Abstract

Introduction

The nano-scale zero-valent iron (NZVI) was used for the removal of arsenite (As(III)) and arsenate (As(V)) in aqueous solution. Batch experiments were conducted to investigate the effects of initial pH, initial arsenic concentration, dissolved oxygen (DO), and ratio of As(III)/As(V) on arsenic removal.

Materials and methods

The NZVI synthesized by using NaBH4 and FeCl3 was put into use right after its synthesis. The arsenic treatment system of recirculation mode consists of a reactor with a liquid volume of 4.4 L, which provides dual function of reactants reaction and particles settling in one unit.

Results and discussion

Consequently, the pseudo-first order rate equations can be used to describe the removal kinetics for As(V) at pH 4 and 7, while the pseudo-second order reaction was observed for As(V) at pH 9 and As(III) at all pH’s studied. Arsenic removal rates of both As(V) and As(III) were lower in the system with lower DO. The rate of As(III) removal decreased with the increase of its initial concentration. In contrast, the removal rate of As(V) still remained significantly high as its initial concentration increased.

Conclusions

This study reveals that low pH and high DO will favor arsenic removal. With the mixture of As(III) and As(V), the total arsenic was removed faster than solution containing As(III) or As(V) alone. In addition, the mixture with higher fraction of As(V) resulted in higher arsenic removal.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Arsenic is a contaminant of concern in groundwater. It is well known that arsenic is stable in several oxidation states, such as the As(III), mainly found in reducing condition, and As(V), stable in oxidizing state. Both are the most common forms of arsenic in natural waters (Smedley and Kinniburgh 2001). Consuming water with high level of arsenic can cause skin, lung, bladder, or kidney cancers and black foot diseases (Mohan and Pittman Jr 2007). Thus, the search for technologies that focus on arsenic removal in groundwater still continues. Some of the technologies that are now being used for the removal of arsenic from groundwater include precipitation, coagulation and filtration, reverse osmosis, electrodialysis, and ion exchange (Triszcz et al. 2009). However, the technologies mentioned above are effective mostly for As(V) removal, and a pre-oxidation step is required to transform As(III) to As(V) (Lackovic et al. 2000).

Adsorption process by using zero-valent iron (ZVI) is a promising alternative for arsenic removal because this sorption media was used to remove both As(V) and As(III) simultaneously, without pre-oxidation step (Sun et al. 2006), and such process does not require the use of additional chemical reagents. Lackovic et al. (2000) first reported arsenic removal by using ZVI in 2000. They reported that ZVI has a high capacity for arsenic remediation. Afterwards, there were many reports about arsenic removal by ZVI. Bang et al. (2005) used iron filings, which were pretreated by acid to remove the oxide layer, for arsenic removal in a batch system. They revealed that the removal rate of As(V) under oxic condition was faster than anoxic condition and the removal rate was higher at pH 4 than at pH 7. Sun et al. (2006) performed experiments by using packed column of iron chippings, which were obtained from industrial waste and screened to less than 20 mesh. Their results show that As(III) was removed more rapidly than As(V) under anaerobic condition, but the reverse phenomenon was observed under aerobic condition. Melitas et al. (2002) demonstrated the effectiveness of packed column of iron fillings for As(V) removal. They concluded that the performance of As(V) removal depends not only on the adsorptive sites of iron oxide generated from reaction, but also on the ability of As(V) reaching those adsorptive sites. However, the problem associated with the use of ZVI is that the reaction time required for the complete removal of arsenic is in days (Jegadeesan et al. 2005). Based on the method of nano-scale zero-valent iron (NZVI) synthesis developed by Lehigh University research group in 1995 (Glavee et al. 1995), it was found that NZVI possesses higher capacity for arsenic removal than micro-scale zero-valent iron (Kanel et al. 2006; Giasuddin et al. 2007).

In natural groundwater, the ratio of As(III) and As(V) can vary significantly, depending on condition of in situ oxidation state of water (Sasaki et al. 2009). There is a lack of documents reporting on treatment of arsenic with different ratios of As(III) and As(V). Thus, this study investigated such aspect of arsenic removal. In addition, the effects of solution pH, initial arsenic concentration, and DO on the rates of arsenic removal by NZVI were studied as well.

