Abstract

Spent sorbents in water treatment processes have potential risks to the environment if released without proper treatment. The aim of this work was to investigate the potential regeneration of commercially prepared nano-TiO2 (anatase) for the removal of Pb (II), Cu (II), and Zn (II) by pH 2 and ethylenediaminetetraacetic acid (EDTA) solutions. The percent of metal adsorption/desorption decreased with the increasing number of regeneration cycles, and the extent of decrease varied for each metal. Competitive effects were observed for the adsorption/desorption of different metals when the nano-TiO2 was regenerated by EDTA solutions. Nano-TiO2 was able to treat simulated metal polluted water with greater than 94 % adsorption and greater than 92 % desorption after four cycles of regeneration using pH 2 solution. These results demonstrated that nano-TiO2 can be regenerated and reused using pH 2 solution compared to an EDTA solution for aquatic metal removal, which makes nanosorbents promising and economically and environmentally more attractive in the application of water purification.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Metals, particularly heavy metals (i.e., Pb, Cu, Zn, etc.), can be toxic at higher concentrations although some of them are essential micro-nutrients for biota (Hashim et al. 2011). A majority of metal pollution in water comes from industries such as metallurgical, tannery, chemical manufacturing, mining, battery manufacturing, and military industries (Cruz Viggi et al. 2010; Fu and Wang 2011; Rao et al. 2007).

Currently, metal removal technologies include, but are not limited to, chemical precipitation, ion-exchange, adsorption, membrane filtration, coagulation–flocculation, and electrochemical methods. Most of these technologies have drawbacks, such as high capital and operational cost or the disposal of residual sludge (Kobya et al. 2005). Among these technologies, ion-exchange, adsorption, and membrane filtration are the most frequently studied (Fu and Wang 2011). Adsorption, which is recognized as an effective and economical method for metal removal, is one of the most promising techniques (Hu 2006). An optimal adsorbent should have high surface area, fast adsorbing rates, high adsorption capacity, and effectiveness when metal concentrations are low (Zhang and Fang 2010).

TiO2 has been used commercially in numerous consumer and industrial applications since the early 1900s, particularly for coatings and pigments (US EPA 2009). Nano-TiO2 has some advantages such as increased specific surface area and an increased number of surface sites when compared with bulk TiO2 (US EPA 2009). Such properties have led to the development or use of nano-TiO2 for a wide variety of applications, one of which is the application of nano-TiO2 as an adsorbent for metal removal due to their high chemical stability in acidic and alkaline solutions and fast rates of sorption, especially for nano-TiO2 in anatase crystal structure form (Engates and Shipley 2011; Gao et al. 2004; Hu et al. 2006; Kim et al. 2003; Shipley et al. 2009; Tratnyek and Johnson 2006; Yang et al. 2007; Zhang 2003).

After nano-TiO2 is used in metal removal, a sludge material containing nano-TiO2 would be generated. Nano-TiO2 as well as the adsorbed metals may be released and enter surface or ground water without proper treatment (US EPA 2009). This, coupled with the need for conservation of raw materials, recycle, recovery, and reuse of waste products, needs to be considered (Hu 2006). Results from sorbent regeneration and reuse are imperative for future practical use of nanoparticles and can render adsorption an economically more attractive metal removal method. Also, it can eliminate the potential environmental effects of nanoparticles used in contaminant removal.

Chelating agents such as EDTA have been proven to be efficient in regenerating sorbents for metal removal (Deng et al. 2007; Gao et al. 2003; Zhou et al. 2009). Deng et al. (2007) showed that 82 % of Pb (II) bound to biomass was recovered by 0.01 M EDTA, which allowed the reuse of the biosorbent (Cladophora fascicularis) (Deng et al. 2007). Gao et al. (2003) used EDTA containing electrolyte solution to desorb Pb and Cd from natural sediment, and their results showed that 90 % freshly sorbed Pb and Cd was desorbed in the first two desorption steps (Gao et al. 2003). EDTA was also found to have the highest efficiency (90 %) in desorbing Cu adsorbed by a magnetic nanoadsorbent, which was modified from chitosan-coated magnetic nanoparticles with α-ketoglutaric acid (Zhou et al. 2009).

Several studies have showed the effectiveness of common ions for the desorption of adsorbed metals from certain types of sorbents (Lezcano et al. 2011). For example, (Lezcano et al. 2011) used NaHCO3 to desorbed Cu from a natural biomass, and a recovery of 76.7 % was observed (Lezcano et al. 2011). Gupta and Rastogi (2008) showed that the around 30 % chromium (VI) was desorbed from nonviable cyanobacterium Nostoc muscorum biomass using CaCl2 and MgCl2 (Gupta and Rastogi 2008). Three and 1 M KCl were proved to be effective in desorbing Pb (99.5 %) and Zn (80.0 %) from natural zeolite (Katsou et al. 2011).

To the best knowledge of the authors, there is not previous data on the regeneration of nano-TiO2 for aquatic metal removal, although a few studies have demonstrated the potential to desorb metals from nano-TiO2 surface using acid or chelating agents (Debnath et al. 2011; Gao et al. 2004; Hu and Shipley 2012). Gao et al. (2004) studied the adsorption/desorption of Cd2+ to large and nanometer-scale anatase, and their results showed that the desorption of Cd2+ from both particle sizes was completely reversible (Gao et al. 2004). Debnath et al. (2011) studied the adsorption/desorption behavior of Cd2+ and Cu2+ on/from nanostructured hydrous titanium oxide (NHTO), and their evaluation on the desorption of adsorbed metal ions from NHTO surfaces showed that 0.01 M EDTA and 0.1 M HCl were the most efficient (Debnath et al. 2011). Hu and Shipley (2012) studied the desorption of Pb (II), Cu (II), and Zn (II) from nano-TiO2 using batch techniques, and desorption was showed to be pH dependent with more than 98 % of all metals desorbed at pH 2 (Hu and Shipley 2012).

In this investigation, commercially prepared nano-TiO2 (anatase) used for Pb (II), Cu (II), and Zn (II) removal was studied for its ability to be regenerated. Metal desorption in solutions of common ions (e.g., Ca2+, Mg2+, HCO3 −, HPO4 2−, etc.), EDTA, and a solution at pH 2 were evaluated to screen the best methods for regeneration. The effects of consecutive regeneration cycles and the presence of coexisting metals on metal adsorption/desorption were evaluated. In addition, the regeneration method was tested for the treatment of synthetic metal-contaminated water using nano-TiO2 as a sorbent.

