Abstract

Purpose

Malachite Green (MG) is used for a variety of applications but is also known to be carcinogenic and mutagenic. In this study, a novel Micrococcus sp. (strain BD15) was observed to efficiently decolorize MG. The purposes of this study were to explore the optimal conditions for decolorization and to evaluate the potential use of this strain for MG decolorization.

Methods

Optical microscope and UV–visible analyses were carried out to determine whether the decolorization was due to biosorption or biodegradation. A Plackett–Burman design was employed to investigate the effect of various parameters on decolorization, and response surface methodology was then used to explore the optimal decolorization conditions. Kinetics analysis and antimicrobial activity tests were also performed.

Results

The results indicated that the decolorization by the strain was mainly due to biodegradation. Concentrations of MG, urea, and yeast extract and inoculum size had significantly positive effects on MG decolorization, while concentrations of CuCl2 and MgCl2, and temperature had significantly negative effects. The interaction between different parameters could significantly affect decolorization, and the optimal conditions for decolorization were 1.0 g/L urea, 0.9 g/L yeast extract, 100 mg/L MG, 0.1 g/L inoculums (dry weight), and incubation at 25.2°C. Under the optimal conditions, 96.9% of MG was removed by the strain within 1 h, which represents highly efficient microbial decolorization. Moreover, the kinetic data for decolorization fit a second-order model well, and the strain showed a good MG detoxification capability.

Conclusion

Based on the results of this study, we propose Micrococcus sp. strain BD15 as an excellent candidate strain for MG removal from wastewater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Malachite Green (MG), a triphenylmethane dye, is extensively used as a dye, food additive, parasiticide, and fungicide in food, dyeing, and fish farming industry throughout the world. This dye is resistant to biodegradation and has toxicological effects on the liver, lungs, and other organs of experimental mammals and other animals. Due to these characteristics, MG has been banned in several countries and listed as a priority chemical for carcinogenicity testing by the US Food and Drug Administration (Srivastava et al. 2004). However, it is still used in many areas of the world due to its low cost, ready efficacy, and lack of suitable alternatives (Shedbalkar and Jadhav 2011). Therefore, the environmental pollution caused by the long-term and extensive usage of MG has become a serious problem.

One method for removing MG from polluted water is the biological treatment which is considered to be an attractive and eco-friendly method. Several microorganisms, including Chlorella sp., Shewanella sp., and Pseudomonas sp., have been reported to degrade MG (Daneshvar et al. 2007; Chen et al. 2010a; Li et al. 2009; Du et al. 2011); however, the efficiency of degradation still needs to be improved, and additional strains with excellent MG-degrading ability also need to be explored. Moreover, the traditional “one-factor-a-time” approach for investigating the effect of operational parameters on decolorization and optimizing the decolorization conditions is time consuming and needs abundant trials. As a more powerful method to investigate decolorization of dyes, the statistical design has received more attention and become popular (Levin et al. 2005).

Several strains of Micrococcus sp. have been isolated to degrade 2-nitrotoluene, nitrobenzene, melamine formaldehyde, and azo dyes in previous studies, whereas no reports are available on biodegradation of triphenylmethane dyes by Micrococcus sp. strains (Mulla et al. 2011; El-Sayed et al. 2006; Saratale et al. 2009; Zheng et al. 2009). In the present study, a novel Micrococcus sp. strain named BD15 with a high MG degradation ability was isolated. Therefore, the aims of this study are to investigate the effect of operational parameters on decolorization and optimize the conditions for decolorization of MG by the strain using statistical design, and to evaluate the potential of this strain for decolorization of MG.

2 Materials and methods

2.1 Dye and chemicals

All chemicals were of analytical grade and purchased from Sinopharm Chemical Reagent Company, China.

2.2 Organism and media

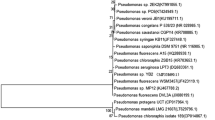

Micrococcus sp. strain BD15 (accession no. GU085223) was isolated from sewage and preserved at the College of Life Sciences, Zhejiang University (Chen et al. 2010b). The phylogenetic tree based on 16S rRNA gene sequences is showed in Fig. 1 in supplementary materials.

Luria–Bertani (LB) medium consists of 10.0 g/L tryptone, 5.0 g/L yeast extract, and 10.0 g/L NaCl, pH 7.0–7.2. Mineral salt medium (MSM) consists of 15.13 g/L Na2HPO4, 3.0 g/L KH2PO4, 0.5 g/L NaCl, 1.0 g/L NH4Cl, 0.491 g/L MgSO4·7H2O, and 0.026 g/L CaCl2·2H2O, pH 7.0.

