Abstract

Background, aim, and scope

Chlorinated volatile organic compounds (CVOCs), widely used in industry as solvents and chemical intermediates in the production of synthetic resins, plastics, and pharmaceuticals, are highly toxic to the environment and public health. Various studies reported that Fenton’s oxidation could degrade a variety of chlorinated VOCs in aqueous solutions. In acidic conditions, ferrous ion catalyzes the decomposition of H2O2 to form a powerful •OH radical. In this study, wastewater from wash of ion-exchange resin containing typical CVOC, 1,2-dichloroethane, was treated using Fenton’s oxidation. To reduce environmental load and processing costs of wastewater, Fenton process as a simple and efficient treatment method was applied to degrade 1,2-dichloroethane of wash water.

Materials and methods

The water samples were collected from three different washing stages of ion-exchange resin. The degradation of 1,2-dichloroethane and total organic carbon (TOC) of wash water of ion-exchange resin by Fenton process was studied with response surface method (RSM). Design of the experiments was conducted by central composite face, and factors included in three models were Fe2+ and H2O2 doses and treatment time. Relevant quadratic and interaction terms of factors were investigated.

Results

According to ANOVA, the model predicts well 1,2-dichloroethane reduction of all water samples and TOC reduction of samples 2 and 3. The Fe2+ and H2O2 doses used in the present study were most suitable when 1,2-dichloroethane concentration of the wash water is about 120 mg L−1. In that case, Fenton’s oxidation reduced 1,2-dichloroethane and TOC up to 100% and 87%, respectively, according to the RSM model. With 90-min reaction time and H2O2 dose of 1,200 mg L−1, the required Fe2+ doses for 1,2-dichloroethane and TOC were 300 and 900 mg L−1, respectively. The optimal H2O2/Fe2+ stoichiometric molar ratio was between 4–6. Then, concentration of Fe2+ was low enough and the amount of residual sludge can thus be reduced. It seems that most of TOC and part of 1,2-dichloroethane were removed by coagulation.

Discussion

Up to a certain extent, increase of Fe2+ and H2O2 doses improved the removal of 1,2-dichloroethane and TOC. High Fe2+ doses increased the formation of ferric-based sludge, and excessive H2O2 doses in sample 2 decreased the degradation of 1,2-dichloroethane. Excess amount of hydrogen peroxide may scavenge hydroxyl radicals, thus leading to loss of oxidative power. Also, the residual hydrogen peroxide of different samples increased with increasing H2O2 dose and H2O2/Fe2+ molar ratio and decreasing treatment time probably also due to scavenging reactions. Due to the saturated nature of 1,2-dichloroethane, the oxidation mechanism involves hydrogen abstraction before addition of hydroxyl radical, thus leading to lower rate constants than for direct hydroxyl radical attack, which for one increases the treatment time.

Conclusions

Complete removal of 1,2-dichloroethane was attained with initial concentration <120 mg L−1. Also, TOC degraded effectively. Wash water with higher concentration of 1,2-dichloroethane requires longer treatment times and higher concentrations of Fe2+ and H2O2 for sufficient 1,2-dichloroethane removal.

Recommendations and perspectives

Due to the results achieved in this study, Fenton’s oxidation could be recommended to be used for organic destruction of wash water of ion-exchange resin. Residual sludge, the main disadvantage in Fenton process, can be reduced by optimizing the ferrous dose or by using heterogeneous treatment where most of the reusable iron remains in the solid phase.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background, aim, and scope

The presence of chlorinated volatile organic compounds (CVOCs) has been identified as one of the most serious environmental concerns in recent years. These compounds are widely used in industries as solvents, dry cleaners, degreasers, and chemical intermediates in the production of synthetic resins, plastics, and pharmaceuticals. Such compounds are highly toxic to the environment and public health (Musialik-Piotrowska and Mendyka 2004). These non-biodegradable compounds are conventionally removed from the liquid phase by adsorption on granulated activated carbon, gas stripping, and biological methods. These methods, however, are costly and require further disposal of spent activated carbon, thus increasing treatment cost. Gas stripping results in secondary air pollution after target compounds have been removed from liquid phase into the air, while biological processes are not suitable due to their slow kinetic reactions in an anaerobic environment (Janda et al. 2004).