Materials and methods

Materials

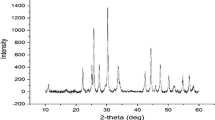

Commercially prepared nano-TiO2 (anatase) from Sigma-Aldrich (St. Louis, MO, USA) was used in the present study. Characteristics of the nano-TiO2 were previously reported by Engates (2010). In summary, surface area was determined by the Brunauer–Emmett–Teller method to be 185.5 m2/g, and the nominal particle size was calculated to be 8.3 nm. X-ray diffraction identified the nanoparticles as crystalline anatase (Engates 2010). The point of zero charge (pzc) of the TiO2 was determined by potentiometric titration to be at pH 5.2, which is consistent with previous literature results of pHpzc (Engates and Shipley 2011; Guzman et al. 2006).

Metal stock solutions were prepared from Pb (NO3)2, ZnSO4, and Cu (NO3)2 (certified ACS grade, Fisher Scientific, Houston, TX, USA), which yielded approximately 500 mg/L for each metal. Experiments conducted at pH 8.00 ± 0.02 were buffered with 0.01 M tris(hydroxymethyl) aminomethane (THAM) and adjusted with 6 N HNO3 to the desired pH. Experiments conducted at pH 2.00 ± 0.02 were adjusted by 0.01 M HNO3 and 0.01 M NaOH solutions to the desired pH. An electrolyte background of 0.01 M NaNO3 was added to all buffer solutions. Ethylenediaminetetraacetic acid (EDTA) solutions were prepared from Na2EDTA (certified ACS grade, Fisher Scientific, Houston, TX, USA). Certified ACS grade NaNO3, CaCl2, MgSO4, NaHCO3, Na2SO4, NaCl, and Na2HPO4 were used for the preparation of common ion solutions.

Water was prepared by reverse osmosis by sand and carbon nanofiltration, using a NANOpure Diamond Barnstead with Hollow Fiber Filter. Tap water, which was treated water from the Edwards Aquifer, was taken from University of Texas at San Antonio and used in this study. HACH standard methods (HachCompany 2008) were used to analyze the turbidity, alkalinity, hardness, silica, phosphate, and sulfate, and metal concentrations in the water were analyzed by Perkin Elmer inductively coupled plasma mass spectroscopy (ICP-MS) and ICP-OES. Results of the composition and water quality parameters were shown in Table 1. Simulated metal polluted water was prepared by spiking the San Antonio tap water with Pb (II), Cu (II), and Zn (II) (1.50 ± 0.18 μmol/L each). The HACH sensION pH meter was used to measure pH and was calibrated daily at pH 4.0, 7.0, and 10.0 using standard solutions.

The software Visual Minteq 3.0 was used for the calculation of Pb (II), Cu (II), and Zn (II) speciation as a function of pH at 1.50 μmol/L and 22 °C. The results are shown in Figure S1. At the Pb (II), Cu (II), and Zn (II) concentrations studied, more than 99 % of M (II) species were M2+ at pH 2. At pH 8, the major species for Pb (II) were Pb2+ and Pb (OH) +, the major species for Cu (II) were Cu2+ and Cu (OH) +, the major species for Zn (II) were Zn2+ and Zn (OH)+, and all of those species were positively charged. None of the metals were showed to be precipitated at either pH. Similar distribution diagrams for Pb (II), Cu (II), and Zn (II) species in aqueous solution were reported in previous literatures (Machida et al. 2004).

Metal analysis methods

Metal concentrations were measured on a Perkin Elmer DRC-e ICP-MS (PerkinElmer, Waltham, MA, USA) having a quadruple mass spectrometer. The plasma is argon gas with a nebulizer gas flow of 0.83 L/min, a lens voltage of 6.5 V, and RF power of 1,200 W. Operating conditions were determined after optimization of each parameter. Metal standards were prepared from 100 μg/mL standard stock solutions (VHG Labs) and diluted to meet the desired calibration standard concentrations of 1, 10, and 100 μg/L. Each calibration standard was acidified with 1 % HNO3 by volume. Coefficients of determination (r 2) were greater than 0.999 in most cases with a relative standard deviation less than 5 %.

Screening experiment: batch adsorption–desorption experiments

Metals (1.50 ± 0.18 μmol/L) were initially adsorbed to 0.1 g/L nano-TiO2 at pH 8.0 in 0.01 M THAM buffer with 0.01 M NaNO3. Metals were added individually at concentrations of 1.56 μmol/L to a 50-mL sealed centrifuge tube and rotated at 25 rotations per minute for 24 h using a LabNet Mini LabRoller Rotator (Bioexpress, Kaysville, UT, USA). Samples were filtered with cellulose acetate 0.45 μm membrane filters (Whatman OE 67) to recover the nano-TiO2 solid. One (5 mL) sample was withdrawn from the supernate and acidified with 1 % HNO3 for ICP-MS analysis to determine the adsorbed concentration of each metal to the nano-TiO2 surface. Desorption experiments were performed for Pb (II), Cu (II), and Zn (II) by adding metal-free desorbing solution to the recovered nano-TiO2 solid. The desorbing solutions included 0–2 μmol/L for Cu (II) and Zn (II), 0–5 μmol/L for Pb (II))EDTA solutions (at pH 8 in 0.01 M NaNO3), and common ion solutions (NaNO3, CaCl2, MgSO4, NaHCO3, Na2SO4, NaCl, Na2HPO4 at pH 8, and an ionic strength of 0.5 M). The recovered nano-TiO2 solids were again rotated for 24 h. Samples were filtered and acidified for ICP-MS analysis. The detection limits for the metals were 0.0005 μg/L for Cu and Pb and 0.001 μg/L for Zn. The experiments were conducted with two replications with statistically similar results each time.

