Abstract

Purpose

Owing to the present complexity and difficulty of concentrated dye wastewater treatment, this work aimed to synthesize a reproducible waste-sorbing material for the treatment of wastewater by forming the dye-conjugating complex hybrid.

Methods

The inorganic/organic hybridization was applied to prepare the objective material by immobilizing waster dye-Mordant blue 9 (MB) with barium sulfate (BaSO4). The composition and pattern of the formed material were determined by spectrometry and characterized by SEM and XRD, and their formation process was clarified. The adsorption of cationic dye-basic blue BO (BB) and copper ion was investigated..

Results

The hybrid of MB alone into growing BaSO4 formed the pineapple-like particles while that of the MB/BB-conjugating complex was the rhombus material. The adsorption of BB on the MB–BaSO4 hybrid was probably attributed to ion-pair equilibrium and that of Cu2+ may result from the complexation. The treatment of dye and heavy metal wastewaters indicated that the MB hybrid material removed 99.8% BB and 97% Cu2+ and the dye-conjugating hybrid with growing BaSO4 100% MB, 99.5% BB, and 44% Cu2+.

Conclusion

The waste MB–BaSO4 hybrid material is efficient to treat cationic dye and Cu2+ wastewater. The dye-conjugating hybridization method is the first to be advanced for in situ wastewater treatment, and it showed a combined effect for the removal of both organic dyes and heavy metals.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The inorganic/organic hybridization is applied extensively to synthesize the functional materials. Organic substances, e.g., dyes, are as the reactive hybrid components used in biomaterial, catalyst, thin-film, photosensitive cell (Takahashi et al. 2006; Xu et al. 2007; Hou et al. 2008). Metal oxides/sulfides are often selected to build the skeleton structure and polymer or surfactant as a soft template controlled the desirable material pattern (Yang et al. 2006; Yu and Yoshimura 2000; Zhou et al. 2009). However, such an advanced method is seldom considered in wastewater pollution control. At present, more than 700,000 tones of dyes are produced worldwide annually, but over 5% are discharged into aquatic environments (Gong et al. 2005; Wang et al. 2009). The colority of a dye-producing wastewater is often more than 50,000 times while that of a dye-using wastewater over 500. Plenty of industrial wastewater containing toxic chemicals, e.g., POPs, heavy metals, is not usually treated effectively especially in developing countries. For example, lots of dye/drug/electronic plants and users are located in Taihu Lake valley, which is the drinking water source of the most developed Yangtze Delta Area. In recent years, the local ecological environment suffered a serious impact and people’s health affected (Yang et al. 2008; Guo 2007). In order to meet the state’s discharge standard, Chinese government makes great efforts to treatment of industrial wastewater in this area. Conventional abiotic, e.g., separative and destructive techniques are often applied to treatment of dye wastewater, some of which combined together to reach a satisfactory effect. Both the adsorption and flocculation are often essential, but the low removal rate, long reaction time, color-returning, and difficult reproduction and sludge disposal restricted the wider use. The waste reuse/recycle is considered as an optimal choice in environmental pollution control (Liu et al. 2008a, b). Though some previous works prepared the silver and calcium sorption materials by immobilizing dyes (Wang and Gao 2009; Wang et al. 2009; Zhao and Gao 2009), their regeneration is impossible. The aim of this work is to synthesize a reproducible waste-sorbing material by immobilizing waste dye with barium sulfate (BaSO4) and develop the dye-conjugating hybrid wastewater treatment method. As is well known, barium sulfate is not soluble in water and/or acidic media, and also it was made easily and simply from soluble barium salt and sulfate. It is used as the hybrid skeleton for preparing the functional material (Nagaraja et al. 2009). As a conventional dye, mordant blue 9 (MB) with two sulfonic groups exhibit a good nucleophilicity with alkaline-earth metals, e.g., Ba2+. Thus, barium sulfate and MB were selected for synthesizing the hybrid and establishing the conjugating hybridization method potentially used in treatment of dye wastewaters.

2 Material and methods

2.1 Instruments and apparatus

A photodiode array spectrometer (Model S4100, Scinco, Korea) with the Labpro plus software (Firmware Version 060105) was used to determine chromaticity and concentration of various color compounds and suspended substance liquids. A Model Analyst 400 atomic absorption spectrophotometer (AAS, Perkin-Elmer Instruments, USA) was used to determine Ba and Cu contents. An X-ray diffractometer (XRD; Model D/max 2550VB3+/PC, Rigaku, Japan) was used for identifying the structure and size of crystal particles. A scanning electronic microscopy (SEM; Model Quanta 200 FEG, FEI Co., USA) was used to measure the size and shape of the materials.

