Abstract

Purpose

[18F]ML-10 is the most advanced radiopharmaceutical for the clinical imaging of the apoptosis phenomenon by PET. The preparation of this radiopharmaceutical on a commercial radiosynthesis module and the requested quality controls for its release are presented herein.

Procedures

ML-10 as reference and its mesyloxy derivative as precursor for labelling with fluorine-18 were prepared. [18F]ML-10 was synthesized via a [18F]fluorine-de-mesyloxy aliphatic nucleophilic substitution via a GE TRACERLab® FX-FN module. Quality controls were performed.

Results

The labelling precursor was obtained in a four step synthesis in 28 % overall yield affording ML-10 in two steps (88 % yield). Pure [18F]ML-10 was obtained with a decay corrected yield of 39.8 % ± 8.4 % (n = 7) in 70 min and a specific activity of 235 ± 85 GBq/μmol at the end of synthesis.

Conclusions

[18F]ML-10 was prepared on a widely available automated module and passed the quality control. A LC/MS method was developed to measure specific radioactivity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Apoptosis is one of the cell death processes which is also called programmed cell death. Apoptosis could be described as a controlled demolition of the cell [1]. This process is carried out in a safe manner without affecting the neighbouring cells especially without any inflammation contrary to the necrosis. The mechanism of apoptosis includes the activation of caspase enzymes leading to functional and structural protein cleavage. Then, nucleus but also mitochondrial system, Golgi apparatus and endoplasmic reticulum undergo fragmentation. This intracellular destructuration of the cell is coupled with membrane changes leading to the expression of phosphatidylserine at the cell surface followed by the formation of vesicles. Those phenomena occurred to facilitate the phagocytosis of the resulting apoptotic bodies.

The apoptosis could result of pathologies (ischemia, autoimmune diseases, neurodegenerative diseases…) but could also be triggered by therapeutic treatment such as irradiation or chemotherapy. The development of in vivo imaging of such an important phenomenon is focusing the attention for several years [2–5], with a lot of potential clinical diagnosis applications [6] especially to assess the therapeutic response in oncology [7–10]. A few single photon emission computed tomography (SPECT) radiopharmaceuticals including 99mTc-labelled annexin-V were used for clinical imaging [2]. Nevertheless, up to very recently, PET radiopharmaceuticals were not available for this purpose [11].

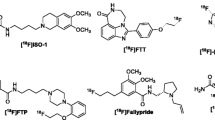

In 2009, 2-(5-[18F]fluoropentyl)-2-methyl malonic acid ([18F]ML-10) was identified and developed by Aposense Ltd as a potent PET radiotracer for imaging the apoptosis (Fig. 1) [12, 13]. [18F]ML-10 is depicted as selective for apoptotic cells versus necrotic cells, its preferential accumulation in cells presenting modifications relative to the apoptotic pathway only, having been demonstrated. In particular, the modification of the cellular membrane by the presence of phosphatidylserine at the surface and the permanent depolarization of this membrane permitted to [18F]ML-10 to penetrate selectively into the apoptotic cell. The irreversible loss of the intracellular pH control led to an acidification and therefore an intracellular accumulation of the radiotracer particularly in the nuclei and cytosol [12]. The presence on [18F]ML-10 structure of lipophilic (fluoropentyl) and polar (malonic acid) moieties allowed its passage through the membrane and its accumulation into the apoptotic cells.

[18F]ML-10 was first tested in an ischemic mouse model [13]. In a middle cerebral artery occlusion mouse model, a higher uptake was observed in the damaged cerebral hemisphere than in the contralateral hemisphere (ratio 2.29 at 90 min after [18F]ML-10 injection). The first administration of [18F]ML-10 in human to evaluate its safety has been just published [14]. The effective dose during a PET scan was about 15 μSv/MBq which is comparable to other PET radiopharmaceutical dosimetry. The radiopharmaceutical was stable and permitted to detect apoptosis in testes which is relevant to the testicular physiology. At least seven clinical trials are running and show the importance of [18F]ML-10 and its potential future. Apart from three images included in reviews [11, 15] and showing [18F]ML-10 uptake in cerebral ischemia or cerebral metastases response to radiation therapy, no pharmacological data were published.