The amount of metals remaining on the surface after each desorption cycle was calculated as the difference between the initial amount of metals adsorbed minus the amount of metals recovered from the supernate. The reliability of the desorption method was checked by mass balance as discussed in a previous paper (Hu and Shipley 2012). Mass balance showed that greater than 95 % of TiO2 was recovered after each cycle of desorption. The presence of the THAM buffer was checked to ensure that there was negligible interference to Pb (II), Cu (II), and Zn (II) adsorption/desorption. Experiments were conducted with the THAM buffer in solution and without the THAM buffer in solution at pH 8 with metals in solution. A negligible statistical difference between the buffers present and not present was observed, confirming that the THAM did not interfere with metal adsorption/desorption. Also, the pH was tested throughout the experiments and remained stable (change within ±0.02).

Regeneration: single metal systems

The solutions exhibiting the highest percent desorption for each metal were used to examine the regeneration potential of the nano-TiO2. In our previous research, desorption of Pb (II), Cu (II), and Zn (II) from nano-TiO2 was found to be pH dependent with greater than 98 % of metal desorbed at pH 2 when they were initially adsorbed at pH 8 with a initial metal concentration of 93.4 ± 2.8 μg/L (Hu and Shipley 2012). Thus, for Cu (II) and Zn (II), the regeneration solutions were a pH 2 solution or a 2-μmol/L EDTA solution. For Pb (II), they were a pH 2 solution or a 4-μmol/L EDTA solution. The recovered nano-TiO2 was then used for cycles of adsorption–desorption following the experiment procedure described in “Screening experiment: batch adsorption–desorption experiments” section. The cycle of adsorption–desorption was carried out for nine cycles of adsorption and eight cycles of desorption.

Regeneration: switching metals systems

To investigate the effect of adsorption/desorption of a previous metal (M1) on the adsorption/desorption of another metal (M2), regeneration experiments were carried out by switching the metals in different adsorption–desorption cycles, using a similar procedure as described in “Screening experiment: batch adsorption–desorption experiments” section. For Cu (II) and Zn (II), the regeneration solutions were a pH 2 solution or a 2-μmol/L EDTA solution. For Pb (II), they were a pH 2 solution or a 4-μmol/L EDTA solution. The cycle of “adsorption (M1)–desorption–adsorption (M2)–desorption” was carried out for a total of three cycles.

Regeneration: multiple metals systems

To investigate the competitive effect of different metals on the adsorption/desorption process, regeneration experiments were carried out by adsorbing Pb (II), Cu (II), and Zn (II) simultaneously (1.22 μmol/L Pb (II), 1.58 μmol/L Cu (II), and 1.55 μmol/L Zn (II)). A similar procedure as described in “Screening experiment: batch adsorption–desorption experiments” section was used for the adsorption–desorption study, and a pH 2 solution or an EDTA (4.0 μmol/L) solution were used for the desorption experiment. The cycle of adsorption–desorption was carried out for nine cycles of adsorption and eight cycles of desorption.

Regeneration: simulated metal polluted water treatment

Spiked tap water was used as simulated metal polluted water for this study. Pb (II), Cu (II), and Zn (II) were added to the tap water simultaneously. The metal concentrations in the spiked tap water were 1.22, 4.19, and 2.62 μmol/L for Pb (II), Cu (II), and Zn (II), respectively. A similar procedure as described in “Screening experiment: batch adsorption–desorption experiments” section was used for the adsorption–desorption with a pH 2 solution being used for the desorption experiments. The number of adsorption–desorption cycles was five cycles of adsorption and four cycles of desorption.

Surface complexation modeling

Surface complexation modeling was conducted to estimate the trends of metals desorption from nano-TiO2 over the full range of EDTA concentration. The adsorption of metals as a function of equilibrium metal concentrations was also estimated by surface complexation modeling to predict the adsorption capacity of nano-TiO2. The diffuse layer model was incorporated into the FITEQL and Visual MINTEQ programs and used for all model predictions. Surface complexation reactions used for modeling are listed in Table 2, while important solution complexation reactions employed in the modeling are presented in Table S1. An assumption that the nano-TiO2 surface was homogeneous and neutral was made. The unoccupied surface sites of TiO2 were expressed as ≡Ti (OH) (OH2), which contains both a surface hydroxyl and a chemisorbed water (Yang and Lee 2005). The specific surface area (in square meters per gram), solid concentration (in grams per liter), and site density (sites per square nanometer) were used to determine the total site concentration of ≡Ti (OH) (OH2) (Hayes et al. 1991; Hu and Shipley 2012). A site density of 2.31 sites/nm2 was employed in this study (Davis and Kent 1990). The intrinsic surface complexation constant (K int) for the reactions of metal-EDTA on the nano-TiO2 surface was determined by FITEQL using a weighted least-squares method (Herbelin and Westall 1999). The K int for protonated (≡Ti (OH2)+) and deprotonated (≡Ti (OH)2 −) nano-TiO2 surface sites was reported by Stone et al. (1993) to be 103.9 and 10−8.7, respectively (Stone et al. 1993). The K int for EDTA complexation on the nano-TiO2 was determined by Yang and Davis (1999) to be 1022.09 (Yang and Davis 1999). The K int for Pb (II), Cu (II), and Zn (II) complexation on the nano-TiO2 was previously determined to be 100.72, 100.68, and 10−0.32 (Hu and Shipley 2012).

Results and discussion

Screening experiment using EDTA and common ion solutions

Regeneration using an EDTA solution

In this study, EDTA solutions at various concentrations were tested for their ability to desorb Pb, Cu, and Zn species from nano-TiO2. To eliminate the possible effect of pH on metal desorption, all EDTA solutions were buffered at pH 8.0, in which negligible amount of metals were desorbed (Hu and Shipley 2012). Results are shown in Fig. 1. Results showed that the percent of metal desorption increased as the concentration of EDTA increased and the majority of adsorbed metals could be desorbed from the nano-TiO2. For Cu (II) and Zn (II), when the EDTA concentration increased from 0.1 to 2.0 μmol/L, the percent of Cu (II) and Zn (II) desorbed increased from 7 and 4 to 97 and 99 %, respectively. For Pb (II), the percent desorbed increased from 1 to 81 % as the EDTA concentration increased from 0.1 to 4 μmol/L, while it slightly increased from 81 to 87 % when the EDTA concentration went from 4 to 5 μmol/L. Compared to Pb (II), Cu (II) and Zn (II) were more readily desorbed at the same EDTA concentration, indicating a higher affinity of Pb (II) to the nano-TiO2 surface. It has been found that Pb (II) was adsorbed mainly through inner-sphere complexation, while Cu and Zn were adsorbed mainly through physical attachment or interaction with surface hydroxyl groups (Hu and Shipley 2012).

