Abstract

Carbonic anhydrase II (CA II) can catalyze the reversible hydration reaction of CO2 at a maximum of 1.4 × 106 molecules of CO2 per second. The crude intracellular enzyme extract containing CA II was derived from Chlorella vulgaris. A successful CO2 capture experiment with the presence of calcium had been conducted on the premise that the temperature was conditioned at a scope of 30–40 °C, that the biocatalyst-nurtured algal growth period lasted 3 days, and that pH ranged from7.5 to 8.5. Ions of K+, Na+, Ca2+, Co2+, Cu2+, Fe3+, Mg2+, Mn2+, and Zn2+ at 0.01, 0.1, and 0.5 M were found to exhibit no more than 30 % inhibition on the residual activity of the biocatalyst. It is reasonable to expect that calcification catalyzed by microalgae presents an alternative to geological carbon capture and sequestration through a chain of fundamental researches carried on under the guidance of sequestration technology.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Currently, the sequestration by a biomimetic route based on enzymatic catalysis of CO2 hydration has become a popular issue worldwide discussed by scientists (Lee et al. 2010).

Specifically, the enzyme of carbonic anhydrase (EC 4.2.1.1), a globular zinc metallic enzyme of a molecular mass of 30,000, can catalyze the reversible hydration reaction of CO2, during the process of which the catalytic velocity of human enzyme HCA II is confirmed to be the fastest and each molecular of which can hydrate a maximum of 1.4 × 106 molecules of CO2 per second (Khalifah and Silverman 1991).

The general enzyme reaction is shown below in Eq. 1 (Heck et al. 1994). It is now generally accepted that the reaction occurs as two half reactions, shown below in Eqs. 2 and 3 (Brauer et al. 2002).

Carbonic anhydrase used in CO2 capture and storage has received much attention by adopting human carbonic anhydrase or bovine carbonic anhydrase. But very few extensive studies (were about) focused on the enzyme from plant tissues (Shimahara et al. 2007). Actually, carbonic anhydrase was found in the algal biomass, such as Chlamydomonas reinhardtii, Scenedesmus obliquus, Dunaliella terteolecta, Chlorella saccharophila, Chlorella vulgaris, Chlorella spirulina, Chlorella pyrenoidosa, and Chlorococcum littorale (Miyachi et al. 2003).

A series of methods were proposed hereinafter to extract the crude extracellular and intracellular enzyme from C. vulgaris and assay the effects on enzymatic activity. Results of empirical researches on the effects of algal growth days required, the metal ions and anions, CO2 concentrations and inhibitors on enzymatic activity, the effect of temperature on enzymatic stability were also explained, as well as the effect of pH on both enzymatic activity and its stability.

Experiments

Microalgae cultivation and growth profile

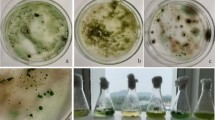

C. vulgaris isolate was obtained by the scientists of Wuhan Aquatic Plants Reservation of Chinese Academy of Science. Two hundred-milliliter flasks containing pH 8.5 of 100 ml BG11 cultivation medium was sterilized, cooled, and inoculated with 10 % (v/v) seed culture (A680nm = 0.2) of the C. vulgaris isolate and incubated at 25 °C and 14-h light each day without shaking (Rippka et al. 1979). Growth profile was recorded against the absorbance at a rate of 680 nm, and cells from the samples that had been removed at 12-h intervals over a period of 5 days were counted by a counting chamber under the Olympus biological microscope CX31 (Lund et al. 1958).

Crude enzyme extract preparation

One-gram moist grown cells (OD680nm = 0.8, a UV-Vis spectrophotometer made in China) was obtained by centrifugation at 800 × g for 10 min at 25 °C. Then they were suspended in 10 ml of pH 8.3 Tris buffer and incubated at 25 °C for 30 min as the extracellular enzyme extract. Intracellular enzyme extract was to rupture 1 g of moist cells in 110 ml of pH 8.3 Tris buffer with an appropriate portion of glass beads on a cell rupture instrument (Fastprep, USA) for six times, 1 min each time, and to centrifuge them at 14,650 × g for 10 min at 4 °C. The supernatant was taken and preserved under 4 °C as the intracellular enzyme extract.

Protein concentration determination

Protein concentrations were determined by the method of Coomassie Brilliant Blue G-250 with bovine serum albumin as standard at 595 nm.