MB (1.00 mM; CI 14855, 50% content, Sigma Co.) and 1.0 mM basic blue BO (BB) (CI 42595, 80% content, Shanghai Ouweida Company) was prepared in deionized water. MB was purified with DMF and acetone before use. Weak acidic pink red B (APRB) and reactive brilliant red K-2BP (RBR) as anionic dyes and ethyl violet (EV) as cationic dyes were selected to examine the adsorption selectivity of hybrid. Besides, a dye-manufacturing wastewater was sampled from Jinjiang Dye Plant (Hangzhou, China).

2.2 Methods

Synthesis of the hybrid materials

One gram of MB and 40 g of sodium sulfate were dissolved in 2,000 ml of deionized water; 500 ml of 20% barium chloride was added slowly under stirring. After 10 min, the liquid was stewed for precipitating the suspending substances for about 30 min. The precipitate was washed with 3,000 ml of deionized water for three times. The final suspending substance liquid with the BaSO4-MB inclusion material was used for further experiments. The liquid was centrifuged for 5 min at 5,000 rpm and then the precipitate dried at 110°C to prepare the material powder. With the same method, a BaSO4–MB–BB conjugating complex hybrid material was prepared with the MB–BB mixture instead of MB according to the sequence: MB (0.1%), BB (0.16%), Na2SO4 (1.5%), and BaCl2 (3.4%).

Composition determination and structural characterization of the materials

Into 15 mg of the hybrid material powder, 50 ml of the EDTA (0.16 M)–aqua ammonia (10%) mixed solution was added for dissolving the material. The MB content was determined by spectrophotometry at 542 nm and the Ba content by AAS. The composition ratio of BaSO4 to MB was calculated. The SEM and XRD of the hybrid particles were measured with the material powder. Besides, the growing particles liquid was sampled for SEM observation in order to investigate the formation process of the hybrid particles when a half of the Ba2+ solution was added, i.e., at about 5 min of the precipitation reaction from beginning.

Treatment of dye and heavy metal wastewaters

Into a series of wastewater mixtures (100 ml) consisting of a BB (0.24 mM) wastewater and a heavy metal wastewater containing 10 mg/L Cu2+, the BaSO4–MB hybrid material was added from 0.2% to 3%. After mixed for 10 min, the liquids were settled for 30 min, and the BB concentration in the supernatants was determined at 615 nm by spectrophotometry and Cu2+ by AAS. In addition, into a series of wastewater mixtures (100 ml) consisting of the MB (0.02–0.20 mM) wastewater and the above BB and heavy metal wastewaters, SO 2−4 was added from 0.80 to 8.0 mM. After mixture, Ba2+ was added from 1.2 to 12 mM. The mole ratio of MB to SO 2−4 and Ba2+ remained at a constant mole ratio, 0.025:1:1.5. All of the liquids were settled for 30 min, and the MB and BB concentrations in the supernatants were determined at 542 and 615 nm by spectrophotometry and Cu2+ by AAS.

2.3 Results and discussion

MB (Fig. 1) was selected to hybridize into growing BaSO4 and their interaction investigated. The three addition sequences of the reactants: SO 2−4 –Ba2+–MB, MB–Ba2+–SO 2−4 , and MB–SO 2−4 –Ba2+ were carried out for optimizing the hybrid condition. From the absorption spectra of the supernatants (Fig. 1), the first sequence obtained the minimal inclusion of MB, where MB was adsorbed only on the BaSO4 particle surface. The prior complexation of Ba2+ with –SO −3 groups of MB occurred in the second sequence. The third sequence is most favorable for loading MB. An additional experiment indicated that the hybrid amount of MB is little if the initial molarity of SO 2−4 is more than that of Ba2+. The excessive Ba2+ is essential to enter the electric double layer of growing BaSO4 particles and attract MB by the electrostatic interaction (Ni et al. 2008; Cong and Yu 2007). The interaction of MB with BaSO4 obeyed the Langmuir adsorption isotherm with 0.05 of the saturation mole number, i.e., one MB maximally binding to 20 of BaSO4 (Fig. 1). According to the optimal synthesis condition, a MB-hybridizing material was prepared, characterized, and used. The composition ratio was determined to be 0.02 of MB to BaSO4. In addition, a new-type dye-conjugating hybrid material was designed and synthesized by loading the mixture of BB with MB into growing BaSO4.