Recently, advanced oxidation processes (AOPs) with strong oxidizing hydroxyl radicals (•OH) have been applied as one of the most promising technologies to degrade recalcitrant compounds into smaller and more biodegradable compounds (Gogate and Pandit 2004a, b; Kurniawan et al. 2006). A simple, efficient AOP, Fenton’s oxidation, where Fe2+/H2O2 mixture produces •OH radicals in a very cost-effective way, has received recent attention (Gogate and Pandit 2004a; Pignatello et al. 2006). Iron salt is locally available and non-toxic, while hydrogen peroxide is inexpensive and an environmentally friendly oxidant. No special equipment is needed and there is no mass transfer limitation due to Fenton’s homogeneous catalytic nature (Lopez et al. 2004). Ferrous ion and hydrogen peroxide are employed under acidic conditions where Fe2+ acting as a catalyst is oxidized to Fe3+ and a strong oxidizing hydroxyl radical is formed from H2O2. Because ferric ions are coagulants, the Fenton process can therefore have the dual function of oxidation and coagulation in the treatment process (Badawy and Ali 2006).

In Fenton’s oxidation, the decomposition of hydrogen peroxide in acidic solution is initiated according to Eq. 1. With the presence of organics, additional reactions occur (Eqs. 2–7; Walling 1975).

Initiation:

Propagation:

Termination:

The efficiency of Fenton’s oxidation relies on the generation rate and the concentration of oxidizing agents formed during Fenton’s reaction. Operational parameters that directly influence the efficiency of the process are source of iron catalyst (e.g., ferrous or ferric salt), concentrations of iron and hydrogen peroxide and their ratio, pH, temperature, and treatment time (Kušić et al. 2007). Due to a variety of process variables, it is reasonable to use statistical methods for the optimization of these variables with a reduced effort on experimentation. Several studies with promising results have focused on the use of response surface method (RSM) applied to Fenton’s oxidation for wastewater treatment (Benatti et al. 2006; Grčić et al. 2009; Zhang et al. 2009). RSM is used to study the relationship of the factors and responses and to evaluate the relative significance of the factors (Myers and Montgomery 2002).

Many studies have demonstrated that Fenton’s oxidation has been capable of degrading a variety of chlorinated VOCs in aqueous solutions (Tang and Huang 1997; Tang and Tassos 1997; Chen et al. 2001; Teel et al. 2001; Seol and Javandel 2008; Grčić et al. 2009). In the oxidation of chlorinated VOCs, the oxidation by-products include CO2, H2O, and, as the only chlorinated by-product, HCl. If the pollutants contain more chlorine atoms than hydrogen atoms, they cannot be efficiently converted to HCl (Musialik-Piotrowska and Mendyka 2004).

The studied wastewater was derived from wash of ion-exchange resin containing residual 1,2-dichloroethane. Based on the Finnish Government Decree on Substances Dangerous and Harmful to the Aquatic Environment 1022/2006 (http://www.finlex.fi/fi/laki/alkup/2006/20061022), 1,2-dichloroethane is a toxic substance which must not be directly discharged into surface water or the sewer of a water supply and sewerage plant. According to this legislation, the total concentration of 1,2-dichloroethane in seawater and inland surface water should be <10 μg L−1. The aim of this study was to reduce the concentration of 1,2-dichloroethane in wash water below 10 mg L−1, which then dilutes for sufficient level in the sewerage plant.

To reduce environmental load and processing costs of wastewater, it is desirable to find a simple and efficient treatment method for the wash water of ion-exchange resin. In this context, this paper estimates the effects of reaction conditions using RSM on degradation of 1,2-dichloroethane and total organic carbon (TOC) of the wash water in Fenton’s oxidation.

2 Materials and methods

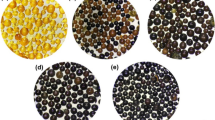

2.1 Wash water of ion-exchange resin

Wastewater samples were collected from Finex Oy (Finland) which produces tailor-made ion-exchange resins and performance polymers. The wastewater contains residual 1,2-dichloroethane which is involved in the sulfonation of polymers. The wash process, daily water consumption 40–60 m3, includes washing and cooking cycles where impurities of polymers are removed. In the present study, the water samples were collected from three different wash process stages. Physicochemical properties of untreated water samples are presented in Table 1.