Enzyme activity assay

The enzyme activity was determined under standard assayable conditions following the electrometric method (Brownell et al. 1991; Wilbur and Anderson 1948; Ramann et al. 2009; Sharma and Bhattacharya 2010). Enzymatic activity per gram of protein unit depended on T 0 (time of no enzyme involved when pH dropped from 8 to 7) and T E (time of enzyme involved when pH dropped from 8 to 7), described in Eq. 4.

Purification of carbonic anhydrase and molecular weight determination

The crude enzyme extract was concentrated through ammonium sulfate-saturated precipitation, and each fraction was determined in line with its enzymatic activity by the electrometric method as well as its protein concentration at 280 nm. Fractions in high CA activity were then subjected to SDS–PAGE using 8 % of gel and low-range protein molecular weight marker as standard.

Effect of growth days on enzyme activity

Measurements of algal growth in enzyme activity were made in triplicates every 24 h. The cell growth was calculated by the measured data of optical density at 680 nm. The moist weight of algal cells after a centrifugation of 5,000 × g for 10 min was also calculated to determine the biomass concentration.

Effect of metal ions and anions on enzymatic activity

The enzyme was remixed with 0.01, 0.1, and 0.5 M solution (v/v = 1:1) of salts of metal ions such as K+, Na+, Ca2+, Co2+, Cu2+, Fe3+, Hg2+, Mg2+, Mn2+, Pb2+, Zn2+, and As3+ and a number of anions like Cl−, NO −3 , SO 2−4 , and HCO −3 for 30 min at 4 °C before enzyme activity assay. The bovine CA agent from Sigma was adopted for a comparative evaluation (Tripp et al. 2004).

Effect of inhibitors on enzyme activity

A widely used CA enzyme inhibitor, acetazolamide (5-acetamido-1-thia-3, 4-diazole-2-sulphonamide) of 0.1, 1.0, and 10 mM were remixed with the enzyme (v/v = 1:1) for 30 min at 4 °C before enzymatic activity assay.

Effect of pH on enzymatic activity and stability

The pH measurements were conducted with a calibrated pH–conductivity mobile meter (MWT, Germany). The pH of the algae (OD680nm = 0.8) was maintained at 6.5, 7.5, 8.5, and 9.5 for the enzymatic activity assay. The effect of pH on enzyme stability was to assay the activity of the enzyme extracted from the broken algal cells remixed with Tris buffer (pH 6.5, 7.5, 8.5, and 9.5; v/v = 1:1).

Effect of temperature on enzyme stability

The effect of temperature on enzyme stability was to assay the enzyme activity at 10, 20, 30, 40, 50, and 60 °C.

Sequestration of CO2 into CaCO3

Two milliliters of enzyme extract was incubated at 25 °C for 2 h in a solution of 50 ml Tris buffer (8.3) and 20 ml 0.1 M calcium chloride saturated with carbon dioxide. The reaction was mixed gently using a magnetic stirrer for 15 min. The sample controlled without enzyme was also similarly treated. The samples of CaCO3 precipitation were then dried in a hot air oven until all moisture evaporated, weighed to determine the amount of carbonate deposited due to enzymatic action, and then calculated per milligram of protein after blank correction (Jansson and Northen 2010; Bond et al. 2001; Bhattacharya et al. 2003).

Results and discussion

CA identification

The molecular weight of purified CA procured from the crude enzyme extract was determined by SDS–PAGE and showed the presence of 29-kDa proteins in C. vulgaris (Fig. 1).

Localization of CA and effect of growth ages on enzymatic activity

The early reported model was designed to graphically explain the general molecular process of what would trigger and control the whole calcification in microalgal cells and how it happened even if so many mechanistic details of proposed models remained controversial. Results from the early experiments indicated that CA in intercellular enzyme appeared to be more massive than that in extracellular enzyme. Therefore, the truth is that the assays of enzymatic activity and stability were all conducted concerning the intercellular enzyme extract. The data of the enzymatic activity assay of the intracellular enzyme extract from samples taken on various growth days were plotted with the exact cell numbers, respectively (Fig. 2). Obviously, the enzymatic activity of C. vulgaris enzyme extract kept as high as 14.3 EU/g from 0 to 3 growing days before it ran down on the fourth day to 9.9 EU/g and on the fifth day to 2.5 EU/g, which was understandable if associated with the knowledge on microbiological metabolism.