2 Materials and methods

2.1 Materials

The chemicals of reagent grade used in this study include FeCl3·6H2O (99%, Merck) and NaBH4 (> 96%; Merck). Both the As(III) and As(V) stock solution were prepared from NaAsO2 (Fluka) and Na2HAsO4·7H2O (J.T. Baker), respectively. H2SO4 and NaOH were used for adjusting the initial solution pH. All chemical solutions were prepared with deionized water (18.2 MΩ Mill-Q).

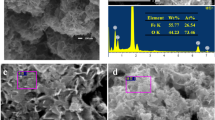

2.2 NZVI synthesis

The NZVI was synthesized according to Glavee et al. (1995). Forty milliliters of 0.25 M NaBH4 were added into 40 mL of 0.045 M FeCl3 aqueous solution. The mixture was agitated by a revolving propeller. The reaction for NZVI formation is shown in Eq. (1).

The NZVI particles formed were separated from the liquid solution using a magnet. Immediately, it was then used in the treatment system. Concerning the NZVI particles characterization, it was dried by freezing dryer for 24 h under the N2-purged environment. The dried NZVI was characterized first by TEM (JEL-2010, Japan) for its particle size. As for the pH with zero charge point, denoted as pHpzc, was determined by using zeta-meter system 3.0+ (Meditop Co., Thailand). Table 1 shows the properties of the synthesized NZVI.

2.3 Reaction system

The NZVI was used in the arsenic treatment system right after it was synthesized. A NZVI dosage of 0.023 g/L was maintained throughout all experiments. As described in earlier study (Anotai et al. 2010), the reactor with liquid volume of 4.4 L was designed to combine the two chambers for both reactants reaction and particles settling in one unit. The external-circulating pump was connected at outlet of the reactor to form a recirculation mode for arsenate removal (see Fig. 1). Five milliliters of the liquid sample treated were taken at each time point and filtered by using a 0.45-μm membrane filter to remove the solids particles from solution before analyses of the residual arsenic concentrations. All samples were stored at 4°C and analyzed within a period of 5 days.

2.4 Analytical methods

The solution pH and ORP were measured by pH and ORP meter (Suntex TS1), while the dissolved oxygen was measured by DO meter (Oxi 330i). The total arsenic, (As(V) and As(III)), was determined by inductively coupled argon plasma and atomic emission spectroscopy using Thermo Scientific Model iCAP 6000 series (Thermo Scientific, USA). Determination of individual arsenic species was conducted by using an anion-exchange cartridge, DSC-SAX 500 mg (Supelco) (Kom et al. 2004). As the arsenic-bearing water samples pass through the cartridge, the As(V) will be retained inside, while the As(III) will be carried out, rendering the separation of As(V) and As(III) from each other. The eluent is then analyzed for the As(III) concentration by ICP. Finally, the As(V) concentration is obtained by subtracting the measured As(III) concentration from the total arsenic concentration.

3 Results and discussion

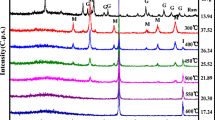

3.1 Effect of initial pH

The initial arsenic concentration (C o) applied was 1,000 μg/L, while the initial pHs of the solution studied were 4.0, 7.0, and 9.0. As presented in Fig. 2, the adsorption reaction of As(III) reached equilibrium at times of 10, 15, and 30 min for pH 4, 7, and 9, respectively, whereas As(V) reached equilibrium at times of 7, 20, and 40 min for the corresponding pHs. The percentage removal at equilibrium for pH 4 was around 81% of the initial arsenic concentration for As(III), and it was 99% for As(V). When the initial solution pH was raised to pH 7, the removal percentage at equilibrium for As(V) decreased to 95%; on the contrary, it increased to 88% for As(III). However, with pH 9, significant reduction in the adsorbed As(III), and As(V) was observed, the removal percentages of which at equilibrium were 65% and 85%, respectively. The results demonstrate that the adsorption performance of arsenic is highly influenced by initial solution pH, as also evidenced by other similar researches (Borah et al. 2009).