2.2 Experimental setup

The effects of Fe2+ and H2O2 doses and reaction time on the degradation of 1,2-dichloroethane of wash water of ion-exchange resin were investigated. The H2O2/Fe2+ stoichiometric molar ratio ranged from 0.9 to 8.2, while the initial pH was 3–4. Fe2+ dose was 300, 600, or 900 mg L−1, whereas H2O2 dose was 500, 1,000, or 1,500 mg L−1. Mixing time was 30, 60, or 90 min. The chemical doses and time were selected based on preliminary tests. Experimental design was conducted to vary all these factors simultaneously over a set of planned experiments and then connect the results by means of a mathematical model. The total required number of runs for this design was 17 (eight for the factorial design, three for the central point, and six for the expansion) for each wastewater sample.

About 0.5 L of wastewater was treated using Fenton’s oxidation at ambient temperatures. After introducing a required amount of 1.0 M FeSO4⋅7H2O, the oxidative reactions were initiated by adding H2O2 (30%, 500–1,500 mg L−1) all at once. The sample was magnetically stirred in a closed, foil-covered reactor at a constant agitation speed. At designated time, the solution was clarified at quiescent conditions before sampling. Since the ferrous and ferric ions interfere with the determination of residual H2O2, the oxidized iron was first precipitated by adjusting the pH to 8.2 by 0.5 M NaOH. The supernatant was collected for chemical analyses of 1,2-dichloroethane and TOC.

2.3 Chemical analyses

The pH and the temperature of water samples were measured by WTW pH 340i/SET pH meter equipped with Sentix 41 pH electrode. The amount of organic material in the samples was determined as TOC using Shimadzu TOC-VCPH analyzer (SFS-EN 1484). The concentration of 1,2-dichloroethane was analyzed using GC-MS equipped with headspace by SGS Inspection Services Oy (Finland; SGSF146, based on ISO 11423-1:1997 and ASTM D2789). Residual H2O2 was measured semiquantitatively by Merckoquant® Peroxide test stripes. Reagents used in the experiments were all of analytical grade provided by J.T. Baker, Merck, or VWR.

2.4 Experimental design and RSM

Data were analyzed by RSM using multiple linear regression (MLR). RSM was undertaken using Umetrics MODDE 8.0 and design of the experiments using central composite face. Factors of three RSM models were Fe2+ and H2O2 doses and reaction time, and their range and levels are presented in Table 2. Responses included in the models were the removal of 1,2-dichloroethane and TOC.

Based on the prediction residual sum of squares (PRESS), the predictive power of an MLR is indicated by Q 2 and calculated as:

where SS is the sum of the squares of observed Y corrected for the mean.

If Q 2 > 0.7 or larger, the model has good predictive ability and small prediction errors. R 2 is the fraction of the variation of the response explained by the model, and “R 2 adjusted” is adjusted for degrees of freedom. Model validity compares model error to pure error. If model validity is larger than 0.25, there is no significant lack of fit in the model. Reproducibility was calculated from the replications at the center points according to Eq. 9:

MSPure error is the mean square of the pure error, while MSTotal corrected is the mean square from the total sum of squares where the constants sum of squares was subtracted.

3 Results

3.1 RSM model quality

According to analysis of variance (ANOVA) in Table 3, the RSM model accurately predicted the removal of 1,2-dichloroethane in all water samples and the removal of TOC in samples 2 and 3. The removal of TOC in sample 1 had low R 2 and Q 2 values due to the pure error of the measurements based on the reproducibility values. The model validities were good for all 1,2-dichloroethane removals, suggesting that the lacks of fit of the responses were not significantly larger than that of the pure errors. For TOC removal in sample 2, the model had the lack of fit. TOC removals in samples 1 and 3 had significant pure errors. According to the model quality values, RSM was a suitable method to study the effects of reaction conditions on 1,2-dichloroethane removal during Fenton’s oxidation.

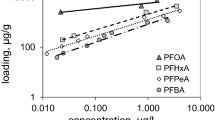

Normalized coefficients of the models are presented in Fig. 1. The quadratic term of reaction time and the interaction term of H2O2 dose with Fe2+ dose were included in the model of sample 1 (Fig. 1a). In the model of sample 2, the quadratic term of H2O2 dose and the interaction term of H2O2 dose with Fe2+ dose were included (Fig. 1b). The quadratic term of Fe2+ dose, the interaction term of H2O2 dose with Fe2+ dose, as well as the interaction terms of reaction time with H2O2 and Fe2+ doses were included in the model of sample 3 (Fig. 1c). Square terms or interaction terms that were not significant at 95% confidence level to any of the responses were not included in the models.