Mueller–Hinton (MH) medium consists of 6.0 g/L beef extract, 1.5 g/L starch, 17.5 g/L acid hydrolysate of casein, and 17.0 g/L agar, pH 7.3 ± 0.1.

2.3 Decolorization experiments

Micrococcus sp. strain BD15 was pre-cultured in LB media by shaking at 200 rpm, at 30°C overnight. The cells were harvested by centrifugation (8,000 rpm, 5 min), washed twice, and resuspended in distilled water. Equal concentrations of cells were used as inoculums with an initial cell mass of 0.2–0.6 g/L (dry weight) for Plackett–Burman experiments and 0.1–0.3 g/L (dry weight) for response surface experiments. At a certain interval, 4-mL samples were collected and centrifuged at 12,000 rpm for 10 min. The supernatant was analyzed using a UV-3100 spectrophotometer at 620 nm (λ max for MG). Controls without inoculation were conducted under the same conditions.

The decolorization percentage of MG was calculated by the following formula:

where DP is the decolorization percentage of MG, A i is the initial absorbance of the MG solution without inoculation, and A f is the final absorbance of the MG solution after inoculation.

The process of MG decolorization by the strain BD15 was also analyzed with an optical microscope (Nikon, YS100). The strain was suspended in MG solution, and images were acquired at various time points.

2.4 Experimental design

2.4.1 Screening of important operational parameters for MG decolorization

The important operational parameters for MG decolorization by Micrococcus sp. BD15 were screened by Plackett–Burman design, which is a very useful tool for screening n variables in only n + 1 trials (Singh and Dikshit 2010). The theoretical linear model for the results of the Plackett–Burman design is as follows:

where Y is the estimated target function, a 0 is the intercept of the linear model, b i is the regression coefficient of the variable, and e is the experimental error of the selected model. A large b i value (either positive or negative) indicates that the corresponding variable has a large effect on decolorization of MG; if the b i value is close to zero, it means that the corresponding variable has little or no effect on the decolorization of MG (Levin et al. 2005). Based on this formula, 16 variables, including concentration of different medium components (glucose, sucrose, lactose, urea, protein extract, yeast extract, CuCl2, MgCl2, ferric citrate, MnCl2, CaCl2, KCl, and MG), inoculum size, pH, and temperature, were selected to investigate their effect on the decolorization of MG by the strain BD15. As shown in Table 1 in the supplementary materials, the high and low levels of each independent variable, as well as center points which are the averages of the high and low levels, were assigned. The Plackett–Burman design for the 16 variables is also presented in Table 1 in the supplementary materials. After 4 h of incubation, the decolorization percentage of MG was determined by the method described above. All experiments were carried out in triplicates, and the mean values were used for analysis. In order to minimize the effect of the uncontrolled factors, the experimental sequence was stochastic. The Minitab 14.0 software was used for the statistical analysis of the Plackett–Burman design.

2.4.2 Optimization of the operational parameters for decolorization using response surface methodology

Response surface method which is usually applied following a screening study was employed to optimize the selected operational parameters for decolorization of MG (Ayed et al. 2010a). A central composite design (CCD), which usually has three groups of design points: two-level factorial design points, axial points, and center points, was applied for the five screened independent variables. The relationship and interrelationship of variables could be described by the following formula:

where Y is the estimated target function, β 0 is the constant of the model, β i is the linear coefficient of the model, β ii is the quadratic coefficient of the model, β ij is the cross-product coefficient of the model, and e is the experimental error of the selected model. The three-level, five-factorial CCD design is shown in Table 2 in the supplementary materials, and the variables selected for CCD were the concentrations of MG, urea, and yeast extract, as well as the inoculum size and temperature. The initial pH value of the MG solution was 7.0, and the incubation time was 1 h. The total trials (=32) include 26 experiments and 6 replications at the design center which is used for evaluation of the experimental error. The experimental sequence was randomized to minimize the effect of the uncontrolled factors. Minitab 14.0 software was applied to analyze the data from the CCD experiments.

2.5 Kinetics study

The kinetics studies were performed under the optimal condition which was determined by the CCD. After inoculation of the strain BD15, 4 mL of samples was collected at several intervals and centrifuged at 12,000 rpm for 10 min. The supernatants were analyzed by a spectrophotometer at 620 nm. All experiments were carried out in triplicates, and the mean values were used for analysis.