a Effect of the addition sequence of the reactants on the occlusion of MB. 1 MB-only; 2 SO 2−4 –Ba2+–MB; 3 MB–Ba2+–SO 2−4 ; 4 MB–SO 2−4 –Ba2+, where 0.75 mM Ba2+, 0.5 mM SO 2−4 , and 0.056 mM MB were added. The third reactant was added after the other reactants were mixed and reacted for 10 min. b Effect of MB (cMB). 1 Change of the mole ratio (γ) of MB to BaSO4 and 2 plots γ−1 vs c −1MB

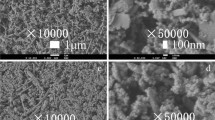

The BaSO4-nongraded particles (50–400 nm) like smooth pebbles were formed (Fig. 2a). The MB hybrid turned the particles into the pineapple-like nongraded aggregates with rough surface (Fig. 2b) but did not affect the formation of BaSO4 by comparing with XRD of BaSO4 (Fig. S1A, B). The discoidal BaSO4–MB hybrid growing particles (400–500 nm) were formed. MB in the reaction system exhibited strong control over the crystallization of BaSO4. Many discoidal particles aggregated together to build a rhombus plate in 2–4 µm of side length. Successively, the others stacked in the plate to form a flower (Fig. 2d). After aging for 4 h, it turned into a long pineapple-like particle (1–4 µm of length). However, the MB–BB-conjugating hybrid formed the rhombus particles (4–5 µm; Fig. 2c). The co-existence of BB has not altered the formation of BaSO4 (Fig. S1 C). The MB–BB-conjugating hybrid process is different from the single MB. First of all, the MB–BB mixture formed the interlaced grids (Fig. 2e, 2), being similar to the polymer template (Meldrum and Colfen 2008). BaSO4 filled in the grids into the oval pattern (0.4 × 1 µm), and then they stacked around one big ovoid until a rhombus material formed.

SEM images of BaSO4-only (a), BaSO4–MB-hybrid material (b), and BaSO4–MB–BB-conjugating hybrid material (c). d SEM images of the growing BaSO4–MB-hybrid particles (1–3 in various magnifications), which was measured from a liquid sampled immediately when a half of Ba2+ solution was added and e those of the growing BaSO4–MB–BB hybrid particles (1, 3, and 4 in various magnifications) and that of the MB–BB complex (2)

The dye hybrid mechanism is speculated. During the growth of the BaSO4–MB hybrid particles (Fig. 3a), MB entered the colloidal electric bilayer to attract on BaSO4 via electrostatic interaction with one –SO −3 group. The other –SO −3 group of MB again attracted Ba2+, and then SO 2−4 captured the Ba2+ to form the BaSO4 outer shell. Thus, a thin MB encircling band may be fixed between wider barium sulfate bands (Fig. 3a, a), being similar to a previous work (Lin and Gao 2009). With increasing hybrid of MB, lots of the caky particles were formed, and they aggregated together into the rhombic particles like as bloomy flower (Fig. 3a, b). After aging, they grew into the pineapple-like material. The hybrid material loading lots of MB charged negatively so it forms plenty of electronegative micro-bodies when dispersed in aqueous media. When a cationic organic substance, e.g., BB was added, it is adsorbed only on the material surface (Fig. 3a, c). The saturate adsorption number of BB just neutralized all the negative charges of MB hybridized (Fig. S2), i.e., \( {\left[ {{{\left( {{\text{BaS}}{{\text{O}}_{\text{4}}}} \right)}_{{\text{5}}0}}\left( {\text{MB}} \right)} \right]_n}^{{\text{2}}n - } + {\text{2}}n{\text{B}}{{\text{B}}^{+} } = {\text{B}}{{\text{B}}_{{\text{2}}n}}{\left[ {{{\left( {{\text{BaS}}{{\text{O}}_{\text{4}}}} \right)}_{{\text{5}}0}}\left( {\text{MB}} \right)} \right]_n} \downarrow \). Even if MB is located in the BaSO4 inside, the adsorption capacity of material has no effect. The possible reason is that the electrostatic induction pulled the MB charges towards the outside surface of particles (Zhao et al. 2005). Different from a conventional sorbent, the adsorption has no correlation with the surface area of material. In the MB–BB mixture, the interlaced complex grid was firstly formed (Fig. 3b, a) via the intermolecular complexation. Lots of Ba2+ bound to the grids via the electrostatic interaction with MB, and they captured SO 2−4 to form BaSO4 filling in grids (Fig. 3b, b). The olivary BaSO4–MB–BB particles stacked together to form the rhombic material (Fig. 3b, c). Different from the surface adsorption above, BB was loaded into the particle inside together with MB. The excessive BB found in the supernatants (Fig. S3) when BB was as over twice high as MB, i.e., the charge equilibrium. The free-template MB–BB-conjugating hybrid realized the simultaneous inclusion of two dyes with a wider visible absorption (450–700 nm) (Fig. S4), and it may be valuable for development of new optical materials (Liu et al. 2008a, b; Fujii et al. 2008).

