Abstract

Purpose

Urbanization and industrialization in China has resulted in a dramatic increase in the volume of wastewater and sewage sludge produced from wastewater treatment plants. Problems associated with sewage sludge have attracted increasing attention from the public and urban planners. How to manage sludge in an economically and environmentally acceptable manner is one of the critical issues that modern societies are facing.

Methods

Sludge treatment systems consist of thickening, dewatering, and several different alternative main treatments (anaerobic digestion, aerobic digestion, drying, composting, and incineration). Agricultural application, landfill, and incineration are the principal disposal methods for sewage sludge in China. However, sewage sludge disposal in the future should focus on resource recovery, reducing environmental impacts and saving economic costs.

Results

The reuse of biosolids in all scenarios can be environmentally beneficial and cost-effective. Anaerobic digestion followed by land application is the preferable options due to low economic and energy costs and material reuse.

Conclusion

It is necessary to formulate a standard suitable for the utilization of sewage sludge in China.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In 2008, it is estimated that 57 billion tons of municipal wastewater was discharged in China, 58% of which came from municipal domestic sewage (Zhang et al. 2010), while the production of municipal wastewater and dewatered sewage in China increased approximately 5% per year on average from 1998 to 2009 as shown in Fig. 1. Sewage sludge as an inevitable by-product of wastewater treatment process presents a number of environmental concerns. Wastewater treatment processes concentrate various pollutants such as heavy metals, organic micro-pollutants, and pathogens into sludge (Wei and Liu 2005). Sludge disposal can thereby result in the release of toxins into the environment and subsequently into the food chain (Pathak et al. 2009). On the other hand, it has been estimated that depending on technology choice, approximately 30∼60% of sewage treatment plant operating costs are related to sludge treatment activities (Muhammad et al. 2011). Therefore, the management of sewage sludge in an economically and environmentally acceptable way is a matter of increasing importance.

An ideal way to solve the issue of sludge waste is to minimize its production in biological wastewater treatment processes, rather than rely on post-treatment. When mechanical wastewater treatment is used, a diversity of approaches for sewage sludge treatment processes and end use exists, each with different associated costs and environmental impacts (Murry et al. 2008). Strategies on end uses of biosolids have traditionally been based on cost, regulatory, environmental, and public acceptance considerations. In recent years, several methods have been used to evaluate their economic and environmental acceptability. Hospido et al (2005) considered land application as an acceptable option for anaerobic digested sludge by evaluating environmental and economic costs of three scenarios (land application, incineration, and pyrolysis of dried sludge), but the environmental impact of construction was ignored. Also little detailed economic analysis information is available for other alternative scenarios. Barber (2009) used a model comparing the environmental impacts and economic costs of different alternative treatment and disposal scenarios. Nevertheless, the transport costs associated with the full range of biosolids management options were not discussed, which may be one of the limiting factors of sludge land application in China. Few investigations have been reported on the environmental and economic impacts of pyrolysis and gasification scenario, partly due to their high cost and scarce application in practice. Therefore, more detailed papers should be investigated for an overall comparison of different treatment and end use of urban sewage sludge, to determine which combinations are more sustainable.

There are 1,258 municipal wastewater treatment plants (WWTPs) in China (Qiu et al. 2010). The method of sewage sludge disposal is carried out using four processes: 45% of the sludge produced is being utilized in agriculture, 3.5% is being incinerated, 34.5% is landfilled including 3.5% with domestic waste, while 3.5% is used in some other areas (Fig. 2). There are political and economic incentives to increase the agriculture application of sludge since it contains large amounts of organic matter and nutrients, such as N and P. However, the reduced availability of land, increased public comprehension of pathogen risk, the potential for food chain contamination by heavy metals, and the risk of uncertainty surrounding organic micropollutants act to limit sludge land application. Landfill is also decreasing because of technology, economic capacity, and new legislation. Incineration due to significant dry solid volume reduction and energy recovery from the sludge can contribute to a sustainable biosolids strategy, but environmental pollution and the cost should be carefully treated. Other disposal options such as pyrolysis, gasification, combustion, and co-combustion of sewage sludge with other materials and use as an energy source in the production of cement or building materials have been intensively investigated (Fonts et al. 2009; Gasafi et al. 2008; Cartmell et al. 2006; Chen et al. 2010). These processes which can recover energy from sewage sludge will probably become the future trends of development (Groß et al. 2008; Shao et al. 2008).

Based on the above considerations, it can be expected that studies for the treatment of sewage sludge shall focus on the following aspects: safe handling, resource recovery, and low economic costs. In all these respects, the recovery of sustainable energy from sewage sludge will be of obvious importance. Another issue of concern is to reduce toxins in sewage sludge before the final treatment and minimize the negative impacts on human and ecosystem health. The aim of this paper is to discuss the current situation and future outlook for sewage sludge treatment and disposal and estimate the environmental and economic impacts of various options from sewage sludge. It also provides some reference for decision makers to better manage sewage sludge