It has been proposed that EDTA forms stable metal–EDTA complexes and the EDTA and the metal–EDTA complexes compete for surface sites on the TiO2 surface (Vohra and Davis 1998; Yang and Davis 1999; Yang and Lee 2005). To better investigate the mechanisms of metal desorption from nano-TiO2 under the effect of EDTA, surface complexation modeling was conducted with the determination of surface complexation constants and the estimation of desorption trends. The intrinsic complexation constants (K int) for the reactions of metal–EDTA onto the nano-TiO2 surface were calculated based on experimental data over the full range EDTA concentrations; the values of logK int that provided the optimal fit of the model to the experimental data are given in Table 2. The calculated logK int values were 21.69 for Pb-EDTA, 21.30 for Cu-EDTA, and 20.01 for Zn-EDTA, which indicated that the three species had similar affinity to the nano-TiO2 surface sites (Giammar et al. 2007). The values of the weighted sum of squares divided by the degrees of freedoms (WSOS/DF) for Pb-EDTA, Cu-EDTA, and Zn-EDTA were 1.41, 0.35, and 3.72, respectively. These represented good fits as the WSOS/DF values were less than 20 (Grossl et al. 1997).

The fit of the model to the metal desorption data as a function of EDTA concentration is shown in Fig. 1. The model fits the desorption of Cu (II) and Zn (II) well with more than 97 % desorption occurring when the EDTA concentration reached 2 μmol/L. This indicated that the mechanism of Cu (II) and Zn (II) desorption from nano-TiO2 could be described as the formation of Cu-EDTA and Zn-EDTA complexes in solution. For Pb (II), deviation was observed between the model prediction and the experimental data, and the prediction of the percent of Pb (II) desorbed was in excess of the experimental data. This might be explained by the presence of complexes such as Pb-HEDTA and Pb-H2EDTA (Zeng et al. 2011), which could lead to the formation of surface species such as ≡Ti(OH)EDTAHPb1− and ≡ Ti(OH)EDTAH2Pb. The formation of those surface species could be potentially important, though they were excluded in our model prediction (Yang and Davis 1999).

Regeneration using common ions solutions

In the present study, common ion solutions (NaNO3, CaCl2, MgSO4, NaHCO3, Na2SO4, NaCl, Na2HPO4 at ionic strength of 0.5 M) were evaluated for their effectiveness in desorbing Pb, Cu, and Zn species from nano-TiO2. Negligible desorption was observed for Pb (II) and Zn (II), while part of the adsorbed Cu (II) was desorbed in NaNO3, NaHCO3, NaCl, and Na2HPO4, as shown in Table 3. These results further confirmed that Pb (II) and Zn (II) adsorption onto-TiO2 was independent of ionic strength and the valence of the electrolyte ions, indicating an inner-sphere complexation mechanism (Fan et al. 2009). Cu (II) most likely adsorbed to weak binding sites or attached through outer-sphere complexation (Hu and Shipley 2012). Desorption of Cu (II) occurred because of the competition from background common ions when the ionic strength was increased (Li et al. 2009). Cu desorption might also be attributed to the complexation of Cu (II) with anions (such as HCO3 − and HPO4 2−), which were present in the common ion solutions (Lezcano et al. 2011). However, even the highest percent of Cu (II) desorption by Na2HPO4 (42.3 %) would not be practical for application.

Based on the results of the screening experiments, EDTA solutions were better at desorbing Pb, Cu, and Zn species than common ion solutions. Our previous research also showed that a pH 2 solution had high efficiency in desorbing Pb, Cu, and Zn species (Hu and Shipley 2012). Thus, pH 2 and EDTA solutions were used for the regeneration studies. The EDTA concentration used for Cu (II) and Zn (II) desorption was 2 μmol/L, while it was 4 μmol/L for Pb (II) desorption. These EDTA concentrations ensured at least 97 % desorption of Cu (II) and Zn (II), and 81 % desorption of Pb (II) as shown in Fig. 1.

Single metal systems

For every single metal, eight adsorption/desorption cycles were conducted to determine the adsorption/desorption potential of the nano-TiO2 after each cycle of regeneration. Desorption was conducted using a solution at pH 2 or an EDTA (2 μmol/L for Cu (II) and Zn (II), 4 μmol/L for Pb (II)) solution. In each cycle, the adsorption/desorption was conducted until steady-state conditions were reached. In Fig. 2a, b, the percent of adsorption/desorption of Pb, Cu, and Zn species are given, respectively, for eight regeneration cycles using pH 2 solution. The percent of adsorption/desorption of Pb, Cu, and Zn species for eight regeneration cycles by EDTA solution were given in Fig. 2c, d, respectively. For nano-TiO2 regenerated by a pH 2 solution, the percent of metal adsorbed remained consistent after eight cycles of regeneration, with around 100, 92, and 98 % of Pb (II), Cu (II), and Zn (II) adsorbed in each cycle (Fig. 2a). However, a decrease was observed in the percent of metal desorbed after each regeneration cycle. The percent of Pb (II), Cu (II), and Zn (II) desorbed decreased from 98 to 62, 99 to 94, and 99 to 85 %, respectively, from the first to the eighth cycle (Fig. 2b).

Percent of Pb (II), Cu (II), and Zn (II) adsorbed and desorbed from nano-TiO2 during consecutive regeneration cycles: a adsorption, pH 2; b desorption, pH 2; c adsorption, EDTA; d desorption, EDTA. Metals were adsorbed at pH 8 individually (1.50 ± 0.18 μmol/L). Error bars represent 5 % error in the metal measurement

For nano-TiO2 regenerated by an EDTA solution, the percent of metal adsorbed slightly decreased with increasing regeneration cycles. Pb (II) adsorption decreased from 100 to 91 %, Cu (II) adsorption decreased from 92 to 70 %, and Zn (II) adsorption decreased from 98 to 86 % from the first to the eighth cycle (Fig. 2c). A major decrease was observed in the percent of metal desorbed for each EDTA regeneration cycle. The percent of Pb (II), Cu (II), and Zn (II) desorbed decreased from 71 to 35, 99 to 42, and 99 to 57 %, respectively, from the first to the eighth cycle (Fig. 2d). Pb (II) was relatively stable in the amount adsorbed during each cycle, while the amount desorbed decreased with each regeneration cycle for both pH 2 and EDTA solutions. This suggests that Pb (II) had higher affinity to the nano-TiO2 surface, and the inner-sphere complexation of Pb (II) onto the surface sites made adsorption harder to reverse than for the other metals (Katsou et al. 2011). For Cu (II) and Zn (II), the affinity for the nano-TiO2 surface is less than Pb, and since desorption decreased with each cycle, less surface sites were available for adsorption during the next regeneration cycle; thus, there was decreasing adsorption over the eight cycles. The decreased desorption may be due to EDTA being a strong chelating agent making it harder to reverse adsorption after continuous cycles and desorption being conducted at pH 8, which previous work show was not ideal for desorption (Hu and Shipley 2012).

