Abstract

Because of the continuous production of large amount of waste tires, the disposal of waste tires represents a major environmental issue throughout the world. This paper reports the utilization of waste tires (hard-to-dispose waste) as a precursor in the production of activated carbons (pollution-cleaning adsorbent). In the preparation of activated carbon (AC), waste rubber tire (WRT) was thermally treated and activated. The tire-derived activated carbon was characterized by means of scanning electron microscope, energy-dispersive X-ray spectroscopy, FTIR spectrophotometer, and X-ray diffraction. In the IR spectrum, a number of bands centred at about 3409, 2350, 1710, 1650, and 1300–1000 cm−1 prove the present of hydroxyl and carboxyl groups on the surface of AC in addition to C═C double bonds. The developed AC was tested and evaluated as potential adsorbent removal of chromium (III). Experimental parameters, such as contact time, initial concentration, adsorbent dosage and pH were optimized. A rapid uptake of chromium ions was observed and the equilibrium is achieved in 1 h. It was also found that the adsorption process is pH dependent. This work adds to the global discussion of the cost-effective utilization of waste rubber tires for waste water treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The demand and use of automobiles, cars and trucks is on an increase. As a result, waste rubber tires (WRT) are generated in continuously increasing amount worldwide. WRT is almost non-biodegradable, and hence has become a serious source of environmental pollution. Hazards associated with scrap tires can cause both health and environmental problems since most of the waste rubber tires are stockpiled or put in landfills. Landfilling the waste tires is an uneconomical and non-environmental friendly strategy of disposal (Chan et al. 2011). The disposal of WRT represents a major environmental issue throughout the world because they occupy large volumes and cause the destabilisation of compacted landfill sites due to their flexible nature (San Miguel et al. 2002). Consequently, the environmentally friendly disposal of WRT seems to be impossible in terms of economy and health. A feasible solution would be to recycle them to be used as raw materials in various applications. In addition to its availability at lower costs, WRT is embodied with a high amount of carbon. Therefore, WRT represents an interesting source of raw material for the preparation of highly mesoporous activated carbons (AC).

AC are nano-porous adsorbents that are widely used in both gas and liquid phase separation processes (Min and Harris 2006). They can be produced from various carbonaceous precursors such as coal, coconut shell, wood, and polymer scrap. Research into the conversion of low-cost waste materials to AC has increased recently; firstly for the need to meet increasing demand for AC, especially in the waste water treatment industry; and secondly to recover economic value of waste materials, especially WRT. The use of inexpensive materials such as wastes with such an aim will certainly lower the production cost of the adsorbent. At present, in fact, low-cost adsorbents are being frequently tested for organic and inorganic pollutants removal from contaminated water.

There are many ways to recycle and reuse waste tires. One potential recycling process is pyrolysis which involves the heating of tires under inert conditions, usually at high temperatures. This is followed by chemical activation process. These tire-derived activated carbons have been applied in removing pollutants such as phenols (Nakagawa et al. 2004; San Miguel et al. 2002; Tanthapanichakoon et al. 2005), dye (Garcia et al. 2007) copper (Helleur 2001) or lead (Alexandre-Franco et al. 2008) from wastewater.

Chromium (III) is released into the environment not only from natural sources but also from human activities. The major use of chromium (III) is in leather-tanning since its first successful trial by an American dye chemist (Stellmach 1990). Tanneries use basic chromium sulphate (CrOHSO4), which contains chrome in the trivalent oxidation state. Other main sources of chromium (III) pollution are mining; cement ceramics and glass industries, uses in dyes, electroplating, and production of steel and other metal alloys, photographic material and corrosive paints (Rana et al. 2004; Rutland 1991). Although Cr (III) is nontoxic or less toxic than Cr (VI), a long-term exposure to trivalent chromium is known to cause allergic skin reactions. Environmental pollution by chromium (III) is a matter of increasing concern.

There are various methods to remove chromium from waste waters. The methods are filtration, chemical precipitation, ion exchange and adsorption. In our previous work, multiwall carbon nanotubes were used for water treatment in removal of various pollutants (Gupta et al. 2011a, b; Saleh and Gupta 2011a, b). Regarding adsorption technology, one of its main drawbacks is associated with the high production cost of adsorbents. To some extent, it may be palliated using cheap precursors, such as WRT.