2 Composition of sewage sludge in China

The composition and characteristics of sewage sludge depend on several factors, such as the origin of the wastewater, the purification treatment of the wastewater, stabilization treatment, time and storage conditions, or the coagulant agents used. Generally, sewage sludge is composed of organic compounds, macronutrients, and a wide range of micronutrients, non-essential trace metals, organic micropollutants, and microorganisms. It should be stated that some parameters are important when considering the ultimate disposal of the processed sludge and energy reuse from the sludge during treatment. Dry matter has an effect on fuel requirements, exhaust gas production at the incineration process, and the cost of sludge transportation. Volatile matter, a measure of the sludge organic content, is the most important parameter regarding the energetic use of sewage sludge. Other factors, such as harmful organic compounds, micropollutants, nutrients, and heavy metal, cannot be neglected. According to Hua et al. (2008), polynuclear aromatic hydrocarbons have become one of the primary pollutants in sludge of Zhejiang WWTPs instead of heavy metals, which has a great influence on agriculture application of sewage sludge. Emerging contaminants such as pharmaceuticals, personal care products, illicit drugs, flame retardants, and perfluorinated compounds should be focused on, due to their endocrine-disrupting properties (Díaz-Cruz et al. 2009). N and P are essential resources especially with respect to P. Natural P deposits of sufficient quality are becoming scare, prompting rapid price increase. As a result, large quantities of sludge are applied to farmland. Heavy metal content which is very sensitive to the wastewater source decides whether sewage sludge can be applied to land or not. The threshold value of heavy metal for sludge end use should meet the Pollutants Control Standard of Sludge (National Standard No. CJ/T 309-2009). Contamination concentration in municipal sludge in China was shown in Table 1.

3 Sewage sludge treatment process and anaerobic digestion

Sludge treatment process

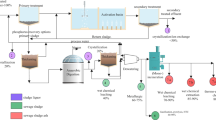

Biosolids management was divided into categories for sludge treatment and end use, which are likely to be realized by different entities—the wastewater treatment plant and the recipient of treated sludge. Sludge treatment systems generally consist of thickening, dewatering, and several alternative main treatments, such as anaerobic digestion, aerobic digestion, drying, composting, and incineration, which are critical in determining biosolids quality and post-treatment options. Anaerobic digestion or composting is used to meet regulatory requirement for pathogen and remnant organic materials reduction prior to land application. Although incineration can significantly decrease dry solid volume and effectively attain a 100% reduction of pathogens and viruses, it produces dioxins, furans, and fly ash, as incurring as higher running/operational costs. Drying is a necessary process prior to thermal utilization of sewage sludge. The moisture content should meet standards regulated by Chinese legislation after sludge treatment.

Life cycle assessment as an environmental information analysis tool to aid planners in the wastewater treatment plant has been extensively applied to sludge treatment. Hong et al (2009) carried out a quantified environmental and economic analysis of six alternative scenarios: dewatering, dewatered sludge composting, dewatered sludge drying, dewatered sludge incineration, incinerated ash melting, and dewatered sludge melting, each with and without digestion. The results show that sewage sludge digestion leads to the lower economic and environmental impacts, while dewatered sludge melting is an environmentally optimal and economically affordable method. Brown et al (2010) exclusively quantified the amount of greenhouse gas (GHG) emissions of different biosolids processing technologies, in order to suggest a cost-effective means for wastewater treatment plants to lower their GHG footprints without increasing capital expenditures. Murry et al. (2008) did an integrated study, comparing nine alternative treatment schemes and arranged them in order of environmental and economic impacts. They proposed that anaerobic digestion (no lime) is overall the most preferable sludge treatment option whereas incineration, particularly coal-fired, is the most costly. A common feature of these methods was the utilization of the resource embodied in sludge; for example, heat drying with compost takes advantage of embodied nutrients, anaerobic digestion, and incineration of sewage sludge takes advantage of embodied energy.

Overall, in order to decrease the environmental and economic impacts during sludge treatment, maximizing potential offsets, including the efficiency of the thickening process, energy capture from anaerobic digestion, and the electricity production rate generated from biogas, is required.

Anaerobic digestion

Anaerobic digestion is considered an essential process in a modern WWTP due to reduction of sludge volume, generation of energy-rich biogas, and production of a nutrient-rich final product. Compared with other technologies, it is the most efficient method to capture energy from biosolids with high water content (Wang et al. 2008b). Barber (2009) reported that the conversion of methane produced from anaerobic digestion to electricity and heat is the main contributor to renewable energy within the WWTP. In the EU, 50% of sewage treatment plants have anaerobic digestion, 18% incorporate aerobic digestion, and 4% lime stabilization, whereas 24% of the plants undertake no sludge stabilization (Werle and Wilk 2010). The same tendency is observed in China, but no detailed available information was reported. However, its application has often been limited by very long retention times and low overall degradation efficiency. In order to increase biodegradability and enhance anaerobic digestion with lower retention time and higher biogas production, various sludge pretreatment techniques have been applied in sludge digestion. These processes include biological (largely thermal phased anaerobic), thermal hydrolysis, mechanical (such as ultrasound, high pressure and lysis), chemical with oxidation (mainly ozonation), alkali (Carrèrea et al. 2010), and combined pretreatment (Kim et al. 2010). These pretreatment schemes have also a beneficial effect on digested sludge quality in terms of pathogens, dewatering properties, heavy metals, and organic pollutants (Carballa et al. 2009). Research shows that advanced digestion options resulted in the lowest carbon emissions and reduced downstream energy and transport requirements regardless of the endpoint of the sludge (Barber 2009). Although the running cost will be increased, pretreatment technology should be included in all new WWTPs as an economically and environmentally acceptable means in the long term.