Switching metals systems

To investigate whether the previous adsorption/desorption of one metal (M1) affected the adsorption/desorption of another metal (M2) and to further investigate the interaction between different metals, regeneration experiments were carried out by switching the metals in different adsorption–desorption cycles. Three cycles of “adsorption (M1)–desorption–adsorption (M2)–desorption” were carried out consecutively. The percent of adsorption/desorption of both the first metal (M1) and the second metal (M2) are given in Tables 4 (pH 2 desorbing solution) and 5 (EDTA desorbing solution, 4 μmol/L for Pb (II), 2 μmol/L for Cu (II) and Zn (II)); it should be noted that the desorption of M2 was carried out for two cycles while the other adsorption/desorption processes were carried out for three cycles.

For nano-TiO2 regenerated by pH 2 solution, for both the first and second metals added, the percent of metal adsorbed remained consistent, while a slight decrease was observed in the percent of metal desorbed through three cycles for both metals (Table 4). For nano-TiO2 regenerated by EDTA solution, for both the first and second metals added, the percent adsorbed decreased slightly with increasing regeneration cycles. For example, for the Pb–Cu system, the percent of Pb (II) and Cu (II) desorbed decreased from 100.0 to 98.1 % and from 94.5 to 88.0 %, respectively, from the first to the third cycle of regeneration (Table 5). A slight decrease was also observed for the percent of Cu (II) and Zn (II) desorbed through the regeneration cycles; however, it did not matter if the metals were added first or second. Repeated measures ANOVA was used to analyze the effect of the M1 adsorption/desorption on the adsorption/desorption of the M2. The statistical analysis was conducted using JMP 9.0 software. Data were checked for their normal distribution and equal variances before ANOVA analysis. A significance level of 0.05 was used in all the statistic analysis. Comparisons were made for the experimental data of M2 with and without previous adsorption/desorption of another metal. The p values for the statistic analysis were given in Tables 4 and 5.

When pH 2 solution was used as the desorbing solution, for all three metals studied, the adsorption of M2 was not significantly affected by the previous adsorption/desorption of M1, with p values greater than 0.05 (Table 4). Desorption of Cu (II) was significantly affected by the previous adsorption/desorption of Pb (II) and Zn (II), which lead to around 6 and 7 % decrease in Cu (II) desorption, respectively (repeated measures ANOVA, p = 0.006 for Pb (II), p = 0.002 for Zn (II); Fig. 2b; Table 4). The adsorption/desorption of Pb (II) had a statistically significant effect on the desorption of Zn (II), around a 7 % decrease compared to when Zn was adsorbed/desorbed by itself (repeated measures ANOVA, p = 0.003; Fig. 2b; Table 4). The decrease in the desorption of M2 could be due to incomplete desorption of M1 in the previous cycle.

When the nano-TiO2 was regenerated by an EDTA solution, adsorption of Cu (II) was significantly affected by the previous adsorption/desorption of Pb (II) and Zn (II), with an increase of 5 and 8 % in Cu (II) adsorption, respectively (repeated measures ANOVA, p = 0.028 for Pb (II), p = 0.007 for Zn (II); Fig. 2c; Table 4). Zn adsorption was also significantly affected by the previous adsorption/desorption of Pb (II), with around 4 % decrease in Zn (II) adsorption (repeated measures ANOVA, p = 0.017; Fig. 2c; Table 4). Pb (II) desorption was enhanced by the previous adsorption/desorption of Cu (II) and Zn (II), with 15 and 13 % increase in Pb (II) desorption (repeated measures ANOVA, p = 0.008 for Cu (II), p = 0.014 for Zn (II); Fig. 2d; Table 4). This result suggests that there might be a synergistic effect but further work is needed for verification. However, no statistically significant effect was observed for all other processes as the p values were greater than 0.05. The enhanced Cu (II) adsorption by the previous adsorption/desorption of Pb (II) and Zn (II) suggested that Cu (II) potentially interacted with the Pb (II) and Zn (II) that remained on the surface of nano-TiO2 after the previous adsorption/desorption (Doula and Ioannou 2003; Katsou et al. 2011).

These results suggest that regenerated nano-TiO2 that was previously used for the removal of one metal could be successfully used for the removal of another metal, especially when the affinity of the other metal to nano-TiO2 surface is higher. However, the adsorption/desorption of metals with higher affinity to the nano-TiO2 surface did affect the adsorption/desorption of lower affinity metals. This indicated that some of the surface sites on the nano-TiO2 could be shared by different metals; in circumstances when surface sites become limited, metals with higher affinity will be more readily adsorbed (Şengil and Özacar 2009).

Multiple metals systems

Since metals are often present together in most waters, it is important to investigate whether different metals can be adsorbed and desorbed from the nano-TiO2 simultaneously and to understand the potential competitive effects. Metals with similar concentrations (1.22 μmol/L for Pb (II), 1.58 μmol/L for Cu (II), and 1.55 μmol/L for Zn (II)) were added. Eight adsorption/desorption cycles were conducted to determine the percent of metal adsorption/desorption from the nano-TiO2 after each cycle of regeneration. pH 2 and EDTA (4 μmol/L) solutions were used as the regeneration solutions. In Fig. 3a, b, the percent of adsorbed and desorbed Pb, Cu, and Zn species are given, respectively, for eight regeneration cycles using a pH 2 solution. The percent of adsorbed and desorbed Pb, Cu, and Zn species for eight regeneration cycles using an EDTA solution are given in Fig. 3c, d. For nano-TiO2 regenerated by a pH 2 solution, the percent of metal adsorption remained consistent after eight cycles of regeneration, with around 100, 91, and 98 % of Pb, Cu, and Zn species adsorbed during each cycle (Fig. 3a); those numbers were similar to the results for single metal systems. However, a decrease was observed in percent of metal desorbed after each regeneration cycle. The percent of Pb, Cu, and Zn species desorbed decreased from 99 to 71, 99 to 82, and 99 to 92 %, respectively (Fig. 3b).

