Abstract

The adsorption of crystal violet from aqueous solution by NaOH-modified rice husk was investigated in a laboratory-scale fixed-bed column. A two-level three factor (23) full factorial central composite design with the help of Design Expert Version 7.1.6 (Stat Ease, USA) was used for optimisation of the dynamic dye adsorption process and evaluation of interaction effects of different operating parameters: initial dye concentration (100–200 mg L−1), flow rate (10–30 mL min−1) and bed height (5–25 cm). A correlation coefficient (R 2) value of 0.999, model F value of 1,936.59 and its low p value (<0.0001) along with lower value of coefficient of variation (1.38 %) indicated the fitness of the response surface quadratic model developed during the present study. Numerical optimisation applying desirability function was used to identify the optimum conditions for a targeted breakthrough time of 12 h. The optimum conditions were found to be initial solution pH = 8.00, initial dye concentration = 100 mg L−1, flow rate = 22.88 mL min−1 and bed height = 18.75 cm. A confirmatory experiment was performed to evaluate the accuracy of the optimised procedure. Under the optimised conditions, breakthrough appeared after 12.2 h and the column efficiency was determined as 99 %. The Thomas model showed excellent fit to the dynamic dye adsorption data obtained from the confirmatory experiment. Thereby, it was concluded that the current investigation gives valuable insights for designing and establishing a continuous wastewater treatment plant.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, adsorption has been extensively studied by researchers worldwide as an efficient and economically sustainable technology for the treatment of dye-stuff effluents (Mittal et al. 2010a, b, 2012a, b; Srinivasan and Viraraghavan 2010; Gupta and Suhas 2009; Gupta and Rastogi 2008a, b, c, 2009; Gupta and Ali 2008; Gupta et al. 2006a, b, c, 2007a, b, c, d, e, 2010; Ali and Gupta 2007; Crini 2006). Compared with the traditional dye wastewater treatment technologies like coagulation, biodegradation, electroflocculation, membrane filtration, ion-exchange, precipitation, ozonation, etc., adsorption has received global attention due its simplicity and flexibility of design, high selectivity and efficiency, low operating cost and high-quality-treated effluent (Gupta and Ali 2001, Gupta et al. 1997, 1998, 1999, 2000, 2004a, b). A wide range of low-cost materials particularly wastes from industries and agricultural operations such as orange peel, banana pith, banana peel, apple pomace, wheat straw, sawdust, coir pith, sugarcane bagasse, tea leaves, rice husk, bamboo, ginger waste, pineapple leaves, tamarind fruit shell, fly ash, bottom ash, bagasse fly ash, etc. has been tested (as such or after some minor treatment) for their efficacy as adsorbent for removal of dyes from aqueous media (Srinivasan and Viraraghavan 2010; Mittal et al. 2005, 2008, 2010c, d; Gupta and Suhas 2009; Gupta et al. 2005, 2006d, 2008; Kurniawan et al. 2006; Aksu 2005). Likewise, in our previous study, we have shown that NaOH-modified rice husk (NMRH) can be used as an effective adsorbent for the removal of hazardous crystal violet (CV) dye from its aqueous solutions (Chakraborty et al. 2011). In order to ascertain the practical applicability of the adsorbent for treatment of real industrial wastewaters, the current study is an extension of our previous investigation by considering the adsorption of CV by NMRH in a fixed-bed column system.