Cartoon illustration for the formation process of the BaSO4–MB hybrid (a) and BaSO4–MB–BB-conjugating hybrid (b). In a, a MB band formed in BaSO4, b pineapple-like BaSO4–MB hybrid after aging, and c the hybrid sorbing BB. In b, a the MB–BB complex formed into the grids, b BaSO4 filled in the grids, and c the rhombic BaSO4–MB–BB hybrid formed

The adsorptions of four dyes on the BaSO4–MB hybrid were carried out: APRB and RBR as anionic dyes and BB and EV as cationic dyes. Both anionic dyes APRB and RBR were hardly adsorbed, but the removal of BB and EV are obvious (Fig. S5 and Fig. 4). When the MB–BaSO4-hybrid sludge was used to treat BB (tube 3 in Fig. 4) and RBR (tube 5) wastewaters, the removal of BB is over 98% (tube 4) while RBR has no removal (tube 6). The MB–BaSO4 hybrid is invalid for acidic dye so the adsorption selectivity resulted from the charge attraction. From tubes 1 and 2 in Fig. 4, a little amount of BaSO4 removed 99% MB. When a BB wastewater was mixed with a MB wastewater according to 2:1 of mole ratio (tube 7), the rapid co-precipitation of the BB–MB-conjugating complex with BaSO4 occurred. The supernatant became colorless (tube 8). In addition to complex BB, MB may form the chelate with heavy metals, e.g., Cu2+ from the MB structure (Fig. 1a). The hybrid material was used to treat a BB–Cu2+ wastewater mixture; 1.5% of the material only added removed 99.8% BB and 97% Cu2+ (Fig. 5). A mixture of MB, BB, and Cu2+ wastewaters was treated with growing BaSO4. The removal rate of MB approached 100% and 0.1 mM MB wastewater only added removed 99.5% BB and 44% Cu2+ (Fig. 5).

Photos illustrated colority change of dye wastewaters. Tube 1: MB (1,670 times of colority), 2 wastewater 1 treated with 8 mM SO 2−4 and 12 mM Ba2+, 3 BB (1,500 times), 4 wastewater 3 treated with 0.1% BaSO4–MB hybrid material, 5 RBR (410 times), 6 wastewater 5 treated with 0.1% BaSO4–MB hybrid material, 7 the BB (1,500 times)–MB (840 times) wastewater mixture, 8 wastewater 7 treated by adding 2 mM SO 2−4 and 3 mM Ba2+. All liquids settled naturally for 20 min

Treatment of the BB (0.24 mM)–Cu2+ (10 mg/L) mixed wastewater with the MB–BaSO4 hybrid material from 0.2 to 3% (curve 1) and that of the \( {\text{MB}}\left( {{c_{\text{MB}}} = 0.0{\text{2}} - 0.{\text{2}}0{\text{ mM}}} \right) - {\text{BB}}\left( {0.{\text{24 mM}}} \right) - {\text{C}}{{\text{u}}^{{\text{2}} + }}\left( {{\text{1}}0{\text{ mg}}/{\text{L}}} \right) \) mixed wastewater by adding SO 2−4 (0.8–8 mM) and Ba2+ (1.2–12 mM) according to the constant mole ratio, 1.5:1:0.025 of Ba2+ to SO 2−4 and MB (curve 2). a Removal of BB (∆c BB) and b that of Cu2+ (∆c Cu). When the growing BaSO4 was used to treat the mixture of three wastewaters, containing MB, BB, and Cu2+, almost all of MB molecules were hybridized into the precipitates, i.e., the removal rates of MB approached 100% in all the wastewaters. Change of MB removal rate was not shown in the figure