Arsenic can exist in different forms, depending on the pH condition. According to this study, the pHpzc for NZVI synthesized was 7.8, while the available literature data of pHpzc for iron oxides was 8.0 (Li et al. 2006). Also, the pK a values reported for As(III) are listed as follows: pK 1 = 9.22, pK 2 = 12.13, and pK 3 = 12.7; and for As(V), they are: pK 1 = 2.2, pK 2 = 6.97, and pK 3 = 11.53 (Raven et al. 1998). In the range of pH 2–7, the dominant form of As(V) is H2AsO −4 , a negatively charged ion, whereas the adsorbent surface shows positive charge. The opposite charges of the ion and the adsorbent surface will lead to the enhancement of the arsenic removal through electrostatic attraction force. For the basic pH condition (7–12), the dominant form of As(V) is HAsO 2−4 , whereas the adsorbent surface becomes negatively charged; thus, the electrostatic repulsion force resulted in decreased adsorption of As(V). Similarly, under conditions of pH 4–7, the dominant form for As(III) is H3AsO3; its neutral charge still resulted in attraction with positively charged adsorbent. However, for the basic pH condition, the dominant forms of As(III) are with the negative charges, H2AsO −3 and HAsO 2−3 , and the adsorbent surface is also negatively charged; hence, the adsorption efficiency was decreased.

To understand the NZVI behavior more in the solution, the pH, DO, and ORP profiles were further illustrated in Fig. 2. The results show that the final solution pH were increased for both As(III) and As(V) when the initial pH were 4 and 7. However, in the case of initial pH 9, the pH value dropped slightly to 8.5–8.7. The pH was observed to increase in the presence of Fe0 due to the reaction of NZVI with water and dissolved oxygen, which resulted in the formation of hydroxide and the consumption of DO in solution. The reactions are presented by Eqs. (2) and (3) (Ruangchainikom et al. 2006).

The Fe2+ present in the aqueous solution can be oxidized by oxygen into Fe3+, which will result in producing corrosion products of different iron (hydr)oxides such as Fe3O4, Fe2O3, FeOOH, Fe(OH)2, and Fe(OH)3, depending on the solution conditions (Triszcz et al. 2009; Giasuddin et al. 2007; Kanel et al. 2005; Huang and Zhang 2005). According to Fig. 2, the ORP value decreased rapidly from positive values to negative ones. Such phenomenon occurs due to electrons being released from the reductant. In only 5 min of reaction, the ORP values have dropped down to the very negative range, indicating that the solution exhibited a state of reducing environment in the presence of NZVI (Ruangchainikom et al. 2006).

In view of NZVI capacity for arsenic removal under various pH conditions, the data presented in Fig. 2 were further analyzed according to Eq. (4) (Borah et al. 2009):

Where m is the mass of the NZVI (g); q o and q e are the arsenic removed by the NZVI (milligrams per gram) at initial and equilibrium conditions, respectively; C o and C e are the initial and equilibrium concentrations of arsenic in solution (millligrams per liter); V is the solution volume (liter). The NZVI capacities to remove As(III) and As(V) under various pH conditions were calculated and presented in Table 2. As depicted in Table 2, higher NZVI capacities (q e) for As(III) and As(V) were observed at lower pH 4 and 7, when compared to that at pH 9. With pH 4 and 7, it is noticed here that the NZVI capacities were not significantly different from each other.

3.2 Effect of initial arsenic concentration

To investigate the effect of initial arsenic concentration, experiments were performed by varying arsenic concentrations from 1,000 to 2,500 μg/L, and the initial solution pH was adjusted to 4. Fig. 3 shows that As(III) removal decreases as the initial concentration of arsenic increases. However, this behavior is not followed by As(V). Initial arsenic concentration imposed no significant effect on As(V) removal. As described earlier, the reason for the difference of adsorption profiles between As(III) and As(V) was related to electrostatic attraction significantly.

In view of adsorption model, the Langmuir and Freundlich isotherms are used in this study to describe the behavior of arsenic adsorption in the NZVI reaction system. The relevant formulas were listed in Eqs. (5) and (6) (Guo et al. 2007), respectively.

where q m is the maximum adsorption capacity (milligrams per gram), b is a constant related to the adsorption energy (liters per milligram), K F is the Freundlich constant denoting the sorption capacity of adsorbent (milligrams per gram), n is the adsorption intensity parameter, and other parameters was defined in Section 3.1.