3.2 Effects of reaction conditions on sample 1

All factors included in the model, namely, H2O2 and Fe2+ doses, reaction time, quadratic term of reaction time, and interaction term of H2O2 dose with Fe2+ dose, influenced 1,2-dichloroethane removal at 95% confidence level. The operational factor affecting TOC removal was Fe2+ dose, which predominantly contributed to the removal of 1,2-dichloroethane (see Fig. 1a).

Increasing the reaction time from 30 to 60 min improved especially 1,2-dichloroethane removal, but also TOC removal, but further increment did not enhance removal efficiency (Fig. 2a, b). In both cases, the degradation substantially improved with an increase in Fe2+ dose. By increasing H2O2 dose, Fe2+ dose can be optimized accordingly. According to the RSM model, the highest removal of 1,2-dichloroethane and TOC were 72% and 35% at initial concentration of 480 and 160 mg L−1, respectively. The H2O2 and Fe2+ doses and reaction time for both responses were 1,500 mg L−1, 900 mg L−1, and 75 min. This suggests that Fenton’s oxidation with these reaction conditions could not generate treated effluent that meet the requirement of the final concentration of 1,2-dichloroethane (≤10 mg L−1).

3.3 Effects of reaction conditions on sample 2

The following factors of the model affected the removal of 1,2-dichloroethane: H2O2 and Fe2+ doses, reaction time, the quadratic term of H2O2 dose, and the interaction term of H2O2 dose with Fe2+ dose. TOC removal depended on the H2O2 and Fe2+ doses at 95% confidence level (see Fig. 1b).

Increasing the reaction time slightly improved the degradation of 1,2-dichloroethane, but it did not enhance TOC removal (Fig. 3a, b). By increasing H2O2 dose up to a certain level, the degradation of 1,2-dichloroethane substantially improved, and in that case, low concentration of Fe2+ is sufficient. However, an increase in Fe2+ dose and keeping low concentration of H2O2 even reduced 1,2-dichloroethane removal. TOC removal improved with an increase in the concentration of Fe2+. By increasing H2O2 dose, Fe2+ dose can be optimized accordingly. According to the RSM model, Fenton’s oxidation reduced 1,2-dichloroethane and TOC up to 100% and 87% with initial concentration of 120 and 110 mg L−1, respectively. With 90-min reaction time and H2O2 dose of 1,200 mg L−1, the required Fe2+ doses for 1,2-dichloroethane and TOC were 300 and 900 mg L−1. The 1,2-dichloroethane concentration <10 mg L−1 was also reached within 30 min and H2O2 and Fe2+ doses of 900 and 300 mg L−1.

3.4 Effects of reaction conditions on sample 3

According to the model, Fe2+ dose, reaction time, the quadratic term of Fe2+ dose, and the interaction terms of Fe2+ dose with H2O2 dose and reaction time were the key factors that controlled the removal of 1,2-dichloroethane at 95% confidence level. TOC removal was affected by Fe2+ dose, reaction time, the quadratic term of Fe2+ dose, and the interaction terms of H2O2 dose with Fe2+ dose and reaction time (see Fig. 1c).

Increasing the treatment time improved both 1,2-dichloroethane and TOC removal (Fig. 4a, b), and thus, H2O2 and Fe2+ doses can be decreased. According to the RSM model, the highest removal efficiencies for 1,2-dichloroethane and TOC were 100% and 89% with initial concentration of 35 and 17 mg L−1, respectively. With 90-min reaction time and H2O2 dose of 1,500 mg L−1, the Fe2+ dose for 1,2-dichloroethane and TOC were 800 and 900 mg L−1, respectively. The initial concentrations of 1,2-dichloroethane and TOC were so low that with all tested combinations of reaction time and H2O2 and Fe2+ doses, the remaining concentrations of 1,2-dichloroethane and TOC were under 10 mg L−1. So from the economical point of view, the lowest doses and reaction time are sufficiently efficient for the degradation.