In most of the dye adsorption studies (batch/continuous) reported so far, the effect of individual parameter on the adsorption process has been investigated, keeping the level of other operating factors constant. A number of experiments need to be performed to determine the optimum levels (which may be unreliable). Such an approach is not only time consuming but also does not depict the combined effect of all the process parameters. In recent years, several types of statistical experimental design methods have been employed to overcome these limitations. Response surface methodology (RSM) has been reported to be a useful experimental design method for studying the combined effect of different variables influencing the adsorption process by carrying out a limited number of experiments (Garg et al. 2009). RSM, initially developed and described by Box and Wilson, is a collection of statistical methods useful for modelling problems where several independent variables (input) influence a dependent response variable (output) with an explicit objective of optimising this response even in the presence of complex interactions (Taniyildizi 2011; Jain et al. 2011; Hasan et al. 2009). RSM is now widely applied to model and optimise different wastewater treatment processes such as adsorption (Chowdhury and Saha 2012), coagulation–flocculation (Wang et al. 2011), Fenton’s oxidation (Benatti et al. 2006), electrochemical oxidation (Korbahti et al. 2007), electrocoagulation (Aleboyeh et al. 2008) and photocatalytic decolorisation (Sakkas et al. 2010). The application of RSM is primarily aimed at achieving higher percentage output, reduced process variability, closer confirmation of output response to nominal and target achievement. Therefore, in light of its widespread application and usefulness, the primary aim of the present study was to investigate the cumulative effect of different operating parameters (initial dye concentration, feed flow rate and bed height) on the breakthrough time for dynamic adsorption of CV by NMRH using RSM. Central composite design (CCD) in RSM with the help of Design Expert Version 7.1.6 (Stat Ease, USA) was used for this purpose. In addition, a numerical optimisation method was employed to determine the optimum conditions for a targeted breakthrough time. A literature review shows that no such study on application of statistical experimental design to continuous fixed-bed adsorption systems has been reported so far. This is the first study on response surface optimisation of a dynamic dye adsorption process. The data presented may be useful towards designing and establishing a continuous wastewater treatment plant.

Materials and methods

NMRH adsorbent

Rice husk was obtained from a local rice mill of Durgapur, West Bengal, India. It was washed thoroughly with distilled water to remove soil and dust. The wet husk was spread on a stainless steel tray and dried in an oven at 353 ± 1 K for 3 h. The dried rice husk was then modified according to the method described in paper (Chakraborty et al. 2011). The characterisation of NMRH adsorbent has been reported elsewhere (Chakraborty et al. 2011).

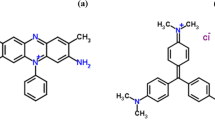

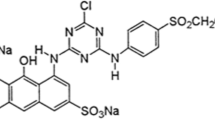

Dye

CV used in this study was of commercial quality (CI, 42,555; MF, C25H30N3Cl; MW, 408, λ max, 580 nm) and was used without further purification. Stock solution (1,000 mg L−1) was prepared by dissolving accurately weighed quantity of the dye in double-distilled water. Experimental dye solution of different concentrations was prepared by diluting the stock solution with suitable volume of double-distilled water. The initial solution pH was adjusted using 0.1 M HCl and 0.1 M NaOH solutions.

Process variables and experimental design

The main objective of this study was to determine the optimum set of operational variables of the dynamic dye adsorption process by applying a standard RSM design called the CCD. A set of three independent variables, viz. initial dye concentration, feed flow rate, and bed height were identified to investigate their influence on the breakthrough time for continuous fixed-bed adsorption of CV by NMRH. The experimental range of the selected process variables with their units and notation is given in Table 1. The response variable, t b (breakthrough time) can be expressed as a function of the independent process variables according to the following response surface quadratic model:

where, β 0 is the constant coefficient, β i, β ii and β ij are the coefficients for the linear, quadratic and interaction effect, x i and x j are the independent variables and ε is the error.

A total of 15 experiments were performed in duplicate according to the CCD matrix in Table 2. The experimental data were analysed by the software, Design Expert Version 7.1.6 (Stat-Ease, USA). The adequacy of the developed model and statistical significance of the regression coefficients were tested using the analysis of variance (ANOVA). The interaction among the different independent variables and their corresponding effect on the response was studied by analysing the response surface contour plots. Multiple response optimisation with desirability function was used to establish the optimum value of the process variables for a targeted breakthrough time.

Fixed-bed adsorption studies

Continuous flow adsorption experiments were conducted in a glass column (3 cm internal diameter and 50 cm height). A known quantity of NMRH was packed into the glass column to yield the desired bed height. A porous sheet was attached at the bottom of the column in order to support the adsorbent bed and to ensure a good liquid distribution inside the column. The top of the bed was covered by a layer of glass beads (1 mm in diameter) in order to avoid the loss of adsorbent and also to ensure a closely packed arrangement. Dye solution of known concentration was pumped downward through the column by a peristaltic pump (PP-EX204C, Miclins, India). All the experiments were carried out at 303 ± 1 K. Samples were collected at the outlet of the column at regular time intervals and the concentration of CV in the effluent was analysed using UV/vis spectrophotometer (U-2800, Hitachi, Japan). Operation of the column was stopped when the effluent CV concentration exceeded a value of 99.5 % of its initial concentration.