As a result of data fitting, model parameters are depicted in Table 3. Based on the correlation coefficient, R 2, the Langmuir isotherm model for As(III) and As(V) has R 2 values of 0.99 and 0.96, respectively, slightly higher than those of the Freundlich isotherm model. Thus, it appears that the Langmuir model can better describe arsenic adsorption in the studied system. Note that the Langmuir isotherm assumes the site energy for adsorption being equal for all surface sites and each site binding only one molecule, i.e., monolayer (Montgomery 1985). As for adsorption capacity, both isotherm models show higher capacity for arsenate than for arsenite.

According to the literature, the essential characteristics of Langmuir isotherm can be disclosed by the dimensionless constant, called separation factor (R L) (Qadeer 2005; ALzaydien 2009), as depicted in Eq. (7).

The R L values can be related to the equilibrium isotherm as follows: R L > 1 unfavorable, R L = 1 linear, 0 < R L < 1 favorable, and R L = 0 irreversible. All calculated R L values are between 0 and 1, indicating favorable sorption has occurred in the reaction system. This can be further evidenced by the Freundlich model parameter, (1/n), the values (0.52; 0.32) of which fall within the range of 0.1–1. Similarly, the studied system is strongly favorable for arsenic adsorption (Namasivayam and Ranganathan 1995).

3.3 Effect of dissolved oxygen

To reveal the role of oxygen in the reaction solution, experiments were designed to explore arsenic removal under oxic and deoxygenated conditions. Prior to reaction, the solution was bubbled with nitrogen gas for 30 min to strip out oxygen from the solution until the DO value was less than 0.5 mg/L, deoxygenated condition. Afterwards, the nitrogen gas remained continuously supplied into the reaction solution. The effect of DO in arsenic removal is shown in Fig. 4. The As(III) removed was more than 80% after 10 min of reaction when the solution was under oxic condition, while 52% was removed under deoxygenated condition. For As(V), 99% and 76% were removed after 7 min of reaction under oxic and deoxygenated conditions, respectively. This indicates that arsenic removal can be enhanced in the presence of oxygen because arsenic can form inner- and/or outer-sphere complexes with the oxygen-induced iron corrosion products such as iron (hydr)oxides, according to several recent spectroscopic studies (Bang et al. 2005; Sunbaek et al. 2005; Mayo et al. 2007; Mishra and Farrell 2005; Zhang et al. 2004). Thus, the presence of DO will enhance the rate of iron corrosion and subsequently improve the arsenic adsorption as well.

3.4 Effect of ratio of As(III) versus As(V)

For field application, the impact of different ratios of As(III)/As(V) on arsenic removal is important. To provide such information, different mass ratios of As(III)/As(V), 3:7, 5:5, and 7:3, were explored. Control experiments with As(III) or As(V) alone in the solution were also investigated. The initial pH was controlled at 7. As shown in Fig. 5(a), the total arsenic removal was higher when the solution contains higher As(V). Interestingly, if both As(III) and As(V) are present, the total arsenic removal is enhanced, as compared to the case when the As(III) alone or As(V) alone is present. It is expected that the solution containing As(V) alone should be the one with the highest arsenic removal since As(V) is removed more easily than As(III). As shown in Fig. 5(a), the total arsenic removal from the highest to the lowest is in the following sequence with respect to As(III)/As(V) ratios of 3:7, 5:5, 7:3, As(V) alone, and As(III) alone. This implies that co-existence of arsenic creates a favorable condition for arsenic removal by NZVI. As is well known, the mechanism of arsenic removal by NZVI involves not only adsorption but also co-precipitation and precipitation (Lackovic et al. 2000; Tyrovola et al. 2007). During the formation of ferric (hydr)oxides, some researchers reported that As(III) was removed by co-precipitation with a lesser degree than As(V) (Waychunas et al. 1995; Hering et al. 1997; Manceau 1995). As evidenced from Fig. 5(b)–(d), the removal percentage of As(V) is always higher than As(III) in all cases of different ratios of As(III) versus As(V). Based on such results, the mechanism of arsenic removal in co-existence of both species was proposed, as shown in Fig. 6. Through its co-precipitation with ferrous or ferric ion, the As(V) may help create new adsorptive sites, which in turn enhance the adsorption of As(III). Therefore, the higher the ratio of As(V) contained in solution, the higher the total arsenic removal. However, comprehensive investigation needs to be conducted to verify the above adsorption mechanism.