4 Discussion

Fenton’s reaction initiates with reactions between H2O2 and Fe2+ generating hydroxyl radicals and Fe3+ (Eq. 1). Generally, the degradation rate of the pollutants improves with increasing Fe2+ concentration due to its role in initiating the decomposition of H2O2 until further addition of Fe2+ becomes inefficient (Kušić et al. 2007). High Fe2+ dose increases the treatment efficiency also by coagulation due to the high concentration of ferric coagulant. It should be noted that excess addition of Fe2+ can result in the generation of high amount of ferric-based sludge after neutralization (Gogate and Pandit 2004a; Sun et al. 2007). Generally, in the present study, increasing concentration of Fe2+ resulted in better removal of 1,2-dichloroethane and especially TOC, but also higher amount of ferric-based sludge was generated. Due to the coagulation effects of Fenton’s reaction (Badawy and Ali 2006), it seems that especially TOC but also a part of 1,2-dichloroethane were removed by coagulation (shown by tentative analysis of precipitate).

In practical applications, the efficient degradation of organic compounds requires sufficient dose of hydrogen peroxide in order to generate enough hydroxyl radicals. But when the so-called critical concentration of hydrogen peroxide is exceeded, the degradation of organic compounds decreases with increasing concentration of hydrogen peroxide. In this case, hydroxyl radicals may be scavenged by hydrogen peroxide, which results in the formation of hydroperoxyl radicals (Kušić et al. 2007; Sun et al. 2007). These are considerably weaker oxidants than the hydroxyl radicals (Pignatello et al. 2006; Kušić et al. 2007) and can react with Fe2+ and Fe3+, therefore leading to the loss of oxidative power. Decreased degradation of 1,2-dichloroethane after a certain hydrogen peroxide dose was clearly evident in the case of sample 2 (see Fig. 3a). Also, the residual hydrogen peroxide of different samples increased with increasing H2O2 dose and H2O2/Fe2+ molar ratio, while decreased treatment time increased the residual hydrogen peroxide. The residual hydrogen peroxide could be a consequence of the scavenging reaction of Fe2+ by hydroxyl radicals (Pignatello et al. 2006), but also of the recombination of hydroxyl radicals (Munter 2001).

The pH values of water samples were not adjusted because the optimum pH for Fenton’s oxidation has been observed to be around 3 in most studies (Kang and Hwang 2000; Neyens and Baeyens 2003; Kušić et al. 2007). At pH higher than 4, free Fe2+ ions decrease due to the formation of ferrous complexes and the precipitation of ferric hydroxides. Also, the oxidation potential of hydroxyl radicals decreases with increasing pH (Lindsey and Tarr 2000; Gogate and Pandit 2004a). Hydrogen peroxide is the most stable in the pH range of 3–4, but after that, its self-decay increases with increasing pH (Kang and Hwang 2000).

Fenton’s oxidation was reported to degrade more effectively unsaturated CVOCs than saturated CVOCs (Devine and Wieland 1992; Tang and Huang 1997; Kastanek et al. 2007). For example, in the treatment of contaminated groundwater, unsaturated vinyl chloride and 1,1-dichloroethene were reported to degrade completely, whereas the removal of saturated 1,2-dichloroethane was only 33% (Devine and Wieland 1992). Evidently, longer reaction times and higher concentrations of Fe2+ and H2O2 are required for sufficient 1,2-dichloroethane removal mainly due to the difficulty of removing chloride atoms from saturated aliphatic compound (Tang and Huang 1997). The first step in the oxidation of 1,2-dichloroethane is hydrogen abstraction instead of the addition of hydroxyl radical and subsequent chlorine atom cleavage (Lal et al. 1988):

The formed unsaturated bond is then attacked by hydroxyl radicals. The rate constants for hydrogen abstraction are several orders lower than rate constants for direct hydroxyl radical attack (Walling 1975; Tang and Huang 1997). Generally, in the present study, longer reaction times and higher concentrations of Fe2+ and H2O2 improved 1,2-dichloroethane removal.

The Fe2+ and H2O2 doses used in the present study were most suitable when 1,2-dichloroethane concentration of the wash water is around 120 mg L−1. According to results, using the H2O2/Fe2+ stoichiometric molar ratio between 4–6, the remaining concentrations of 1,2-dichloroethane was under 10 mg L−1. In that case, low concentration of Fe2+ was enough, and thus, the residual sludge can be reduced. In optimal treatment conditions (H2O2 dose 900 mg L−1 and Fe2+ dose 300 mg L−1), the amount of sludge was 500 mg L−1. Estimated costs for chemicals and sludge treatment will be about 2.90 EUR per cubic meter.. Higher doses are required for higher 1,2-dichloroethane concentrations, but by increasing the reaction time, the doses can be reduced. On the other hand, due to the fluctuations of 1,2-dichloroethane concentration in wastewater, additional treatment process should be considered to meet surely the required effluent concentration.

