Abstract

Introduction

In this study, we explore the identity of a range of polyfluorinated surfactants (PFS) used for food contact materials, primarily to impart oil and water repellency on paper and board. PFS are of interest, as they can be precursors of poly- and perfluorinated alkyl substances (PFAS), of which several are persistent and are found worldwide in human blood and in the environment.

Materials and methods

To determine the elemental composition of PFS, we combined information from patents, chemical suppliers and analyses of industrial blends using ultra performance liquid chromatography-negative electrospray ionisation quadrupole time-of-flight mass spectrometry.

Results

At a high pH of 9.7, both non-ionic and anionic PFS were ionised and were recognised by negative mass defects of exact masses, and neutral fragment losses of n × 20 or n × 100 Da. More than 115 molecular structures were found in industrial blends from the EU, US and China, belonging to the groups of polyfluoroalkyl-mono- and di-ester phosphates (monoPAPS, diPAPS and S-diPAPS), -ethoxylates, -acrylates, -amino acids, -sulfonamide phosphates and -thio acids, together with residuals and synthesis byproducts. In addition, a number of starting materials such as perfluorooctane sulfonamide N-alkyl esters were analysed. Di- and trialkylated PAPS and S-diPAPS were found in migrates from European food contact materials.

Conclusion

This study highlights the need to monitor for more types of PFS in order to map the sources of PFAS in humans and the environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

There is a gap in knowledge when it comes to establishing a quantitative link between the levels of the fluorinated compounds in human blood with the local environmental sources (Lau et al. 2007; Leo et al. 2008). While a gradual decrease in the concentrations of perfluorinated compounds was found in the seawater from the Northern to the Southern hemisphere (Ahrens et al. 2009), the human blood concentrations were similar for Europeans and Australians with western lifestyles (Toms et al. 2009). Meanwhile, a Chinese study found that the monitored perfluorinated compounds (perfluorinated alkyl carboxylic acids, PFCA and perfluorinated alkyl sulfonates, PFSA) only accounted for 30–70% of the total organic fluorine present in human blood (Leo et al. 2008). Neither can intake via dust and air (Trudel et al. 2008), or through food or from food contact materials explain human blood levels or profiles of PFCA and PFSA, which are the fluorochemicals that predominantly are monitored for (Leo et al. 2008; Tittlemier et al. 2007; Falandysz et al. 2006; Renner 2007).

However, a recent study by D’eon et al. (2009) studied the profiles of a different kind of fluorochemicals, the dialkyl polyfluorinated phosphate ester surfactants (diPAPS) in food contact paper fibres and in sludge from waste water treatment plants, and found that they matched the profiles of diPAPS in human blood. DiPAPS contain a perfluorinated chain in its structure (see Table 1), and rats biotransform diPAPS to perfluorooctanoic acid (PFOA), which is a PFCA (D’eon and Mabury 2007). This point towards food contact materials as a source of diPAPS and PFCA in human blood and in sludge (Lee et al. 2010). Huset et al. (2008) also suggested that PFCA and PFSA precursors might be present in waste water, to explain why PFCA and PFSA levels increased from the influent to the effluent stream of a Swiss wastewater treatment plant. Runoff from sludge spread onto German fields was in a study by Skutlarek et al. (2006) furthermore determined to be the source of a PFAS contamination of drinking water, which caused elevated PFAS levels in the blood of children (Hölzer et al. 2008). Fluorochemicals from sludge furthermore polluted the groundwater in Düsseldorf, and PFAS in the water was observed to upconcentrate in apples and other vegetables—which led to a ban on watering crops with the contaminated water (Düsseldorf 2010). It is therefore of interest to explore which fluorochemicals are being used, to see if the list of currently monitored fluorochemicals is incomplete.

Commercial fluorochemicals are from a technical point of view, very useful chemicals, which are used to impart water, oil and stain repellency onto materials and act as dispersion and levelling agents. Apart from being used in paper and board, such as for food packaging, they are also used for, e.g. textiles, metals, stones, in cleaning agents, in nano-materials, fire fighting foams, lubricants, paintings and inks, in plastics, pharmaceuticals and pesticides. Fluoropolymers, such as polytetrafluoroethylene and fluorosilicones, and polyfluorinated surfactants (PFS) are major uses, where PFS alone have an estimated worldwide annual discharge of 3,200–3,700 tonnes (Prevedouros et al. 2006; Saéz et al. 2008). Of this, 33% of the production of fluorinated substances in Europe is used for packaging made of paper and board (Lange et al. 2006; van der Putte et al. 2010). For direct food contact, it is estimated that of all food packaging, the paper accounts for ca. 20%, with 17% being coated paper (e.g. plastics, aluminium or chemical coatings (Ringman-Beck 2010)) and the remaining 3.5% being uncoated paper. When the PFS-coated paper and board is in direct contact with food, PFS can migrate to the food and be a direct source of human exposure to PFS (Begley et al. 2005 and 2008). Upon intake and excretion, the more or less degraded PFS will end up in wastewater and sludge, from where they are likely to further pollute the environment and re-enter the food chain.

At present, most environmental and human exposure studies monitor for the perfluorinated or fluorotelomer alcohol-derived PFAS, which either are or have been used as starting materials to synthesise end-use fluorochemicals. These PFAS contain only one poly- or perfluorinated alkyl chain (i.e. they are mono-alkylated). Examples are the anionic PFCA (e.g. PFOA), PFSA (e.g. perfluorooctane sulfonic acid, PFOS) and non-ionic fluorotelomer alcohols (FTOH, a perfluorinated carbon chain coupled to CH2CH2-OH). Please refer to Table 1 for structures. In contrast, the end-use paper and board coatings are more complex PFS, which can be dialkylated, polymeric and contain several functional groups. Such complex PFS which contain perfluorinated chains can be precursors of monoalkylated perfluorinated compounds, as in the case of diPAPS degrading to PFCA. Whereas analytical standards can be bought for an increasing variety of the mono-alkylated PFAS and their degradation products, no analytical standards are commercially available for the widely used commercial fluorochemicals. Commercial fluorochemicals are sold as industrial blends, which apart from mixtures of PFS, also often contain solvents such as polyethylene glycol, which makes them challenging to analyse.