4 Conclusions

This study was conducted to investigate performance of NZVI as adsorptive media in removing arsenic from aqueous solutions. The effects of different parameters such as initial solution pH, DO, initial arsenic concentration, and As(III)/As(V) ratio were studied. Arsenic in the form of As(V) can be removed easier than As(III) for the studied pH values. Concerning the DO effect, the presence of oxygen will help remove arsenic through oxygen-induced corrosion products of iron. In the case of initial concentration, the increase in As(V) did not greatly affect its removal rate, whereas the performance of As(III) removal decreased with the increase of its initial concentration. The presence of both As(III) and As(V) results in better removal of total arsenic than the presence of As(V) or As(III) alone. This study also reveals that the higher the mass fraction of As(V) present, the higher the amount of total arsenic can be removed.

References

Alzaydien AS (2009) Adsorption of methylene blue from aqueous solution onto a low-cost natural Jordanian tripoli. Am J Environ Sci 5:197–208

Anotai J, Liao CH, Ruangchanikom C (2010) Nitrate removal by Fe0/CO2 process using an innovative continuous flow reactor. J Environ Eng Manage 20:77–84

Bang S, Johnson MD, Korfiatis GP, Meng X (2005) Chemical reactions between arsenic and zero-valent iron in water. Water Res 39:763–770

Borah D, Satokawa S, Kato S, Kojima T (2009) Sorption of As(V) from aqueous solution using acid modified carbon black. J Hazard Mater 162:1269–1277

Giasuddin AM, Kanel SR, Choi H (2007) Adsorption of humic acid onto nanoscale zerovalent iron and its effect on arsenic removal. Environ Sci Technol 41: 2022–2027.

Glavee GN, Klabunde KJ, Sorensen CM, Hadjipanayis GC (1995) Chemistry of borohydride reduction of iron (II) and iron (III) ions in aqueous and nonaqueous media. Formation of nanoscale Fe, FeB, and Fe2B powders. Inorg Chem 34:28–35

Guo H, Stuben D, Berner Z (2007) Adsorption of arsenic(III) and arsenic(V) from groundwater using natural siderite as the adsorbent. J Colloid Inter Sci 315:47–53

Hering JG, Chen PY, Wilkie JA, Elimelech M (1997) Arsenic removal from drinking water during coagulation. J Environ Eng 123:800–807

Huang YH, Zhang TC (2005) Effects of dissolved oxygen on formation of corrosion products and concomitant oxygen and nitrate reduction in zero-valent iron systems with or without aqueous Fe2+. Water Res 39:1751–1760

Jegadeesan G, Mondal K, Lalvani SB (2005) Arsenate remediation using nanosized modified zerovalent iron particles. Environ Prog 24:289–296

Kanel SR, Greneche JM, Choi H (2006) Arsenic(V) removal from groundwater using nano scale zero-valent iron as a colloidal reactive barrier material. Environ Sci Technol 40:2045–2050

Kanel SR, Manning B, Charlet L, Choi H (2005) Removal of arsenic(III) from groundwater by nanoscale zero-valent iron. Environ Sci Technol 39:1291–1298

Kom I, Kim J, Kim KW (2004) Arsenic speciation and sorption kinetics in the As-hematite-humic acid system. Colloids Surf A 234:43–50

Lackovic JA, Nikolaidis NP, Dobbs GM (2000) Inorganic arsenic removal by zero-valent iron. Environ Eng Sci 17:29–40

Li X, Elliott DW, Zhang W (2006) Zero-valent iron nanoparticles for abatement of environmental pollutants: materials and engineering aspects. Solid State Mater Sci 31:111–122