The wash water with 1,2-dichloroethane concentration about 28 mg L−1 was also tested with UV photolysis and UV/H2O2 oxidation process (Vilhunen et al. 2009). The highest removal of 1,2-dichloroethane and TOC (70% and 31%) was achieved in 60 min with H2O2 concentration of 200 mg L−1 and UV radiation (intensity of UV light (254 nm) was 24.4 mW/cm2). Evidently, UV/H2O2 oxidation process can be suitable for waters with low concentration of 1,2-dichloroethane, but higher concentrations need more effective methods such as Fenton’s oxidation.

5 Conclusions

The wash water of ion-exchange resin containing residual 1,2-dichloroethane was treated by classic Fenton’s oxidation. The influence of Fe2+ and H2O2 doses and reaction time on the degradation of 1,2-dichloroethane and TOC was investigated by RSM. Water samples were collected from three different washing stages of ion-exchange resin.

According to ANOVA, the model predicts well 1,2-dichloroethane reduction of all water samples and TOC reduction of samples 2 and 3. The Fe2+ and H2O2 doses used in the present study were most suitable when 1,2-dichloroethane concentration of the wash water is around 120 mg L−1. In that case, the Fenton’s oxidation was effective to degrade 100% of 1,2-dichloroethane and 78% of TOC according to the RSM model. With 90-min reaction time and H2O2 dose of 1,200 mg L−1, the required Fe2+ doses for 1,2-dichloroethane and TOC were 300 and 900 mg L−1, respectively. The 1,2-dichloroethane concentration <10 mg L−1 was also reached within more economical reaction conditions: 30 min and H2O2 and Fe2+ doses of 900 and 300 mg L−1, respectively. The optimal H2O2/Fe2+ stoichiometric molar ratio was between 4–6. Thus, low concentration of Fe2+ was sufficient and the residual sludge can be reduced. It seems that most of TOC and part of 1,2-dichloroethane were removed by coagulation. Longer treatment times and higher concentrations of Fe2+ and H2O2 or combined treatment processes are required for wash water with higher concentration of 1,2-dichloroethane.

6 Recommendations and perspectives

Due to the promising results achieved in this study, Fenton’s oxidation may be recommended to be used for organic destruction of wash water of ion-exchange resin. Residual sludge, the main disadvantage in Fenton’s oxidation, can be minimized by optimizing the ferrous dose or by using heterogeneous treatment where most of the reusable iron remains in the solid phase. Although classic Fenton’s oxidation has low operational costs and simple equipment, heterogeneous Fenton’s oxidation as a more economical alternative together with integrated treatment and also pilot-scale experiments are recommended for further study.

References

Badawy MI, Ali MEM (2006) Fenton’s peroxidation and coagulation processes for the treatment of combined industrial and domestic wastewater. J Hazard Mater B136:961–966

Benatti CT, Granhen Tavares CR, Guedes TA (2006) Optimization of Fenton’s oxidation of chemical laboratory wastewaters using the response surface methodology. J Environ Manag 80:66–74

Chen G, Hoag GE, Chedda P, Nadim F, Woody BA, Dobbs GM (2001) The mechanism and applicability of in situ oxidation of trichloroethylene with Fenton’s reagent. J Hazard Mater B87:171–186

Devine JS, Wieland HL (1992) Onsite pilot testing of UV-enhanced oxidation and chemical oxidation by Fenton’s reagent. In Air & Waste Management 85th Annual Meeting & Exhibition, Kansas City, Missouri, June 21–26, 1992

Gogate PR, Pandit AB (2004a) A review of imperative technologies for wastewater treatment I: oxidation technologies at ambient conditions. Adv Environ Res 8:501–551

Gogate PR, Pandit AB (2004b) A review of imperative technologies for wastewater treatment II: hybrid methods. Adv Environ Res 8:553–597

Grčić I, Vujević D, Šepčić J, Koprivanac N (2009) Minimization of organic content in simulated industrial wastewater by Fenton type processes: a case study. J Hazard Mater 170:954–961