To the authors’ knowledge, the use of tire-derived activated carbons for removal of chromium (III) has not been investigated. The present study aims to assess the applicability of activated carbon derived from the waste rubber tires for the adsorptive removal of chromium (III) from aqueous solution and to investigate the effect of operating parameters on the adsorption process. The parameters studied include contact time, initial chromium concentration, adsorbent dosage and initial solution pH.

Experimental

Reagents and chemicals

The starting material used in the study was size-reduced residual rubber obtained from waste rubber tires. Nitric acid and chromium nitrate were all obtained from Sigma-Aldrich. Chromium solutions of different initial concentrations were prepared by diluting the stock solution in appropriate proportions. In order to prevent metal contamination from laboratory glassware, glassware was kept overnight in a 10 % (v/v) HNO3 solution. All commercial reagents were purchased from Sigma-Aldrich and used as received unless otherwise stated.

Preparation of adsorbent

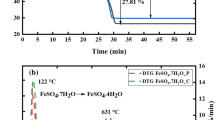

Activated carbon was prepared from waste rubber tires via carbonization, chemical treatment and steam activation. The waste rubber tires were cleaned, thoroughly washed with deionized water, and then dried in an oven at 120°C for 4 h. For carbonization, the dried material was then heated to approximately 500°C for 6 h. This was followed by treatment with hydrogen peroxide solution (6 %) for 24 h to oxidize adhering organic impurities. The material was washed with deionized water and dried in vacuum oven. The dried material was activated to 900°C for 2 h (N2 flow = 225 mL min-1). Then, it was removed from the furnace and cooled in a desiccator. The material was then treated with 4 M nitric acid solution to remove the ash content and was then washed with deionized water. The product was finally dried in an oven at 120°C for 1 day.

Equipment and characterization

The IR spectra of the samples were recorded on a MATTSON FTIR-100 spectrophotometer using KBr pellets over the range 4000–400 cm−1. Pellets were prepared by mixing approximately 1 mg of AC sample with about 300 mg of KBr in an agate mortar, and then pressing the mixture at a pressure of 12 Pa for 3 min. The as-prepared AC was characterized by X-ray diffraction (XRD; Shimadzu XRD Model 6000) to determine crystalline nature of the AC. The morphology and microstructure of AC were examined by means of field emission scanning electron microscope (FESEM, FEI Nova-Nano SEM-600, Netherlands). Along with SEM, the energy-dispersive X-ray spectroscopy (EDX) was measured to obtain the elements presented in AC. A nitrogen adsorption isotherm (Brunauer–Emmett–Teller) was obtained to determine the specific surface area.

The method used to determine the point of zero charge (PZC) of AC was as follows: dilute aqueous solutions of NaOH and HCl were employed to prepare 12 solutions in the range from pH 1.0–12.0. Next, 20*mL aliquots of these solutions were pipetted into polyethylene vials, allowed to equilibrate for 5 h and the pH of these was recorded before and after addition of 100.0 mg AC samples to each solution. Each vial was capped, shaken and allowed to equilibrate overnight. The final pH was measured and a plot of initial vs. final pH revealed plateaus indicative of the points of zero charge (PZC).

Adsorption experiments

To examine the adsorption activity of AC, adsorption experiments were carried out using a Pyrex reaction cell equipped with a shaking system. Batch adsorption experiments were conducted by adding the 0.5 g of adsorbent to 100 mL of different Cr (III) test solutions (10–100 mg/L) at different pH (2–9) in an Erlenmeyer flask (250 mL capacity). The initial solution pH was adjusted using 0.1 M HCl or 0.1 M NaOH. The flasks were agitated at different speed (0–150 rpm) in a rotary shaker for different contact time (10–160 min). All experiments were conducted at 25°C. The initial and final concentrations of chromium were analysed by using inductively coupled plasma mass spectrometry (ICP-MS). The adsorption kinetics was investigated by taking aliquot of the solution after the desired contact time and the filtrate were analysed. The chromium uptake was determined as:

where C o and C are the initial and final chromium concentrations (in milligrams per liter), respectively, V is the volume of solution (in liters) and w is the weight of the activated carbon (in grams).

