Abstract

α-HCH, β-HCH, and γ-HCH (lindane) were listed as persistent organic pollutants in the Stockholm Convention. Therefore, they need to be globally addressed including the wastes remaining from historic use and production. While at most lindane production sites the unintentionally produced 85 % HCH waste isomers have been deposited, at a former pesticide factory in Hamburg-Moorfleet HCH waste isomers have been recycled from 1953 to 1984 by thermal decomposition to chlorobenzenes and resulted in high polychlorinated dibenzo-p-dioxin/polychlorinated dibenzofuran (PCDD/PCDF)-contaminated residues. The management of the PCDD/PCDF-contaminated waste from the former pesticide factory in Hamburg has been assessed and quantified. Based on past accredited PCDD/PCDF measurements, the registered 3,700 tonnes of disposed thermal HCH decomposition residue contained 333 to 854 kg of PCDD/PCDF toxicity equivalent (I-TEQ) in 53–102 tonnes total sum of PCDD/PCDF. The wastes have been deposited together with other wastes in landfills in Hamburg and other parts of Germany. For the Georgswerder landfill (Hamburg), where approximately 50 % of the PCDD/PCDF is disposed, current and previous situation and remediation activities are described. While PCDD/PCDF leaching from the landfill is controlled and incinerated, more water soluble organochlorines (vinyl chloride, cis-1,2-dichlorethene, chlorobenzenes) and benzene remain as a challenge for groundwater management. A comprehensive aftercare program has been established and will need to be operated by future generations including renewal of containment systems. Former lindane/HCH productions need—in addition to HCH deposits—to be assessed for possible recycling practice of HCH and related PCDD/PCDF-containing deposits. This could systematically be addressed within the Stockholm Convention implementation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In 2009, α-HCH, β-HCH, and lindane (industrial γ-HCH) were accepted at the fourth meeting of the Conference of Parties (UNEP 2009) for inclusion in the Stockholm Convention persistent organic pollutants (POPs) list on 26th of August 2009. Thus, lindane and the two key waste isomers are to be addressed on a global basis, including stockpiles and wastes remaining as a legacy from the historic use and production of HCH/lindane (Jit et al. 2010; Vijgen 2006a, b; Vijgen et al. 2011; Wycizk et al. 2012). This amendment of the Convention will enter into force for parties from the 26th of August 2010 onwards, and parties should report on their implementation plans from August 2012.

In the production of lindane (γ-HCH), approximately 85 % waste isomers are produced in the chlorination step of benzene (Bodenstein 1972; Vijgen 2006a; Vijgen et al. 2011). It was a common practice to separate the active gamma-isomer and then to dump the remaining 85–90 % waste, which consisted mainly of α-HCH and some β-, δ-, and ε-HCH. These have generated the globes largest POPs stockpile (Vijgen 2006a; Vijgen et al. 2011).

To make use of the chlorinated waste isomers and to avoid such dumping, at some factories the waste HCH isomers have been recycled to produce other products such as chlorobenzenes and its derivatives (Jürgens and Roth 1989; Weber et al. 2006). This procedure might still be practiced today at two factories in India (Jit et al. 2010; Vijgen et al. 2011). The recycling approach to produce chlorobenzenes was invented at an HCH production in Hamburg-Moorfleet in the early 1950s. The factory commenced lindane production in 1951 and stored the waste isomers on site for the first 3 years. The recycling activities started in 1953 with the production of trichlorobenzene and tetrachlorobenzene which in further reaction steps were used to synthesize 2,4,5-trichlorophenoxyacetic acid ester (2,4,5-T) and O,O-dimethyl-O-(2,5-dichloro-4-bromophenyl)monothiophosphate (bromophos) as marketable pesticides. The production of 2,4,5-T and the decomposition of HCH resulted in the generation of highly polychlorinated dibenzo-p-dioxin/polychlorinated dibenzofuran (PCDD/PCDF)-contaminated waste (Degler and Uentzelmann 1984; Jürgens and Roth 1989; Sievers and Friesel 1989; Weber et al. 2008a; Vijgen et al. 2011). While 2,3,7,8-TCDD was for the first time already discovered in this 2,4,5-T production in 1956 by Sorge (Holmstedt 1981), the high PCDD/PCDF contamination of the HCH decomposer residue was only discovered in 1984 and resulted in the closure of this factory (Jürgens and Roth 1989). Most of the PCDD/PCDF ended up in waste streams and were deposited on landfills (Bürgerschaft Hamburg 1985; Universität Bayreuth, Tritschler and Partner GmbH 1995a, b; Sievers and Friesel 1989) or were destroyed on an incinerator ship in the open sea. The landfilling of POPs results in large challenges for the respective sites and is particularly a nonsustainable approach when long-term perspectives are considered (Weber et al. 2011). Therefore, it is important to gather and describe experiences and management practices at landfills in which large amounts of POPs wastes have been disposed.