Overall, the aim of this study was therefore to search for PFS in both industrial blends used to coat food paper and board packaging, and in the packaging itself. More specifically, the scopes were to determine:

-

typical m/zs of anionic and nonionic PFS by ultra performance liquid chromatography-negative electrospray ionisation quadrupole time-of-flight mass spectrometry (UPLC-ESI–-QTOF MS)

-

sets of precursor and product ion m/zs for selected PFS, which can be used in future target searches and quantification of PFS

-

the approximate quantities of PFS in extracts of paper and board food packaging. A proper quantification was unfortunately not possible, as appropriate analytical standards were not commercially available

1.1 Sources of PFS in paper and board for food contact

Ionic PFS is a large group of surfactants which contain a polar head group, to which typically one to two alkyl groups of varying chain lengths are attached. Examples of anionic PFS are the FTOH derived mono- and diPAPS and S-diPAPS (Begley et al. 2005, 2008), the perfluoroalkyl sulfonamide derived phosphates or the polyfluoro alkyl thioether acids (Dupont 2010, Mason Surfactants 2010). Table 1 gives an overview of the structures, acronyms, common names and uses of PFS investigated in this study. CAS numbers are not provided, as most of the investigated PFS in the industrial blends do not have CAS numbers. Non-ionic and polymeric PFS are other groups of surfactants, represented by, e.g. polyfluoro–alkoxylates and polyfluoro–acrylates, which increasingly are used for paper and board food contact materials. These polyfluoro-alkoxylates can contain one or several chains of alkoxylate units ((CX2)nO), where X typically is H or F, but also Br or Cl (US FDA 2010a), coupled to an alkyl chain and/or a perfluorinated alkyl chain (F(CF2) x ). Examples given in Table 1 include the fluoro ethoxylate industrial blends such as Zonyl FSN and Zonyl FSO containing CH2CH2O groups attached to a fluorinated chain. Another example of a polyether PFS is Fomblin HC/P2-1000 containing CH2CH2, CF2CF2O and CF2O groups. This ionic perfluoropolyether (PFPE) has a fluorinated polymeric backbone and ionic phosphate groups at its terminal ends (Solvay 2010).

The non-ionic polymeric PFS have polymeric backbones (e.g. an acrylate or mixed copolymer), to which fluorinated side chains can be anchored. Such PFS, with repeating monomer units can be challenging to study by chromatography, because of the many homologues only differing by one unit of, e.g. CF2 or CX2CX2O. The non-ionic PFS have mostly been studied from a technical perspective (e.g. Larsen et al. 2006; Fitzpatrick et al. 2004), and the few methods previously developed for these PFS in relation to environmental pollution, mainly for sludge and soil, had difficulty in separating the homologue series by liquid chromatography-mass spectrometry (LC-MS; Schröder et al. 2003; Schröder and Meesters 2005; Knepper et al. 2005; Frömel and Knepper 2008).

In food contact materials, most focus has been on the monoalkylated PFAS, which generally have been found in rather low levels (Tittlemier et al. 2007; Fromme et al. 2007; Vestergren et al. 2008). However, migration of PFOA from PFS-impregnated paper into popcorn resulted in mg kg-1 levels in microwave produced popcorn (Begley et al. 2005, 2008), and PFCA was also found in the gas phase of microwaved popcorn (Sinclair et al. 2007). The actual PFS paper coatings have been studied less, but the United States Food and Drug Administration (US FDA) has published studies on PFS paper coatings by mass spectrometry (Ackerman et al. 2009), and migration of PFS into pure and emulsified oils, where the latter gave the highest migration (Begley et al. 2005, 2008). The group of Scott Mabury has also published several papers on diPAPS, which are relevant to paper and board food packaging (D’eon and Mabury 2007, 2009; Lee et al. 2010).

The migration potentials of chemicals in food contact materials into food are directly linked to the initial concentration of loosely bound chemicals in the packaging (Piringer and Baner 2008). From this perspective, PFS are likely to migrate and be a source of food contamination, as they are used in high levels (0.1–4 wt.%; Dupont 2010, Ciba/BASF Ciba BASF 2000–2010, Iengo and Pavazotti 2007), and they—as well as their precursors, breakdown products and impurities—are loosely bound to the material, e.g. by wet-end deposition onto the cellulose. Prolonged contact time and high temperatures in contact with the food usually increase migration. Also for this reason are PFS of interest, as they are recommended for paper and boards used when the storage times are long or the temperatures are high in contact with fats, where other coatings fail. Finally, because paper and board typically is used for single-use packaging, the exposure can be high, because the consumers risk to be repeatedly exposed to the high initial levels of PFS.

1.2 Which PFS are of toxicological relevance to human health?

With regards to intake via food, only chemicals of a size corresponding to a molecular weight less than 1,000 g mol−1 (corresponding to a ca. C70 linear hydrogenated alkyl chain) are considered able to pass over the human intestinal barrier (EFSA 2008). As fluorine atoms are heavier than hydrogen atoms, a similar C70 perfluorinated alkyl chain would weigh up to 3,600 g mol−1. It would therefore be relevant to monitor for PFS molecules weighing up to at least m/z 3,600.

FTOH are used in both Europe and the US as one of the major starting compounds to synthesise PFS (Kissa 2002). DiPAPS which are derived from FTOH, can be biotransformed to FTOH, and further on to unsaturated acids and aldehydes to PFCA (Martin et al. 2005; D’eon and Mabury 2007). FTOH and their oxidation products have toxic effects in themselves, including developmental and endocrine disruption (Lau et al. 2007; Joensen et al. 2009; Maras et al. 2006). For PFCA, it has been shown that the longer the perfluorinated chains (>C5), the stronger the persistence and strength of binding to proteins is (Prieto et al. 2004), and the more bioaccumulative they become. PFOA is thus bioaccumulative, a suspected carcinogen (Lau et al. 2007) and an endocrine disrupter for both men and women (Jensen and Leffers 2008). Therefore, PFS which can contain perfluoro chains as long as F(CF2)18, are of interest as precursors of PFCA. PFOS and its derivatives are considered persistent organic pollutants with various toxic effects (Lau et al. 2007), and are prohibited in North America, and in the EU since 2008 (Jensen and Leffers 2008). However, PFOSF and derivatives hereof are still being produced and sold in Asia, from where pollution can spread from production sites or via consumed products. Information is sparser on human toxicity of the generally long chain fluoroalkoxylates, but as they contain perfluorinated chains, they have the potential to be precursors of PFCA as well, and are therefore relevant to monitor for.

