS and GLDA are presented. For all concentrations, the adsorption of Cu(II) complexes with IDS, EDDS and GLDA on Lewatit MonoPlus M 800 and Ionac SR7 was a very fast process, reaching the maximum adsorption capacity after about 10–20 min for the anion exchanger with the trimethylene functional groups and after about 30–40 min for the anion exchanger with the tripropylene functional groups. In the same way, the adsorption of Cd(II) complexes was fast, reaching about 98 % of saturation in 30–40 min. Fast kinetics is desirable in the waste waters treatment because it provides high adsorption capacities in short time.

In addition, the variation in the amount of the Cu(II) and Cd(II) complexes removed by these two anion exchangers could be related to the nature and concentration of the functional groups (active sites) responsible for interaction with the copper complexes. It is evident that for Lewatit MonoPlus M 800 the effectiveness of the anion exchanger process is greater than for Ionac SR7. For the initial concentration of 3 × 10−3 M it was found that the amount of the sorbed Cu(II)-IDS, Cu(II)-EDDS and Cu(II)-GLDA complexes in the M(II)-L = 1:1 system for Lewatit MonoPlus M 800 was equal to 28.09, 21.47 and 27.81 mg g−1 whereas for Ionac SR7 to 21.95, 18.42 and 22.97 mg g−1, respectively. It was also found that the sorption process depends on the type of the complexes formed. In the case of EDDS the effectiveness is the lowest, probably due to the formation of large species which can be partially excluded from the resin phase (sieve effect). The obtained results are in the agreement with those obtained for the other anion exchangers such as Lewatit MonoPlus M 500 and Lewatit MonoPlus M 600 (Kołodyńska et al. 2009). Moreover, the important parameter is also the monodispersity of the used anion exchangers. In the preparation process, the precise control and optimization of the reaction parameters can result in highly crosslinked particles with a narrow or even monodisperse size distribution. Therefore the monodyspersive anion exchangers of this type are characterized by much better physicochemical properties compared to the traditional heterodyspersive anion exchangers. It is worth noting that the main aim in production of monodisperse ion exchangers was to improve kinetic parameters and already in the production stage the grain size from 0.6 mm and the heterogeneity coefficients in the range 1.1–1.2 are obtained. Additionally, due to uniform column packing the monodisperse ion exchangers are characterized by over 12 % large ion exchange capacities, quicker exchange of kinetics and much higher mechanical resistance, which is essential from the economical point of view.

In the studies two kinetic models are employed to fit the experimental kinetic data of adsorption of Cu(II) and Cd(II) complexes with IDS, EDDS and GLDA on these anion exchangers, i.e. the pseudo first order (PFO) and the pseudo second order (PSO). The model of higher values of R 2 indicates that it describes the adsorption kinetics more successfully. From the kinetic model analysis using the determination coefficient, the PSO model was the best in describing the transport of the Cu(II) and Cd(II) complexes from the bulk solution onto the surface of the anion exchangers (Tables 2 and 3).

The adsorption equilibrium of species can be correlated using several adsorption isotherms. The most popular is the Langmuir adsorption model. It assumes that all adsorption sites are equivalent, there are no interactions between the adsorbed molecules and the adjacent sites and adsorption is of the monolayer type. By comparison, the Freundlich equation is valid for heterogeneous sorption on the surface containing several sites.

The equilibrium adsorption isotherms for Cu(II), Zn(II), Cd(II) and Pb(II) complexes with IDS, EDDS and GLDA were measured at room temperature (295 K) and a controlled solution pH value 6.5 for IDS complexes, 6.0 for EDDS complexes and 9.0 for GLDA complexes. Under these conditions, based on the spatial diagrams of IDS, EDDS and GLDA, sorption of [ML]2− or [MHL]− type complexes (where: L = ids4−, edds4− and glda4−) should proceed. It can be presented using the following equations:

where R is the anion exchange matrix with the functional group.