Moreover, preparation of ML-10 as reference compound as well as an appropriated precursor for labelling with fluorine-18 has not been, to our knowledge, reported to date. Additionally, radiosynthesis of [18F]ML-10 is only shortly described, with some discrepancies and without complete description of the process [13]. Herein, we fully describe the preparation of ML-10 and its mesylate derivative as labelling precursor as well the radiosynthesis of [18F]ML-10 based on a [18F]fluorine-de-mesyloxy aliphatic nucleophilic substitution, the implementation of the process on a commercially available TRACERLab FX-FN module and the quality controls requested for the release of the radiopharmaceutical preparation for human applications.

Materials and Methods

Materials

All reagents and chromatography solvents were purchased from Fluka or Sigma-Aldrich (Saint-Quentin Fallavier, France) and were used without further purification. Anhydrous tetrahydrofuran and acetonitrile were obtained from a Mbraun SPS-800 solvents delivery system.

Instrumentation

1H, 13C and 19F NMR spectra were recorded on a Bruker DRX 400 MHz spectrometer, at 400.13 MHz (1H), 100.16 MHz (13C) and 376.4 MHz (19F). Chemical shifts were reported as parts per million (δ ppm) using tetramethylsilane (TMS) as internal standard or by reference to proton resonances resulting from incomplete deuteration of the NMR solvent. Coupling constants are given in hertz (Hz) and coupling patterns are abbreviated as: s (singlet), d (doublet), t (triplet), m (multiplet), dt (doublet of triplet). High resolution mass spectra (HRMS) were obtained on a Waters Q-TOF micro spectrometer by electrospray ionisation (ESI). Thin layer chromatographies (TLC) were run on pre-coated aluminium plates of silica gel 60F254 (Merck) and R f were established using an UV-lamp at 254 nm or using either acidic vanillin solution or ninhydrin solution. Radioactive TLC were measured using an Instant Imager® Packard apparatus. Silica gel chromatographies were performed on 40–63 mesh silica gel 60 (Merck) columns. Melting points were determined on a Barnstead Electrothermal IA 9100 melting point apparatus and are uncorrected.

No-carrier-added aqueous [18F]fluoride was produced by the 18O[p,n]18F nuclear reaction of a target consisting of 18O-enriched water (>97 %, Eurisotop, France) irradiated with a 18 MeV proton beam (IBA Cyclone 18/9 cyclotron). Radioactivity measurements were carried out with a Capintec R15C ionization chamber. Radiosynthesis were performed using a standard Tracerlab® FX-FN module (GE HealthCare). Analytical HPLC was realized with a Waters 600 pump and controller, a UV detector (UV-975, Jasco) coupled with a NaI probe radioactive detector (Novelec, France) using a Nucleodur C18 Gravity column (250 × 4.6 mm, Macherey-Nagel). Gas chromatography (GC) was performed on a 3800 Varian apparatus equipped with a flame ionization detector (FID) using a packed column (1 % Rt-1000 on CarboBlack B 60/80, length: 8 ft, ID: 2.0 mm, Restek). Both HPLC and GC were acquired by a Chromeleon software (Dionex). LC/MS analyses were performed with an Alliance HPLC system (e2695, Waters) coupled with a Acquity SQD (3100 Mass Detector, Waters) and analysed using the MassLynx software (V4.1, Waters). Chemical purity of compounds was established by HPLC and was more than 98 %.

Preparation of Di-Tert-Butyl 2-[5-(Benzyloxy)Pent-1-yl]Malonate (2)

Di-tert-butyl malonate (326 μl, 1.46 mmol) was added to a suspension of sodium hydride (38 mg, 1.53 mmol) in dry tetrahydrofuran (7 ml) at 0 °C. The solution was stirred at room temperature for 2 h and cooled down to 0 °C. Benzyl 5-bromopent-1-yl oxide 1 (300 mg, 1.17 mmol) in dry tetrahydrofuran (5 ml) was added dropwise over a period of 30 min. The mixture was stirred for 2 h at room temperature and further heated at 50 °C overnight. Then brine (15 ml) was added to the reaction mixture followed by extraction with diethyl ether (3 × 25 ml). Then, the combined organic layer were dried (MgSO4) and the solvent was removed in vacuo. The residue was purified by chromatography on silica gel (heptanes/diethyl ether, 95:5) to yield the product 2 as a colourless oil (191 mg, 42 %). 1H NMR (CDCl3): 7.36–7.26 (5H, m), 4.48 (2H, s), 3.45 (2H, t, 3 J H-H = 6.5 Hz), 3.09 (1H, t, 3 J H-H = 7.6 Hz), 1.82–1.76 (2H, m), 1.66–1.58 (2H, m), 1.44 (18H, s), 1.40–1.24 (4H, m). 13C NMR (CDCl3): 169.0, 138.7, 128.3, 127.6, 127.5, 81.2, 72.9, 70.3, 54.0, 29.5, 28.5, 27.9, 27.1, 25.9. HRMS (m/z): [M + Na]+ calcd for C23H36O5Na: 415.2460, found: 415.2447. HPLC purity: acetonitrile/water, 80:20, t r = 17.9 min.