Currently, combined sludge digestion with other processes to achieve maximum utilization has attracted more and more attention. Using energy released by microbial decomposition to complete water evaporation in the process of biological drying is a promising method for dewatering sludge. There are some advantages in this process such as low-cost and energy consumption since no fossil fuel is depleted in such systems. Moreover, CO2 emission can also be significantly reduced, while the remaining sludge can be converted into amino acid salt with a content of 90% amino acid after acidification. An effective project like this has already been applied in Qinhuangdao City, China.

4 Ways of sludge disposal and utilization

4.1 Main disposal methods in China

Landfill

Landfill is economical and low energy consumption due to its low-technology processes. However, it is a significant source of CH4 and N2O, which are greenhouse gases with a high global warming potential. Leachate containing P and heavy metal can threaten surface and ground waters, and none of the nutrient or energy content is recovered from landfill. Biosolid management technologies for very small towns, with limited technical and financial resources, may justifiably consider investing in biofiltration or methane trapping and flaring at their local landfill (Peters and Rowley 2008).

Land application

Land application of sewage sludge has a great incentive in view of its fertilities and soil conditioning properties. It has been shown that the use of sewage sludge-derived soil amendments can improve soil physical properties, such as porosity, aggregate stability, bulk density, water retention and movement, and sequester carbon in the soil, thereby reducing atmospheric CO2 content and global warming potential (Wang et al. 2008a; Poulsen and Bester 2010). The environmental offset in electricity and fuel consumption is also great when sludge is used in place of synthetic fertilizers (Murry et al. 2008).

Land application of sewage sludge is convenient and low requirements. Various stabilized biosolids such as slurry, dewatered cake, and dried pellets can be applied to land (Wang et al. 2008b). However, sludge utilization can be limited due to its heavy metal, organic micropollutants, and pathogen content. Heavy metal concentrations depending on the relative contributor of industrial wastewaters to the overall flow can be decreased from sludge via source control. Pathogens are removed by pretreatment such as thermophilic anaerobic digestion, hygienization, or composting.

There are several different schemes (digestion, drying, and composting) for land application of sewage sludge. Economically and environmentally, anaerobic digestion followed by using the sludge as fertilizer is better than heat drying and composting. However, composting has potential environment benefits over anaerobic digestion. Compost can meet stricter pathogen standards. The composted product is dryer and less odorous than anaerobic digested sludge and easier to store, as well as being more socially acceptable. Currently, composting has been practiced large-scale in Shenyang, China (Cao et al. 2011).

Land application is available only when the sludge quality meets the local criteria with respect to pathogens and heavy metal content. In addition, the doses and rates of sludge application should also be carefully considered. Reports show that excessive application of sludge has increased the bioavailability of heavy metals, which might pose a serious risk to human health (Singh and Agrawal 2008). While long-term application of sewage sludge can result in leaching of P and heavy metals, the risks of which are greater than the transfer of heavy metals into plant tissue and the food chain in the case of crops (Kidd et al. 2007).

In addition, recovery of N and P should also be taken seriously. It is generally accepted that with the rapid urbanization in China, increasing amounts of N and P are entering the cities through food consumption. It is estimated that N and P contained in urban sewage sludge were 31,500 and 23,600 tons, respectively, in 2009. With increasing urbanization, the improvement of sewage treatment systems and nutrient use efficiency in food production systems, it is anticipated that nutrients contained in the urban waste stream are likely to increase dramatically in China in the next 10–20 years. Although the absolute amounts of N and P in sewage sludge are not great as compared to chemical fertilizers applied to agricultural land in China, their emission to the environment will have serious impacts on water quality and ecosystem health. P, as a nonrenewable resource, is becoming depleted, and production of P fertilizer is increasingly more expensive, thus threatening food security globally. Therefore, recovery of nutrients from sewage sludge in a sustainable way is becoming an important challenge for environmental engineers.

Recently, struvite (MgNH4PO4·6H2O) has been recognized as an alternative way of recovering N and P from urban waste stream. Recovered struvite can be used as a good fertilizer product with slow-release rate, higher purity, and lower heavy metal contents (Gilbert 2009; Warmadewanthi 2009). Presently, the struvite crystallization process has been used at laboratory-, pilot-, and full-scale trials in developed countries successfully (Jordaan et al. 2010; Ueno and Fujii 2001; Laridi et al. 2005; Suzuki et al. 2006). As for China, relevant research works are being carried out with most of the work focusing on lab scale presently (Wan et al. 2009; Huang et al. 2009; Wang et al. 2010). More efforts should be devoted to pilot and full-scale applications of struvite crystallization in real wastewater.

In Chinese rural regions, land application of sewage sludge has attracted more attention due to lower economic costs than other disposal methods. Continuous no-till is an effective management practice to sequester C and increase surface soil C content, it leads to the improvement in soil moisture availability (Spargo et al. 2008). Therefore, it can be used as an appropriate way to solve water shortage and declining soil quality, which is an important issue in China. As labor charges and transportation costs also are important factors, a cost–benefit analysis of its land application should be done prior to its use. Research on emerging contaminants (detergents, plasticizers, pharmaceuticals, etc.) should be required because the risks that sludge contains unknown potentially hazardous organic micropollutants have caused increasing opposition among farmers and the food industry (Poulsen and Bester 2010). China is a large country with a variety of soils and a wide range of climates. Various technologies may be needed for each specific circumstance. Sludge users should be trained with proper technologies to apply sludge in environmentally and friendly ways.