2.6 Antimicrobial activity tests

Bacillus subtilis B19 and Escherichia coli K12 were selected as standard organisms to test the antimicrobial activity of MG and its degradation products. The strains were pre-cultured in LB medium at 37°C overnight. The cultures were swabbed onto MH agar plates with an initial bacterial concentration of OD600 = 0.5. The antibiotic paper disks with 10 μL MG or its degradation products were then put onto the agar plates, after which the plates were incubated at 37°C overnight. The zone of inhibition was measured to evaluate the antimicrobial activity.

The superoxide dismutase (SOD) activity was measured using a UV-3100 spectrophotometer. After overnight incubation, the cells were collected by centrifugation at 6,000 rpm for 10 min, washed three times with distilled water, and then resuspended in distilled water (control), MG solution (100 mg/L), or a solution of MG degradation products, respectively. After 2 h of incubation, the cells were collected, and the enzyme extract was prepared according to our previous study (Du et al. 2011). The SOD activity was measured at 550 nm using an A001-1 enzyme kit (Nanjing Jiancheng Bioengineering Institute, Jiangsu Province, China). One unit of SOD is defined as the amount of samples required for 50% inhibition of cytochrome C reduction.

3 Results and discussion

3.1 Optical microscope and UV–visible analysis of decolorization of MG by strain BD15

The Micrococcus sp. strain BD15 was observed to decolorize MG (100 mg/L) efficiently in MSM medium. The decolorization process was analyzed using an optical microscope, and the images in Fig. 2 in the supplementary materials clearly displayed that the color caused by MG in the solution faded over time. The cells darkened in color 2 min after their suspension in the solution and then began to lighten again after 2 min, suggesting that MG was quickly absorbed and then degraded by the cells. After decolorization for 30 min, the cells were almost colorless indicating that the MG decolorization was mainly caused by biodegradation. In order to further determine whether the decolorization is due to the biodegradation or biosorption, UV–visible analysis (200–800 nm) was carried out before and after decolorization. The UV–visible spectrum in Fig. 1 showed that the peak at 620 nm (λ max for MG) decreased significantly after decolorization; meanwhile, a new peak was observed at 370 nm after decolorization. Besides, the peaks at 206 and 253 nm before decolorization shifted to 209 and 248 nm after decolorization, respectively, and the intensity of these peaks increased significantly after decolorization. According to the previous report, if the bacterial decolorization of dyes is caused by biosorption, the absorption peaks will decrease proportionally after decolorization; while the absorption peaks will decrease completely or a new peak will appear if the decolorization is caused by biodegradation (Ayed et al. 2009). Therefore, the decolorization of MG by the strain BD15 was mainly due to biodegradation since a new peak appeared at 370 nm after decolorization.

3.2 Results of Plackett–Burman design and factor screening

In order to investigate the effect of different operational parameters on decolorization of MG by the strain and screen the important factors, the Plackett–Burman design was employed in the next step. Table 1 in the supplementary materials represents the results of the Plackett–Burman design with respect to the decolorization of MG by the strain. The decolorization percentage of MG was in the range of 0% (run 2) to 100% (run 16), indicating that the selected variables have significant effects on decolorization of MG. The effects of variables and a statistical analysis of the Plackett–Burman design are presented in Table 3 in the supplementary materials. The values of R 2 and adjusted R 2 were 98.9% and 95.3%, respectively, which indicated that the model was appropriate. As shown in Table 3 in the supplementary materials, temperature (20–36°C) had a negative effect on decolorization, which meant that a relatively low temperature was required for decolorization. The initial pH of the medium in the tested range had a positive effect on decolorization, but the effect was insignificant (p > 0.05). Most of the carbon and nitrogen sources (sucrose, lactose, urea, and yeast extract) tested could enhance the decolorization by the strain since their effect and coefficient values were positive. Among the metal ions tested, only Ca2+ had a significantly positive effect on decolorization, while the others had a negative or no effect on the decolorization. Besides, a relatively higher inoculum size and lower MG concentration could enhance the decolorization. Therefore, the model equation for decolorization can be expressed as follows:

where DP is decolorization percentage; A is temperature; C through N are the concentrations of glucose, lactose, urea, protein extract, yeast extract, CuCl2, MgCl2, ferric citrate, CaCl2, and KCl, respectively; O is the inoculum size; and P is the concentration of MG (p < 0.05).