Preparation of Di-Tert-Butyl 2-[5-(Benzyloxy)Pent-1-yl]-2-Methylmalonate (3)

To a suspension of sodium hydride (385 mg, 15.29 mmol) in dry tetrahydrofuran (40 ml) was added 2 (3.0 g, 7.64 mmol) in dry tetrahydrofuran (60 ml) at 0 °C. The solution was stirred at room temperature for 1 h and cooled to 0 °C. Methyl iodide (4.76 ml, 76.43 mmol) was added dropwise over a period of 30 min and the mixture was stirred at room temperature overnight. Then brine (50 ml) was added at 0 °C and reaction mixture was extracted with diethyl ether (3 × 75 ml). The combined organic layer was dried (MgSO4) and the solvent was removed in vacuo. The residue was purified by chromatography on silica gel (pentane/diethyl ether, 95:5) to yield the product 3 as a colourless oil (2.36 g, 76 %). 1H NMR (CDCl3): 7.33–7.26 (5H, m), 4.48 (2H, s), 3.44 (2H, t, 3 J H-H = 6.5 Hz), 1.78–1.74 (2H, m), 1.65–1.58 (2H, m), 1.43 (18H, s), 1.40–1.34 (2H, m), 1.28 (3H, s), 1.27–1.19 (2H, m). 13C NMR (CDCl3): 171.8, 138.6, 128.3, 127.5, 127.4, 80.7, 72.8, 70.2, 54.5, 35.3, 29.6, 27.8, 26.6, 23.9, 19.6. HRMS (m/z): [M + Na]+ calcd for C24H38O5Na: 429.2617, found: 429.2624. HPLC purity: acetonitrile/water, 80:20, t r = 25.1 min.

Preparation of Di-Tert-Butyl 2-(5-Hydroxypent-1-yl)-2-Methylmalonate (4)

Under hydrogen atmosphere (1.3 bars), compound 3 (2.2 g, 5.42 mmol) was stirred overnight in presence of 10 % palladium on activated charcoal (115 mg) in methanol (50 ml). The reaction mixture was filtered off (Millex OR, 0.22 μm) and then the solvent was removed in vacuo to give the product 4 as a colourless oil (1.67 g, 97 %). No further purification was required. 1H NMR (CDCl3): 3.62 (2H, t, 3 J H-H = 6.6 Hz), 1.78–1.74 (2H, m), 1.60–1.53 (2H, m), 1.43 (18H, s), 1.38–1.33 (2H, m), 1.29 (3H, s), 1.27–1.20 (2H, m). 13C NMR (CDCl3): 171.8, 80.8, 62.9, 54.6, 35.3, 32.5, 27.9, 26.1, 24.0, 19.7. HRMS (m/z): [M + H]+ calcd for C17H33O5: 317.2328, found: 317.2331. HPLC purity: water/acetonitrile, 60:40, t r = 8.2 min.