4.2 Thermochemical processes for sludge

Incineration

Incineration of sewage sludge is a process in which its organic matter is completely transformed into CO2 and H2O under high-temperature and aerobic conditions, while inorganic compounds remain in the ash. It is an effective way to dispose of sludge with advantages such as large reduction of sludge volume, thermal destruction of toxic organic compounds, and minimization of odor generation. The final sludge volume after incineration is approximately 10% of that after mechanical dewatering (Fytili and Zabaniotou 2008). The energy produced in the incineration process can be used for drying the mechanically dewatered sludge cake prior to the incineration process or can be used for the production of electricity. The amount of energy produced strongly depends upon the water content of the sludge and performance of the incineration.

Incineration as an attractive disposal method has been applied worldwide. For example, the amount of sludge being incinerated in Denmark has already reached 24% of the sludge produced, 20% in France, 15% in Belgium, and 14% in Germany, while in USA and Japan the percentage has increased to 25% and 55%, respectively (Fytili and Zabaniotou 2008). Incineration of sewage sludge consists of two types: mono- and co-combustion, with mono-combustion being even more predominant. Multiple hearth and fluidized bed furnaces are the most prevalent technologies, and the latter is higher efficiency due to low fuel consumption and emissions (Werle and Wilk 2010). Depending on the moisture content and Btu value in biosolids, supplemental fuel may be required to achieve the adequate combustion conditions.

The main problems for combustion of sludge are high running cost and environmental impacts. Environmental problems relate to the accumulation of heavy metals in ashes and exhaust gases to the atmosphere. The former can be solved by using incineration ash as raw materials in cement manufacturing, during which process heavy metals are immobilized in cement (Murry et al. 2008). Exhaust gases consist of dioxins, furans, and other pollutants (CO2, NOx, N2O, and SOx). Emissions of dioxins and furans are not generally a problem if temperatures above 600°C are kept and flue gases are rapidly cooled below 400°C. N2O can effectively be eliminated by increasing the combustion temperature to 880°C. Addition facilities such as electrostatic precipitators, wet scrubber system, etc. are also needed to comply with the strict exhaust gas emission standards. Large investment for the purification of flue gases may raise social objections (Brown et al. 2010; Hospido et al. 2005).

Co-combustion of sewage sludge with other natural resources (coal, lignite, or wood) or municipal solid waste is also an alternative method for the management of sewage sludge. Environmentally and economically, technology scenarios for co-combusting of biosolids meet Waste Incineration Directive emission criteria and provide a net energy gain, but absence of policy and legal clarity, supply chain insecurity, and market immaturity hinder the development of co-combustion (Cartmell et al. 2006).

Incineration is suitable for cities; for example, Hangzhou has switched to incineration as the preferred option in sewage management, where land is very valuable. To avoid the high operation cost for sludge incineration and also to improve the energy recovery efficiency, exploiting new types of sewage sludge incinerators, implementation of a combined heat and power production unit at incineration plants, and the use of the polluted drying gas in the incineration process are feasible. It is expected that incineration will play an increasingly important role in sewage management in China in the coming decade.

Pyrolysis

Pyrolysis is a thermal decomposition of organic substances in the absence of air or in an oxygen-deficient atmosphere. The products of pyrolysis are bio-gas (non-condensable), bio-oil (condensable volatiles), and carbonaceous bio-char residue all of which have a potential end use and can be maximized by modulating the process conditions (Yu et al. 2011). Compared to incineration, pyrolysis has some potential advantages. One advantage is that the conversion of the combustible gases into electrical power can be achieved more efficiently. In addition, the formation and emission of toxic organic compounds, such as dioxins, NOx, and SOx, can be avoided in pyrolysis with low oxygen concentration.

Using steam pyrolysis to treat sludge is currently a practice being conducted in China, for example, in the city of Shenzhen. After treatment, the moisture content of sludge is reduced from 80% to 50%, resulting in the final sludge volume decreasing by 60%. During this process, pathogen and odor can be thoroughly removed. The treatment sludge can be made into organic fertilizer, which can be used for horticulture and forestry cultivation. It is a proof of concept for the sustainable development of the circular economy.

Other technologies, such as production of bio-oil from the pyrolysis of sewage sludge, have attracted attention due to the non-renewable nature and the increasing price of fossil fuel. Because the mechanism of such a process is complex, many parameters such as temperature, sewage sludge types, retention time, and the catalysts used affect bio-oil production. Literature concerning the production of bio-oil from sludge has demonstrated that the temperature and volatile solid content were the primary factors affecting oil and char yields. The maximum oil yield was achieved with primary sludge at 500°C, and the optimum pyrolysis temperature for waste activated sludge was 400°C (Kim and Parker 2008). It is also stated that the optimal pyrolysis temperature for bio-oil production is 450°C (Park et al. 2010). Experimental studies on pyrolysis liquids obtained from different sewage sludge have come to very interesting conclusions: High sewage sludge ash content favored the decrease in the char yield and the generation of nonvolatile gases, while the sewage sludge with less content of oxygen-containing compounds would favor the quality of the pyrolysis liquids (Fonts et al. 2009). It elucidates some recommendable characteristics in order to use sewage sludge as pyrolysis feedstock. Metal oxide catalysts can have different influence on pyrolysis. The presence of Fe2O3 and ZnO probably inhibited the decomposition of organic matters in demineralized sludge samples to generate more solid residues, while Al2O3, CaO, and TiO2 promoted the degradation of organic matters to produce less solid residues. Al2O3 and TiO2 may decrease pyrolysis time, while CaO, Fe2O3, and ZnO may prolong pyrolysis time (Shao et al. 2010). It is therefore important to formulate optimal catalysts for such systems.