1.3 Legislation on migration limits for PFS in Europe

The EU legislation for food contact plastics, the ‘Plastic Directive’, contains specific migration limits for PFOA and some polyfluorinated monomers, but not for PFS (EU Commission 2002). For paper and board specific legislation does not yet exist, and as a consequence PFS have no specific migration limits. Nevertheless, the Framework Regulation applies to all types of food contact materials (EU Commission 2004), and according to its Article 3, all parts of the food packaging chain must ensure that migration of chemicals from food contact materials to food should not occur in levels harmful to human health. In lack of harmonised EU legislation, national legislations can be used. In Europe, in particular the German National legislation for paper and board is used by industry, and it lists 10 PFS allowed to be used in Germany (BfR 2009). Outside of EU, China and, in particular, the US has an explicit regulation of paper and board, including lists of coatings (US FDA website). Currently there is an US-EPA initiative for the industry to voluntary eliminate the US production of long chain PFCA precursors by 2015 (US EPA 2010). In addition, the Council of Europe has issued a list of coatings and inks for paper and board, which is not legally binding, but informative on the uses of various types of coatings (Forrest 2007). Despite the lack of specific EU limit values and rules for migration testing, the European Commission issued in March 2010 a recommendation (EU Commission 2010), stating that all EU member states should monitor for fluorinated compounds in food in 2010/2011. In particular, foods containing proteins (fish, milk, meat) and of vegetable origin should be analysed, and in addition to the PFCA, PFSA and FTOH, it was recommended that diPAPS and monoPAPS also should be included in the monitoring.

2 Materials and methods

A description of chemicals, instrumentation, suppliers and more details about instrument settings is given in the supporting information (SI).

2.1 Sampling and sample preparation

The 14 papers and board materials intended for contact with food at high temperatures were sampled from retailers in Denmark. For the identification study, extracts were made with the purpose to obtain high PFS concentrations that would enable their detection by screening methods, while migrates were made to resemble migration to food. After removal of the food product, the paper and boards were rinsed for salts with distilled, deionised water, and 1 dm2 was collected. Food contact material that had not been in contact was chosen if possible. To make extracts, 50 cm2 was taken from two samples (1 dm2 in total) and placed in 50 mL polypropylene centrifuge screw-cap tubes. Forty milliter of 95% ethanol, preheated to 60°C, was poured over the subsamples (full immersion). The tubes were capped and ultrasonicated for 2 h at 60°C. For the migration testing, composite sampling was performed to limit the variation from sample in-homogeneity: 10 subsamples of each 1 cm2 were taken from each of 10 samples, giving a total area of 100 cm2. The same procedure as for the extracts was used, but the samples were placed in a thermostated oven, and not ultrasonicated. Immediately after ended migration, the food simulant was decanted into new tubes and centrifuged for 10 min at 9,000 rpm. The supernatants were filtered through 0.2 μm nylon filtres into HPLC vials. The clean-up of the samples was deliberately kept simple (centrifugation and filtering) to make the analysis non-discriminative. Some extracts and migrates were cloudy with a gel-like structure, that could not be spun down. In the final procedure, the extracts/migrates were therefore left to settle overnight in a refrigerator (5°C), and then filtered. Before use, migrates and standard solutions were given ca. 2 min of ultrasonification to release adsorbed PFS from the walls. To focus the chromatographic peaks, the samples were diluted with water or methanol/water, to a solvent strength less than the initial mobile phase solvent strength, and injected directly into the LC-MS system.

2.2 Chemical analysis

The full method is described in the SI. Briefly a Waters UPLC Acquity system was coupled to a Micromass QTOF Ultima Global. The UPLC (Waters, Milford, USA) was equipped with a binary solvent delivery system and a Waters Acquity BEH C18 column (150 × 2.1 mm i.d., 1.7 μm particle size) kept at 45°C. Each of the mobile phases A (water/methanol, 95/5, v/v) and B (methanol), were adjusted to pH 9.7 with ammonium hydoxide. The optimised UPLC gradient method had an initial composition of 95% A, 0–3 min linear to 40% A, 3–24 min linear to 5% A, 24–31 min linear to 2% A, 31–33 min curved to initial composition, isocratic from 33 to 35 min., and a flow of 0.28 mL min−1. The MS was operated in the negative electrospray ionisation (ESI–) mode, at a desolvation temperature of 300°C, a desolvation gas flow of 700 L h−1 (N2) and a capillary voltage of −3 kV. The MS was calibrated externally immediately before the analysis from m/z 181 to 1,472 Da, and m/zs from 75 to 1,500 Da were recorded. In the MSMS mode, the quadrupole resolution was set to resolve ions with m/z ± 1.5. MassLynx v. 4.1 (Micromass) was used for data processing and calculation of exact theoretical isotopic masses. Exact m/zs are given with four decimal places (theoretical), accurate experimental m/zs with two decimal places, and nominal masses are used when readability is of importance. At pH 9.7, it was possible to separate and detect monovalent anionic, and nonionic PFS, whereas divalent anions, e.g. monoPAPS, were not sufficiently retained to be satisfactorily separated.

2.3 Semi-quantitative analysis of diPAPS and S-diPAPS and quality assurance

The calculations were made by comparing the average peak areas (from two injections) of diPAPS (789, 889, i.e. xx89 series) or S-diPAPS (921, 1021, i.e. xx21 series) for the samples vs. a known concentration of diPAPS in an industrial blend (Zonyl NF) with an approximate content of 19.5% of fluorinated compounds. Conversion of units from mg L−1 food simulant to mg kg−1 food was done using CEN guidelines (CEN 2002). The principle is to convert the concentration in mg L−1 food simulant, into migration per unit area of the extracted packaging (mg dm−2), and then to convert to mg kg−1 food by using the actual packaging area and mass of food (the so-called surface-to-area-to-volume ratio). Procedural and solvent blanks were analysed between every five and 10 samples, and standard addition with Zonyl NF was used to check if there was matrix interference, e.g. due to ion suppression. As this was not the case, external calibration was used for the semi-quantification. Internal standards were not used, as those available, e.g. 13C PFOA, were rather dissimilar from diPAPS and S-diPAPS, and therefore could not be expected to respond in the same way as the diPAPS, due to variations in extractions and instrumental conditions. The LOD for the diPAPS in the migrates (analysed by triple quadrupole MSMS) were calculated as 3 × RSD + blank = 15–22 μg L−1 and in the extracts (quantification by QTOF MS) to 0.2–0.7 mg L−1 for 6:2/6:2, 8:2/8:2, 10:2/10:2 diPAPS, 0.2 mg L−1 for PFOA and 0.008 mg L−1 for PFOS. Further details about the quantification are given in SI.