Preparation of Di-Tert-Butyl 2-[5-(Methylsulfonyloxy)Pent-1-yl]-2-Methylmalonate (5)

Under nitrogen atmosphere, methanesulfonyl chloride (294 μl, 3.79 mmol) was added to alcohol 4 (400 mg, 1.26 mmol) in dry pyridine (2 ml). The solution was stirred for 4 h at room temperature. Then, brine (10 ml) was added at 0 °C and reaction mixture was extracted with diethyl ether (3 × 15 ml). The combined organic layer was dried (MgSO4) and the solvent was removed in vacuo. The residue was purified by chromatography on silica gel (100 % dichloromethane) to yield 5 as a colourless oil (490 mg, 90 %). 1H NMR (CDCl3): 4.20 (2H, t, 3 J H-H = 6.5 Hz), 2.98 (3H, s), 1.78–1.71 (4H, m), 1.43 (18H, s), 1.42–1.38 (2H, m), 1.29 (3H, s), 1.28–1.22 (2H, m). 13C NMR (CDCl3): 171.7, 81.0, 69.9, 54.5, 37.4, 35.2, 28.9, 27.9, 25.8, 23.6, 19.7. HRMS (m/z): [M + Na]+ calcd for C18H34O7NaS: 417.1923, found: 417.1909. HPLC purity: acetonitrile/water, 70:30, t r = 10.9 min.

Preparation of Di-Tert-Butyl 2-(5-Fluoropent-1-yl)-2-Methylmalonate (6)

Under nitrogen atmosphere, a tetrabutylammonium fluoride solution in tetrahydrofuran (1 M, 0.55 ml, 0.55 mmol) was added to a solution of mesylate 5 (185 mg, 0.47 mmol) in dry acetonitrile (9 ml) and the mixture was heated at reflux for 3.5 h. Then tetrabutylammonium fluoride in tetrahydrofuran (1 M, 0.25 ml, 0.25 mmol) was further added to complete the reaction and the resulting solution was heated to reflux for 1 h. The reaction mixture was quenched at room temperature with water (20 ml) and the aqueous layer was extracted with diethyl ether (3 × 15 ml). The combined organic layers were dried (MgSO4) and the solvent was removed in vacuo. The residue was purified by chromatography on silica gel (heptanes/ethyl acetate, 95:5) to give 6 as a colourless oil (136 mg, 90 %). 1H NMR (CDCl3): 4.42 (2H, dt, 2 J H-F = 47.3 Hz, 3 J H-H = 6.2 Hz), 1.79–1.62 (4H, m), 1.43 (18H, s), 1.41–1.37 (2H, m), 1.29 (3H, s), 1.28–1.22 (2H, m). 13C NMR (CDCl3): 171.8, 84.5 (1 J C-F = 164 Hz), 80.9, 54.6, 35.2, 30.2 (2 J C-F = 19.7 Hz), 27.9, 25.6 (3 J C-F = 5.6 Hz), 23.8, 19.7. 19F NMR (CDCl3): −218.4. HRMS (m/z): [M + Na]+ calcd for C17H31O4FNa: 341.2104, found: 341.2102. HPLC purity: acetonitrile/water, 80:20, t r = 11.7 min (95 %).

Preparation of 2-(5-Fluoropent-1-yl)-2-Methyl-Malonic Acid (ML-10)

Di-tert-butyl malonate 6 (136 mg, 0.43 mmol) in TFA (8 ml) was stirred for 1 h at room temperature. TFA was removed in vacuo to give ML-10 as a white powder (80 mg, 91 %), mp: 103–105 °C. 1H NMR (CDCl3): 9.83 (2H, bs), 4.43 (2H, dt, 2 J H-F = 47.2 Hz, 3 J H-H = 5.9 Hz), 1.95–1.87 (2H, m), 1.77–1.64 (2H, m), 1.48–1.20 (7H, m).13C NMR (CDCl3): 177.6, 83.9 (1 J C-F = 164 Hz), 54.6, 35.7, 29.0 (2 J C-F = 19.7 Hz), 25.4 (3 J C-F = 5.0 Hz), 24.4, 23.1. 19F NMR (CDCl3): −218.4. HRMS (m/z): [M + Na]+ calcd for C9H15O4FNa: 229.0852, found: 229.0855. HPLC purity: water/acetonitrile/TFA, 70:30:0.1, t r = 11.4 min.