This paper summarizes the total PCDD/PCDF inventory of the deposited waste from the HCH recycling process and 2,4,5-T production from the pesticide factory in Hamburg-Moorfleet, Germany. Past and current conditions at the Georgswerder landfill in Hamburg, where approximately 50 % of the PCDD/PCDF inventory (157–403 kg dioxin toxicity equivalent (I-TEQ)) and 30 % of organochlorines (5,780 tonnes) have been deposited, are described.Footnote 1 This case highlights the significant challenges and efforts required to contain organochlorine waste deposits. It also shows the legacy this will create for future generations.

Materials and methods

Pollutant inventory data (PCDD/PCDF, HCH, and others) which were largely only in German literature and in governmental reports have been reviewed and compiled in this paper and in the supporting information. For the first time, the entire dataset of deposits of residues from the pesticide factory of Hamburg has been calculated for their PCDD/PCDF content.

Dioxin inventory data from decomposition of HCH waste isomers have been reevaluated considering a recent measurement of the historic residue from the thermal decomposition of HCH to trichlorobenzene (Vijgen et al. 2011). For the PCDD/PCDF analyzed in the 1980s for anisole residue and for the R-acid residue, the isomer-specific 2,3,7,8-analysis was not available at that time and only 2,3,7,8-TCDD results have been reported and were considered.

Past and current municipal government monitoring records from the Georgswerder landfill in Hamburg have been compiled. Oil leachate samples were taken and analyzed for PCDD/PCDF at irregular intervals less frequent than once a year. By contrast, water leachate has been analyzed on a monthly basis at the inflow duct of the purification plant. Groundwater samples have been taken monthly from the inlet of the groundwater purification plant, every 3 months from extraction wells, and annually from about 40 observation wells in the contaminant plume and its surroundings. Additionally, some samples from hazardous waste basins within the landfill have been analyzed. The organic pollutant datasets are based on these measurements, which have been done by various accredited commercial laboratories or by the environmental laboratory of the environmental administration of Hamburg based on national standard procedures and in accordance with the state of the art analysis available.

Results and discussion

PCDD/PCDF containing wastes from HCH recycling and 2,4,5-T production

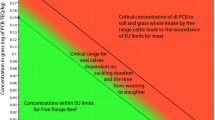

At the former pesticide factory in Hamburg-Moorfleet, the HCH waste isomers were recycled from 1953 to 1984 (Jürgens and Roth 1989) by thermal decomposition at around 250–260°C to produce technical trichlorbenzene (Fig. 1). In this reaction step, a highly PCDD/PCDF-containing residue, the so-called decomposer residue, was produced containing PCDD/PCDF in the percent range (1.4 % to 2.7 %) with I-TEQ in the high parts per million range (90–230 ppm) (Jürgens and Roth 1989; Vijgen et al. 2011, Supporting Information Table 2). The total landfilled PCDD/PCDF amount in the 3,700 tonnes registered HCH decomposition residue of this factory is estimated to be 53–102 tonnes for sum PCDD/PCDF and 333–854 kg of PCDD/PCDF I-TEQ. This PCDD/PCDF load was disposed in eight landfills (Table 1). The total landfilled organochlorine waste from this factory was approximately 16,000 tonnes which included about 2,500 tonnes of nonrecycled HCH waste isomers (particularly the so-called “delta-paste”)Footnote 2 (Table 1).

The produced technical trichlorobenzene was then either chlorinated to tetrachlorobenzene or used in the synthesis of 2,5-dichloro-4-bromophenol for bromophos production (Fig. 1). In these production steps, an anisole residue was generated with a dioxin-like toxicity of 1 ppm (Weber et al. 2006).

The tetrachlorobenzene was hydroxylated with sodium hydroxide in methanol to form 2,4,5-trichlorophenol. In this production step, a tetrachlorobenzene waste fraction and an anisole waste fraction were generated (Fig. 1). Also, these waste fractions contained PCDD/PCDF but at lower levels of 0.37 ppm 2,3,7,8-TCDD for the anisole and 32 ppb I-TEQ for the tetrachlorobenzene waste fraction (Universität Bayreuth, Tritschler and Partner GmbH 1995a).

The 2,4,5-trichlorophenol reacted with chloroacetic acid to form 2,4,5-T. The waste fraction from this reaction step is a mother liquor (so-called R-acid) containing the remaining chloroacetic acid, tri/tetrachlorobenzene, and some 2,4,5-trichlorophenol and PCDD. The measured concentration of 2,3,7,8-TCDD in this residue was 80 ppm (Bürgerschaft Hamburg 1985). The estimated amount of PCDD/PCDF deposited from these waste fractions (excluding the HCH decomposition residue) was “only” 23 kg I-TEQ (Table 1).

At some of the landfills where wastes from this pesticide factory were deposited, the total landfill volume is unknown (Münchehagen) or the type of waste is unknown (Gerolsheim/Pfalz) (Table 1). Also, information about waste disposed before 1964 is not available. Therefore, the total landfilled PCDD/PCDF amounts from this factory could be considerably higher than the documented data.