In addition, the MB–BaSO4 hybrid and the dye-conjugating hybridization method were also used to treat a dye-manufacturing wastewater sampled from JinJiang Dye Plant; 5% of the hybrid material removed 70% color and 60% COD (Fig. S6). The dye-conjugating hybridization method is more effective, which removed nearly 100% color and 90% COD in the presence of 3.2 mM MB as the conjugating compound of waste dye molecules. By comparing the above method with use of the other adsorbents such as bottom ash, organo-attapulgite, urea resin, and wollastonite with 9–70 mg/g of the adsorption capacity of dyes (Mittal et al. 2009; Ozdemir et al. 2009; Gupta and Shukla 1996; Chen and Zhao 2009), the in situ hybridization method is more effective. Beyond doubt, the dye hybrid may be used as a cost-effective sorbent for cationic dye and heavy metal wastewater treatment and the dye-conjugating hybridization method is more suitable for the cooperative treatment of wastewaters mixture.

3 Conclusions

Unlike the other inorganic skeletons (Yang et al. 2006; Yu and Yoshimura 2000), e.g., calcium carbonate (Chen et al. 2008; Sonnenberg et al. 2007; Kulak et al. 2007), barium sulfate was rarely selected in mineralization reactions (Nagaraja et al. 2009; Yu et al. 2003). However, it is more suitable for use in wastewater treatment owing to its water insoluble and acid-resistant. Not only the contaminants, e.g., MB, BB, and Cu2+ loading in barium sulfate were not released, but also a simple reproduction of the hybrid adsorbent may be performed in 0.1–1 M sulfuric acid media from dye-contaminating sludge. Therefore, this work developed an eco-friendly way for “using waste to treat waste.”

References

Chen H, Zhao J (2009) Adsorption study for removal of Congo red anionic dye using organo-attapulgite. Absorption 15:381–389

Chen SF, Yu SH, Jiang J, Li FQ, Liu YK (2008) Polymorph Discrimination of CaCO3 Mineral in an Ethanol/Water Solution: Formation of Complex Vaterite Superstructures and Aragonite Rods. Chem Mater 18:115–122

Cong HP, Yu SH (2007) Hybrid ZnO-Dye hollow spheres with new optical properties from a self-assembly process based on Evans blue dye and cetyltrimethylammonium bromide. Adv Funct Mater 17:1814–1820

Fujii K, Iyi N, Sasai R, Hayashi S (2008) Preparation of a Novel Luminous Heterogeneous System: Rhodamine/Coumarin/Phyllosilicate Hybrid and Blue Shift in Fluorescence Emission. Chem Mater 20:2994–3002

Gong RM, Li M, Yang C, Sun YZ, Chen J (2005) Removal of cationic dyes from aqueous solution by adsorption on peanut hull. J Hazard Mater 121B:247–250

Guo L (2007) Doing Battle With the Green Monster of Taihu Lake. Science 317:1166

Gupta GS, Shukla SP (1996) Treatment of carpet effluents by adsorption on wollastonite. J Indian Chem Soc 73:61–65

Hou K, Song Q, Nie D, Li F, Bian Z, Liu L, Xu L, Huang C (2008) Synthesis of Amphiphilic Dye-Self-Assembled Mesostructured Powder Silica with Enhanced Emission for Directional Random Laser. Chem Mater 20:3814–3820

Kulak N, Iddon P, Li Y, Armes SP, Colfen H, Paris O, Wilson RM, Meldrum FC (2007) Quantitative Single Molecule Measurements on the Interaction Forces of Poly(l-glutamic acid) with Calcite Crystals. J Am Chem Soc 129:3729–3736

Lin J, Gao HW (2009) SDBS@BaSO4: an efficient wastewater-sorbing material. J Mater Chem 19:3598–3601

Liu R, Zhao X, Wu T, Feng P (2008a) Tunable Redox-Responsive Hybrid Nanogated Ensembles. J Am Chem Soc 130:14418–14419

Liu WZ, Huang F, Liao YQ, Zhang J, Ren GQ, Zhuang ZY, Zhen JS, Lin Z, Wang C (2008b) Treatment of CrVI-containing Mg(OH)2 nanowaste. Angew Chem Int Ed 47:5619–5622