To evaluate the degradation efficiency, the percentage of removal was calculated as

Results and discussion

Characterization analysis

The SEM image confirms the morphology and microstructure of AC, as presented in Fig. 1. An EDX analysis was also used to analyse tire-derived carbons and provide its composition. The microanalysis spectrum of the components of the AC is depicted in Fig. 2. It shows clearly the presence of C and O peaks as component elements of the AC sample. Table 1 presents the EDX quantitative microanalysis of the AC. The quantitative analysis depicts the compositions calculated from the peak areas. It was found that carbon and oxygen were the only common components in the AC.

To determine the composition and physical properties of the product, XRD was obtained. The X-ray diffraction pattern, Fig. 3 of the AC, confirms that the tire-derived activated carbons have a mixed nature of amorphous and crystalline structure.

Figure 4 depicts the IR spectra of the tire-derived activated. The spectrum displays a number of bands centred at about 3719, 3400, 2350, 1710, 1650, 1580 and 1300–1000 cm−1. The band at 3400 cm−1 is attributed to stretching (O–H) vibration in hydroxyl groups. The band at 2350 cm−1 is attributed to C≡C stretching vibration in alkyne group (Deng et al. 2009). The bands at 1710 and 1650 cm−1 are ascribable in turn to stretching (ν) (C═O) vibrations of carboxyl and carbonyl in acidic oxygen surface groups. The carboxylic acid group are usually presumed to take part in the adsorption of metal ions from aqueous solution (Huang et al. 2003). The band at 1580 cm−1 is attributed to C═C double bonds (Yang and Qiu 2009). The assignment of the carbonyl band to an ester is confirmed by observation of a strong band in the C–O stretching region at about 1180 cm−1 (broad band 1100–1300 cm−1; Fei Lian et al. 2011; Almazan-Almazan et al. 2006).

Results of the adsorption activity

Effect of contact time

The influence of contact time on the adsorption capacity of AC is shown in Fig. 5. It is obvious that there is a rapid uptake of Cr (III) within the first 40 min. This fast uptake can be explained by the creation of more active sites on the surface of the AC by the treatment process during the preparation of AC from waste rubber tires. In addition, the large surface area of the AC could play a factor in enhancing the removal of Cr (III). The surface area of AC was measured to be 465 m2/g. Equilibrium was obtained at almost 1 h and henceforth onwards, the adsorption rate slows down gradually and no further adsorption is observed beyond 1 h.

Effect of initial concentration of chromium

The effect of the initial concentration of chromium on the adsorption process was also investigated. As depicted in Fig. 6, the removal rate of Cr (III) is dependent on the initial concentration. This is reasonable since the more the Cr (III) ions available in the solution, the faster the adsorption due to the enhancement in contact.

Effect of activated carbon dosage

The effect of the AC dosage on the adsorption process was studied. The percentage removal of chromium ions varied linearly with the amount of the adsorbent as shown in Fig. 7. With the increase of adsorbent dosage, the time needed to reach equilibrium is reduced. This is due to the increase of efficient adsorption sites at higher dosages.

Effect of agitation speed

The contact between the adsorbent and adsorbate is affected by the agitation speed. This effect was investigated by a range from 0 to 150 rpm, Fig. 8. The adsorption of Cr (III) was low without or at low agitation speed and gradually increases by increasing the agitation speed to 150 rpm. This effect can be attributed to the decrease in boundary layer thickness around the adsorbent particles by increasing the degree of mixing.

pH effect

The pH is an important factor in influencing the adsorption process since the solution pH can play an important role in the kinetic of the adsorption process. In order to study the effect of this parameter on adsorption Cr (III), the experiments were carried out at pH values of 2, 3, 4, 6, 7 and 9. With the solution at pH 9, precipitation of Cr3+ species was observed. Thus, solutions of other pH values were studied. The results obtained showed that the efficiency of the AC on the adsorption of Cr (III), was pH dependent, Fig. 9. For the Cr3+ solution at pH 2, the removal of Cr (III) was very low, even after long contact times with the adsorbent. Therefore, at such pH, the chromium ions were not adsorbed to feasible extent (Gupta et al. 2011a, b). This can be explained by the ionic mobility of [H3O]+ in water which is high as compared with most other ions. This is because of its high concentration at such pH and its high mobility in the adsorptive aqueous solutions. The proton favourably competes with Cr (III) for surface active sites of the adsorbent (Greenwood and Earnshaw 1989; Alexandre-Franco et al. 2011). The PZC of the developed materials was determined and found to be 3.8. This further explained their low adsorption activity at solutions of pH 3.