3 Search for PFS in industrial blends for food paper and board

3.1 Methodology

3.1.1 Information about the elemental composition

Industrial chemicals can be difficult to buy or get samples of, and if obtained they often lack information on the chemical names, CAS numbers, molecular structures or elemental compositions, which complicates the chemical analyses. The content of the active fluorinated chemical can range from, e.g. 20–100%, see Table 1. The rest can be solvents such as ethylene glycol, additives, fluorinated monomer residuals, impurities, by-products from the synthesis and breakdown products, and this ‘matrix’ can interfere with analysis. To gain more knowledge of the molecular structure, we therefore searched patents and technical literature, and calculated the exact isotopic m/z for likely elemental compositions. These were sorted in increasing m/z, and used to obtain extracted ion chromatograms (EIC) from total ion chromatograms (TIC).

3.1.2 Search for fluorinated compounds by use of their negative mass defect

Even if the elemental composition is known, the deprotonated molecule might fragment in source or have adducts attached, so peaks can be challenging to find in the MS scan spectra. We therefore developed a method to search specifically for m/zs of fluorinated molecules. Negative ESI of fluorinated compounds has the advantage that specific fluorinated product ions and neutral losses are formed. Meanwhile, most matrix components are not ionised, causing the background noise in ESI− to be relatively low. In the initial step, we searched for m/zs below nominal masses in each scan of the mass spectra; PFOA for example has a nominal mass of 413 Da, but an exact mass of 412.9659 Da. This so-called “negative mass-defect” (NMD) for per-fluorinated compounds, arise because fluorine has an exact mass less than unity (18.998 Da), whereas hydrogen has a mass larger than unity (1.008 Da). Polyfluorinated compounds containing both F and H will therefore have mass defects below unity or closer to unity than is the case for compounds with only C-H bonds, where the latter will have positive mass defects. PFS having a hydrogenated part of the molecule that is greater than the fluorinated part, will not stand out, as their NMD does not differ greatly from, e.g. oxygen containing non-fluorinated compounds.

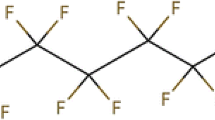

3.1.3 Homologue series

In the third step, we exploited that most PFS are synthesised by telomerisation, which is a process where CF2 = CF2 units are added stepwise to the telogen (e.g. F(CF2CF2)I) to get PFS of increasing alkyl chain length. As a consequence, homologue series spaced by 100 Da (C2F4 units, 99.994 Da) are formed. The m/z of a likely PFS candidate was used as the starting point to search for homologue series with m/z ± n⋅100 (Kissa 2002), using EIC. Figure 1 shows examples of diPAPS and S-diPAPS peaks separated by 100 Da.

The peaks in the extracted ion chromatogram (EIC) represent the xx89 series of diPAPS in the industrial blend Zonyl NF (first), the industrial blend Zonyl UR (second) and in popcorn bag migrate (third). The diPAPS elute from 11 to 21 min, whereas the chromatographic peaks eluting from 23 to 26 min are tri-alkylated phosphates (triPAPS) fragmenting in-source to diPAPS. Chromatographic peaks representing the xx21 series of S-diPAPS in popcorn bag migrate (fourth)

3.1.4 MS and MSMS fragmentations

During structure elucidation, co-eluting peaks and in-source fragmentations must be avoided if possible, as they obscure the MS spectra and complicates the determination of the deprotonated molecules. However, the stability of the precursor ions can vary significantly. The FTOH, for instance, fragmented extensively in the source during MS experiments, whereas the FC807, a PFOS derivative, did not fragment at all. Losses of neutral molecules, e.g. HF (20 Da), were typical, in particular for FTOH, fluoroethoxylates and the fluoroacrylate Zonyl TM. HF losses have previously been observed as the main fragmentation process for H-containing polyfluorinated in contrast to perfluorinated compounds (Kissa 2002; Voogt and Saéz 2006), which fragmented in their carbon backbone. Such carbon backbone fragmentations were also observed, but subsequent to fragmentations next to hetero-atoms, e.g. oxygen, nitrogen or sulphur, see for instance FF 10 in Fig. S1 in SI.

3.2 Types of PFS for food contact materials

The PFS in the industrial blends analysed in this study, were either intermediates for PFS synthesis, or PFS for paper and board coatings (see Table 1). The EIC of the most predominant fluorinated ions are shown in Fig. 2. A homologue series of, e.g. FTOH ions with m/z 363, 463, 563, 663,…xx63 is referred to as x63, or as m/z 363:xx63. More than 115 individual elemental PFS compositions in the industrial blends were found, in the range of m/z 100–1,500, without counting the industrial starting chemicals such as the PFOS and PFOSA mixtures, impurities or structural isomers (Trier et al. 2010). In Table S1 (in SI), the precursor and product ions, and their suggested elemental compositions are listed for a subset of the PFS studied. These precursor-to-product-ion transitions can be used to set up quantitative ESI--MSMS methods.

Extracted ion chromatograms (EIC) (span ± 0.2 Da) for the major fluorinated peaks in the PFS analysed in this study at concentration of 5 μg mL−1 of the total industrial blend (i.e. not corrected for purity). For Zonyl FSO only one of the homologue series is shown (for clarity), but it is similar to Zonyl FSN, which is shown in Fig. 3

Fluorotelomer alcohols

can be used to synthesise PFS. The industrial FTOH blend, Zonyl BA-L was ionised at pH 9.7 and the six homologues from 4 to 16:2 FTOH were seen (see Fig. 2a). This mixture forms the basis for making other FTOH-derived PFS, though some producers currently are switching to a narrower range of short chain FTOH, starting from 4:2 FTOH. The [M-H]− precursor ions of m/z ×63 were only vaguely visible and instead base peaks of either ×03 (loss of 3 HF) or ×55 [M-H-108]- dominated. We are presently investigating the fragmentation mechanism leading to these dominant base peaks.