However, the acceptance of this technology may be limited by the low economic value of the product, as well as the relative complexity of the processing equipments. The economic viability of pyrolysis may be improved if the yield of oil were enhanced or if value-added products such as adsorbents could be produced from the pyrolysis chars.

Gasification

Technologies which allow the utilization of wastes as fuel are of great importance. Theoretically, almost all organic wastes with moisture content of 5∼30% can be gratified (Fytili and Zabaniotou 2008). However, not all bio-fuel can lead to the successful gasification. Sewage sludge can be well utilized in gasification because of its inexpensive and high organic matter content. Gasification is the thermal process by which the carbonaceous content of sewage sludge is converted to combustible gas and ash in a reducing atmosphere. The gas produced can be burnt in gas engines and turbines to produce energy. Compared to incineration, gasification, due to the fact that it is a net chemically reductive process, can prevent some problems, including the need for supplemental fuel, emissions of sulfur oxides, nitrogen oxides, heavy metals, fly ash, and the potential production of chlorinated dibenzodioxins and dibenzofurans.

During the process of gasification, one of the main problems to be solved is tar production. Tars are complex mixtures of condensable hydrocarbons, aromatic compounds, oxygen-containing hydrocarbons, and polycyclic aromatic hydrocarbons. These compounds can condense in pipes and filters, obstructing them. They can also affect the fuel line and the injectors of internal combustion engines by condensing in the compressors or transfer lines, which makes the use of gasification impossible for wide application. Tar reduction is therefore important for gasification of sewage sludge.

Gasification of sewage sludge for hydrogen production is a problem in need of attention. Hydrogen is a valuable high-quality fuel. Unlike the fuels used today, it is free of carbon. As a result, no climate-influencing carbon dioxide is released during combustion or use in a fuel cell (Gasafi et al. 2008). On the other hand, the use of hydrogen is more extensive than that of methane. It is therefore beneficial to derive hydrogen from the gasification of sludge. Currently, almost all hydrogen produced is by steam reforming of natural gas, and for the near term, this method of production will continue to dominate. Researchers are developing a wide range of advanced processes for producing hydrogen economically from sustainable resources. As reported, steam as the gasifying agent increased the hydrogen yield by three times as compared to air gasification, and using sewage sludge as a feedstock yielded more hydrogen than paper and food waste under the same gasification conditions (Nipattummakul et al. 2010). Although gasification may be a beneficial way in the future management of the sludge problem, little has been done in China.

4.3 Other treatment methods for sludge

As secondary fuel in cement plants

Cement is well-known as a very basic and widely used material for building and civil engineering construction. However, the manufacture of cement is one of the largest contributors to global CO2 emissions due to traditional fuels such as gas, oil, or coal combustion in clinker kilns. Therefore, the use of alternative fuels in clinker kilns has become an appealing practice worldwide. The substitution of fossil (not renewable) fuels by alternative fuels provides solutions to environmental problems such as waste management and climate change, thus bringing economic benefits not only to cement plants but also to the general society (Kara et al. 2009). The use of sewage sludge as secondary fuel in energy-intensive industrial processes, such as cement production, seems to be a worthwhile option. Although sludge substituted as a co-fuel produces less electricity, it confers advantages such as a reduction in the use of fossil fuels and raw materials, the consequent reduction of CO2 emissions, waste valorization, and decreases cement production costs. Some research results have shown that the option of using sewage sludge as combustible in processes with high-energy demand working is feasible and without health risks for the residents living nearby (Rovira et al. 2010; Schuhmacher et al. 2009). Zabaniotoua and TheofiloubGreen (2008) also confirmed that sewage sludge as a kind of fuel in cement factories may hold a key to providing a reliable, low-cost source of energy, while helping to make the most abundant supply of energy and coal last even longer. In China, the use of sewage sludge as secondary fuel in cement plants has gradually been applied in practice. In one Hangzhou cement plant, sewage sludge as second fuel has been successfully applied in cement manufacturing. Through communicating with the engineer of the cement plant, we know that this process not only realized the comprehensive utilization of sludge but also had no additional adverse effects on environment compared to only when fossil fuel was used.