Manceau A (1995) The mechanism of anion adsorption on iron oxides: evidence for the bonding of arsenate tetrahedra on free Fe(O, OH)6 edges. Geochim Cosmochim Acta 59:3647–3653

Mayo JT, Yavuz C, Yean S, Cong L, Shipley H, Yu W, Falkner J, Kan A, Tomson M, Colvin VL (2007) The effect of nanocrystalline magnetite size on arsenic removal. Sci Technol Adv Mater 8:71–75

Melitas N, Wang J, Conklin M, O'Day P, Farrell J (2002) Understanding soluble arsenate removal kinetics by zero-valent iron media. Environ Sci Technol 36:2074–2081

Mishra D, Farrell J (2005) Evaluation of mixed valent iron oxides as reactive adsorbents for arsenic removal. Environ Sci Technol 39:9689–9694

Mohan D, Pittman CU Jr (2007) Arsenic removal from water/wastewater using adsorbents - A critical review. J Hazard Mater 142:1–53

Montgomery JM (1985) Water Treatment: Principles and Design, 2nd edn. Wiley, Chichester, p 1275

Namasivayam C, Ranganathan K (1995) Removal of Pb(II) by adsorption onto waste Fe(III)/Cr(III) hydroxide from aqueous solution and radiator manufacturing industry wastewater. Ind Eng Chem Res 34:869–873

Qadeer R (2005) Adsorption of neodymium ions on activated charcoal from aqueous solutions. J Radioanalytical Nucl Chemis 265:377–381

Raven KP, Jain A, Loeppert RH (1998) Arsenite and arsenate adsorption on ferrihydrite: kinetics, equilibrium, and adsorption envelopes. Environ Sci Technol 32:344–349

Ruangchainikom C, Liao CH, Anotai J, Lee MT (2006) Characteristics of nitrate reduction by zero-valent iron powder in the recirculated and of CO2- bubbled system. Water Res 40:195–204

Sasaki K, Nakano H, Wilopo W, Miura Y, Hirajima T (2009) Sorption and speciation of arsenic by zero-valent iron. Colloids Surf A 347:8–17

Smedley PL, Kinniburgh DG (2001) A review of the source, behaviour and distribution of arsenic in natural waters. Appl Geochem 17:517–568

Sunbaek B, Mark DJ, George PK, Meng X (2005) Chemical reactions between arsenic and zero-valent iron in water. Water Res 39:763–770

Sun H, Wang L, Zhang R, Sui J, Xu G (2006) Treatment of groundwater polluted by arsenic compounds by zero valent iron. J Hazard Mater B129:297–303

Triszcz JM, Porta A, Einschlag FSG (2009) Effect of operating conditions on iron corrosion rates in zero-valent iron systems for arsenic removal. Chem Eng J 150:431–439

Tyrovola K, Peroulaki E, Nikolaidis NP (2007) Modeling of arsenic immobilization by zero valent iron. Eur J Soil Biol 43:356–367

Waychunas GA, Davis JA, Fuller CG (1995) Geometry of sorbed arsenate on ferrihydrite and crystalline FeOOH: Re-evaluation of EXAFS results and topological factors in predicting sorbate geometry, and evidence for monodentate complexes. Geochim Cosmochim Acta 59:3655–3661

Zhang W, Singh P, Paling E, Delides S (2004) Arsenic removal from contaminated water by natural iron ores. Miner Eng 17:517–524

Acknowledgements

This research was sponsored by (1) Taiwan National Science Council (NSC) under project No.: NSC 97-2221-E-041-010-MY3 and (2) Thailand Research Fund through the Royal Golden Jubilee Ph.D. Program. Appreciation goes to Dr. Ma. Lourdes P. Dalida, University of the Philippines, Diliman for her valuable comments and polishing of this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Vera Slaveykova

Rights and permissions

About this article

Cite this article

Tanboonchuy, V., Hsu, JC., Grisdanurak, N. et al. Impact of selected solution factors on arsenate and arsenite removal by nanoiron particles. Environ Sci Pollut Res 18, 857–864 (2011). https://doi.org/10.1007/s11356-011-0442-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-011-0442-3