The significance of coefficients of the variables was checked by the p values. Among the factors tested, concentrations of CuCl2, MG, glucose, urea, and yeast extract, as well as inoculum size and temperature, had a significant influence (p < 0.01) on decolorization (Table 3 in the supplementary materials); however, concentrations of CuCl2 and glucose had a significantly negative effect, indicating that these two factors should not be included in CCD experiments. Therefore, concentrations of MG, urea, and yeast extract, as well as inoculum size and temperature, were selected as the variables of CCD experiments to further optimize the decolorization conditions.

3.3 Results of CCD and optimization of experimental conditions

3.3.1 Development of regression and model equation

In order to further optimize the decolorization conditions and study the interactions between the significant factors on decolorization, CCD experiments were carried out following the Plackett–Burman design. The experimental values and predicated values of decolorization percentage are presented in Table 2 in the supplementary materials. The experimental decolorization percentage ranged from 45.4% to 87.9% after incubation for 1 h, which confirmed that the selected factors had a significant influence on decolorization. The variance (ANOVA) and regression coefficients of the selected model are presented in Tables 4 and 5 in the supplementary materials. Based on the data, the R 2 and adjusted R 2 values were 97.0% and 91.5%, respectively, which indicated that the model could be used as a predictor of the decolorization percentage. Therefore, a fitted quadratic model for decolorization of MG could be written in the form of the following equation:

where DP is decolorization percentage, and A through D are the five independent variables of CCD. The F value and p value of the regression were 17.73 and <0.001, respectively, suggesting that the model was highly significant. The p value of the linear and interaction terms was also <0.01, indicating that the linear terms B, C, D and interaction terms AC, AD, BC, CD, and DE had significant influence on decolorization of MG by the strain. Besides, the F value and p value of the “lack of fit” term were 1.15 and 0.447, respectively, which suggested that the “lack of fit” term was not significant relative to the pure error and further indicated that the model fitted the response (decolorization percentage) well.

3.3.2 Effect of interactive factors

The contour plots which were obtained using Minitab 14.0 software are presented in Figs. 2, 3, and 4. Figure 2 showed the combined effect of temperature and the other four tested factors on decolorization. The decolorization percentage decreased as concentration of MG increased from 100 to 300 mg/L, and the interaction between concentration of MG and temperature is insignificant (Fig. 2a). From Fig. 2b, the decolorization percentage first increased and then decreased with increasing temperatures, while the decolorization percentage decreased first and then increased as the inoculum size increased. Besides, the interaction between the two variables (temperature and inoculum size) was significant. Figure 2c showed that the decolorization percentage increased as concentration of urea increased from 0.5 to 1.0 g/L, and a higher decolorization percentage was observed under the condition of 25–28°C and 0.9–1.0 g/L urea. Meanwhile, the interaction between temperature and concentration of urea was significant. Figure 2d indicated that the interaction between concentration of yeast extract and temperature was significant, and the highest decolorization percentage was observed at 27–28°C and 0.7–0.8 g/L yeast extract.

Figure 3 presents the combined effect of the varying concentrations of MG, urea, and yeast extract and inoculum size on decolorization. It was observed that the decolorization percentage decreased as concentration of MG increased from 100 to 300 mg/L (Fig. 3). Figure 3a showed that as concentration of MG decreased, the decolorization percentage increased with inoculum size up to the optimal level, and the interaction between the two variables could significantly affect decolorization. Figure 3b and c indicated that the interaction between the concentration of MG and urea and between the concentration of MG and yeast extract was insignificant.

Figure 4 presents the combined effect of the concentration of urea and yeast extract and inoculum size on decolorization. Figure 4a showed a significant interaction between the concentration of urea and inoculum size, and higher decolorization was observed when inoculum size was 0.1 g/L and concentration of urea was 1.0 g/L. Figure 4b indicated that the interaction between the concentration of yeast extract and inoculum size was insignificant. As shown in Fig. 4c, the interaction between the concentration of yeast extract and urea was significant, and >66% decolorization was observed under the condition of 0.95–1.0 g/L urea and 0.7–1.0 g/L yeast extract. Therefore, the CCD results indicated the interaction between AC, AD, BC, CD, and DE could significantly affect decolorization of MG by the strain, while it could not be observed by the traditional “one-factor-a-time” approach.

3.3.3 Model validation and experimental confirmation

Validation of the selected quadratic model was tested by another three runs of experiments under the optimal conditions obtained from CCD. The optimal operational parameters obtained from CCD were as follows: the concentrations of urea, yeast extract, and MG were 1.0, 0.9, and 100 mg/L, respectively; the inoculum size was 0.1 g/L (dry weight), and the temperature was 25.2°C. The results of the confirmation experiments showed that 96.9% decolorization was observed under the optimal conditions, which was within the confidence interval (92.4%). Therefore, the selected quadratic model is a good fit for the response.