[18F]ML-10 Radiosynthesis Assays

[18F]Fluoride produced by the cyclotron was trapped on an ion exchange resin (Waters QMA light, ABX), separated from 18O-enriched water and eluted with a solution of potassium carbonate. Kryptofix 2.2.2 (6.8 mg, 18 μmol) was added to the [18F]fluoride (35–70 MBq) containing solution of K2CO3 (2.1 mg, 15 μmol). The complex was dried by successive evaporation with acetonitrile at 105 °C under a nitrogen stream. Then a solution of the labelling precursor 5 (4 mg, 10 μmol) dissolved in acetonitrile (1 ml) was added to the dried [K/K222]+ 18 F- complex and the sealed reaction vial was heated for 20 min at 90 ° C. Aliquots (15 μl) were taken at 5, 10, 15 and 20 min, diluted with methanol (200 μl) and subjected to radio-TLC analysis. The radiofluorination yields were determined from radio-TLC (heptanes/ethyl acetate, 90:10) representing the percentage of radioactivity area of the labelled product [18F]-6 related to the total radioactivity. The identity of [18F]-6 was confirmed by TLC comigration and HPLC coelution. Then, hydrochloric acid (500 μl, 3N or 2N) was added to the radiofluorination reaction vessel and the reaction mixture was vigorously stirred at 110 ° C for 20 min. Aliquots (15 μl) were taken at 5, 10, 15 and 20 min and were subjected to radio-TLC analysis after dilution with methanol (200 μl). The hydrolysis of [18F]-6 was followed by radio-TLC. The identity of [18F]ML-10 was confirmed by HPLC coelution.

Radiosynthesis of [18F]ML-10 on the GE Tracerlab FX FN Module

[18F]Fluoride (typically 22 GBq) produced by the cyclotron was trapped on an ion exchange resin (Waters QMA light, ABX), separated from 18O-enriched water and eluted with a mixture of potassium carbonate (2.1 mg, 15 μmol) and Kryptofix 2.2.2 (6.8 mg, 18 μmol) in acetonitrile/water (0.6 ml, 1:1, vial 1). The mixture was heated to 90 °C under reduce pressure. Acetonitrile (0.5 ml, vial 2) was added and the mixture was further heated at 90 °C under reduce pressure. The labelling precursor 5 (4 mg, 10 μmol) in acetonitrile (1 ml, vial 3) was added and the reaction mixture was heated at 90 °C for 15 min. Then, hydrochloric acid (500 μl, 3N, vial 4) was added to the reaction mixture and was stirred at 115 ° C for 15 min. After cooling down to 35 ° C, neutralization solution (1,000 μl, sodium hydroxide 1N/sodium acetate 0.25N, vial 5) was added into the reaction vessel. The reaction mixture was injected in HPLC to perform the purification by reversed phase HPLC (Nucleosil 100-7C18, Macherey-Nagel, 250 × 16 mm, mobile phase: water/acetonitrile/acetic acid, 70/30/0.5; flow rate: 16 ml min−1; t r = 11 min). The collected fraction containing the pure [18F]ML-10 was diluted with water (60 ml) and passed through a solid phase extraction cartridge (Oasis® Plus HLB, Waters). The cartridge was washed with water (10 ml, vial 9). [18F]ML-10 was eluted with ethanol (1.2 ml, vial 8) and diluted with saline (11 ml, vial 7). The radiolabelled product was filtered through a sterile filter (Millex® GP, 0.22 μm, Millipore). The radiosynthesis time was 70-75 min including purification and formulation. Radiochemical yield was 39.8 ± 8.4 % (n = 7) decay-corrected related to the [18F]fluoride.

Quality Control

Aliquot (10 μl) of the [18F]ML-10 final solution was injected on an analytical reversed phase column (Nucleodur 100-5C18 Gravity, Macherey-Nagel, 250 × 4.6 mm, mobile phase: water/acetonitrile/TFA, 70:30:0.1; flow rate: 1 ml min−1; t r = 11.4 min). The radiochemical purity was greater than 99 %. Co-injection of [18F]ML-10 and non-radioactive ML-10 (1 mg/ml) assessed the identity of the radiopharmaceutical with a UV detection at 211 nm.

The pH of the clear and colourless final solution was 5 to 6. The measurement of Kryptofix 2.2.2 concentration was achieved by the colour spot test described by Mock et al. [16] and was less than 0.022 mg/ml. The residual solvent quantification was performed following the GC procedure defined by Klok et al. [17].