Results and discussion

Response surface quadratic model

Results obtained by performing the continuous flow adsorption experiments according to the CCD matrix are presented in Table 2. The quadratic model equation relating the breakthrough time to the tested independent variables in terms of coded variables as developed by the software is given by Eq. 2.

The ANOVA is considered to be useful to test the statistical significance of the response surface quadratic model. The ANOVA results (Table 3) of the quadratic model suggest that the model was highly significant, as it is evident from the Fisher’s F value (1,936.59) with a low probability value (p < 0.0001). The goodness of fit of the model was further checked by the correlation coefficient (R 2) between the experimental and model predicted values of the response variable (Fig. 1). A fairly high R 2 value of 0.9997 implies that the regression model was statistically significant and only 0.0003 % of the total variations was not explained by the model. The predicted correlation coefficient (pred. R 2 = 0.9992) also shows good agreement with the adjusted correlation coefficient (adj. R 2 = 0.9690). A coefficient of variance of 1.38 % suggests better precision and reliability of the data obtained by performing the experiments while a non-significant lack of fit value (more than 0.05) implies validity of the quadratic model (Hamsaveni et al. 2001). Overall, the ANOVA analysis indicates the applicability of the model to predict the breakthrough time for continuous fixed-bed adsorption of CV by NMRH within the limits of the experimental factors.

A regression analysis of the model equation (Table 4) shows that the main as well as the interaction effects of initial dye concentration, flow rate and bed height were highly significant (p < 0.0001). Also, the square effect of flow rate and bed height was highly significant (p < 0.0001).

Interaction effect of adsorption process variables

In order to study the interaction among the different independent variables and their corresponding effect on the response, contour plots were drawn (Figs. 2, 3 and 4). A contour plot is a graphical representation of a three dimensional response surface as a function of two independent variables, maintaining all other variables at fixed level. These plots can be helpful in understanding both the main and interaction effects of the independent variables on the response (Jain et al. 2011).

The combined effect of initial dye concentration and feed flow rate on breakthrough time is shown in the contour plot of Fig. 2. The breakthrough time decreases with increase in both the initial dye concentration as well as the feed flow rate within the experimental range. Such behaviour can be explained by the fact that all adsorbents have a fixed number of binding sites which become saturated at a certain concentration. With increasing inlet dye concentration, the binding sites on the adsorbent surface become more quickly saturated, resulting in earlier breakthrough. Also at higher flow rates, the residence time of the dye solution in the column decreases and hence the dye molecules do not have enough time to capture the binding sites on the adsorbent surface or diffuse into the pores of the adsorbent, leaving the column before equilibrium occurs (Saha et al. 2012a).

Figure 3 depicts the interaction effect of initial dye concentration and bed height on the breakthrough time. Within the experimental range, the response function, i.e. the breakthrough time decreases with increasing initial dye concentration. On the contrary, the breakthrough time increases with increasing bed height. The observed trend can be attributed to the fact that increasing bed height results in an increased availability of binding sites for the adsorption process. The dye molecules have more time to contact with the adsorbent resulting in delayed breakthrough (Saha et al. 2012b).

The contour plot in Fig. 4 shows the combined effect of flow rate and bed height on the breakthrough time for continuous adsorption of CV by NMRH. The interactive effect of flow rate and bed height has a significant impact on the breakthrough time. The breakthrough time decreases with increasing flow rate while it increases with increasing bed height. Such breakthrough pattern can be explained in terms of residence time of the dye molecules in the column as well as the availability of binding sites, as already mentioned.