Fluoroalkyl sulfonates, amides, alkyl amide, carboxylate and acrylate intermediates

FF-248 (Fig. 2b) is a mixture of four PFAS, and FX-8 (PFOSF, Fig. 2c) is a starting compound for PFOS derivatives, and the minor peak eluting just before its major peak, is probably a branched isomer (Martin et al. 2005). FF-09 is a PFOSA ethyl ester, which is a synthesis intermediate that is seen as the last set of peaks in Fig. 2d, where the first set of peaks is a large PFOS residual. The identity of FF-10 (Fig. 2e) is somewhat unclear, as the papers that followed the chemical said that it was an alkyl-PFOSA, but the information on the internet says that it is N-ethyl-N-perfluorooctyl-sulfonylaminoethanol (Wuhan 2010). The LC-MS analyses show that FF-10 contains both ethyl- and propyl perfluorooctyl-sulfonylaminoethanol, present as the two set of peaks in Fig. 2e and Table 1. A more appropriate name would therefore have been alkyl-sulfonylaminoethanol. The fluoroacrylate intermediate, Zonyl TM (Fig. 2f) is a FTOH derivative to make polymeric fluoroacrylates. These can, e.g. be used to impregnate textiles but are also used in microwave susceptors in food contact materials (US FDA 2010b). Zonyl TM contains a homologue series of at least 10 structures fragmenting to CxF2x + 1 ions with x = 5,6,7,8…14. The MS spectra of the Zonyl TM homologues have many m/zs in common with mass spectra of FTOH. In all these industrial intermediates there are other fluorinated impurities, e.g. PFCA, PFSA and FTOH, and what seems to be closely eluting isomers with identical precursor ion m/z (see FT-248, Fig. 2b). In contrast, the analytical standards, such as the PFOSA shown in Fig. 2h, only contain one chromatographic peak. That technical standards are different from pure analytical standards is also known for linear PFOS vs. technical PFOS, which has both linear and branched isomers (see Fig. 2g). These impurities and isomers must also be included in the methods, in order to quantify all the PFS (Trier et al. 2010). In lack of analytical standards, the varying response factors of the isomers are likely to cause systematic errors and variation between quantifications made in different laboratories.

Fluoroalkyl thio ether carboxylate intermediates

Zonyl FSA (Fig. 1i) is a fluoroalkyl thio ether carboxylate. The EICs contain five chromatographic peaks, corresponding to x = 4,6,8,10,12.

Fluoroalkyl phosphates and fluoroalkyl thio ether phosphates

Zonyl FSE (Fig. 1j), Zonyl UR (Fig. 1k) and Zonyl NF (Fig. 1l) all contain diPAPS (in total 12 elemental compositions). Zonyl NF is approved for food contact by the German BfR (5 mg dm−2, but not in contact with alcohol) and the US FDA. The EICs of diPAPS in Zonyl NF and UR, show several chromatographic peaks eluting between 11 and 21 min (see Fig. 1). These peaks can be identified as homologue series of diPAPS containing different number of C2F4 units, while the closely eluting peaks are structural isomers. Interestingly, a second series of compounds elute between 23 and 26 min and was seen consistently in both industrial blends (Zonyl NF and UR) and in migrates. These compounds have the same accurate m/zs as the diPAPS, but their significantly later retention times implicate that they must stem from larger molecules. It is known that monoPAPS and triPAPS are formed as by-products of the diPAPS synthesis (Kissa 2002, p. 55). We have recently shown that a synthesised 8:2/8:2/8:2 triPAPS standard did match the retention time and the MSMS spectrum of one of the peaks (Trier et al. 2010). It is therefore reasonable to assume that the other late eluting peaks also are triPAPS with other combinations of chain lengths. MonoPAPS and polyfluoropolyether (PFPE) di-(monoPAPS) (present in the industrial blend Fomblin HC/P2 1,000) being di- and tetravalent anions, were not retained on this end-capped C18 column. To obtain good spectra for identification and narrow peaks for quantification, they must be analysed by a different type of separation, i.e. mixed polar phase chromatography, ion chromatography or capillary electrophoresis, or possibly on a C18 column after protonising one on the anions at pH <2. The S-diPAPS shown in Fig. 1 and also in Fig. 2n were observed in several microwave popcorn migrates, but we did not obtain, neither an analytical nor an industrial diPAPS standard to compare it against. It is manufactured by Ciba under the name Lodyne P208E (Tentschert et al. 2010).

Fluoroalkyl sulfonamide phosphates

FC 807 (Fig. 2o) is a dialkylated fluoroalkyl sulfonamide phosphate, containing both sulfonate and amide groups. Apart from the two main PFS, it contained several isomers and starting material impurities, such as PFOSA. This structure is potentially a PFOS derivative. We also analysed industrial standards from a Chinese supplier of fluoroalkyl phosphates, named FF-807 (Fig. 2p), which resembles the FC-807, but contained many more chromatographic peaks.

Fluoroalkoxylates (fluoroethers)

Zonyl FSN (Fig. 3) and FSO (Fig. 2q) are fluoroethoxylates. The EIC for Zonyl FSN in Fig. 3 shows five homologue series of (CF2CF2)x separated by Δm/z = 100, and by several minutes in retention time. Another series of closely eluting homologues can be seen where the mass peaks are separated by Δm m/z = 44 corresponding to an ethoxylate (CH2CH2O) unit. The m/zs fit the patented brutto formula F(CF2)x(C2H4O)yH for fluoroethoxylates (Zonyl FSN and Zonyl FSO), and 66 elemental compositions were identified within m/z 75–1,500. These are non-ionic so-called mixed fluoro surfactants, with a perfluorinated water and oil repellent part, and an ethoxylate part that can mix with olefins, making them useful for applications on plastics such as polystyrene. The MS fragmentation pattern of the fluoroethoxylates are similar to the FTOH (e.g. m/z 355, 383, 403, 423 for 8:2 FTOH), and in addition they show sequential losses of CH2CH2O repeat units.

Extracted ion chromatograms of fluoroethoxylates present in the industrial blend Zonyl FSN. Five homologue series can be observed, each separated by Δm/z of 100 corresponding to CF2CF2 units. Within each of these homologues, a second homologue series is observed. In the second homologues series flouroethoxylates are separated by Δm/z of 44 corresponding to CH2CH2O units

Fluoroalkyl amino carboxylic acids

Lodyne 2000 (Fig. 2r) is an example of a di-fluoroalkyl tertiary amine carboxylic acid, which is used as a coating for food contact paper and board. The patent did not give the exact structure, but only three unspecified bonds attached to nitrogen (Ciba 2010). A possible structure that fits with the elemental composition is given in Table 1. The structure has been deduced from the homologue series of five elemental compositions shown in Fig. 2r. In addition, two other types of structures are present which give the predominant m/zs 1,138 and 1,238 (Tentschert et al. 2010), as well as m/zs 1,193 and 1,293. As the structures were not deduced, they are not shown in Fig. 2r, but they are clearly containing fluorinated moieties and a suggestion of their elemental composition is given for m/zs 1,138 and 1,238 in Table 1.