The isotherms for the Cu(II)-IDS and Zn(II)-EDDS complexes on Lewatit MonoPlus M 800 and Ionac SR7 are presented in Figs. 5 and 6. The calculated Langmuir and Freundlich parameters are collected in Table 4.

As follows from the obtained results, the Langmuir equation fits better the experimental data than the Freundlich equation. The values of the separation factor, R L, indicating the nature of the adsorption process are also presented in Table 4. They can be classified by R L > 1 unfavourable, R L = 1 linear; 0 < R L < 1 favourable; R L = 0 irreversible. In the present study, these values are lower than 1, which indicates that the sorption process is favourable for all systems. Moreover, based on the obtained maximum sorption capacities for heavy metal complexes with IDS, EDDS and GLDA, the following affinity series can be arranged for Lewatit MonoPlus M 800 and for Ionac SR 7: Pb(II) > Cd(II) > Zn(II) > Cu(II).

It was also found that the sorption of Cu(II) complexes with IDS, EDDS and GLDA is strongly affected by the accompanying ions presence. In the case of the system without Cl−, NO3 − and SO4 2− ions, Lewatit MonoPlus M 800 and Ionac SR7 are characterized by high affinity for anionic complexes of [ML]2− or [MHL]− types. At the initial concentration of 1 × 10−3 M, almost 100 % sorption of these complexes was observed (the data are presented as Supplementary Material). However, in the presence of the above-mentioned ions (concentration 100 mg L−1), it was found that SO4 2− ions noticeably decrease the sorption capacity (by about 14 % for Lewatit MonoPlus M 800 and 22 % for Ionac SR7). It is in agreement with the fact that strongly and moderately basic anion exchangers exhibit great affinity for sulfate(VI) and nitrate(V) ions (according to the series SO4 2− > NO3 −).

Conclusions

Heavy metal complexes of Cu(II), Zn(II), Cd(II) and Pb(II) with IDS, EDDS and GLDA were removed from the aqueous solution using the commercially available strongly basic anion exchangers Lewatit MonoPlus M 800 and Ionac SR7. Comparing the types of the used anion exchangers, the strongly basic one of type 1 (Lewatit MonoPlus M 800) was found to be much better than the anion exchanger of type 3 (Ionac SR 7). The sorption capacity sequence was: Pb(II) > Cd(II) > Zn(II) > Cu(II). The equilibrium data were analysed using the Langmuir and Freundlich sorption isotherm models and the first was found to be the most appropriate. The experimental data were well described by the pseudo second order mechanism. Increasing the contact time and the initial metal ions in the presence of IDS, EDDS and GLDA concentrations resulted in an increase in their sorption efficiency. The pH of the solutions has an obvious effect on the sorption of Cu(II), Zn(II), Cd(II) and Pb(II) complexes with used complexing agents. In the case of the anion exchange process, pH value should be maintained above 4.0 in order to enable the anionic complexes sorption.

References

Blanchard G, Maunaye M, Martin G (1984) Removal of heavy metals from waters by means of natural zeolites. Water Res 18:1501–1507

Borowiec M, Hoffmann J (2005) New biodegradable chelating compounds for micronutricient fertilizers. In: Górecki H, Dobrzański Z, Kafarski P (eds) Development in Production and use of new agrochemicals. Czech-Pol Trade, Prague, pp 38–41

Borowiec M, Polańska P, Hoffmann J (2007) Biodegradability of the compounds introduced with microelement fertilizers into the environment. Polish J. Chem. Technol 9:38–41

Brochure of ADOB (2012) Biodegradable IDHA chelates

Brochure of Baypure CX 100. Baypure CX 100 a new environmentally friendly alternative to conventional complexing agents-product guide of Lanxess. http://www.baypure.com/bp/en

Brochure of Dissolvine GL-38 (2007) AkzoNobel Functional Chemicals

Brochure of Enviomet™ (2009) Biodegradable chelat Enviomet TM – product guide of Innospec Inc