Optimisation using the desirability function

In the Design Expert software’s numerical optimisation, the possible goals are maximise, minimise, target, in range and set to an exact value (factors only). Therefore, in the present study, the desired goal for each factor as well as for the response function was selected from the menu. A weight is usually assigned to each goal in order to adjust the shape of the particular desirability function. The goals are then combined to an overall desirability function. Desirability is an objective function. It can normally range from zero to one for any given response. A desirability value of one represents the ideal case while a zero indicates that one or more responses fall outside the desirable limits. The numerical optimisation identifies a point that will maximise the desirability function. The possibility of finding the best local maximum can generally be increased by starting from several points in the design space (Amini et al. 2008).

In this study, we assumed that if a continuous dye treatment unit operates for 12 h/day, then the breakthrough must also appear exactly after 12 h in order to get the best quality effluent. Therefore, we set a target of 12 h for the breakthrough time. A maximum level of 100 mg L−1 was set for the initial dye concentration while the level of flow rate and bed height were set within the range of 10–30 mL min−1 and 5–25 cm, respectively in order to achieve maximum desirability. The importance of each goal was adjusted with respect to the other goals. Figure 5 shows a ramp desirability that was generated from 10 optimum points via numerical optimisation. The best local maximum was found to be at initial dye concentration of 100 mg L−1, feed flow rate of 22.88 mL min−1 and bed height of 18.75 cm. A desirability value of 0.998 indicates that the estimated function can well represent the experimental model and desired conditions.

Confirmation experiments

The numerical optimisation suggested the optimum values of the different independent variables as initial dye concentration, 100 mg L−1; flow rate, 22.88 mL min−1; and bed height, 18.75 cm to achieve the targeted breakthrough time of 12 h. A further experimental test was conducted under the conditions predicted by the model. The breakthrough profile thus obtained is illustrated in Fig. 6. The breakthrough appeared after 12.2 h, which is very close to the targeted value. Hence the findings of the response surface optimisation were validated. Under these conditions, the total amount of effluent (V eff, total) that can be treated by a continuous dye treatment unit per day before breakthrough occurs is calculated as follows:

where, F is the feed flow rate (in millilitres per minute) and t b is the breakthrough time (in hours).

The total amount of dye sent through the column per day (m total) is calculated as:

where, C o is the initial dye concentration (in milligrammes per litre)

The total quantity of dye adsorbed in the column per day (m ad) is calculated as:

where C ad is the adsorbed dye concentration = influent dye concentration (C 0)—effluent dye concentration (C e)

The efficiency of the column can be calculated as:

The fixed-bed adsorption data obtained from the confirmatory experiment were fitted to the bed depth service time (BDST) model (Han et al. 2008) and the Thomas model (Uddin et al. 2009) to describe the fixed-bed adsorption dynamics of CV.

where N 0 is the maximum volumetric sorption capacity (in milligrammes per litre), Z is the bed height in the column (in centimetres), k is the sorption rate constant (in litres per milligramme per minute), u is the linear velocity (in centimetres per minute), k Th is the Thomas rate constant (in millilitres per milligramme per minute), q o is the equilibrium adsorbate uptake (in milligrammes per gramme), m is the mass of the adsorbent in the column (in grammes) and t e is the time at which dye concentration in the effluent reaches 99.5 % of the initial dye concentration (in minutes).

The calculated model parameters along with the correlation coefficient values (R 2) are listed in Table 5. The high R 2 value for the Thomas model indicates the applicability of the model in describing the dynamic adsorption data of CV by NMRH. It is noteworthy to mention here that the Thomas model is based on the assumption that the process follows Langmuir kinetics of adsorption-desorption with no axial dispersion and the model is suitable for describing adsorption processes where external and internal diffusion limitations are absent (Hasan et al. 2010; Singh et al. 2011).

Conclusions

In the present study the optimum operating parameters for continuous fixed-bed adsorption of CV dye by NMRH was determined using RSM. A 23 CCD was used to study the effect of initial dye concentration, feed flow rate and bed height on the breakthrough time. An empirical quadratic model equation was developed for the dynamic adsorption process. ANOVA of the quadratic model suggests that the model was highly significant. The experimental values were found to be in good agreement with the values predicted by the model. The interaction effect of the experimental parameters on the breakthrough time was established by contour plots. The parameters were found to have significant effects on the breakthrough time. The optimum conditions for a targeted breakthrough time of 12 h, as determined using multiple response optimisation with desirability function, were initial dye concentration = 100 mg L−1, flow rate = 22.88 mL min−1 and bed height = 18.75 cm. Under the optimised conditions, the breakthrough appeared after 12.2 h. The Thomas kinetic model showed excellent fit to the continuous fixed-bed adsorption data. The efficiency of the column operation under the optimised condition was estimated to be around 99 %. Overall, it can be said that the application of RSM is an effective approach for optimisation and modelling of the dynamic dye adsorption process. The data presented in this investigation can be further extrapolated for designing and establishing a continuous wastewater treatment plant.