LC/MS was performed using a XBridge column (C18, 3.5 μm, Waters, 2.1 × 50 mm) with acetonitrile/water/formic acid (85:15:0.1) as eluent at a flow rate of 0.3 ml/min. The quantification of ML-10 (t r = 4.4 min) was realized by integration at m/z = 207 corresponding to the [M + H]+ ion. Standard solutions (0.1, 0.5, 1, 5 and 10 μg/ml) were injected (3 μl). Samples of the [18F]ML-10 solution were injected (10 μl) to determine their ML-10 concentration. The radioactive concentration was measured by counting the final solution (100 μl) of [18F]ML-10.

Results and Discussion

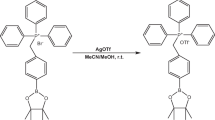

Synthesis of ML-10 as reference as well as the mesyloxy derivative 5 as precursor for labelling with fluorine-18 is described in Scheme 1. Deprotonation of the di-tert-butyl malonate by NaH followed by addition of the 5-bromopentyl benzyl ether 1 [18] gave 2 with a moderate yield of 42 % and the di-addition product in 20 % yield. The deprotonation by NaH of malonate 2 and subsequent addition of a large excess of methyl iodide afforded the intermediate 3. After filtration, the deprotection of the alcohol by catalytic hydrogenation led quantitatively to 4. The fluorination precursor 5 was obtained by reaction with mesyl chloride in pyridine. The synthesis of the non-radioactive ML-10, needed to assess the identification of the radiotracer by HPLC coelution and to establish the specific radioactivity, was envisaged from the labelling precursor 5 by nucleophilic substitution with fluoride or by direct deoxofluorination from alcohol 4.

The direct fluorination of the alcohol 4 by DAST was tested and led to the fluorinated compound 6 in about 20 % yield. Following the procedure described in the Aposense’s patent for ML-10 analogues [19], the fluorination from the mesylate precursor 5 with KF and K2.2.2 in presence of K2CO3 mimicking the conditions used in radiochemistry, led to the fluorinated product 6 in 56 % yield. When the reaction of the mesylate 5 occurred with tetrabutylammonium fluoride (TBAF), the fluorinated intermediate 6 was obtained within 90 % yield. The removal of the tert-butyl protective group with trifluoroacetic acid (TFA) afforded ML-10 quantitatively.

Radiosynthesis of [18F]ML-10 is based on a [18F]fluorine-de-mesyloxy aliphatic nucleophilic substitution and used the activated, no-carrier-added, K[18F]/K2.2.2 complex (Scheme 2). All runs were performed using 10 μmoles of the mesylated derivative 5. The use of small amounts of K2.2.2 (6.8 mg) and potassium carbonate (2.1 mg) compared to classical reaction conditions (22 mg and 7 mg, respectively) gave high [18F]fluoride incorporation yield in acetonitrile (1 ml) at 90 °C. The kinetic of the radiolabelling reaction was studied by radioTLC (Fig. 2). The radiofluorination, leading to [18F]-6 was fast but we observed variations in the radiochemical yield at 5 or 10 min reaction times (see error bars representing the s.e.m. in Fig. 2). The reaction time retained for the automation was 15 min in order to assure a high reliability.

The hydrolysis of the tert-butyl esters of intermediate [18F]-6 to afford [18F]ML-10 was more reliable using HCl at a concentration of 3N than 2N and when it was performed at 115 °C rather than at 90 °C. To simplify the automation of the radiosynthesis, this hydrolysis occurred in a one-pot reaction by direct addition of the hydrochloric acid to the radiofluorination reaction mixture. We tried to perform a prepurification on a solid phase extraction (SPE) on a C18 cartridge before the HPLC injection but the acidic solution was not retained on the C18 phase. The solution was cooled down and buffered by a solution containing sodium hydroxide and sodium acetate to obtain a pH about 4. The mixture was injected onto a reversed phase semi-preparative column using an eluent containing water/acetonitrile/acetic acid (70:30:0.5). The pure fraction containing [18F]ML-10 was collected (retention time: 11 min; 1.2–2.1 min fraction) and diluted with water to eliminate the HPLC eluent by SPE. Different C18 cartridges were tested but led to very weak loading rate of the labelled product on the solid phase. The most efficient one was the Oasis® HLB Plus (Waters) presenting a quantitative loading rate when the product was sufficiently diluted in water (acetonitrile <10 %). [18F]ML-10 was eluted from the SPE cartridge with 1.2 ml of ethanol (European Pharmacopeia (Eur. Ph.) quality excipient) and diluted with saline (11 ml). The final product contained less than 10 % of ethanol. The radiotracer was filtered on a sterile Millex® filter (0.22 μm) with negligible loss of radioactivity.