Percent of Pb (II), Cu (II), and Zn (II) adsorbed and desorbed from nano-TiO2 during consecutive regeneration cycles: a adsorption, pH 2; b desorption, pH 2; c adsorption, EDTA; d desorption, EDTA. Metals were adsorbed at pH 8.0 simultaneously (1.22 μmol/L. Pb (II), 1.58 μmol/L Cu (II), and 1.55 μmol/L Zn (II)). Error bars represent 5 % error in the metal measurement

For nano-TiO2 regenerated by EDTA solution, the percent of metal adsorbed decreased with each regeneration cycle, especially for Cu (II). Pb (II) adsorption decreased from 100 to 97 %, Cu (II) adsorption decreased from 92 to 49 %, and Zn (II) adsorption decreased from 99 to 74 % (Fig. 3c). The percent of Pb (II) desorbed by each addition of EDTA was small. The percent of Pb (II), Cu (II), and Zn (II) desorbed decreased from 2 to 0.4, 67 to 30, and 40 to 4 %, respectively (Fig. 3d); these results were much lower compared to when the metals were individually desorbed. Spent nano-TiO2 regenerated by both methods showed the ability to adsorb and desorb Pb (II), Cu (II), and Zn (II) simultaneously, especially when it was regenerated by a pH 2 solution.

To further evaluate whether there were competitive effects among different metals during the adsorption/desorption process, experimental data were analyzed statistically by one-way ANOVA and repeated measures ANOVA. One-way ANOVA was used to check whether the adsorption of one metal was affected by the presence of other metals in the first cycle using the fresh nano-TiO2. Results showed that the presence of Cu (II) and Zn (II) did not significantly affect the adsorption of Pb (II) (one-way ANOVA, p = 0.356; Figs. 2a, c and 3a, c), the presence of Pb (II) and Zn (II) did not significantly affect the adsorption of Cu (II) (one-way ANOVA, p = 0.242; Figs. 2a, c and 3a, c), and the presence of Pb (II) and Cu (II) did not significantly affect the adsorption of Zn (II) (one-way ANOVA, p = 0.089; Figs. 2a, c and 3a, c). The absence of a competitive effect might be due to the high specific surface area of the nano-TiO2, which provided sufficient surface sites for metal adsorption even in a multiple-metal system. However, if the adsorption amount is pushed to reach the adsorption edge, competitive effects may exist between different metals (Trivedi and Axe 2000).

Repeated measures ANOVA was used to check whether the adsorption/desorption of one metal was affected by the coexistence of the other two metals in consecutive regeneration cycles. For pH 2 regenerated nano-TiO2, through the eight cycles of regeneration, the coexistence of Cu (II) and Zn (II) did not significantly affect the adsorption of Pb (II) (repeated measures ANOVA, p = 0.191; Figs. 2a and 3a); the coexistence of Pb (II) and Cu (II) did not significantly affect the adsorption of Zn (II) (repeated measures ANOVA, p = 0.072; Figs. 2a and 3a); however, the coexistence of Pb (II) and Zn (II) significantly affected the adsorption of Cu (II), though the decrease in Cu (II) adsorption was relatively small (around 4 %) (repeated measures ANOVA, p = 0.0002; Figs. 2a and 3a). For the desorption process, none of the metals were affected by the coexistence of the other two metals (repeated measures ANOVA, Pb (II): p = 0.083; Cu (II): p = 0.071; Zn (II): p = 0.096; Figs. 2b and 3b), which indicated that pH 2 solution was efficient in desorbing the metals simultaneously.

For EDTA regenerated nano-TiO2, through the eight cycles of regeneration, Pb (II) adsorption was significantly affected by the coexistence of Cu (II) and Zn (II), with less desorption (7 % less) occurring after eight cycles of regeneration (repeated measures ANOVA, p = 0.0001; Figs. 2c and 3c); Cu (II) adsorption was significantly affected by the coexistence of Pb (II) and Zn (II), with a decrease in desorption of around 20 % after eight cycles of regeneration (repeated measures ANOVA, p = 0.0005; Figs. 2c and 3c); and no significant effect of Pb (II) and Cu (II) on Zn (II) adsorption was observed (repeated measures ANOVA, p = 0.184; Figs. 2c and 3c). Desorption of metals in EDTA solution was found to be significantly affected by coexisting metals (repeated measures ANOVA, Pb (II): p = 0.0005; Cu (II): p = 0.003; Zn (II): p = 0.0001; Figs. 2d and 3d). When metals were desorbed simultaneously, desorption decreased around 35 % for Pb (II), 10 % for Cu (II), and 50 % for Zn (II) when compared to desorption in a single metal system. These results indicated that Pb (II) and Zn (II) were more competitive during the adsorption process, while Cu (II) was more competitive during the desorption process. However, further research is needed to investigate the selectiveness of the nano-TiO2 surface sites.

Simulated metal polluted water systems

Figure 4 shows the simultaneous adsorption/desorption of Pb (II), Cu (II), and Zn (II) from nano-TiO2 (0.1 g/L) in consecutive regeneration cycles in simulated metal polluted water. A pH 2 solution was used for regeneration. Simulated metal polluted water was prepared by spiking San Antonio, TX, USA tap water with metals, which formed a total of 1.22 μmol/L Pb (II), 4.19 μmol/L Cu (II), and 2.62 μmol/L Zn (II) in the water. The composition of the San Antonio, TX, USA tap water before spiking is detailed in Table 1. The pH for the water was 7.92, which was similar to other adsorption experiments (pH 8.0). Several ions were present in the water such as Ca2+, Mg2+, Cl−, SO4 2−, and HCO3 − (Table 1). Pb (II), Cu (II), and Zn (II) were effectively adsorbed and desorbed simultaneously, with greater than 94 % of metal adsorption and greater than 92 % of metal desorption throughout the cycles (Fig. 4). The regeneration study of multiple metals in deionized water also showed greater than 90 % metal adsorption and greater than 91 % metal desorption through the first five cycles (Fig. 3a, b).