3.3 Analysis of food contact materials

As PFS are both water- and oil repellent, neither pure oil nor pure water are appropriate food simulants. PFS are, however, soluble in emulsified systems, such as foods and in alcohols. In the absence of EU legislation on paper and board, the food simulant was therefore chosen to be 95% ethanol, which both is used for the extraction of paper and board (prEN 15519, 2007), and is also a fatty food substitute simulant for plastics (Technical Directives, EU Commission 2002). Migration times and temperatures were taken from the technical directives on plastics (60°C, 2-h test, 1 dm2). The sample inhomogeneity was reduced by use of composite sampling. Of the 14 samples (see Table 2), diPAPS were detected in five samples, and in four of these S-diPAPS were also present, see Figs. 1 and 2n, with the highest migration from microwave popcorn bags (Hjorth et al. 2008).

Only minor traces of PFOA were present, possibly because we used a lower migration temperature (60°C), compared to the microwave conditions (up to 280°C) in the US study (Begley et al. 2005). In popcorn migrates, we detected semi-quantitative PFS (diPAPS and S-diPAPS) concentrations of 0.2–0.7 mg kg−1 food, which correlate well with the US levels in popcorn bags (0.2–1.4 mg kg−1) tested with a less severe food simulant (30% ethanol), but single sided (Begley et al. 2008). Other PFS, such as the SN-diPAPS (FC-807 or FF 807) or di (N-ethyl perlfluoroalkyl) N-propanoic acid (Lodyne 2000) were not found in these samples. In the burger box migrate a diPAPS series was also seen, but in lower concentrations. Other PFS might have been present that could not be detected with our method or which were below the MS screening detection limits of ca. 0.008–0.7 mg L−1 (for PFOS, PFOA and 6:2/6:2, 8:2/8:2 and 10:2/10:2 diPAPS). This shows that paper and board food packaging indeed is a source of human and environmental exposure to these polyfluorinated surfactants, which are precursors to the persistent PFCA.

4 Conclusion

In this study, more than 115 PFS were detected in industrial blends and in addition synthesis by-products, such as PFOS, PFOSA and triPAPS were present. The polyfluoro-ethoxylates had the greatest number of homologues, which had different numbers of repeat monomer units, CF2CF2 or CH2CH2O that were chromatographically separated. A number of the PFS studied are PFOS derivatives, which are prohibited in Europe and North America, but which still are commercially available from outside the EU. DiPAPS, triPAPS and S-diPAPS were also detected in five of 14 samples migrates from paper and board food contact materials, sampled in 2008. To our knowledge it is the first time DiPAPS and S-diPAPS have been reported to migrate from European food contact materials. This is of environmental and human health concern as diPAPS can be metabolised to PFCA. The PFS typically had fluorinated chain lengths from C6 to C16, where in particular the longer perfluorinated chains could be an issue, as they are more bioaccumulative than the short chains (Guo et al. 2008). The PFS which have been studied here are only a subset of what currently is used in food contact materials (US FDA 2010a; BfR 2009). In addition, new products are being introduced onto the market, based on polymeric and short chain fluorochemistry. To get an overview of the sources of fluorochemicals, it would be relevant to monitor for current and emerging, but also for formerly used PFS, which might be persistent. The presence of several fluorinated compounds in the blends and in the migrates, show the mixture of PFS that humans are being exposed to, and hence the relevance of performing toxicity tests not only on single PFS, but also of mixtures of PFS. In addition to discovering emerging fluorinated compounds, this study also identified a gap of knowledge and of specific EU legislation on PFS in food contact materials, such as paper and board. At present, there is an urgent lack of access to both old and emerging industrial blends, and to analytical standards of the many homologues of PFAS and their structural isomers. Analytical standards are essential to achieve accurate quantifications and thus exposure estimates of PFS in food, humans and environmental matrices. Future work in our group will focus on setting up quantitative methods, tied to a basic understanding of how PFS bind to and are released from various matrices and surfaces. These methods will be used in surveys and enforcement campaigns on PFS in food and in a more types of paper and board in contact with food.

References

Ackerman LK, Noonan GO, Begley TH (2009) Assessing direct analysis in real-time-mass spectrometry (DART-MS) for the rapid identification of additives in food packaging. Food Addit Contam 26(12):1611–1618

Ahrens L, Barber JL, Xie ZX, Ebinghaus R (2009) Longitudinal and latitudinal distribution of polyfluorinated compounds in surface water of the Atlantic ocean. Environ Sci Technol 43(9):3122–3127

Begley TH, White K, Honigfort P, Twaroski ML, Neches R, Walker RA (2005) Perfluorochemicals: potential sources of and migration from food packaging. Food Addit Contam 22(10):1023–1031, 9

Begley TH, Hsu W, Noonan G, Diachenko G (2008) Migration of fluorochemical paper additives from food-contact paper into foods and food simulants. Food Addit Contam A 25(3):384–390

BfR (2009) Standard XXXVI. Paper and board for food contact. Federal Institute for Risk Assessment, Germany. Available from: http://bfr.zadi.de/kse/faces/resources/pdf/360-english.pdf;jsessionid=E5B3AC7FF5657548764CF8E20472A52D. Accessed on 23 June 2010

CEN (2002). TC194.standard: EN 1186-1 to 15:2002, Materials and articles in contact with foodstuffs–plastics, and EN 13130–1:2004: Materials and articles in contact with foodstuffs—plastics substances subject to limitation–part 1. Available from: http://www.cen.eu/. Accessed on 12 May 2010.

Ciba (BASF) (2000–2010). Available from: http://www.ciba.com/ind-pap-eff-bar-lodyne.htm. Accessed on 2 April 2010.

D’eon JC, Mabury SA (2007) Production of perfluorinated carboxylic acids (PFCAs) from the biotransformation of polyfluoroalkyl phosphate surfactants (PAPS): exploring routes of human contamination. Environ Sci Technol 41(13):4799–4805

D’eon JC, Crozier PW, Furdui VI, Reiner EJ, Libelo EL, Mabury SA (2009) Observation of commercial fluorinated material, the polyfluoroalkyl phosphoric acid diesters, in human sera, wastewater treatment plant sludge, and paper fibers. Environ Sci Technol 43(12):4589–4594

Dupont de Nemours EI (2010). DuPontTM Zonyl Fluorosurfactants (2001, (4/01) P-200125.8, No. H-49731-3. Printed in USA), and DuPontTM Zonyl Fluorochemical Intermediates (2001, (8/02) P-200125.8, No. H-49730-4, Printed in USA) and DuPont Foraperle. Available from: http://www2.dupont.com/. Accessed on 14 May 2010.