Cokesa Ž, Lakner S, Knackmuss HJ, Rieger PG (2004a) A stereoselective carbon-nitrogen lyase from Ralstonia sp. SLR7 cleaves two of three isomers of iminodisuccinate. Biodegratadion 15:229–239

Cokesa Ž, Knackmuss HJ, Rieger PG (2004b) Biodegradation of all stereoisomers of the EDTA substitute iminodisuccinate by Agrobacterium tumefaciens BY6 requires an epimerase and a stereoselective C-N Lyase. App. Environ. Microbiol 70:3941–3947

Crouch AM, Khotseng LE, Polhuis M, Williams DR (2001) Comparative study of cyclic voltammetry with potentiometric analysis for determining formation constants for polyaminocarboxylate-metal ion complexes. Anal Chim Acta 48:231–237

Dudzinska MR, Clifford DA (1991/1992) Anion exchange studies of lead-EDTA complexes. React Polym 16:71–80

Dybczyński R (1964) Separation of rare earths on anion exchange resins. IV. Influence of temperature on anion exchange behaviour of the rare earth ethylenediaminetetracetate. J Chromatogr 14:79–96

Environmental risk assessment of complexing agents (2001) UCC Umweltchemie Consulting on behalf of Umweltbundesamt. Germany, Berlin

Freundlich HFM (1906) Über die adsorption in lösungen. Z Phys Chem 57:385–470

Hering JG, Morel FM (1990) Kinetics of trace metal complexation: ligand-exchange reactions. Environ. Sep. Technol 24:242–252

Ho YS, McKay G (1998) Sorption of dye from aqueous solution by peat. Chem. Eng J 70:115–124

Hubicka H, Hubicki Z (1992) Studies on purification of yttrium(III) from neodymium(III) on chelation ion exchangers of amino-acid type. Hung J Ind Chem 20:255–258

Hubicki Z, Jakowicz A (2003) Studies on sorption of copper(II) complexes with IDA and NTA acids on strongly and weakly basic anion exchangers. Desalination 155:121–130

Jones PW, Williams DR (2002) Chemical speciation simulation used to assess the efficiency of environment-friendly EDTA alternatives for use in the pulp and paper industry. Inorg. Chim. Acta 339:41–50

Juang RS, Shiau LD (1998) Ion exchange equilibria of metal chelates of ethylenediaminetetraacetic acid (EDTA) with Amberlite IRA 68. Ind Eng Chem Res 37:555–560

Juang RS, Lin SH, Wang TY (2003) Removal of metal ions from the complexed solutions in fixed bed using a strong acid ion exchange resin. Chemosphere 53:1221–1228

Juang RS, Lin SH, Kao HC, Theng MH (2005) Effect of formaldehyde on Cu(II) removal from synthetic complexed solutions by ion exchange. Chemosphere 59:1355–1360

Juang RS, Kao HC, Liu FY (2006) Ion exchange recovery of Ni(II) from simulated electroplating waste solutions containing anionic ligands. J Hazard Mater 128:53–59

Knepper TP (2003) Synthetic chelating agents and compounds exhibiting complexing properties in the aquatic environment. Trends Anal. Chem 22:708–724

Kołodyńska D (2009) Iminodisuccinic acid as a new complexing agent for removal of heavy metal ions from industrial effluents. Chem. Eng J 152:277–288

Kołodyńska D, Hubicka H, Hubicki Z (2009) Studies of application of monodisperse anion exchangers in sorption of heavy metal complexes with IDS. Desalination 239:216–228

Kołodyńska D (2010) The effect of the novel complexing agent in removal of heavy metal ions from waters and wastewaters. Chem. Eng J 165:835–845

Kołodyńska D (2011) The chelating agents of a new generation as an alternative to conventional chelators for heavy metal ions removal from different waste waters, In: Ning RY (ed) Expanding issues in desalination. InTech Publishers, pp 339–371

Langmuir I (1916) The constitution and fundamental properties of solids and liquids. J Am Chem Soc 38:2221–2295