The situation of the Georgswerder landfill in Hamburg containing approximately 50 % of the total PCDD/PCDF amount is summarized in this paper. Other landfills/deposits are not addressed further in this paper. Some of the deposits located in Hamburg were partly described in other studies (Bürgerschaft Hamburg 1985; Sievers and Friesel 1989; Fiedler et al. 1993; Universität Bayreuth, Tritschler and Partner GmbH 1995a, b). The pollution and remediation activities on the former pesticide factory area in Hamburg-Moorfleet are described in another paper in this ESPR issue (Weber and Varbelow 2012).

Structure of the Georgswerder landfill

The closed Georgswerder landfill in Hamburg, formerly one of the biggest waste disposal sites in Europe, has a consolidated waste volume of about 7 million cubic meter disposed of between 1948 and 1979. The landfill covers a ground surface of 45 ha and is about 40 m high. The waste mainly consists of 5.04 million tons municipal waste and bulky waste and 1.77 million tons of excavated soil, as well as demolition waste and covering material. Moreover, in 10 basins, about 150,000 m³ of liquid hazardous waste was deposited between 1967 and 1974 (Fig. 2). On average, one basin covers an area of one soccer field and is several meters in depth. After the basins were filled with liquids, solid household waste has been deposited on top of it in order to “immobilize” or rather cover the hazardous waste. It has been estimated that one-fifth of the entire hazardous waste is deposited in the liquid hazardous waste basins no. 5 and no. 6 (Fig. 2).

In addition to the 10 liquid hazardous waste basins, four barrel depots have been set up. These contain about 100,000 drums of varying sizes filled with chemical wastes (Fig. 2) (Wolf 1986; Umweltbehörde Hamburg 1995; Sokollek et al. 2003). The impounded leachate level inside the landfill had a height of 14 m in 1988 (Umweltbehörde Hamburg 1988). This has decreased over the last 20 years to a height of 8 m and a total water volume of approx 500,000 m3 (Fig. 3) with only a minor change in recent years (see “Securing of the landfill”).

Profile of the Georgswerder landfill with varied impounded leachate levels (1988 to 2010), groundwater levels and the subsoil geology. The numbers correspond to the quantity of the landfill water balance components (mean values from 1996 to 2009, Sokollek 2010a)

The total amount of chlorinated hydrocarbons in the oil phase in the landfill is estimated at several thousand tons (Umweltbehörde Hamburg 1995). It is documented that 5,780 tons hazardous wastes from the former pesticide factory in Hamburg-Moorfleet was deposited at the Georgswerder landfill in Hamburg; 1,750 tonnes of this hazardous waste is HCH decomposition residues and has been deposited in closed barrels (Bürgerschaft Hamburg 1985, Table 1). It is estimated that these decomposition residues contain 25–48 tonnes of sum PCDD/PCDF and 157–403 kg I-TEQ (Table 1).

Chemical analyses of the landfill leachate (water phase) before the discovery of dioxin (1983)

Water leachate, also some oil leachate (oil phase), was leaking out of the landfill, mainly around its eastern and western foothills. At sampling point S7 (Fig. 2), some oil leachate from the main leakage area in the eastern foothills was collected in an oil/water separator. The (water) effluent of this separator and water leachate from all over the landfill flowed into an inner peripheral trench surrounding the entire area. Since April 1981, the drain water of this trench was discharged via another oil/water separator into the municipal sewer located on the west side of the landfill at point SI (Fig. 2) (Götz 1984, 1985; Schumacher 1985, 1987; Wolf 1986; Umweltbehörde Hamburg 1988). This municipal sewer led to the city's sewage treatment plant in Hamburg. The collected oil leachate has been incinerated in a hazardous waste incinerator in Hamburg at that time.

Comprehensive chemical investigations of the leachate at the inflow into the municipal sewer at point SI have been performed. Concentrations of COD, DOC, ammonium, alkali metals, calcium, and magnesium were similar to the values known from other landfills. For arsenic and heavy metals, the concentrations were even lower compared with the leachate of other German municipal landfills. Organic trace pollutants were measured at the parts per trillion level and lower parts per billion level for the following pollutants: volatile chlorinated hydrocarbons; chlorobenzenes; chlorophenols; HCHs; benzene, toluene, ethylbenzene, and xylenes (BTEX); and polycyclic aromatic hydrocarbons (PAHs) (Götz 1984).