3.4 Kinetics study

The kinetics of decolorization was investigated under the optimal conditions obtained from CCD experiments. According to the report by Das et al. (2010), the kinetics of microbial decolorization can be described by the following equations:

where C t (milligrams per liter) is the concentration of MG at time t, C 0 is the initial concentration of MG; t (minutes) is the incubation time, and k 0, k 1, and k 2 are the zero-order, first-order, and second-order rate constants, respectively. The data from the kinetics study were plotted based on the above equations and depicted in Fig. 5. The results indicated that the kinetic data for decolorization fitted Eq. 3 better, since the R 2 of the model was 0.907 while it was only 0.259 and 0.665 for the other two models, respectively. Therefore, the decolorization of MG by strain BD15 could be well described by the second-order model, and almost 97% of MG (100 mg/L) could be removed within 1 h under the optimal conditions.

3.5 Antimicrobial activity of MG and its degradation products

The antimicrobial activity of MG and its degradation products for E. coli K12 and B. subtilis B19 are presented in Fig. 6. As shown in Fig. 6a and b, it showed a significant inhibition zone for both E. coli K12 and B. subtilis B19 when MG was added into the paper disks, and the size of the inhibition zone was significantly smaller when degradation products of MG were added (Fig. 6c), suggesting that degradation products of MG were less toxic than MG. The SOD activity of the cells also can be a reference aspect for environmental pollution (Lyubenova et al. 2009; Lin et al. 2009). The SOD activity was determined, and the data indicated that the SOD activity for both E. coli K12 and B. subtilis B19 treated with MG was highest, followed by that treated with degradation products of MG, and lowest when the cells were treated with water (Fig. 6d), which meant that the toxicity of degradation products of MG decreased compared to MG. Therefore, this strain showed a good MG detoxification ability.

3.6 Comparison of MG decolorization ability of strain BD15 with other microorganisms

The microbial decolorization of MG has been investigated previously, and selected information was summarized in Table 1. Comparatively, the decolorization efficiency of MG by Shewanella decolorationis NTOU1 was the highest in the previous reports, and the decolorization by the strain could reach to 66.1% within 1 h (Table 1). In the present study, it was observed that the Micrococcus sp. BD15 could remove 97% of MG (100 mg/L) within 1 h, indicating that this strain is an efficient strain to degrade MG. Moreover, Micrococcus sp. has been reported to degrade 2-nitrotoluene, nitrobenzene, melamine formaldehyde, and azo dyes (Mulla et al. 2011; El-Sayed et al. 2006; Saratale et al. 2009; Zheng et al. 2009), while no reports were available on the biodegradation of triphenylmethane dye. This study was the first attempt to investigate the potential of Micrococcus sp. BD15 for biodegradation of MG (a triphenylmethane dye), and the results showed that this strain exhibited excellent MG biodegradation ability.

4 Conclusion

Micrococcus sp. strain BD15 was firstly reported to have a high MG degradation ability in the present study. The effect of operational parameters on decolorization and the optimal conditions for decolorization by the strain were determined based on the Plackett–Burman design and response surface methodology. The kinetics of decolorization by the strain could be well described by the second-order model. Moreover, the strain showed a good MG detoxification capability. These results suggested that this strain might be an ideal candidate strain for the biodegradation of MG. Besides, further works will focus on the biodegradation mechanism of MG by the strain and the practical application of this strain.

References

Ayed L, Chaieb K, Cheref A, Bakhrouf A (2009) Biodegradation of triphenylmethane dye Malachite Green by Sphingomonas paucimobilis. World J Microbiol Biotechnol 25:705–711

Ayed L, Khelifi E, Jannet HB, Miladi H, Cheref A, Achour S, Bakhrouf A (2010a) Response surface methodology for decolorization of azo dye Methyl Orange by bacterial consortium: produced enzymes and metabolites characterization. Chem Eng J 165:200–208

Ayed L, Chaieb K, Cheref A, Bakhrouf A (2010b) Biodegradation and decolorization of triphenylmethane dyes by Staphylococcus epidermidis. Desalination 260:137–146

Chen CH, Chang CF, Liu SM (2010a) Partial degradation mechanisms of malachite green and methyl violet B by Shewanella decolorationis NTOU1 under anaerobic conditions. J Hazard Mater 177:281–289