As material source for the production of cement

In China, due to rapid population growth and urbanization, the volume of cement produced has increased dramatically. For instance, about 8.62 × 108 and1.65 × 109 t of cement were produced in China in 2003 and 2009, respectively (National Bureau of statistics of China 2004, 2010), corresponding to an increase of 91% in just 7 years. Portland cement clinker production consumes massive amounts of raw materials (limestone, clay, etc.), as well as large amounts of energy. Therefore, looking for alternative and more economical raw materials is also becoming an immediate concern. The major chemical compositions of some waste sludge are CaO, Al2O3, Fe2O3, and SiO2, which are also the main chemical compositions of cement raw materials. In theory, sewage sludge could be used in cement production. Moreover, there are several advantages of using a cement kiln for sludge treatment. Toxic organic pollutants in the sludge are completely oxidized, and because of the high process temperature, heavy metals are immobilized in the cement (Murry et al. 2008). For a cement plant, direct heat drying followed by end use in cement production is a superior handling scenarios due to the higher calorific value of raw sludge than digestion sludge. However, the water use is significant because the kiln requires additional electricity but the total process does not provide a biosolid product to displace the use of nitrogen and phosphorus fertilizer, which may be a limiting factor for scare water region (Peters and Rowley 2009).

An example of this was Jiaxing (Zhejiang Province) wastewater treatment plant, which made a pilot-scale experiment with a cement company nearby. They used dewatered sludge cake as a raw material for the production of the cement. In the experimental process, natural drying was used for sludge dewatering. The content of solid achieved more than 80% after 2 days of treatment and can therefore meet the requirement for cement production. Cement produced with sewage sludge as a partial raw material has little or no difference from general cement (Shen 2008). In addition, there are some advantages in this process: (1) sludge after dewatering has realized stabilization and becomes odorless, (2) organic pollutants and pathogens have been destructed completely because of high temperatures in the cement kiln, and (3) the cost is low due to no depletion of mineral materials. These results demonstrated the feasibility of sewage sludge as a material in the process of cement production. Based on these results, it has been concluded that it is a good choice for reducing pressure on the environment by using sewage sludge as a secondary raw material in cement production.

PHA production from sewage sludge

Polyhydroxyalkanoates (PHAs) are the polymers of hydroxyalkanoates that accumulate carbon/energy or reducing-power storage material in various microorganisms (Zabaniotoua and TheofiloubGreen 2008). Currently, PHAs have attracted increasing interest as promising alternatives to conventional plastics due to their biodegradability and capability of being produced from renewable resources (Beun et al. 2002). A number of organisms found in activated sludge are known to have the ability to accumulate PHAs, but the actual amounts of PHAs found in excess activated sludge are very low. Aerobic dynamic feeding (ADF) is one of the most promising techniques for improving the efficiency of PHAs accumulation in activated sludge (Chua et al. 2003). A number of studies have been carried out on PHA production with activated sludge using the ADF technique (Lemos et al. 2006; Chen and Li 2008; Dionisi et al. 2004). Chen and Li (2008) reported that a maximum polymer fraction of 50% (on a COD basis) in the biomass could be obtained using activated sludge enriched by ADF. There are also studies on seeking inexpensive carbon sources to reduce the cost of production and to improve productivity. Sewage sludge containing high organic matter has been shown to be a good potential as a feed stock material for PHA production. Chen and Wu (2010) reported in their investigation that volatile fatty acid obtained from the co-digestion of food wastes and dewatered excess sludge could be used for the PHA production process because of its high yield and relatively low nitrogen and phosphorus concentrations.

PHA production for large-scale application is at pilot phase, in the course of the development process, possibilities of reducing the cost in a desired way by using novel, technically feasible, ecologically compatible, and economically and industrially efficient methods are being studied. It is expected in the future that PHA production from sewage sludge for commercialization will be possible.

5 Perspectives

This paper reviews present and future directions of sewage sludge management in China. Up until now, most of the sewage sludge produced in the process of wastewater treatment has been used in agriculture or disposed of in landfills, or via incineration. Sewage sludge is rich in resources including nutrients and energy. Given the vast population and rapid urbanization in China, sewage sludge represents a major issue in environment and resource management. To resolve this issue, we propose that a holistic approach should be taken to manage sewage sludge in China, and future research and commercialization should focus on the following aspects:

-

Life-cycle analysis of food and water consumption in urbanized regions to provide a full account of nutrient flow within urban ecosystems and to calculate the value of sewage sludge within a given boundary/region

-

Diverse resource recovery systems (for nutrients, bio-energy, and raw substances for building materials) should be developed and applied for sewage sludge management, and in many cases, these systems should be integrated and optimized depending on the quality of sewage sludge and the scale of the region producing sewage sludge. Cost–benefit analysis should also be conducted so that the best technology available can be selected for different scenarios

-

Novel and environmentally friendly materials derived from sewage sludge, such as PHA, are appealing, and the potential of different bacterial species and recombinant strains should be explored further in the context of increased PHA yield and productivity

-

For sustainable management of sewage sludge, frameworks for risk assessment should be developed for different options of resource recovery, and the risks should be communicated to the public

-

New energy policies and regulations such as the climate change levy and enforcing source control to municipal sewers are critical in determining the sustainability of the future in sludge management

References

Barber WP (2009) Influence of anaerobic digestion on the carbon footprint of various sewage sludge treatment options. Water Environ J 23:170–179

Beun JJ, Dircks K, Van Loosdrecht MCM, Heijnen JJ (2002) Poly-β-hydroxybutyrate metabolism in dynamically fed mixed microbial cultures. Water Res 36:1167–1180

Brown S, Beecher N, Carpenter A (2010) Calculator tool for determining greenhouse gas emissions for biosolids processing and end use. Environ Sci Technol 44:9509–9515