As shown in Fig. 9, however, the adsorption of Cr3+ slightly increased at pH 3. The removal was remarkably increased at pH 4. At this relatively high pH, a decreased competition by [H3O]+ could enable the Cr3+ ion to become adsorbed. Also, it should be taken into account that the ease of deprotonation of acidic surface groups of the adsorbent and hence of ionic exchange with the Cr3+ would be greater with the rise of pH in the adsorptive solution (Alexandre-Franco et al. 2011). The result can be further explained based on the reported speciation diagrams (Zhang et al. 2008; Richard and Bourg 1991; Chuan and Liu 1996). At pH less than 3.6, Cr (III) is present as Cr3+ while at pH higher than 4 and lower than 6.5, it is present as Cr(OH)2+ Cr(OH) +2 . However, it is present as neutral Cr (OH)3 species at pH between 7 and 12. Then, it is not surprising to see a decrease in the adsorption of Cr3+ at pH 7, which denotes a lower adsorptive/adsorbent chemical affinity (Saleh et al. 2011c). It may be due to the change produced in the coordination sphere of the Cr3+ ion from an aquo-cation to hydroxo-complexes, and hence in the interaction of the Cr3+ ion with the surface groups of the AC surface.

Adsorption isotherm

Figure 10 shows the equilibrium adsorption isotherms of the Cr (III) onto rubber tire-derived carbon adsorbent which reveals that the equilibrium adsorption capacity (q e) increased with the adsorbate concentration (C e) in the presence of 0.50 g of absorbent. A possible reason being that the concentration provides an important driving force to overcome all mass transfer resistances of all molecules between the aqueous and solid phases.

Such isotherms give important information regarding the adsorbate–adsorbent interactions and are important in the design and analysis of sorption systems.

Isotherm data was applied to the Langmuir adsorption models; the linearized form of which is (Gupta et al. 2006a, b; 2007a, b; 2008a, b; 2009a, b, c; 2010;

Where C e is the equilibrium concentration of the metal ions (in milligrams per liter), q e is the amount of Cr (III) adsorbed per gram of adsorbent (in milligrams per gram), Q 0 and b are Langmuir constant relating to the adsorption capacity (in milligrams per gram) and the energy of adsorption (in liters per gram), respectively. The parameters and correlation coefficients obtained from the plots of Langmuir (1/q e vs 1/C e) as given in Fig. 11, are listed in Table 2.

Higher correlation coefficients (R 2 > 0.99; Table 2) and the linearity of plot as shown in Fig. 11 suggests the applicability of the Langmuir model with the Cr (III) getting adsorbed onto the adsorbent surface to form a monolayer. A comparable adsorption efficiency of the rubber tire-derived carbon adsorbent is revealed in Table as compared to other low-cost adsorbents for Cr (III) removals.

Conclusions

Waste rubber tires have been used to prepare activated carbon and the products obtained have been characterized by means of scanning electron microscope, energy-dispersive X-ray spectroscope, FTIR spectrophotometer, and X-ray diffraction. The resultant AC was tested as adsorbents for the removal of Chromium (III). Adsorption kinetics of the Cr3+ removal is fast at the beginning and then slowly increases. The extent to which the adsorption process occurs is strongly dependent on the pH of the Cr3+ solution, being larger at pH range of 4–6. The conversion of waste rubber tires into activated carbon is recommended. This is because the process is considered to be a doubly effective solution for environmental pollution. From one side, it represents a cleaning way to dispose the waste tires and in other side it is an economic source of carbonaceous materials.