Effect of ions and inhibitor on enzyme stability

According to the elemental analysis based on a sample of catalyst support which had been used for over 1,000 h in a postcombustion sulfate treatment system in a representative 2000 MW Plant Power (Xiamen, China), the elements of Co, Cu, Fe, Mn, Pb, Mg, K, As, Hg, and S were detected at their specific wave lengths in the sample, which actually dominated the ion choices, and evidently, these ions strongly and negatively influenced the CA activity in this investigation and in the earlier reported statistics. The enzyme stability under the effect of 11 species of metal ions and four species of anion groups of various concentrations was expressed in the percentage of residual activity if the initial activity was defined as 100 % (Table 1). The highest concentration (0.5 M) of K+, Na+, Ca2+, Hg2+, Pb2+, and HCO −3 was found to retain more residual enzyme activity in crude C. vulgaris enzyme extract than in bovine CA enzyme. Each assayed concentration (0.01, 0.1, and 0.5 M) of Na+, Ca2+, Hg2+, and Pb2+ was separately found to retain more residual enzyme activity in crude C. vulgaris enzyme extract than in bovine CA enzyme. Ions of K+, Na+, Ca2+, Co2+, Cu2+, Fe3+, Mg2+, Mn2+, and Zn2+ at various concentrations (0.01, 0.1, and 0.5 M) were found to exhibit no more than 30 % inhibition on the residual enzyme activity of crude C. vulgaris enzyme extract. Of all the anion groups of Cl−, NO −3 , HCO −3 , and SO 2−4 at various concentrations (0.01, 0.1, and 0.5 M), NO −3 , was found to exhibit most inhibition on the residual enzyme activity of crude C. vulgaris enzyme extract, which was in agreement with the study by Bond et al. reported in 2001. What needs to be specially emphasized is that Zn2+ at various concentrations (0.01, 0.1, and 0.5 M) was found to exhibit zero effect on both crude C. vulgaris enzyme extract and bovine CA enzyme. The data of the enzyme activity assay under the effect of the specific CA inhibitor of acetazolamide were plotted in Fig. 3. Acetazolamide was one of the inhibitors which were a class of pharmaceuticals suppressing the activity of carbonic anhydrase (Leibman et al. 1961). It was distinctively found to exhibit significant inhibition of 26, 73, and 90 % at respective concentrations of 0.1, 1.0, and 10 mM on the enzymatic activity of crude C. vulgaris enzyme extract.

Effect of pH and temperature on enzymatic activity and stability

The pH variations synchronizing the function of time at different initial pH that tended to boom ended at pH 9.77–9.90 after 90 h of incubation at 25 °C and within 14-h lightening each day without shaking. The pH variations of C. vulgaris' growth were recorded in Fig. 4a. It is worth noticing that pH 8.5–9.5 was the optimal alkaline condition for biocalcification. The data of the enzymatic activity assay of C. vulgaris samples under various cultivating pH and of various pH conditions were plotted in Fig. 4b. The enzymatic stability assay showed that the alkali pretreatment of the enzyme extract, in a range of pH 5.5–9.5, certainly enhanced the carbonate productivity. In contrary to that, the enzyme activity assay showed the alkaline conditions in C. vulgaris incubation to have enhanced the carbonate productivity due to the highest enzyme activity of 18.6 EU/g from pH 6.5 to 7.5 but completely restrained it down to the least enzyme activity of 11.3 EU/g from pH 7.5 to 9.5 (Fig. 4a).

To speak of the thermal stability of the crude enzyme extract, it showed that the residual enzyme activity of the crude enzyme extract had dropped to 50 % and finally to zero after it was boiled at 100 °C for 7 min and 30 min, respectively. It has been reported that the immobilized CA exhibited impressive thermal stability even at 65 °C. The data of the enzymatic activity assay under fluctuating temperature conditions were recorded in Table 2, while the data at 50 and 60 °C were missing because the reaction of H2CO3 ionization was too fast to detect. It confirmed one fact that the reactive velocity of the enzymatic activity assay increased while the temperature elevated, and it was too fast to be detectable while the temperature rose to 40 °C or higher. It should not be misunderstood that the enzyme activity increased as a function of temperature increased, which was definitely contrary to the common knowledge on enzyme.

Functions of CA in CO2 fixation and CaCO3 formation

The addition of crude enzyme extract to the CO2-saturated CaCl2 solution resulted in the enhanced carbonate precipitation. The CaCO3 precipitation weight induced by the extracellular and intercellular enzyme extract were respectively 72 and 160 mg per milligram of protein, compared with the purified enzyme from Citrobacter freundii-induced 225 mg CaCO3 per milligram of protein by exactly the same preparation method. The results of the localization of enzyme of CA function helped the understanding of the results of sequestrating CO2 into CaCO3 by crude extracellular and intracellular enzyme extract. There are reasons for the sequestration capacity to be improved by using an overexpressed functional immobilized enzyme.