Meldrum FC, Colfen H (2008) Controlling Mineral Morphologies and Structures in Biological and Synthetic Systems. Chem Rev 108:4332–4432

Mittal A, Kaur D, Malviya A, Mittal J, Gupta VK (2009) Adsorption studies on the removal of coloring agent phenol red from wastewater using waste materials as adsorbents. J Colloid Interface Sci 337:345–354

Nagaraja BM, Jung KD, Ahn BS, Abimanyu H, Yoo KS (2009) Catalytic Decomposition of SO3 over Pt/BaSO4 Materials in Sulfur-Iodine Cycle for Hydrogen Production. Ind Eng Chem Res 48:1451–1457

Ni W, Yang Z, Chen H, Li L, Wang J (2008) Coupling between Molecular and Plasmonic Resonances in Freestanding Dye − Gold Nanorod Hybrid Nanostructures. J Am Chem Soc 130:6692–6693

Ozdemir FA, Demirata B, Apak R (2009) Adsorptive Removal of Methylene Blue from Simulated Dyeing Wastewater with Melamine-Formaldehyde-Urea Resin. J Appl Polym Sci 112:3442–3448

Sonnenberg L, Luo Y, Schlaad H, Seitz M, Colfen H, Gaub HE (2007) Quantitative Single Molecule Measurements on the Interaction Forces of Poly(l-glutamic acid) with Calcite Crystals. J Am Chem Soc 129:15364–15371

Takahashi Y, Kasai H, Nakanishi H, Suzuki TM (2006) Test strips for heavy-metal ions fabricated from nanosized dye compounds. Angew Chem Int Ed 45:913–916

Wang HY, Gao HW (2009) Preparation of Calcium Oxalate - Bromopyrogallol Red Inclusion Sorbent with Wastewater for Treatment of Dye and Heavy Metal Wastewaters. Environ Sci Pollut Res 16:339–347

Wang HY, Ma LM, Li T, Zhang YL, Gao HW (2009) Synthesis of Ag(SCN)/tetrabromo-tetrachlorofluorescein inclusion material and application to synthetic dye. Colloids Surf A 333:126–132

Xu CS, Kim H, Yang H, Hayden CC (2007) Multiparameter Fluorescence Spectroscopy of Single Quantum Dot − Dye FRET Hybrids. J Am Chem Soc 129:11008–11009

Yang R, Wang ZL, Springs (2006) Rings, and Spirals of Rutile-Structured Tin Oxide Nanobelts. J Am Chem Soc 128:1466–1467

Yang M, Yu JW, Li ZL, Guo ZH, Burch M, Lin TF (2008) Taihu Lake Not to Blame for Wuxi’s Woes. Science 319:158a

Yu SH, Yoshimura M (2000) Direct Fabrication of Ferrite MFe2O4 (M = Zn, Mg)/Fe Composite Thin Films by Soft Solution Processing. Chem Mater 12:3805–3810

Yu SH, Antonietti M, Colfen H, Hartmann J (2003) Growth and Self-Assembly of BaCrO4 and BaSO4 Nanofibers toward Hierarchical and Repetitive Superstructures by Polymer-Controlled Mineralization Reactions. Nano Lett 3:379–382

Zhao DH, Gao HW (2009) Turning Calcium Carbonate into a Cost-effective Wastewater-sorbing Material by Occluding Waste Dye. Environ Sci Pollut Res. doi:10.1007/s11356-009-0111-y

Zhao SX, Castle GSP, Adamiak K (2005) Comparison of conduction and induction charging in liquid spraying. J Electrostat 63:871–876

Zhou Y, Kogiso M, Shimizu T (2009) Necklace-like Chains of Hybrid Nanospheres Consisting of Pd Nanocystals and Peptidic Lipids. J Am Chem Soc 131:2456–2457

Acknowledgments

This work was supported by the State Key Laboratory Foundation of Ministry of Science and Technology of China (Grant No. PCRRY09004 and PCRRY09008) and the National Key Technology R&D Program of China (No. 2006BAJ08B10).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Hailong Wang

Electronic supplementary materials

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gao, HW., Lin, J., Li, WY. et al. Formation of shaped barium sulfate-dye hybrids: waste dye utilization for eco-friendly treatment of wastewater. Environ Sci Pollut Res 17, 78–83 (2010). https://doi.org/10.1007/s11356-009-0249-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-009-0249-7