These conditions were used to realize the automation on a GE Tracerlab FX-FN module. No modification of the module was necessary. The radiosynthesis was performed in 70 min and the radiochemical yield was 39.8 % ± 8.4 % (n = 7) decay-corrected at the end of bombardment. Typically, from 22 GBq of [18F]fluorine produced by the cyclotron, 6 GBq of [18F]ML-10 was obtained. The final solution concentration was around 600 MBq/ml.

Quality control was performed on aliquots of the final solution obtained from the radiosynthesis module before any other dilution. The radiochemical purity of [18F]ML-10 was established by HPLC and was more than 99 % (Fig. 3). The identification of [18F]ML-10 was checked by co-injection and coelution of the radiopharmaceutical with the non-radioactive standard compound ML-10 (1 mg/ml) UV detected at 211 nm. The chemical purity was assessed by the HPLC analysis at 211 nm and was more than 98 % (Fig. 3). No Krytofix 2.2.2 was detected in the solution (<0.022 mg/ml) when the Eur. Ph. limit was 0.22 mg/ml. Acetic acid was chosen for the purification rather than trifluoroacetic acid (TFA) differing from the described procedure [13] to avoid its quantification in the final solution. Using the HPLC-conditions described above, the total amount of acetic acid present in the collected fraction would be about 150 mg. Even if the SPE formulation procedure would not be efficient, an amount of more than 5 mg acetic acid in 10 ml of saline changes significantly the pH of the solution. In consequence, if the pH of the final solution is more than 4, the acetic acid content in the final solution could never reach the Eur. Ph. maximum tolerated amount per administration (50 mg). The measurement of the pH could be used as a good indicator of the presence of large amount of acetic acid. The washing of the cartridge with 10 ml of water permitted to obtain the product containing acetonitrile amounts (30-70 ppm) inferior to the Eur. Ph. limit (420 ppm).

Due to the low UV absorption coefficient of the ML-10, the measurement of the specific radioactivity could not be achieved using a UV detector. Then, we developed a LC/MS method in order to measure a posteriori the specific radioactivity. The radioactivity concentration was determined at the end of synthesis. The following day, the sample of the decayed solution was injected in the LC/MS system to quantify the concentration of 19F-compound. It has to be reminded that the theoretical specific radioactivity of the fluorine-18 is 63,000 GBq/μmol and the usual observed specific radioactivity varies from 35 to 350 GBq/μmol and implies a 180 to 1,800-fold dilution of the fluorine-18 radiolabelled radiopharmaceutical by the stable fluorine-19. In this case, the a posteriori measurement of the concentration of ML-10 would not be significantly changed by the decay of the radioactive component. The LC/MS was performed on a simple quadrupole mass detector and the quantification was made at m/z = 207. The quantification was linear (R 2 = 0.9993) between 0.3 and 30 ng of ML-10 and the sample concentrations were between 1.7 and 9 ng in 10 μl of the final solution. The effective specific radioactivity of the [18F]ML-10 was 235 ± 85 GBq/μmol (n = 7) at the end of synthesis, i.e., 6-fold higher than described by Reshef et al. [13]. The major by-product of the radiosynthesis should result of the elimination of the mesylate leading to the corresponding alkene product. No trace of this compound was observed by LC/MS at m/z = 187.

Conclusions

Herein, we described the synthesis of ML-10 and its mesyloxy derivative as precursor for labelling with fluorine-18. The preparation of radiolabelling precursor was achieved in four steps from commercially available chemicals and obtained in 28 % overall yield. Then, ML-10 was obtained in two additional steps and 88 % yield from the labelling precursor by nucleophilic substitution of the mesylate group using TBAF followed by the removal of the butyl ester protective group with TFA.

The radiosynthesis of the [18F]ML-10 was performed using the commercial GE TracerLab® FX-FN module, which is commonly available in clinical PET centres. The radiosynthesis was realized by a classical nucleophilic substitution from [18F]fluoride followed by an acidic protective group hydrolysis. The HPLC purification and the reformulation by SPE using an Oasis® HLB cartridge afforded pure [18F]ML-10. The radiosynthesis was reliable with good radiochemical yields (25 % non-decay-corrected). The quality control was defined, demonstrated the purity of the radiopharmaceutical and its conformity with a clinical use, and includes a LC/MS method to measure the specific radioactivity.