Potential industrial use of CA in postcombustion CO2 capture technologies

In 2010, China led in emitting into the global atmosphere about a quarter of the total CO2 pollutants in the world. It is no doubt that this urgent problem of the exhausted gasses from coal burning and fossil fuel combustion must be tackled in the first place. We proposed our research as a start for a friendly environmental process performed in aqueous solution at near-ambient temperatures of high CO2 fixation in CaCO3 precipitation, as other scientists reported (Ramann et al. 2009). Further study was suggested to immobilize the crude enzyme extract to extend the CA lifetime under the severe environmental conditions such as high temperature (Matulis et al. 2005).

Conclusions

It is reasonable to expect that calcification by microalgae presents an alternative to geological carbon capture and sequestration. Trials of these finding should be especially encouraged in small coal-fired power plants or cement manufactories in China and in India which could contribute an impact in the mitigation of global greenhouse gas emissions worldwide.

References

Bhattacharya S, Schiavone M, Chakrabarti S (2003) CO2 hydration by immobilized carbonic anhydrase. Biotechnol Appl Biochem 38:111–117

Bond GM, Stringer J, Brandvold DK (2001) Development of integrated system for biomimetic CO2 sequestration using the enzyme carbonic anhydrate. Energy Fuel 15:309–316

Brauer M, Perez-Lustres JL, Weston J (2002) Quantitative reactivity model for the hydration of carbon dioxide by biomimetic zinc complexes. Inorg Chem 41:1454–1463

Brownell PF, Bielig LM, Grof CPL (1991) Increased carbonic anhydrase activity in leaves of sodium-deficient C4 plants. Aust J Plant Phys 18:589–592

Heck RW, Tanhauser SM, Manda R (1994) Catalytic properties of mouse carbonic anhydrase V. J Biol Chem 269:24742–24746

Jansson C, Northen T (2010) Calcifying cyanobacteria—the potential of biomineralization for carbon capture and storage. Curr Opin Biotechnol 21:365–371

Khalifah RG, Silverman DN (1991) The carbonic anhydrases: Cellular physiology and molecular genetics. Plenum, New York, pp 49–70

Lee SW, Park SB, Jeong SK (2010) Review on carbon dioxide storage based on biomineralization strategies. Micron 41:273–282

Leibman KC, Alford D, Boudet RA (1961) Nature of the inhibition of carbonic anhydrase by acetazolamide and benzthiazide. J Pharmacol Exp Ther 131:271–274

Lund JWG, Kipling C, Cren D (1958) The inverted microscope method of estimating algal numbers and the statistical basis of estimations by counting. Hydrobiologia 11:143–170

Matulis D, James K, Salemme R (2005) Thermodynamic stability of carbonic anhydrase: measurements of binding affinity and stoichiometry using thermofluor. Biochem 2005(44):5258–5266

Miyachi S, Iwasaki I, Shiraiwa Y (2003) Historical perspective on microalgal and cyanobacterial acclimation to low and extremely high CO2 conditions. Photosynth Res 77:139–153

Ramann R, Kannan K, Denvor S (2009) Bio-sequestration of carbon dioxide using carbonic anhydrase enzyme purified from Citrobacter freundii. World J Microbiol Biotechnol 25:981–987

Rippka R, Deruelles J, Waterbury J, Herdman M, Stanier R (1979) Generic assignments, strain histories and properties of pure cultures of cyanobacteria. J Gen Microbiol 111:1–61

Sharma A, Bhattacharya A (2010) Enhanced biomimetic sequestration of CO2 into CaCO3 using purified carbonic anhydrase from indigenous bacterial strains. J Mol Catal B Enzym 67:122–128

Shimahara H, Yoshida T, Shibata Y et al (2007) Tautomerism of histidine 64 associated with proton transfer in catalysis of carbonic anhydrase. J Biol Chem 282:9646–9656

Tripp BC, Bell CB, Cruz F (2004) A role for iron in an ancient carbonic anhydrase. J Biol Chem 279:6683–6687

Wilbur KM, Anderson NG (1948) Electrometric and colorimetric determination of carbonic anhydrase. J Biochem 176:147–154

Acknowledgment

The authors are thankful to Jiangsu Planned Projects for Postdoctoral Research Funds.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Li, L., Fu, Ml., Zhao, Yh. et al. Characterization of carbonic anhydrase II from Chlorella vulgaris in bio-CO2 capture. Environ Sci Pollut Res 19, 4227–4232 (2012). https://doi.org/10.1007/s11356-012-1077-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-012-1077-8