Luo C, Shen Z, Li X (2011) Enhanced phytoextraction of Cu(II), Pb(II), Zn(II) and Cd(II) with EDTA and EDDS. Chemosphere 59:1–11

Nelson F, Day RA Jr, Kraus KA (1960) Anion exchange studies – XXX. A number of elements in ethylenediaminetetraacetic acid solutions. J Inorg Nucl Chem 15:140–150

Nishikiori T, Okuyama A, Naganawa H, Takita T, Hamada M, Takeuchi T, Aoyagi T, Umezawa H (1984) Production by actinomycetes of (S, S)-N, N’-ethylenediamine disuccinic acid, an inhibitor of phospholipase-C. J Antibiot 37:426–427

Nowack B (2007) Chelating agents – overview and historical perspective. In: Nowack B, Giger W (eds) Complexing agents between science, industry, authorities and users. Monte Verità, Ascona, Switzerland

Schowanek D, Feijtel TC, Perkins CM, Hartman FA, Federle TW, Larson RJ (1997) Biodegradation of [S, S], [R, R] and mixed stereoisomers of ethylene diamine disuccinic acid (EDDS), a transition metal chelator. Chemosphere 34:2375–2391

Seetz J (2007) Bound by biodegradability. Soap Perfumery Cosmetics 4:75–76

Seetz J, Stanitzek (2008) GLDA: The new green chelating agent for detergents and cosmetics. SEPAWA Congress and European Detergents Conference Proceedings. 15–17 October 2008 pp 17–22

Siegert W (2008) Can new biodegradable complexing agents replace tetrasodium EDTA to boost preservatives? SÖFW J 1:38–41

Takahashi R, Fujimoto N, Suzuki M, Endo T (1997) Biodegradabilities of ethylenediamine-N, N’-disuccunic acid (EDDS) and other chelating agents. Biosci Biotechnol Biochem 61:1957–1959

Takahashi R, Yamayoshi K, Fujimoto N, Suzuki M (1999) Production of (S, S)-ethylenediallaine-N. N’-disuccinic acid from ethylenediamine and fumaric acid by bacteria. Biosci Biotechnol Biochem 63:1269–1273

Treichel H, Goldstein A, George M, Bohling D, Rentsch J, Oltersdorf A, Zimmer M, Ostrowski S, Mowat I, Wang L, Kern W (2011) Removal of trace metals using a biodegradable complexing agent. Photovolt. Intern. 5:81–93

Vandevivere P, Saveyn H, Verstraete W, Feijtel W, Schowanek D (2001a) Biodegradation of metal-[S, S]-EDDS complexes. Environ Sci Technol 35:1765–1770

Vandevivere P, Hammes F, Verstraete W, Feijtel W, Schowanek D (2001b) Metal decontamination of soil, sediment and sewage sludge by means of transition metal chelate [S, S]-EDDS. J Environ Eng 127:802–811

Vasilev VP, Katrovtseva AV, Gorelov IP, Tukumova NV (1996) Stability of complexes of Ni(II) with iminodisuccinic acid. J Inorg Chem 41:1320–1323 (in Russian)

Vasilev VP, Katrovtseva AV, Bychkova SA, Tukumova NV (1998) Stability of complexes of Co(II) and Cu(II) with iminodisuccinic acid. J Inorg Chem 43:808–809 (in Russian)

Wu LH, Luoa YM, Xing XR, Christie P (2004) EDTA-enhanced phytoremediation of heavy metal contaminated soil with Indian mustard and associated potential leaching risk. Agr. Ecosyst. Environ 102:307–318

Wódkiewicz L, Dybczyński R (1968) Anion exchange behaviour of the rare earth complexes with trans-1.2-diaminocyclohexane-N.N′-tetraacetic acid. J Chromatogr 32:394–402

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Céline Guéguen

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 116 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Kołodyńska, D. Application of a new generation of complexing agents in removal of heavy metal ions from different wastes. Environ Sci Pollut Res 20, 5939–5949 (2013). https://doi.org/10.1007/s11356-013-1576-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-013-1576-2