Chen XJ, Jin DF, Ding HT, Lin H, Zhao YH (2010b) Isolation and characterization of decabromodiphenyl ether (BDE-209)-degrading bacteria. J Zhejiang Univ-Agric Life Sci 36:521–527

Daneshvar N, Khataee AR, Rasoulifard MH, Pourhassan M (2007) Biodegradation of dye solution containing Malachite Green: Optimization of effective parameters using Taguchi method. J Hazard Mater 143:214–219

Das D, Charumathi D, Das N (2010) Combined effects of sugarcane bagasse extract and synthetic dyes on the growth and bioaccumulation properties of Pichia fermentans MTCC 189. J Hazard Mater 183:497–505

Deng DY, Guo J, Zeng GQ, Sun GP (2008) Decolorization of anthraquinone, triphenylmethane and azo dyes by a new isolated Bacillus cereus strain DC11. Int Biodeter Biodegr 62:263–269

Du LN, Wang S, Li G, Wang B, Jia XM, Zhao YH, Chen YL (2011) Biodegradation of malachite green by Pseudomonas sp. strain DY1 under aerobic condition: characteristics, degradation products, enzyme analysis and phytotoxicity. Ecotoxicology 20:438–446

El-Sayed WS, El-Baz AF, Othman AM (2006) Biodegradation of melamine formaldehyde by Micrococcus sp. strain MF-1 isolated from aminoplastic wastewater effluent. Int Biodeter Biodegr 57:75–81

Jadhav JP, Govindwar SP (2006) Biotransformation of malachite green by Saccharomyces cerevisiae MTCC 463. Yeast 23:315–323

Levin L, Forchiassin F, Viale A (2005) Ligninolytic enzyme production and dye decolorization by Trametes trogii: application of the Plackett-Burman experimental design to evaluate nutritional requirements. Process Biochem 40:1381–1387

Li LT, Hong Q, Yan X, Fang GH, Ali SW, Li SP (2009) Isolation of a malachite green-degrading Pseudomonas sp. MDB-1 strain and cloning of the tmr2 gene. Biodegradation 20:769–776

Lin XY, Xu XH, Yang CH, Zhao YH, Feng ZH, Dong YY (2009) Activities of antioxidant enzymes in three bacteria exposed to bensulfuron-methyl. Ecotox Environ Safe 72:1899–1904

Lyubenova L, Nehnevajova E, Herzig R, Schröder P (2009) Response of antioxidant enzymes in Nicotiana tabacum clones during phytoextraction of heavy metals. Environ Sci Pollut Res 16:573–581

Mulla SI, Hoskeri RS, Shouche YS, Ninnekar HZ (2011) Biodegradation of 2-nitrotoluene by Micrococcus sp. strain SMN-1. Biodegradation 22:95–102

Saratale RG, Saratale GD, Chang JS, Govindwar SP (2009) Ecofriendly degradation of sulfonated diazo dye C.I. Reactive Green 19A using Micrococcus glutamicus NCIM-2168. Bioresource Technol 100:3897–3905

Shedbalkar U, Jadhav JP (2011) Detoxification of Malachite Green and textile industrial effluent by Penicillium ochrochloron. Biotechnol Bioproc E 16:196–204

Singh SS, Dikshit AK (2010) Optimization of the parameters for decolourization by Aspergillus niger of anaerobically digested distillery spentwash pretreated with polyaluminium chloride. J Hazard Mater 176:864–869

Srivastava S, Sinha R, Roy D (2004) Toxicological effects of malachite green. Aqua Toxicol 66:319–329

Zheng CL, Qu BC, Wang J, Zhou JT, Wang J, Lu H (2009) Isolation and characterization of a novel nitrobenzene-degrading bacterium with high salinity tolerance: Micrococcus luteus. J Hazard Mater 165:1152–1158

Acknowledgments

This study was supported by the National Natural Science Foundation of China (31070079), the Science and Technology Project of Zhejiang Province (2008C13014-3, 2010C13G2010074), and the International Cooperation Project in Science and Technology of Zhejiang Province (no. 2008C14038).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor Hailong Wang

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 13494 kb)

Rights and permissions

About this article

Cite this article

Du, LN., Zhao, M., Li, G. et al. Highly efficient decolorization of Malachite Green by a novel Micrococcus sp. strain BD15. Environ Sci Pollut Res 19, 2898–2907 (2012). https://doi.org/10.1007/s11356-012-0796-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-012-0796-1