Cao XH, Meng XJ, Meng XZ (2011) Recycling to soils: a sustainable way of sludge disposal and its practice in China. Adv Mater Res 183–185:1417–1422

Carballa M, Omil F, Lema JM (2009) Influence of different pretreatments on anaerobically digested sludge characteristics: suitability for final disposal. Water Air Soil Pollut 199:311–321

Carrère H, Dumas C, Battimelli A et al (2010) Pretreatment methods to improve sludge anaerobic degradability: A review. J Hazard Mater 183:1–15

Cartmell E, Gostelow P, Riddell-black D et al (2006) Biosolids-a fuel or a waste? An integrated appraisal of five co-combustion scenarios with policy analysis. Environ Sci Technol 40:649–658

Chen H, Li XL (2008) Effect of static magnetic field on synthesis of polyhydroxyalkanoates from different short-chain fatty acids by activated sludge. Bioresour Technol 99:5538–5544

Chen H, Wu HY (2010) Optimization of volatile fatty acid production with co-substrate of food wastes and dewatered excess sludge using response surface methodology. Bioresour Technol 101:5487–5493

Chen HX, Mab XW, Dai HJ (2010) Reuse of water purification sludge as raw material in cement production. Cem Concr Compos 32:436–439

Chua ASM, Takabatake H, Satoh H, Mino T (2003) Production of polyhydroxyalkanoates (PHA) by activated sludge treating municipal wastewater: effect of pH, sludge retention time (SRT), and acetate concentration in influent. Water Res 37:3602–3611

Díaz-Cruz MS, García-Galán MJ, Guerra P et al (2009) Analysis of selected emerging contaminants in sewage sludge. Trends Analyt Chem 28:1263–1275

Dionisi D, Majone M, Papa V, Beccari M (2004) Biodegradable polymers from organic acids by using activated sludge enriched by aerobic periodic feeding. Biotechnol Bioeng 85:569–579

Fonts I, Azuara M, Gea G, Murillo MB (2009) Study of the pyrolysis liquids obtained from different sewage sludge. J Anal Appl Pyrolysis 85:184–191

Fytili D, Zabaniotou A (2008) Utilization of sewage sludge in EU application of old and new methods—a review. Renew Sustain Energ Rev 12:116–140

Gasafi E, Reinecke MY, Kruse A, Schebek L (2008) Economic analysis of sewage sludge gasification in supercritical water for hydrogen production. Biomass Bio-energy 32:1085–1096

Gilbert N (2009) Environment: the disappearing nutrient. Nature 461:716–718

Groß B, EderG GP, Horst J, Kimmerle K (2008) Energy recovery from sewage sludge by means of fluidized bed gasification. Waste Manage 28:1819–1826

Hong JL, Hong JM, Otaki M, Jolliet O (2009) Environmental and economic life cycle assessment for sewage sludge treatment process in Japan. Waste Manage 29:696–703

Hospido A, Moreira MT, Martín M, Rigola M (2005) Environmental evaluation of different treatment processes for sludge from urban wastewater treatments: anaerobic digestion versus thermal processes. Int J LCA 10:336–345

Hua L, Wu WX, Liu YX, Tientchen CM, Chen YX (2008) Heavy metals and PAHs in sewage sludge from twelve wastewater treatment plants in Zhejiang Province. Biomed Environ Sci 21:345–352

Huang Y, Lin JQ, Li HL (2009) Study on the composition and crystal shape of the precipitate obtained by struvite precipitation from wastewater for phosphorous recovery. Acta Scienctiae Circumstanitiae 29:353–359

Jordaan EM, Ackerman J, Cicek N (2010) Phosphorus removal from anaerobically digested swine wastewater through struvite precipitation. Water Sci Technol 61:3228–3234

Kara M, Günay E, Tabak Y, Yildiz S (2009) Perspectives for pilot scale study of RDF in Istanbul, Turkey. Waste Manage 29:2976–2982

Kidd PS, Domínguez-Rodríguez MJ, Díez J, Monterroso C (2007) Bioavailability and plant accumulation of heavy metals and phosphorus in agricultural soils amended by long-term application of sewage sludge. Chemosphere 66:1458–1467

Kim Y, Parker W (2008) A technical and economic evaluation of the pyrolysis of sewage sludge for the production of bio-oil. Bioresour Technol 99:1409–1416

Kim DH, Jeong E, Oh SE, Shin HS (2010) Combined (alkaline + ultrasonic) pretreatment effect on sewage sludge disintegration. Water Res 44:3093–3100

Laridi R, Auclair JC, Benmoussa H (2005) Laboratory and pilot-scale phosphate and ammonium removal by controlled struvite precipitation following coagulation and flocculation of swine wastewater. Environ Technol 26:525–536

Lemos PC, Serafim LS, Reis MAM (2006) Synthesis of polyhydroxyalkanoates from different short-chain fatty acids by mixed cultures submitted to aerobic dynamic feeding. J Biotechnol 122:226–238

Muhammad N, Siddiquee, Rohani S (2011) Lipid extraction and biodiesel production from municipal sewage sludges: A review. Renewable Sustainable Energy Rev 15:1067–1072

Murry A, Horvath A, Nelson K (2008) Hybrid life-cycle environmental and cost inventory of sewage sludge treatment and end-use scenarios: a case study from China. Environ Sci Technol 42:3163–3169