References

Alexandre-Franco M, Fernández-González C, Macías-García A, Gómez-Serrano V (2008) Uptake of lead by carbonaceous adsorbents developed from tire rubber. Adsorption 14:591–600

Alexandre-Franco M, Fernández-González C, Alfaro-Domínguez M, Gómez-Serrano V (2011) Adsorption of cadmium on carbonaceous adsorbents developed from used tire rubber. J Environ Manag 92:2193–2200

Almazan-Almazan MC, Paredes JI, Perez-Mendoza M, Domingo-Garcia M, Fernandez-Morales I, Martinez-Alonso A, Lopez-Garzon FJ (2006) Surface characteristics of activated carbons obtained by pyrolysis of plasma pretreated PET. J Phys Chem B 110:11327–11333

Atieh MA, Bakather OY, Tawabini BS, Bukhari AA, Khaled M, Alharthi M, Fettouhi M, Abuilaiwi FA (2010) Removal of chromium (III) from Water by using modified and nonmodified carbon nanotubes. J Nanomater 1–9

Chan OS, Cheung WH, McKay G (2011) Preparation and characterisation of demineralised tyre derived activated carbon. Carbon 49:4674–4687

Chantawong V (2004) Adsorption of Heavy Metals by Montmorillonite, The Joint International Conference on “Sustainable Energy and Environment (SEE)”1-3 December, Hua Hin, Thailand, 548–551

Chuan MC, And Liu JC (1996) Release behavior of chromium from tannery sludge. Wat Res 30:932–938

Cossich ES, Tavares CRG, Ravagnani TMK (2002) Biosorption of chromium(III) by Sargassum sp. Biomass Electron J Biotechnol 5(2):133–141

Deng H, Yang L, Tao GH, Dai JL (2009) Preparation and characterization of activated carbon from cotton stalk by microwave assisted chemical activation—application in methylene blue adsorption from aqueous solution. J Hazard Mater 166:1514–1521

Fei-Lian FH, Chen W, Xing B, Zhu L (2011) Sorption of apolar and polar organic contaminants by waste tire rubber and its chars in single- and bi-solute systems. Environ Pollut 159:850–857

Garcia ITS, Nunes MR, Carreo NLV, Wallaw WM, Fajardo HV, Probst LFD (2007) Preparation and characterization of activated carbons from thread of tire waste. Pol’ımeros 17:329–333

Greenwood NN, Earnshaw A (1989) ×. Pergamon, Oxford

Gupta VK, Mittal A, Gajbe V, Mittal J (2006a) Removal and recovery of the hazardous azo dye acid orange 7 through adsorption over waste materials: bottom ash and de-oiled soya. Ind Eng Chem Res 45:1446–1453

Gupta VK, Mittal A, Kurup L, Mittal J (2006b) Adsorption of a hazardous dye, erythrosine, over hen feathers. J Colloid Interface Sci 304(1):52–57

Gupta VK, Jain R, Varshney S (2007a) Electrochemical removal of the hazardous dye Reactofix Red 3 BFN from industrial effluents, 2007. J Colloid Interface Sci 312(2):292–296

Gupta VK, Jain R, Varshney S (2007b) Removal of Reactofix golden yellow 3 RFN from aqueous solution using wheat husk—an agricultural waste. J Hazard Mater 142:443–448

Gupta VK, Rastogi A (2008a) Equilibrium and kinetic modelling of cadmium (II) biosorption by nonliving algal biomass Oedogonium sp. from aqueous phase. J Hazard Mater 153:759–766

Gupta VK, Rastogi A (2008b) Sorption and desorption studies of chromium (VI from nonviable cyanobacterium Nostoc muscorum biomass. J Hazard Mater 154:347–354

Gupta VK, Rastogi A (2009a) Biosoprtion of hexavalent chromium by raw and acid-treated green alga Oedogonium hatei from aqueous solutions. J Hazard Mater 163:396–402

Gupta VK, Goyal RN, Sharma RA (2009b) Novel PVC membrane based alizarin sensor and its application; Determination of vanadium, zirconium and molybdenum. Inter J Electrochem Sci 4:156–172

Gupta VK, Al Khayat M, Singha AK, Pal MK (2009c) Nano level detection of Cd (II) using poly(vinyl chloride) based membranes of Schiff bases. Anal Chimica Acta 634:36–43