References

Aksu Z (2005) Application of biosorption for the removal of organic pollutants: a review. Process Biochem 40:997–1026

Aleboyeh A, Daneshvar N, Kasiri MB (2008) Optimization of C.I. Acid Red 14 azo dye removal by electrocoagulation batch process with response surface methodology. Chem Eng Process 47:827–832

Ali I, Gupta VK (2007) Advances in water treatment by adsorption technology. Nat Protoc 1:2661–2667

Amini M, Younesi H, Bahramifar N, Lorestani AAZ, Ghorbani F, Daneshi A, Sharifzadeh M (2008) Application of response surface methodology for optimization of lead biosorption in an aqueous solution by Aspergillus niger. J Hazard Mater 54:694–702

Benatti T, Tavares CRG, Guedes TA (2006) Optimization of Fenton’s oxidation of chemical laboratory wastewaters using the response surface methodology. J Environ Manage 80:66–74

Chakraborty S, Chowdhury S, Saha PD (2011) Adsorption of crystal violet from aqueous solution onto NaOH-modified rice husk. Carbohydr Polym 86:1533–1541

Chowdhury S, Saha PD (2012) Scale-up of a dye adsorption process using chemically modified rice husk: optimization using response surface methodology. Desalin Water Treat 37:331–336

Crini G (2006) Non-conventional low-cost adsorbents for dye removal: a review. Bioresour Technol 97:1061–1085

Garg UK, Kaur MP, Sud D, Garg VK (2009) Removal of hexavalent chromium from aqueous solution by adsorption on treated sugarcane bagasse using response surface methodological approach. Desalination 249:475–479

Gupta VK, Ali I (2001) Removal of DDD and DDE from wastewater using bagasse fly ash, a sugar industry waste. Water Res 35:33–40

Gupta VK, Ali I (2008) Removal of Endosulfan and Methoxychlor from water on carbon slurry. Environ Sci Technol 42:76–770

Gupta VK, Rastogi A (2008a) Sorption and desorption studies of chromium(VI) from nonviable cyanobacterium Nostoc muscorum biomass. J Hazard Mater 154:347–354

Gupta VK, Rastogi A (2008b) Biosorption of lead(II) from aqueous solutions by non-living algal biomass Oedogonium sp. and Nostoc sp.—a comparative study. Colloids Surf B 64:170–178

Gupta VK, Rastogi A (2008c) Equilibrium and kinetic modeling of cadmium(II) biosorption of nonliving algal biomass Oedogonium sp. from aqueous phase. J Hazard Mater 153:759–766

Gupta VK, Rastogi A (2009) Biosorption of hexavalent chromium by raw and acid-treated green alga Oedogonium hatei from aqueous solutions. J Hazard Mater 163:396–402

Gupta VK, Suhas (2009) Application of low-cost adsorbents for dye removal—a review. J Environ Manage 90:2313–2342

Gupta VK, Rastogi A, Dwivedi MK, Mohan D (1997) Process development for the removal of zinc and cadmium from wastewater using slag—a blast furnace waste material. Sep Sci Technol 32:2883–2912

Gupta VK, Mohan D, Sharma S (1998) Removal of lead from wastewater using bagasse fly ash—a sugar industry waste material. Sep Sci Technol 33:1331–1343

Gupta VK, Mohan D, Sharma S, Park KT (1999) Removal of chromium(VI) from electroplating industry wastewater using bagasse fly ash—a sugar industry waste material. Environmentalist 19:129–136

Gupta VK, Srivastava SK, Tyagi R (2000) Design parameters for the treatment of phenolic wastes by carbon columns (obtained from fertilizer waste material). Water Res 34:1543–1550