Measurement data from the landfill body and PCDD/PCDF data from leachates since 1983

After 2,3,7,8-TCDD (“Seveso dioxin”) had been discovered in the oil phase of leachates in 1983, a comprehensive chemical investigation program was carried out. Prior to 1983, the oil leachate had not been analyzed for chemical pollutants. Most of the oil leachate seeped out at point S7 (Fig. 2). The results of the PCDD/PCDF measurements in the oil leachate at S7 during the period 1985 to 1992 (Supporting information Table 2) can be summarized as follows: The PCDD/PCDF concentrations were in the range of 26.1 to 741 μg/kg I-TEQ with an average of 273 μg/kg I-TEQ. 2,3,7,8-TCDD levels ranged between 3 and 75 μg/kg with an average of 38.9 μg/kg. The total PCDD/PCDF concentrations ranged between 2,950 and 54,900 μg/kg with an average of 34,100 μg/kg. The PCDD/PCDF homologue pattern (Fig. 4) and 2,3,7,8-congener distribution (Supporting information Table 2) were dominated by the pattern of the HCH decomposition residues. The contribution of 2,3,7,8-TCDD (with an average 15 % of the dioxin toxicity equivalent (I-TEQ)) in the oil leachates was however considerably higher compared to the contribution of 2,3,7,8-TCDD in the HCH decomposition residues (approximately 0.3 % of the I-TEQ). Therefore, the PCDD/PCDF amount from wastes of 2,4,5-T production (R-acid or anisoles) deposited in the landfill is probably higher than the documented wastes (Table 1) or the HCH decomposer residues deposited in barrels are not/less subjected to leaching (yet). The corrosion status of these barrels has not been assessed but is a matter of future concern (Weber et al. 2011). Also, in a few samples, high octachlorodibenzofuran (OCDF) levels were detected (Supporting information Table 2). This indicates that wastes dominated by OCDF have also been deposited in the landfill.

The HCH levels in the oil leachate at S7 were 1,300–5,000 ppm, and the chlorobenzene concentrations were 4,100–40,000 ppm, dominated by tetrachlorobenzenes (Umweltbehörde Hamburg 1988). The oil phase of the leachate was and is still gathered and destroyed in hazardous waste incinerators.

Analytical data of the six liquid hazardous waste basins sampled in 1985 are listed in Supporting Information Table 1. The liquid hazardous waste basin no. 5 is by far most heavily contaminated with chlorinated organics with an organic phase heavier than water (“heavy oil leachate”) with a density of 1.192 g/cm3. The main components were 1,2,3,4-tetrachlorobenzene (64.2 %), other chlorobenzenes (18.6 %), volatile chlorinated hydrocarbons (2.6 %), and 2.8 % of aromatic solvents as well as other contaminants.

The second highest contamination is the liquid hazardous waste basin no. 6. Two samples were taken here. In the organic phase which was lighter than water (“light oil leachate”), the content of aromatic solvents amounted to 11.6 and 15.2 % and the content of volatile chlorinated hydrocarbons was 5.6 and 3.6 %, whereas the sum of the chlorobenzene values was 9.8 and 3.2 % (Götz 1985, 1986a, b; Umweltbehörde Hamburg 1988).

Subsequent investigations in 1992 and 2003 produced similar results, confirming the high levels of contaminants of the oil phases in the liquid hazardous waste basins (BWS 2004). Moreover, water phase samples from the different liquid hazardous waste basins taken from 1985 to 2003 showed somewhat high organic loads in the milligrams per liter range. These measurements suggest that the pollutant concentrations have not changed substantially in the landfill liquids (water phase and oil phase) over the last two decades.

Dioxin analyses of the leachate in the inner peripheral trench

After dioxin was detected in 1983, the landfill leachate and the inner peripheral trench were also analyzed for dioxin. At the inlet of the municipal sewer (point SI, Fig. 2), 7.7 ng/l total PCDD and 5.2 ng/l OCDD were measured. 2,3,7,8-TCDD has not been detected at a detection limit of 0.1 ng/l (Umweltbehörde Hamburg 1988). In sum, the chemical analyses mentioned above including the dioxin measurements revealed that even before remediation of the landfill started it was permissible to discharge the landfill leachate from the inner peripheral trench into the municipal sewer system (Wolf 1986). Elevated dioxin concentrations were found at some points in the sediments of this trench (Götz 1986a). The inner peripheral trench continued to exist until the beginning of the 1990s. Then, it has been replaced by a new leachate-collecting system consisting of drains, pumping shafts, and control shafts.

Investigations in the surroundings of the landfill before the remediation of the landfill

Investigations of the air above and in the proximity of the landfill as well as investigations of the soil in the surroundings of the landfill produced no evidence for contamination by dioxin or by other pollutants from the landfill (Umweltbehörde Hamburg 1995). Also, in the surface waters in the surroundings of the landfill, no relevant dioxin contamination caused by the landfill could be detected. The dioxin concentrations in the sediments of these surface waters were at the background level (Schumacher 1987). Since 1981, all leachate of the landfill was collected in the inner peripheral trench and was discharged into the municipal sewer (Fig. 2). Thus, no landfill leachate has reached the surface waters in the surroundings of the landfill since 1981. That means, even before the securing of the landfill, the surface waters in the landfill vicinity were not contaminated by the landfill. Only in the bottom sediments of the surface water of the “Östliche Georgswerder Wettern” elevated dioxin concentrations were analyzed. The explanation for this lies in the fact that before 1981 the leachate of the landfill's inner peripheral trench was discharged into this surface water (Schumacher 1987).