Düsseldorf Landeshauptstadt Umweltsamt (2010) Available from: http://www.duesseldorf.de/umweltamt/altlast/pft_grundwasserverunreinigung.shtml. Accessed on 24 June 2010

EU Commission (2002) Plastics Directive: 2002/72/EC Commission Directive of 6 August 2002 relating to plastic materials and articles intended to come into contact with foodstuffs. (Plastics: unofficial consolidated version including 2002/72/EC, 2004/1/EC, 2004/19/EC, 2005/79/EC, 2007/19/EC, 2008/39/EC)

EU Commission (2004) Framework Regulation: Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food and repealing Directives 80/590/EEC and 89/109/EEC (L338/4)

EU Commission (2010) COMMISSION RECOMMENDATION of 17 March 2010 on the monitoring of perfluoroalkylated substances in food, 2010/161/EU, L 68/22–23, Official Journal of the European Union 18.3.2010

European Food Safety Authority (EFSA) (2008) Food contact materials: note for guidance for petitioners presenting an application for the safety assessment of a substance to be used in food contact materials prior to its authorisation, p. 25. http://www.efsa.europa.eu/cs/BlobServer/Scientific_Document/CEF_note_for_guidance_FCM_evaluation_2008.08.07.pdf. Accessed on 30 July 2008.

Falandysz J, Taniyasu S, Gulkowska A, Yamashita N, Schulte-Oehlmann U (2006) Is fish a major source of fluorinated surfactants and repellents in humans living on the Baltic Coast? Environ Sci Technol 40(3):748–775

Fitzpatrick F, Ramaker H-J, Schoenmakers P, Beerends R, Verheggen M, Phillipsen H (2004) Characterisation of fluorinated copolymers using liquid chromatography coupled on-line to mass spectrometry, with automated data interpretation. J Chromatogr A 1043:239–248

Forrest MJ (2007) Coatings and inks for food contact materials. Smithers Rapra Techology, report no. 186, ISSN: 0889-3144 or ISBN 1 84735 079 8

Frömel T, Knepper T (2008) Mass spectrometry as an indispensable tool for studies of biodegradation of surfactants. Trac 27(11):1091–1106

Fromme H, Schlummer M, Möller A, Gruber L, Wolz G, Ungewiss J, Böhmer S, Dekant W, Mayer R, Liebl B, Twardella D (2007) Exposure of an adult population to perfluorinated substances using duplicate diet portions and biomonitoring data. Environ Sci Technol 41(22):7928–7933

Guo J, Resnick P, Efimenko K, Genzer J, De Simonoe JM (2008) Alternative fluoropolymers to avoid the challenges associated with perfluorooctanoic acid. Ind. Eng. Chem. Res. 47:502–508

Hjorth K, Christensen JH, Trier X (2008) Migration of fluorochemicals from food contact paper into food simulants—analysed by LC-MS-MS and D-PLS. Master thesis, Dept. of Basic Sciences and Environment, Faculty of Life Science. Copenhagen University

Hölzer J, Midasch O, Rauchfuss K, Kraft M, Reupert R, Angerer J, Kleeschulte P, Marschall N, Wilhelm M (2008) Biomonitoring of perfluorinated compounds in children and adults exposed to perfluorooctanoate-contaminated drinking water. Environ Health Perspect 116:651–657

Huset CA, Chiaia AC, Barofsky DF, Jonkers N, Kohler H-PE, Ort C, Giger W, Field JA (2008) Occurrence and mass flows of fluorochmicals in the Glatt Valley watershed, Switzerland. Env Sci Technol 42:6369–6377

Iengo B, Pavazotti P (2007) Use of carboxylic perfluoropolyethers for the oleo-repellent paper sizing. European Patent EP 1 484 445 B1, published in Bulletin 2007/28. Available from: http://www.freepatentsonline.com/EP1484445.html. Accessed on 9 May 2010.

Jensen AA, Leffers H (2008) Review article. Emerging endocrine disrupters: perfluoroalkylated substances. Int J Androl 31:161–169

Joensen UN, Bossi R, Leffers H, Jensen AA, Skakkebæk NE, Jørgensen N (2009) Do perfluoroalkyl compounds impair human semen quality? Environ Health Perspect 117(6):923–927

Kissa E (2002) Fluorinated surfactants, 2nd edn. Marcel Dekker, New York

Knepper T, de Voogt P, Barceló D (2005) Analysis and fate of surfactants in the aquatic environment, Amsterdam, The Nertherlands

Lange FT, Schmidt C, Brauch H-J (2006) Perfluoroalkylcarboxylates and sulfonates. Emerging contaminants for drinking water supplies? Association of River Waterworks–RIWA. Available from: www.riwa-rijn.org/e_publikaties/137_ptfe_report.PDF. Accessed on 12 June 2010

Larsen BL, Stchur P, Szostek B, Bachmura SF, Rowand RC, Prickett KB, Korzeniowski SH, Buck RC (2006) Method development for the determination of residual fluorotelomer raw materials and perflurooctanoate in fluorotelomer-based products by gas chromatography and liquid chromatography mass spectrometry. J Chromatogr A 1110(1–2):117–124

Lau C, Anitole K, Hodes C, Lai D, Pfahles-Hutchens A, Seed J (2007) Perfluoroalkyl acids: a review of monitoring and toxicological findings. Toxicol Sci 99(2):366–394

Lee H, D’eon J, Mabury SA (2010) Biodegradation of polyfluoroalkyl phosphates as a source of perfluorinated acids to the environment. Envion Sci Technol 44(9):3305–3310

Leo W, Yeung Y, Miyake Y, Taniyusu S, Wang Y, Yu H, So MK, Jiang G, Wu Y, Li J, Giesy JP, Yamashita N, Lam PKS (2008) Perfluorinated compounds and total and extractable organic fluorine in human blood samples from China. Environ Sci Technol 42(21):8140–8145

Maras M, Vanparys C, Muylee F, Robbens J, Berger U, Barber JL, Blust R, De Coen W (2006) Estrogen-like properties of fluorotelomer alcohols as revealed by MCF-7 breast cancer cell proliferation. Environ Health Perspect 114:100–105

Martin JW, Mabury SA, O’Brien PJ (2005) Metabolic products and pathways of fluorotelomer alcohols in isolated rat hepatocytes. Chem Biol Interact 155:165–180

Mason Surfactants (2010) Available from: http://www.masonsurfactants.com—search for fluorinated surfactants. Accessed on 14 April 2010.