Janda V, Vasek P, Bizova J, Belohlav Z (2004) Kinetic models for volatile chlorinated hydrocarbons removal by zero-valent iron. Chemosphere 54:917–925

Kang YW, Hwang K-Y (2000) Effects of reaction conditions on the oxidation efficiency in the Fenton process. Water Res 34:2786–2790

Kastanek F, Maleterova Y, Kastanek P, Rott J, Jiricny V, Jiratova K (2007) Complex treatment of wastewater and groundwater contaminated halogenated organic compounds. Desalination 211:261–271

Kurniawan TA, Lo W-H, Chan GYS (2006) Radicals-catalyzed oxidation for degradation of recalcitrant compounds from landfill leachate. Chem Eng J 125(1):35–57

Kušić H, Lončarić Božić A, Koprivanac N (2007) Fenton type processes for minimization of organic content in coloured wastewaters: Part I: process optimization. Dyes Pigments 74:380–387

Lal M, Schöneich C, Mönig J, Asmus K-D (1988) Rate constants for the reactions of halogenated organic radicals. Int J Radiat Biol 54:773–785

Lindsey ME, Tarr MA (2000) Quantitation of hydroxyl radical during Fenton oxidation following a single addition of iron and peroxide. Chemosphere 41:409–417

Lopez A, Pagano M, Volpe A, Di Pinto AC (2004) Fenton’s pre-treatment of mature landfill leachate. Chemosphere 54:1005–1010

Munter R (2001) Advanced oxidation processes—current status and prospects. Proc Estonian Acad Sci Chem 50:59–80

Musialik-Piotrowska A, Mendyka B (2004) Catalytic oxidation of chlorinated hydrocarbons in two-component mixtures of selected VOCs. Catal Today 90:139–144

Myers R, Montgomery D (2002) Response surface methodology: process and product optimization using designed experiments, 2nd edn. Wiley, New York

Neyens E, Baeyens J (2003) A review of classic Fenton’s peroxidation as an advanced oxidation technique. J Hazard Mater 98:33–50

Pignatello JJ, Oliveros E, MacKay A (2006) Advanced oxidation processes for organic contaminant destruction based on the Fenton reaction and related chemistry. Crit Rev Env Sci Tec 36:1–84

Seol Y, Javandel I (2008) Citric acid-modified Fenton’s reaction for the oxidation of chlorinated ethylenes in soil solution systems. Chemosphere 72:537–542

Sun J-H, Sun S-P, Fan M-H, Guo H-Q, Qiao L-P, Sun R-X (2007) A kinetic study on the degradation of p-nitroaniline by Fenton oxidation process. J Hazard Mater 148:172–177

Tang WZ, Huang CP (1997) Stochiometry of Fenton’s reagent in the oxidation of chlorinated aliphatic organic pollutants. Environ Technol 18:13–23

Tang WZ, Tassos S (1997) Oxidation kinetics and mechanisms of trihalomethanes by Fenton’s reagent. Water Res 31(5):1117–1125

Teel AL, Warberg CR, Atkinson DA, Watts RJ (2001) Comparison of mineral and soluble iron Fenton’s catalysts for the treatment of trichloroethylene. Water Res 35(4):977–984

Vilhunen S, Vilve M, Vepsäläinen M, Sillanpää M (2009) Removal of organic matter from a variety of water matrices by UV photolysis and UV/H2O2 method. Manuscript

Walling C (1975) Fenton’s reagent revisited. Acc Chem Res 8:125–131

Zhang H, Choi HJ, Canazo P, Huang C-P (2009) Multivariate approach to the Fenton process for the treatment of landfill leachate. J Hazard Mater 161:1306–1312

Acknowledgment

The financial support from EU, City of Mikkeli and Finex Oy is gratefully acknowledged. The authors thank the European Commission (EC) for the Marie Curie Fellowship for transfer of knowledge (no. MTKD-CT-2006-042637).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Ake Bergman

Rights and permissions

About this article

Cite this article

Vilve, M., Vilhunen, S., Vepsäläinen, M. et al. Degradation of 1,2-dichloroethane from wash water of ion-exchange resin using Fenton’s oxidation. Environ Sci Pollut Res 17, 875–884 (2010). https://doi.org/10.1007/s11356-009-0291-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-009-0291-5