Gupta VK, Singh P, Rahman N (2004a) Adsorption behavior of Hg(II), Pb(II), and Cd(II) from aqueous solution on Duolite C-433: a synthetic resin. J Colloid Interface Sci 275:398–402

Gupta VK, Ali I, Saini VK (2004b) Removal of chlorophenols from wastewater using red mud: an aluminium industry waste. Environ Sci Technol 38:4012–4018

Gupta VK, Ali I, Saini VK, Gerven TV, der Bruggen BV, Vandecasteele C (2005) Removal of dyes from wastewater using bottom ash. Ind Eng Chem Res 44:3655–3664

Gupta VK, Mittal A, Kurup L, Mittal J (2006a) Adsorption of a hazardous dye, erythrosine, over hen feathers. J Colloid Interface Sci 304:52–57

Gupta VK, Mittal A, Krishnan L, Mittal J (2006b) Adsorption treatment and recovery of the hazardous dye, Brilliant Blue FCF, over bottom ash and de-oiled soya. J Colloid Interface Sci 293:16–26

Gupta VK, Mittal A, Jain T, Mathur M, Sikarwar S (2006c) Adsorption of Safranin-T from wastewater using waste materials—activated carbon and activated rice husks. J Colloid Interface Sci 303:80–86

Gupta VK, Mittal A, Gajbe V, Mittal J (2006d) Removal and recovery of the hazardous azo dye Acid Orange 7 through adsorption over waste materials: bottom ash and de-oiled soya. Ind Eng Chem Res 45:1446–1453

Gupta VK, Jain R, Varshney S (2007a) Electrochemical removal of the hazardous dye Reactofix Red 3 BFN from industrial effluents. J Colloid Interface Sci 312:292–296

Gupta VK, Jain R, Mittal A, Mathur M, Sikarwar S (2007b) Photochemical degradation of the hazardous dye Safranin-T using TiO2 catalyst. J Colloid Interface Sci 309:464–469

Gupta VK, Ali I, Saini VK (2007c) Defluoridation of wastewaters using waste carbon slurry. Water Res 41:3307–3316

Gupta VK, Jain R, Varshney S (2007d) Removal of Reactofix golden yellow 3 RFN from aqueous solution using wheat husk—an agricultural waste. J Hazard Mater 142:443–448

Gupta VK, Ali I, Saini VK (2007e) Adsorption studies on the removal of Vertigo Blue 49 and Orange DNA13 from aqueous solutions using carbon slurry developed from a waste material. J Colloid Interface Sci 315:87–93

Gupta VK, Mittal A, Gajbe V, Mittal J (2008) Adsorption of basic fuchsin using waste materials—bottom ash and deoiled soya—as adsorbents. J Colloid Interface Sci 319:30–39

Gupta VK, Rastogi A, Nayak A (2010) Adsorption studies on the removal of hexavalent chromium from aqueous solution using a low cost fertilizer industry waste material. J Colloid Interface Sci 342:135–141

Hamsaveni DR, Prapulla SG, Divakar S (2001) Response surface methodological approach for the synthesis of isobutyl butyrate. Process Biochem 36:1103–1109

Han R, Ding D, Xu Y, Zou W, Wang Y, Li Y, Zou L (2008) Use of rice husk for the adsorption of Congo red from aqueous solution in column mode. Bioresour Technol 99:2938–2946

Hasan SH, Srivastava P, Talat M (2009) Biosorption of Pb(II) from water using biomass of Aeromonas hydrophila: central composite design for optimization of process variables. J Hazard Mater 168:1155–1162

Hasan SH, Ranjan D, Talat M (2010) Agro-industrial waste ‘wheat bran’ for the biosorptive remediation of selenium through continuous up-flow fixed-bed column. J Hazard Mater 181:1134–1142

Jain M, Garg VK, Kadrivelu K (2011) Investigation of Cr(VI) adsorption onto chemically treated Helianthus annus: optimization using response surface methodology. Bioresour Technol 102:600–605

Korbahti BK, Aktas N, Tanyolac A (2007) Optimzation of electrochemical treatment of industrial paint wastewater with response surface methodology. J Hazard Mater 148:83–90