Gupta VK, Rastogi A, Nayak A (2010) Adsorption studies on the removal of hexavalent chromium from aqueous solution using a low cost fertilizer industry waste material. J Colloid and Interface Sci 342(1):135–141

Gupta VK, Agarwal S, Saleh TA (2011a) Synthesis and characterization of alumina-coated carbon nanotubes and their application for lead removal. J Hazard Mater 185(1):17–23

Gupta VK, Agarwal S, Saleh TA (2011b) Chromium removal combining the magnetic properties of iron oxide with adsorption properties of carbon nanotubes. Water Res 45(6):2207–2212

Helleur R, Popovic N, Ikura M, Stanciulescu M, Liu D (2001) Characterization and potential applications of pyrolytic char from ablative pyrolysis of used tires. J Anal Appl Pyrol 58–59:813–824

Huang H, Tang L, Wu CZ (2003) Characterization of gaseous and solid product from thermal plasma pyrolysis of waste rubber. Environ Sci Technol 37:4463–4467

Min A, Harris AT (2006) Influence of carbon dioxide partial pressure and fluidization velocity on activated carbons prepared from scrap car tyre in a fluidized bed. Chem Eng Sci 61:8050–8059

Nakagawa K, Namba A, Mukai SR, Tamon H, Ariyadejwanich P, Tanthapanichakoon W (2004) Adsorption of phenol and reactive dye from aqueous solution on activated carbons derived from solid wastes. Water Res 38(7):1791–1798

Rana P, Mohan N, Rajagopal C (2004) Electrochemical removal of chromium from wastewater by using carbon aerogel electrodes. Water Res 38:2811–2820

Richard FC, Bourg ACM (1991) Aqueous geochemistry of chromium: a review. Wat Res 25:807–816

Rutland FH (1991) Environmental compatibility of chromium-containing tannery and other leather product wastes at land disposal sites. J Am Leather Chem Assoc 86:364–375

Saleh TA (2011) The influence of treatment temperature on the acidity of MWCNT oxidized by HNO3 or a mixture of HNO3/H2SO4. Appl Surf Sci 257:7746–7751

Saleh TA, Gupta VK (2011a) Functionalization of MWCNT with tungsten oxide and its application for sun-light-induced degradation of rhodamine B. J Colloid Interface Sci 362(2):337–344

Saleh TA, Gupta VK (2011b) Synthesis of MWCNT/MnO2 and their application for simultaneous oxidation of arsenite and sorption of arsenate. Appl Catal B Environ 106(1–2):46–53

San Miguel G, Fowler GD, Sollars CJ (2002) The leaching of inorganic species from activated carbons produced from waste tyre rubber. Water Res 36:1939–1946

San-Miguel G, Fowler GD, Sollars CJ (2002) Adsorption of organic compounds from solution by activated carbons produced from waste tyre rubber. Sep Sci Technol 37(3):663–676

Stellmach JJ (1990) The commercial success of chrome tanning: a study and commemorative. J Am Leather Chem Assoc 85(11):407–454

Tanthapanichakoon W, Ariyadejwanich P, Japthong P, Nakagawa K, Mukai SR, Tamon H (2005) Adsorption-desorption characteristics of phenol and reactive dyes from aqueous solution on mesoporous activated carbon prepared from waste tires. Water Res 39(7):1347–1353

Yang J, Qiu K (2009) Preparation of activated carbon by chemical activation under vacuum. Environ Sci Technol 43:3385–3390

Zhang N, Suleiman JS, He M, Hu B (2008) Chromium(III)-imprinted silica gel for speciation analysis of chromium in environmental water samples with ICP-MS detection. Talanta 75:536–543

Acknowledgment

The author(s) would like to acknowledge the support provided by King Abdulaziz City for Science and Technology (KACST) through the Science & Technology Unit at King Fahd University of Petroleum & Minerals (KFUPM) for funding this work through project No.10-WAT1400-04.as part of the National Science, Technology and Innovation Plan

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Gupta, V.K., Ali, I., Saleh, T.A. et al. Chromium removal from water by activated carbon developed from waste rubber tires. Environ Sci Pollut Res 20, 1261–1268 (2013). https://doi.org/10.1007/s11356-012-0950-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-012-0950-9