Piringer OG, Baner AL (2008) Plastic packaging: interactions with food and pharmaceuticals, 2nd edn. Wiley, Weinheim

prEN 15519:2007: E, European Committee for standardization (2007) Paper and board intended to come into contact with foodstruffs—preparation of an organic solvent extract. CEN, Brussels

Prevedouros K, Cousins IT, Buck RC, Korzeniowski SH (2006) Sources, fate and transport of perfluorocarboxylates. Environ Sci Technol 40:32–44

Prieto G, Sab’ın J, Ruso JM, Gonz’alez-P’erez A, Sarmiento F (2004) A study of the interaction between proteins and fully-fluorinated and fully-hydrogenated surfactants by ζ-potential measurements. Colloids Surf A Physicochem Eng Asp 249:51–55

Renner R (2007) PFOA in people. Environ Sci Technol 41(13):4497–4500

Ringman-Beck J (2010) Food contact: time for the industry to take the lead. Food Packag Bull 19(4&5):16–18

Sáez M, Voogt PD, Parsons JR (2008) Persistence of perfluoroalkylated substances in closed bottle tests with municipal sewage sludge. Environ Sci Pollut Res 15:472–477

Schröder HF, Meesters RJW (2005) Stability of fluorinated surfactants in advanced oxidation processes—a follow up of degradation products using flow injection–mass spectrometry, liquid chromatography–mass spectrometry and liquid chromatography–multiple stage mass spectrometry. J Chromatogr A 1082:110–119

Schröder HF, Knepper TP, Barceló D, Voogt Pd (eds) (2003) Analysis and fate of surfactants in the aquatic environment, 1st edn. Elsevier Science BV. Wilson & Wilsons Comprehensive Analytical Chemistry, Amsterdam

Sinclair E, Kim SK, Akinleye HB, Kannan K (2007) Quantitation of gas-phase perfluoroalkyl surfactants and fluorotelomer alcohols released from nonstick cookware and microwave popcorn bags. Environ Sci Technol 41:180–1185

Skutlarek D, Exner M, Färber H (2006) Perfluorinated surfactants in surface and drinking waters. Environ Sci Pollut Res 13(5):299–307

Solvay Solexis (2010) April 21st. Available from: http://www.solvaysolexis.com/. Accessed on 12 May 2010.

Tentschert J, Kappenstein O, Richter S, Luch A, Pfaff K (2010) Development of a screening method for perfluorinated compounds. Presented as poster at the 2nd Fluoro Surfactant workshop, 17–19 June 2010, Idstein, Germany

Tittlemier SA, Pepper K, Seymour C, Moisey J, Bronson R, Cao XL, Dabeka R (2007) Dietary exposure of Canadians to perfluorinated carboxylates and perfluorooctane sulfonate via consumption of meat, fish, fast foods, and food items prepared in their packaging. J Agric Food Chem 55(8):3203–3210

Toms LML, Calafat AM, Kato K, Thompson J, Harden F, Sjödin A, Mueller JF (2009) Polyfluoroalkyl chemicals in pooled blood serum from infants, children, and adults in Australia. Environ Sci Technol 43(11):4194–4199

Trier X, Nielsen NJ, Christensen JH (2010) Mass spectrometric detection of structural isomers of polyfluorinated di- and tri-alkylated phosphate ester surfactants in coatings for food paper and board. Submitted to ESPR, June 2010

Trudel D, Horowitz L, Wormuth M, Scheringer M, Cousins IT, Hungerbuhler K (2008) Estimating consumer exposure to PFOS and PFOA. Risk Anal 28:251–269

US EPA (2010) http://epa.gov/oppt/pfoa/pubs/stewardship/index.html. Accessed on 10 Dec 2010

US FDA (2010a) April 30th. Available from: http://www.accessdata.fda.gov/scripts/fcn/fcnNavigation.cfm?rpt=fcsListing&page=12. Accessed on 14 May 2010

US FDA (2010b) regulations 176.160 and 176.170 and effective food-contact-notifications (FCN’s) website: FDA http://www.fda.gov/Food/FoodIngredientsPackaging/FoodContactSubstancesFCS/ucm116567.htm. Accessed on 26 Nov 2010

van der Putte I, Murin M, van Velthoven N, Affourtit F (2010) Analysis of the risks arising from the industrial use of perfuorooctanoic acid (PFOA) and ammonium perfluorooctanoate (APFO) and from their use in consumer articles. Evaluation of the risk reduction measures for potential restrictions on the manufacture, placing on the market and use of PFOA and APFO. European Commision DG-Enterprise, Final report of Contract 30-CE-0230115/00-70 implementing Framework Contract 30-CE-0220929/00-38

Vestergren R, Cousins IT, Trudel D, Wormuth M, Scheringer M (2008) Estimating the contribution of precursor compounds in consumer exposure to PFOS and PFOA. Chemosphere 73(10):1617–1624

Voogt Pd, Saéz M (2006) Analytical chemistry of perfluoroalkylated substances. Trends Anal Chem 25(4):326–342

Wuhan Fengfan (2010) Chem. Co. Available from: http://fengfan-chem.diytrade.com. Accessed on 6 May 2010.

Acknowledgement

Donation of industrial blends and synthesised standards by Wuhan Fengfan Chemical Co. Ltd., China, The Danish Veterinary and Food Administration and by ISPRA/The EU Commission is much appreciated. The environmental research school RECETO, Food-DTU and KU-LIFE funded the Ph.D. study, and Lundbeck and the Cowi foundations funded the UPLC system. Thanks to Karen Hjorth, M.Sc. for work on the migration/extractions of food packaging materials and to Giorgio Tomasi and Nikoline Juul Nielsen for the work on the Matlab figures using in-house routines.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Ake Bergman

Electronic supplementary materials

Detailed method information

Supporting information 1

DOC 69.5 kb

Table S1

Precursor and product ions of a selection of PFS (DOCX 15.2 kb)

Table S2

Method performance parameters of the UPLC-ESI--QTOF MS method for diPAPS, PFOA and PFOS (DOCX 11.8 kb)

Table S3

LC retention times and MS parameters for the HPLC-ESI--QqQ MS method for diPAPS and S-diPAPS (DOCX 11.4 kb)

Rights and permissions

About this article

Cite this article

Trier, X., Granby, K. & Christensen, J.H. Polyfluorinated surfactants (PFS) in paper and board coatings for food packaging. Environ Sci Pollut Res 18, 1108–1120 (2011). https://doi.org/10.1007/s11356-010-0439-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-010-0439-3