Kurniawan TA, Chan GYS, W-h L, Babel S (2006) Comparisons of low-cost adsorbents for treating wastewaters laden with heavy metals. Sci Total Environ 366:409–426

Mittal A, Kurup L, Gupta VK (2005) Use of waste materials—bottom ash and de-oiled soya, as potential adsorbents for the removal of Amaranth from aqueous solutions. J Hazard Mater 117:171–178

Mittal A, Gupta VK, Malviya A, Mittal J (2008) Process development for the batch and bulk removal and recovery of a hazardous, water-soluble azo dye (Metanil yellow) by adsorption over waste materials (bottom ash and de-oiled soya). J Hazard Mater 151:821–832

Mittal A, Mittal J, Malviya A, Gupta VK (2010a) Removal and recovery of Chrysoidine Y from aqueous solutions by waste materials. J Colloid Interface Sci 344:497–507

Mittal A, Mittal J, Malviya A, Kaur D, Gupta VK (2010b) Decoloration treatment of a hazardous triarylmethane dye, Light Green SF (yellowish) by waste material adsorbents. J Colloid Interface Sci 342:518–527

Mittal A, Jain R, Mittal J, Varshney S, Sikarwar S (2010c) Removal of Yellow ME7GL from industrial effluent using electrochemical and adsorption techniques. Int J Environ Pollut 43:308–323

Mittal A, Jain R, Mittal J, Shrivastava M (2010d) Adsorptive removal of hazardous dye Quinoline yellow from wastewater using coconut-husk as potential adsorbent. Fresen Environ Bull 19:1–9

Mittal A, Thakur V, Gajbe V (2012a) Evaluation of adsorption characteristics of an anionic azo dye brilliant yellow onto hen feathers in aqueous solutions. Environ Sci Pollut Res. doi:10.1007/s11356-012-0756-9

Mittal A, Thakur V, Gajbe V (2012b) Adsorptive removal of toxic azo dye Amido Black 10B by hen feather. Environ Sci Pollut Res. doi:10.1007/s11356-012-0843-y

Saha PD, Chakraborty S, Chowdhury S (2012a) Batch and continuous (fixed-bed column) biosorption of crystal violet by Artocarpus heterophyllus (jackfruit) leaf powder. Colloids, Surf B 92:262–270

Saha PD, Chowdhury S, Mondal M, Sinha M (2012b) Biosorption of Direct Red 28 (Congo red) from aqueous solutions by eggshells: batch and column studies. Sep Sci Technol 47:112–123

Sakkas VA, Islam AM, Stalikas C, Albanis TA (2010) Photocatalytic degradation using design of experiments: a review and example of the Congo red degradation. J Hazard Mater 175:33–44

Singh KP, Gupta S, Singh AK, Sinha S (2011) Optimizing adsorption of crystal violet dye from water by magnetic nanocomposite using response surface modelling approach. J Hazard Mater 186:1462–1473

Srinivasan S, Viraraghavan T (2010) Decolorization of dye wastewaters by biosorbents: a review. J Environ Manage 91:1915–1929

Taniyildizi ST (2011) Modeling of adsorption isotherms and kinetics of reactive dyes from aqueous solution by peanut hull. Chem Eng J 168:1234–1240

Uddin MT, Rukanuzzaman M, Khan MKR, Islam MA (2009) Adsorption of methylene blue from aqueous solution by jackfruit (Artocarpus heteropyllus) leaf powder: a fixed-bed column study. J Environ Manage 90:3443–3450

Wang J-P, Chen Y-Z, Wang Y, Yuan S-J, Yu H-Q (2011) Optimization of the coagulation-flocculation process for pulp mill wastewater treatment using a combination of uniform design and response surface methodology. Water Res 45:5633–5640

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Vinod Kumar Gupta

Rights and permissions

About this article

Cite this article

Chowdhury, S., Chakraborty, S. & Saha, P.D. Response surface optimization of a dynamic dye adsorption process: a case study of crystal violet adsorption onto NaOH-modified rice husk. Environ Sci Pollut Res 20, 1698–1705 (2013). https://doi.org/10.1007/s11356-012-0989-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-012-0989-7