National Bureau of Statistics of China (2004) National report on economy and social development in 2003. National Bureau of Statistics of China, Beijing (in Chinese)

National Bureau of Statistics of China (2010) National report on Economy and Social Development in 2009. National Bureau of Statistics of China, Beijing (in Chinese)

Nipattummakul N, Ahmed II, Kerdsuwan S, Gupta AK (2010) Hydrogen and syngas production from sewage sludge via steam gasification. Int J Hydrogen Energy 35:11738–11745

Park HJ, Heo HS, Park YK et al (2010) Clean bio-oil production from fast pyrolysis of sewage sludge: effects of reaction conditions and metal oxide catalysts. Bioresour Technol 101:S83–S85

Pathak A, Dastidar MG, Dastidar STR (2009) Bioleaching of heavy metals from sewage sludge: a review. J Environ Manage 90:2343–2353

Peters GM, Rowley HV (2009) Environmental comparison of biosolids management systems using life cycle assessment. Environ Sci Technol 43:2674–2679

Poulsen TG, Bester K (2010) Organic micropollutant degradation in sewage sludge during composting under thermophilic conditions. Environ Sci Technol 44:5086–5091

Qiu Y, Shi HC, He M (2010) Nitrogen and phosphorous removal in municipal wastewater treatment plants in China: a review. Int J Chem Eng 10:1155–1165

Rovira J, Mari M, Nadal M, Schuhmacher M, Domingo JL (2010) Partial replacement of fossil fuel in a cement plant: risk assessment for the population living in the neighborhood. Sci Total Environ 08:5372–5380

Schuhmacher M, Nadal M, Domingo JL (2009) Environmental monitoring of PCDD/Fs and metals in the vicinity of a cement plant after using sewage sludge as a secondary fuel. Chemosphere 74:1502–1508

Shao JG, Yan R, Chen HP, Yang HP, Lee DH (2010) Catalytic effect of metal oxides on pyrolysis of sewage sludge. Fuel Process Technol 91:1113–1118

Shen DP (2008) The exploitation of sludge treatment and disposal in municipal wastewater plant. China Municipal, Engineering 5:45–46 (in Chinese)

Singh RP, Agrawal M (2008) Potential benefits and risks of land application of sewage sludge. Waste Manage 28:347–358

Spargo JT, Alley MM, Follett RF, Wallace JV (2008) Soil carbon sequestration with continuous no-till management of grain cropping systems in the Virginia Coastal Plain. Soil Tillage Research 100:133–140

Suzuki K, Tanaka Y, Kuroda K, Hanajima D, Fukumoto Y, Yasuda T (2006) The technology of phosphorous removal and recovery from swine wastewater by struvite crystallization reaction. JARQ 40:341–349

Ueno Y, Fujii M (2001) Three years experience of operating and selling recovered struvite from full-scale plant. Environ Technol 22:1373–1381

Wan R, Lv X, Zhu G, Xu W (2009) Study on phosphorus recovery by induced crystallization. China Water & Wastewater 25:82–85 (in Chinese)

Wang X, Chen T, Ge YH, Jia YF (2008a) Studies on land application of sewage sludge and its limiting factors. J Hazard Mater 160:554–558

Wang HL, Brown SL et al (2008b) Technological options for the management of biosolids. Environ Sci Pollut Res 15:308–317

Wang CC, Hao XD, Wang P, Lan L (2010) The analysis and characterization of precipitates obtained from struvite (MAP) precipitation. Chinese J Environ Chem 29:759–763 (in Chinese)

Warmadewanthi LJC (2009) Recovery of phosphate and ammonium as struvite from semiconductor wastewater. Sep Purif Technol 64:368–373

Wei Y, Liu Y (2005) Effects of sewage sludge compost application on crops and cropland in a 3-year field study. Chemosphere 59 (9):1257–1265

Werle S, Wilk RK (2010) A review of methods for the thermal utilization of sewage sludge: the Polish perspective. Renew Energy 35:1914–1919

Yu T, Wei Z, Ren ZY, Chen DD (2011) Estimation of a novel method to produce bio-oil from sewage sludge by microwave pyrolysis with the consideration of efficiency and safety. Bioresour Technol 102:2053–2061

Zabaniotoua A, TheofiloubGreen C (2008) Energy at cement kiln in Cyprus—use of sewage sludge as a conventional fuel substitute. Renewable Sustainable Energy Rev 12:531–541

Zhang XH, Deng SH, Wu J, Jiang WJ (2010) A sustainability analysis of a municipal sewage treatment ecosystem based on energy. Ecol Eng 36:685–696

Acknowledgments

Authors would like thank Dr P.N. Williams for proofreading the manuscript. This work was supported by Hangzhou Administration of Science and Technology (20091633F12) and Wenzhou Administration of Science and Technology (H20100051). Y-G Z is partly supported by the Chinese Academy of Sciences (KZCX2-YW-Q02-06) and the Ministry of Science and Technology (2009DFB90120).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Chen, H., Yan, SH., Ye, ZL. et al. Utilization of urban sewage sludge: Chinese perspectives. Environ Sci Pollut Res 19, 1454–1463 (2012). https://doi.org/10.1007/s11356-012-0760-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-012-0760-0