Percent of Pb (II), Cu (II), and Zn (II) adsorbed and desorbed from nano-TiO2 during consecutive regeneration cycles in simulated polluted water made of San Antonio tap water. Metals were adsorbed at pH 8.0 simultaneously (1.22, 4.19, and 2.62 μmol/L for Pb (II), Cu (II), and Zn (II)) and desorbed using pH 2.0 solution. Error bars represent 5 % error in the metal measurement

To evaluate whether the presence of other ions in the tap water had an effect on the adsorption/desorption of metals, statistical comparisons were made between the results for multiple metal systems and the results for simulated metal polluted water system. Pb (II) adsorption was founded to be similar from multiple metal systems and simulated metal polluted water, with almost complete adsorption (repeated measures ANOVA, p = 0.161; Figs. 3a and 4). The percent of Cu (II) adsorbed in simulated metal polluted water was statistically significant with an increase in adsorption around 6 % than in the multiple metal system (repeated measures ANOVA, p < 0.0001; Figs. 3a and 4). The increased amount of Cu (II) adsorbed could be due to the interaction of Cu (II) with ions (such as Cl−) in the tap water, which formed complexes that attached to the nano-TiO2 surface and increased the overall adsorption of Cu (II) (Gedik and Imamoglu 2008; Katsou et al. 2011). The percent of Zn (II) adsorption/desorption were shown to be statistically significant (repeated measures ANOVA, p = 0.0008 for adsorption, p = 0.037 for desorption; Figs. 3 and 4). However, no statistically significant difference was observed for Pb (II) and Cu (II) desorption between the simulated water and the multiple metal system (repeated measures ANOVA, p = 0.061 for Pb (II), p = 0.196 for Cu (II); Figs. 3b and 4).

Conclusion

Out of all the regeneration methods tested, pH 2 solution was determined to be the most effective. Surface complexation modeling indicated that the mechanism of metal desorption by EDTA was due to the formation of metal–EDTA complexes, and the competition between EDTA and metal–EDTA complexes for the attachment on surface sites. In the single metal system, nano-TiO2 was successfully regenerated and reused for eight cycles. Nano-TiO2 regenerated from the removal of a previous metal could be successfully used for the removal of another metal. No competitive effect was observed for metals adsorbing onto fresh nano-TiO2 surface. Nano-TiO2 was able to be regenerated and reused for the adsorption/desorption of multiple metals simultaneously. Nano-TiO2 was successfully regenerated using pH 2 solution and reused for the removal of Pb (II), Cu (II), and Zn (II) from simulated metal polluted water, with greater than 94 % of adsorption and greater than 92 % of desorption after four cycles of regeneration.

The results suggest three important points that will improve the capabilities of researchers to develop practical methods for the application of nano-TiO2 as a sorbent in water purification: (1) pH 2 and EDTA solutions were the most efficient in regeneration suggesting that regeneration of nano-TiO2 can be achieved by simple and low-cost treatment technologies; (2) the capabilities for the nano-TiO2 to be regenerated and reused in a multiple metals system and simulated polluted water well meet the requirements for a practical treatment process, where different pollutants are often present together; and (3) regeneration of nano-TiO2 could potentially be used to recover the toxic but valuable heavy metals, which would be useful for industrial applications.

References

Cruz Viggi C, Pagnanelli F, Cibati A, Uccelletti D, Palleschi C, Toro L (2010) Biotreatment and bioassessment of heavy metal removal by sulphate reducing bacteria in fixed bed reactors. Water Res 44(1):151–158

Davis JA, Kent D (1990) Surface complexation modeling in aqueous geochemistry. Rev Mineral Geochem 23(1):177–260

Debnath S, Nandi D, Ghosh UC (2011) Adsorption–desorption behavior of cadmium(II) and copper(II) on the surface of nanoparticle agglomerates of hydrous titanium(IV) oxide. Journal of Chemical & Engineering Data 56(7):3021–3028

Deng L, Su Y, Su H, Wang X, Zhu X (2007) Sorption and desorption of lead (II) from wastewater by green algae Cladophora fascicularis. J Hazard Mater 143(1–2):220–225

Doula MK, Ioannou A (2003) The effect of electrolyte anion on Cu adsorption–desorption by clinoptilolite. Microporous and Mesoporous Materials 58(2):115–130

Engates KE (2010) Characterization, sorption, and exhaustion of metal oxide nanoparticles as metal adsorbents. Ph.D., The University of Texas at San Antonio

Engates K, Shipley H (2011) Adsorption of Pb, Cd, Cu, Zn, and Ni to titanium dioxide nanoparticles: effect of particle size, solid concentration, and exhaustion. Environ Sci Pollut Res 18(3):386–395

Fan Q, Shao D, Lu Y, Wu W, Wang X (2009) Effect of pH, ionic strength, temperature and humic substances on the sorption of Ni(II) to Na–attapulgite. Chem Eng J 150(1):188–195

Fu F, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manage 92(3):407–418

Gao Y, Kan AT, Tomson MB (2003) Critical evaluation of desorption phenomena of heavy metals from natural sediments. Environ Sci Technol 37(24):5566–5573

Gao Y, Wahi R, Kan A, Falkner J, Colvin V, Tomson M (2004) Adsorption of cadmium on anatase nanoparticles—effect of crystal size and pH. Langmuir 20(22):9585–9593

Gedik K, Imamoglu I (2008) Removal of cadmium from aqueous solutions using clinoptilolite: influence of pretreatment and regeneration. J Hazard Mater 155(1–2):385–392

Giammar DE, Maus CJ, Xie L (2007) Effects of particle size and crystalline phase on lead adsorption to titanium dioxide nanoparticles. Environ Eng Sci 24(1):85–95

Grossl PR, Eick M, Sparks DL, Goldberg S, Ainsworth CC (1997) Arsenate and chromate retention mechanisms on goethite. 2. Kinetic evaluation using a pressure-jump relaxation technique. Environ Sci Technol 31(2):321–326

Gupta VK, Rastogi A (2008) Sorption and desorption studies of chromium(VI) from nonviable cyanobacterium Nostoc muscorum biomass. J Hazard Mater 154(1–3):347–354