Securing of the landfill

In 1984/85, the decision to remediate the landfill was mainly driven by concerns about the large dioxin inventory and the whole pollutant potential (Umweltbehörde Hamburg 1995). The idea was to dry out the landfill body and then to keep it dry. The main approach of the remediation concept was to contain the entire landfill. Moreover, a plan was made to extract as much as possible the oil and water phase from the hazardous liquid waste basins. The specific suggestion was to completely excavate the highly contaminated basins no. 5 and no. 6 (Umweltbehörde Hamburg 1988). By doing so, the overall pollutant potential should be significantly reduced and a large part of the liquid and therefore potentially mobile fraction would have been removed so that the remaining pollutants inside the landfill could be kept immobile so that they could not leak into the groundwater anymore.

Around year 1995, however, a paradigm shift took place. The hazards of groundwater pollution were increasingly recognized, and the necessity of the remediation was mainly justified by groundwater threats. The comprehensive monitoring system gave evidence of an extended pollution of the near-surface aquifer with volatile chlorinated hydrocarbons like vinyl chloride and aromatic solvents like benzene. It appears that these pollutants have continued to leak from the landfill into the groundwater (Umweltbehörde Hamburg 1995). From then on, the removal of the groundwater contaminant plume (Fig. 5) became one of the main remediation goals (Umweltbehörde Hamburg 1995; Schnittger 2001).

The remediation concept realized basically consisted of four parts:

-

1.

A multilayered landfill cover system,

-

2.

A peripheral leachate collecting system with a multistep purification plant,

-

3.

A landfill gas extraction system, and

-

4.

Remediation of the contaminated groundwater with pump and treat systems.

The groundwater cleanup approach involved the installation of a pumping well system, which pumps contaminated groundwater from the aquifer and then treats it to remove organic contaminants. The extraction of landfill gas started in 1985. A multilayered landfill cover system was built from 1988 to 1995. The leachate purification plant construction and operation started in 1988, and the groundwater remediation system began to operate in 1997. The securing costs of the landfill were approximately 100 million EUR. Since 1995, about 150,000 m3 of water leachate and about 150 m³ of oil leachate have been collected. Most of the water leachate has been extracted by the peripheral drainage system, whereas most of the oil leachate was withdrawn by means of 10 vertical wells in the area of the liquid hazardous waste basins no. 5 and 6. These wells were driven from 1998 to 2006. Finally, the wells had to be closed due to a relatively low efficiency and to technical problems. On average (from 1996 to 2009), about 12,000 m3 of leachate was collected annually from the peripheral drains (see Fig. 3), containing only some cubic meters of oil. The vertical flow of water leachate into the groundwater aquifer was in the range of 5,000 to 10,000 m³ per year (Fig. 3). According to a new water balance model, this value has decreased to 3,000 m³ per year at present (Gillbricht et al. 2012). It is estimated that approx 500,000 m3 of liquids is still inside the landfill. The impounded leachate level has decreased to a height of 8 m over the last 20 years. But the speed of the lowering has reduced markedly in recent years (Fig. 3). Taking this into account, the original concept target of landfill body immobilization (“drying out the landfill”) is obviously not attainable (Sokollek 2010b).

The operation costs of the landfill amount to approximately 700,000 EUR/year of which the portion of the monitoring measures is between 50,000 and 150,000 EUR/year (Sokollek et al. 2008; Sokollek 2010a).

The plan to excavate the above-mentioned liquid hazardous waste basins or the barrel depots has been abandoned due to costs and technical problems (Umweltbehörde Hamburg 1995). Moreover, the planned “enforced” liquid extraction was not deemed feasible (Schnittger 2001). Consequently, the huge amount of pollutants (dioxin, volatile chlorinated hydrocarbons, chlorobenzenes, chlorophenols, HCHs, PAHs, BTEX, and other contaminants) stored inside the landfill has not been reduced through the remediation so far and remains as a legacy to be further managed by future generations.

Groundwater organic pollution and its remediation

In the groundwater, no dioxins have been detected at a detection limit of 0.1 ng/l for single congeners (Umweltbehörde Hamburg 1988). The main contaminants were and still are volatile chlorinated hydrocarbons (vinyl chloride, cis-1,2-dichlorethene), chlorinated benzenes, and benzene.

Figure 5 shows the contamination plumes of volatile chlorinated hydrocarbons in the near-surface quaternary aquifer for 1997, 2002, and 2009. In the 1980s and up to 1997, the plume was orientated south-westwards. Later on, the plume moved southwards, caused by a hydraulic-engineering intervention in the surface water “Dove Elbe Wettern,” which is located about 450 m south of the landfill border. In 2005, the front of the plume reached this surface water. Therefore, it was necessary to change the pumping well system. Two new-built wells started operating in the axis of this plume in 2011 (Sokollek 2010a).