Moreover, the simple and straightforward radiosynthesis described herein should be readily implemented on other commercially available automated module in a clinical GMP environment.

References

Taylor RC, Cullen SP, Martin SJ (2008) Apoptosis: controlled demolition at the cellular level. Nat Rev Mol Cell Biol 9:231–241

Faust A, Hermann S, Wagner S et al (2009) Molecular imaging of apoptosis in vivo with scintigraphic and optical biomarkers—a status report. Anticancer Agents Med Chem 9:968–985

Blankenberg FG (2008) In vivo imaging of apoptosis. Cancer Biol Ther 7:1525–1532

Blankenberg FG (2008) In vivo detection of apoptosis [proceeding]. J Nucl Med 49(Suppl 2):81S–95S

De Saint-Hubert M, Prinsen K, Mortelmans L, Verbruggen A, Mottaghy FM (2009) Molecular imaging of cell death. Methods 48:178–187

Lahorte CM, Vanderheyden JL, Steinmetz N et al (2004) Apoptosis-detecting radioligands: current state of the art and future perspectives. Eur J Nucl Med Mol Imaging 31:887–919

Nguyen QD, Aboagye EO (2010) Imaging the life and death of tumors in living subjects: preclinical PET imaging of proliferation and apoptosis. Integr Biol (Cambridge) 2:483–495

Michalski MH, Chen X (2011) Molecular imaging in cancer treatment. Eur J Nucl Med Mol Imaging 38:358–377

Haberkorn U, Markert A, Mier W, Askoxylakis V, Altmann A (2011) Molecular imaging of tumor metabolism and apoptosis. Oncogene 30:4141–4151

Aboagye EO (2010) The future of imaging: developing the tools for monitoring response to therapy in oncology: the 2009 Sir James MacKenzie Davidson Memorial lecture [proceeding]. Br J Radiol 83:814–822

Reshef A, Shirvan A, Akselrod-Ballin A, Wall A, Ziv I (2010) Small-molecule biomarkers for clinical PET imaging of apoptosis. J Nucl Med 51:837–840

Cohen A, Shirvan A, Levin G et al (2009) From the Gla domain to a novel small-molecule detector of apoptosis. Cell Res 19:625–637

Reshef A, Shirvan A, Waterhouse RN et al (2008) Molecular imaging of neurovascular cell death in experimental cerebral stroke by PET. J Nucl Med 49:1520–1528

Hoglund J, Shirvan A, Antoni G et al (2011) 18F-ML-10, a PET tracer for apoptosis: first human study. J Nucl Med 52:720–725

Larson S (2010) Newsline, oncology. J Nucl Med 51:19N–25N

Mock B, Winkle W, Vavrek M (1997) A color spot test for the detection of Kryptofix 2.2.2 in [18F]FDG preparations. Nucl Med Biol 24:193–195

Klok RP, Windhorst AD (2006) Residual solvent analysis by gas chromatography in radiopharmaceutical formulations containing up to 12 % ethanol. Nucl Med Biol 33:935–938

Mahidhar YV, Rajesh M, Chaudhuri A (2004) Spacer-arm modulated gene delivery efficacy of novel cationic glycolipids: design, synthesis, and in vitro transfection biology. J Med Chem 47:3938–3948

Ziv I, Shirvan A (2005) NST Neurosurvival technologies Ltd. Perturbed membrane-binding compounds and methods of using the same [patent]. WO/2005/067388

Acknowledgements

We thank O. Tirel for performing the cyclotron irradiation. This work was supported by the “Région de Basse-Normandie” and the “Commissariat à l’énergie atomique et aux énergies alternatives” (CEA).

Conflict of Interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sobrio, F., Médoc, M., Martial, L. et al. Automated Radiosynthesis of [18F]ML-10, a PET Radiotracer Dedicated to Apoptosis Imaging, on a TRACERLab FX-FN Module. Mol Imaging Biol 15, 12–18 (2013). https://doi.org/10.1007/s11307-012-0574-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11307-012-0574-y