Guzman KAD, Finnegan MP, Banfield JF (2006) Influence of surface potential on aggregation and transport of titania nanoparticles. Environ Sci Technol 40(24):7688–7693

HachCompany (2008) Water analysis handbook. Hach, Loveland

Hashim MA, Mukhopadhyay S, Sahu JN, Sengupta B (2011) Remediation technologies for heavy metal contaminated groundwater. J Environ Manage 92(10):2355–2388

Hayes KF, Redden G, Ela W, Leckie JO (1991) Surface complexation models: an evaluation of model parameter estimation using FITEQL and oxide mineral titration data. J Colloid Interface Sci 142(2):448–469

Herbelin A, Westall J (1999) FITEQL 4.0: a computer program for determination of chemical equilibrium constants from experimental data. Department of Chemistry, Oregon State University, Corvallis

Hu J (2006) Fundamental investigation on removal and recovery of heavy metals from synthetic wastewater using magnetic nanoparticles. Ph.D., Hong Kong University of Science and Technology (Hong Kong)

Hu J, Shipley HJ (2012) Evaluation of desorption of Pb (II), Cu (II) and Zn (II) from titanium dioxide nanoparticles. Sci Total Environ 431:209–220

Hu J, Chen G, Lo IMC (2006) Selective removal of heavy metals from industrial wastewater using maghemite nanoparticle: performance and mechanisms. J Environ Eng 132(7):709–715

Katsou E, Malamis S, Tzanoudaki M, Haralambous KJ, Loizidou M (2011) Regeneration of natural zeolite polluted by lead and zinc in wastewater treatment systems. J Hazard Mater 189(3):773–786

Kim MS, Hong KM, Chung JG (2003) Removal of Cu (II) from aqueous solutions by adsorption process with anatase-type titanium dioxide. Water Res 37(14):3524–3529

Kobya M, Demirbas E, Senturk E, Ince M (2005) Adsorption of heavy metal ions from aqueous solutions by activated carbon prepared from apricot stone. Bioresour Technol 96(13):1518–1521

Lezcano JM, González F, Ballester A, Blázquez ML, Muñoz JA, García-Balboa C (2011) Sorption and desorption of Cd, Cu and Pb using biomass from an eutrophized habitat in monometallic and bimetallic systems. J Environ Manage 92(10):2666–2674

Li J, Hu J, Sheng G, Zhao G, Huang Q (2009) Effect of pH, ionic strength, foreign ions and temperature on the adsorption of Cu(II) from aqueous solution to GMZ bentonite. Colloids and Surfaces A: Physicochemical and Engineering Aspects 349(1–3):195–201

Machida M, Kikuchi Y, Aikawa M, Tatsumoto H (2004) Kinetics of adsorption and desorption of Pb (II) in aqueous solution on activated carbon by two-site adsorption model. Colloids and Surfaces A: Physicochemical and Engineering Aspects 240(1):179–186

Rao GP, Lu C, Su F (2007) Sorption of divalent metal ions from aqueous solution by carbon nanotubes: a review. Sep Purif Technol 58(1):224–231

Şengil İA, Özacar M (2009) Competitive biosorption of Pb2+, Cu2+ and Zn2+ ions from aqueous solutions onto valonia tannin resin. J Hazard Mater 166(2–3):1488–1494

Shipley HJ, Yean S, Kan A, Tomson M (2009) Adsorption of arsenic to magnetite nanoparticles: effect of particle concentration, ph, ionic strength, and temperature. Environ Toxicol Chem 28(3):509–515

Stone AT, Torrents A, Smolen J, Vasudevan D, Hadley J (1993) Adsorption of organic compounds possessing ligand donor groups at the oxide/water interface. Environ Sci Technol 27(5):895–909

Tratnyek PG, Johnson RL (2006) Nanotechnologies for environmental cleanup. Nano Today 1(2):44–48

Trivedi P, Axe L (2000) Modeling Cd and Zn sorption to hydrous metal oxides. Environ Sci Technol 34(11):2215–2223

US EPA (2009) Nanomaterial case studies: Nanoscale titanium dioxide (external review draft). US Environmental Protection Agency, Washington, DC

Vohra MS, Davis AP (1998) Adsorption of Pb (II), EDTA, and Pb (II)-EDTA onto TiO2. J Colloid Interface Sci 198(1):18–26

Yang JK, Davis AP (1999) Competitive adsorption of Cu (II)-EDTA and Cd (II)-EDTA onto TiO2. J Colloid Interface Sci 216(1):77–85

Yang JK, Lee SM (2005) EDTA effect on the removal of Cu (II) onto TiO2. J Colloid Interface Sci 282(1):5–10

Yang Y, Chen H, Pan G (2007) Particle concentration effect in adsorption/desorption of Zn(II) on anatase type nano TiO2. J Environ Sci 19(12):1442–1445

Zeng G, Pang Y, Zeng Z, Tang L, Zhang Y, Liu Y, Zhang J, Lei X, Li Z, Xiong Y, Xie G (2011) Removal and recovery of Zn2+ and Pb2+ by imine-functionalized magnetic nanoparticles with tunable selectivity. Langmuir 28(1):468–473

Zhang W-X (2003) Nanoscale iron particles for environmental remediation: an overview. Journal of Nanoparticle Research 5(3):323–332

Zhang L, Fang M (2010) Nanomaterials in pollution trace detection and environmental improvement. Nano Today 5(2):128–142

Zhou Y-T, Nie H-L, Branford-White C, He Z-Y, Zhu L-M (2009) Removal of Cu2+ from aqueous solution by chitosan-coated magnetic nanoparticles modified with α-ketoglutaric acid. J Colloid Interface Sci 330(1):29–37

Acknowledgments

We acknowledge financial support from the National Science Foundation through the Broadening Participation Research Initiation Grants in Engineering (EEC-0823685) and the Civil and Environmental Engineering Program at the University of Texas at San Antonio.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 37 kb)

Rights and permissions

About this article

Cite this article

Hu, J., Shipley, H.J. Regeneration of spent TiO2 nanoparticles for Pb (II), Cu (II), and Zn (II) removal. Environ Sci Pollut Res 20, 5125–5137 (2013). https://doi.org/10.1007/s11356-013-1502-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-013-1502-7