About 65,000 m³ of groundwater is pumped and treated annually. In 2009, for example, about 43 kg of chlorobenzenes, 18 kg of vinyl chloride, and 3 kg of benzene were removed from the groundwater. The maximum concentration of various toxins in the groundwater below the landfill is as follows: In 2010, the total volatile chlorinated hydrocarbons were 6,400 and 5,200 μg/l at two observation wells. The highest concentrations were measured for vinyl chloride and cis-1,2-dichloroethene. The vinyl chloride measurements from 1986 to 2011 are shown in Fig. 6. At the observation well with the highest concentration of total chlorobenzenes, levels were variable over the years from 5,100 μg/l in 1998 to 700 μg/l in 2001 and then 4,800 μg/l in 2008. The main components were 1,2,4-trichlorobenzene and 1,3-dichlorobenzene. Remarkable HCH values are only to be found at one observation well near the liquid hazardous waste basin no 6. Here, the concentrations were in the range of 100 μg/l. The highest levels of BTEX were measured in 2011, reaching 900 μg/l. Hence, the infiltration of contaminants into the groundwater is an ongoing process which shows no signs of a decreasing trend.

Computer modeling suggests that after approximately 25 years of pumping, the contaminant plume south of the landfill area should be cleaned. However, directly underneath the landfill, an aquifer section will remain polluted due to the long-term contaminant leakage of the landfill body. For that reason, groundwater pumping at the southern landfill border will be necessary for a very long time, to prevent the reformation of a contaminant plume (Sokollek 2010a).

Future use and aftercare

A comprehensive aftercare program has been established that includes a monitoring scheme for the landfill body, a control frame for the cover system, and a monitoring strategy to protect the groundwater and surface waters (Table 2). The only surface water to be surveyed so far is the Dove Elbe Wettern south of the landfill which is impacted by the groundwater contamination plume (Fig. 5).

In the frame of the International Building Exhibition (IBA Hamburg 2013), the secured Georgswerder landfill is planned to be transformed into an ecological energy hill (“Energieberg”), where different types of renewable energy such as wind, solar, landfill gas, and geothermal energy will be presented. Parts of the landfill area will be opened to the public (Kilger et al. 2010). On the other hand, the landfill and its cover system and all other engineered structures will require intense aftercare measures for a long time with particular care when the area is opened to the public. It is expected that after about a hundred years of aftercare, future generations will have to renew/renovate the containment system. At that time, they will probably have to reevaluate the feasibility of a final decontamination of the landfill, e.g., removing its hazardous waste (Sokollek 2010a).

Conclusions

This article discussed the recycling of HCH waste isomers and related production of 2,4,5-T and bromophos. It outlined the legacy created by a former pesticide factory in Hamburg-Moorfleet, Germany that operated from the 1950s to 1984. During that time, it produced approximately 3,700 tonnes of decomposition residue from HCH recycling containing approximately 53–102 tonnes PCDD/PCDF and 333 to 854 kg I-TEQ which have been deposited at six landfills in Germany (Table 1). This amount can be compared with the national German PCDD/PCDF inventory of 126.5 g TEQFootnote 3 submitted to the Stockholm Convention (UBA 2008) or compared with the total PCDD/PCDF releases of 58.5 kg I-TEQ/year from 68 countries having established inventories for the Stockholm Convention (UNEP 2011). Since α-HCH, β-HCH, and lindane have entered the Stockholm Convention, parties to the convention will address these new listed POPs in their national implementation plans from August 2012 onwards including the related waste deposits.

The paper gives an overview on the situation of the Georgswerder landfill where approximately 50 % of the total dioxin inventory of the former pesticide factory has been deposited in closed barrels as well as 150,000 m3 liquid hazardous waste in 10 basins from different companies. Oil leachate from the landfill contains considerable PCDD/PCDF, HCH, chlorobenzene, BTEX, PAH, as well as volatile chlorinated hydrocarbon contaminates (Supporting information Table 1). These oil leachates are being incinerated.

The landfill has been secured from 1985 to 1997 at a cost of approximately 100 million EUR. At a 2010 symposium held 25 years since the renovation efforts began,Footnote 4 the success of the securing measures was emphasized. However, around 2005, the head of a contaminated groundwater plume containing volatile chlorinated organics reached surface water. This pointed out the necessity of improving the pumping well system. Two newly built wells started operating near the head of the actual plume in 2011. Computer modeling suggests that after approximately 25 years of pumping, the contaminant plume south of the landfill area will be cleaned up. Because the aquifer below the landfill appears to be permanently polluted, groundwater pumping at the southern landfill border will be necessary for a very long time. Future generations will have to maintain aftercare and eventually renew the securing measures or to perform the final decontamination of this site.

Notes

In 2010, a symposium on 25 years of remediation of the Georgswerder landfill has been held. Some key findings are summarized in this paper: http://www.hamburg.de/energieberg-georgswerder/2344370/25-jahre-deponie-georgswerder-fachtagung.html

Germany submitted PCDD/PCDF releases to air (for 2004).

See footnote 1.

References

Bodenstein G (1972) Disposal of wastes from lindane manufacture. In: Uhlmann E, Verlag K (eds) Lindane monograph of an insecticide. Schillinger, Freiburg im Breisgau, pp 23–77

Bürgerschaft Hamburg. (1985): Bürgerschaft der Freien und Hansestadt Hamburg, 11. Wahlperiode. Drucksache 11/3774, 26.02.1985

Degler H-D, Uentzelmann D (Ed.) (1984) In supergift dioxin. Spiegel Buch, Rudolf Augstein GmbH Co. KG Hamburg, Germany

Fiedler H, Hub M, Hutzinger O (1993) Stoffbericht Hexachlorcyclohexan (HCH); HCH in Altlasten Text und Berichte zur Altlastenbearbeitung , Band 9/93, Landesanstalt für Umweltschutz Baden-Württemberg

Gillbricht C, Effenberger M, Sokollek V (2012) Gesicherte Altlasten in der Nachsorge – Erfahrungen aus Standorten in Hamburg. ITVA – Altlastensymposium, 22.-23.03.2012, Hamburg, Proceedings 51-57

BWS GmbH (2004) Untersuchung und Bewertung der Stauwasserbeschaffenheit der Deponie Georgswerder. Bericht im Auftrag der Behörde für Umwelt und Gesundheit, Fachamt Altlastensanierung (unpublished)

Götz R (1984) Untersuchungen an Sickerwässern der Mülldeponie Georgswerder in Hamburg. Müll und Abfall 12:349–356

Götz R (1985) Polychlorierte Dibenzodioxine (PCDD), polychlorierte dibenzofurane (PCDF) und andere toxische organische Substanzen in Sickerfluessigkeiten der Muelldeponie Georgswerder/Hamburg. Vom Wasser 65:215–228

Götz R (1986a) Chlorinated dioxins and dibenzofurans in leachate and sediments of the sanitary landfill in Hamburg-Georgswerder. Chemosphere 15:1981–1984

Götz R (1986b) Chemismus der dioxinhaltigen Sickeröle der Deponie Georgswerder/Hamburg. Müll und Abfall 1(86):2–8

Holmstedt B (1981) Prolegomena to Seveso. Arch Toxicol 44:211–230

Jit S, Dadhwal M, Kumari H, Jindal S, Kaur J, Lata P, Niharika N, Lal D, Garg N, Gupta SK, Sharma P, Bala K, Singh A, Vijgen J, Weber R, Lal R (2010) Evaluation of hexachlorocyclohexane contamination from the last lindane production plant operating in India. Env Sci Pollut Res 18(4):586–597

Jürgens H-J, Roth R (1989) Case study and proposed decontamination steps of the soil and groundwater beneath a closed herbicide plant in Germany. Chemosphere 18:1163–1169

Kilger R, Haupt T, Weisleder S (2010) Deponie Georgswerder – Umgestaltung zum Energieberg. Altlastenspektrum 19(04/10):165–171

Schnittger P (2001) Sanierung der Deponie Georgswerder in Hamburg in Handbuch der Altlastensanierung, RdNr. 7, C. F. Müller Verlag, Hüthig GmbH & Co. KG Heidelberg, Germany. http://www.hamburg.de/contentblob/141902/data/veroeff-georgswerder-sanierung.pdf

Scholz B, Engler M (1987) Determination of polychlorinated dibenzo-p-dioxins and dibenzofurans in wastes of technical hexachlorocyclohexane. Chemosphere 16:1829–1834

Schumacher E (1985) Dioxine in der Deponie Georgswerder – Bekanntwerden, Untersuchungen, Gefährdungsabschätzung. Abfallwirtschaft in Forschung und Praxis, Band 14:81–84

Schumacher E (1987) Untersuchungsergebnisse von PCDD/PCDF-Messungen auf Deponien. VDI-Bericht Nr 634:219–233

Sievers S, Friesel P (1989) Soil contamination patterns of chlorinated organic compounds: looking for the source. Chemosphere 19:691–698

Sokollek V (2010a) Nachsorge der Deponie Georgswerder - Erfahrungen aus der Eigenkontrolle. – 25 Jahre Sanierung der Deponie Georgswerder, Proceedings, ed. Freie und Hansestadt Hamburg, Behörde für Stadtentwicklung und Umwelt:23-45. http://www.hamburg.de/contentblob/2356970/data/tagungsband-25-jahre-dgw.pdf

Sokollek V (2010b) Nachsorge der Deponie Georgswerder: Zwei Jahrzehnte Erfahrungen aus der Eigenkontrolle. Altlastenspektrum 19(04/10):172–179

Sokollek V, Steinert B, Melchior S, Moosmann L (2003) Results from thirteen years of monitoring the encapsulated Georgswerder landfill (Hamburg) In: ConSoil 2003, 8th International FZK/TNO conference on contaminated Soil, conference proceedings. C 2582, 10 pp

Sokollek V, Melchior S, Berger K, Steinert B, (2008) Zwanzig Jahre Überwachung und Nachsorge der gesicherten Deponie Georgswerder/Hamburg. – Skládkový Workshop (Deponieworkshop) Liberec – Zittau 2008, 27. – 28. 11. 2008, Technická Univerzita v Liberci, Hochschule Zittau/Görlitz, sborník konference, 131-148. http://www.hamburg.de/altlastensanierung/141886/gorgswerder-veroeffentlichungen.html

UBA (2008) Nationaler Durchführungsplan unter dem Stockholmer Abkommen zu persistenten organischen Schadstoffen (POPs). Forschungsbericht 205 67 444 UBA-FB 001094

Umweltbehörde Hamburg (1988) Sanierung der Deponie Georgswerder

Umweltbehörde Hamburg (1995) Deponie Georgswerder Sanierung 1984-95

UNEP (2009) Report of the conference of the parties of the Stockholm Convention on persistent organic pollutants on the work of its fourth meeting. UNEP/POPS/COP.4/38. 8. May 2009; http://chm.pops.int/Programmes/NewPOPs/DecisionsRecommendations/tabid/671/language/en-US/Default.aspx

UNEP (2011) Assessment of PCDD/PCDF release inventories—status 2011. PCDD/PCDF Release Inventories – Toolkit Update 2. Draft report 12/2011

Universität Bayreuth, Tritschler & Partner GmbH (1995a) Dioxin-Bilanz für Hamburg, Abschlussbericht, Im Auftrag von: Freie und Hansestadt Hamburg, Umweltbehörde, Kapitel 3. http://www.hamburg.de/contentblob/112354/data/dioxinbilanz.pdf

Universität Bayreuth, Tritschler & Partner GmbH (1995b) Dioxin-Bilanz für Hamburg, Zusammenfassender Endbericht. Hamburger Umweltberichte 51/95, Freie und Hansestadt Hamburg, Umweltbehörde

Vijgen J (2006a) The legacy of lindane HCH isomer production. http://ew.eea.europa.eu/Agriculture/Agreports/obsolete_pesticides/lindane_production.pdf/. Accessed 10 Feb.2012

Vijgen J (2006b) The legacy of indane HCH isomer production. Annexes. IHPA, January 2006 http://ew.eea.europa.eu/Agriculture/Agreports/obsolete_pesticides/lindane_annexes.pdf. Accessed 10 Feb 2012

Vijgen J, Abhilash PC, Li Y-F, Lal R, Forter M, Torres J, Singh N, Yunus M, Tian C, Schäffer A, Weber R (2011) HCH as new Stockholm Convention POPs—a global perspective on the management of lindane and its waste isomers. Env Sci Pollut Res. 18: 152-162. http://www.springerlink.com/content/g62g810418512421/fulltext.pdf

Weber R, Varbelow G (2012) The dioxin/POPs legacy of pesticide production in Hamburg: part 1—remediation of production site. Env Sci Pollut Res. doi:10.1007/s11356-012-1011-0

Weber R, Behnisch PA, Brouwer A, van Bavel B, Lindstroem G, Zennegg M, Schilling B, Paepke O (2006) Contemporary relevance of dioxin and dioxin-like compound contaminations in residues from recycling of HCH waste. Organohalogen Compd 68:905–910

Weber R, Gaus C, Tysklind M, Johnston P, Forter M, Hollert H, Heinisch H, Holoubek I, Lloyd-Smith M, Masunaga S, Moccarelli P, Santillo D, Seike N, Symons R, Torres JPM, Verta M, Varbelow G, Vijgen J, Watson A, Costner P, Woelz J, Wycisk P, Zennegg M (2008a) Dioxin- and POP-contaminated sites—contemporary and future relevance and challenges. Env Sci Pollut Res 15:363–393

Weber R, Tysklind M, Gaus C (2008b) Dioxin—Contemporary and future challenges of historical legacies (editorial, dedicated to Otto Hutzinger). Env Sci Pollut Res 15:96–100

Weber R, Watson A, Forter M, Oliaei F (2011) Persistent organic pollutants and landfills—a review of past experiences and future challenges. Waste Manag Res 29(1):107–121

Wycisk P, Stollberg R, Neumann C, Gossel W, Weiss H, Weber R (2012) Integrated methodology for assessing the HCH groundwater pollution at the multi-source contaminated mega-site bitterfeld/wolfen. Env Sci Pollut Res. doi:10.1007/s11356-012-0963-4

Wolf K (1986) The Hamburg-Georgswerder dumping ground. Situation, problems and administrative arrangements for production a rehabilitation plan. In: Assink JW, van den Brink WJ (eds) Contaminated soil. Martinus Nijhoff Publishers, Dordrecht, pp 723–728

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(XLS 38 kb)

Rights and permissions

About this article

Cite this article

Götz, R., Sokollek, V. & Weber, R. The dioxin/POPs legacy of pesticide production in Hamburg: Part 2—waste deposits and remediation of Georgswerder landfill. Environ Sci Pollut Res 20, 1925–1936 (2013). https://doi.org/10.1007/s11356-012-0986-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-012-0986-x