Abstract

Root stress is a big problem for lettuce farming in tropical climates, especially temperature root stress. Black root rot, a final stage of the temperature root stress, leads to huge production loss. This paper presents the IoTs based root stress detection system for lettuce cultures. The proposed detection algorithm is based on the leaf energy balance and transpiration patterns. Unlike image sensors based detection methods, leaf energy balance principle and transpiration patterns measured from a lettuce leaf are considered as the key features to address the lettuce root stress conditions. The challenge of detecting lettuce stress by using a leaf sensor is to estimate the non-linear function of stomatal conductance. This paper has clarified the concept of detecting lettuce root stress using the transpiration patterns as well. Graphically, the combination of infrared temperature and light intensity sensors is appropriate to deal with the lettuce root stress detection. The proposed detection algorithm has been designed to detect three conditions of root stress problems: normal, root stress, and black root rot conditions. The infrared sensors are very suitable for the sensitive leaf like lettuce. To evaluate the proposed leaf sensor, the experiments are set up to show that the proposed detection algorithm can accurately detect the temperature root stress in different conditions. Moreover, the detection algorithm based leaf area index (LAI) has been discussed to the proposed detection algorithm. In addition, the performance of the proposed detection algorithm has been compared to the LAI based algorithm. The detection accuracy of the proposed detection method is 95% with different root stress conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With global hunger on the rise again, the food and agricultural organization of the United Nations (FAO) has issued a sobering forecast on world food production. If global population reaches 9.1 billion by 2050, the FAO says that world food production will need to rise by 70%, and food production in the developing world will need to double [1].

To increase the world food production, the agriculture need to be improved the productivity. Especially, the countries located near the earth equator are appropriate to be considered because sunlight at this area is sufficient for making food twelve months a year. According to the lettuce cultures, the farmer can harvest the lettuce for 12 crops. However agriculture in tropical countries is unavoidable to face the strong net radiation caused by the sunlight. The precision sensor solution including the Internet of Things (IoT) is very suitable to be the key of success for modern agricultures.

Precision farming is very important to help the farmer to realize the high quality productivity. Sensor technologies are the best solutions to do this. According to the root stress problem caused by the high temperature root stress, there are two groups of leaf sensor methods: external change based methods and internal change based methods.

Currently, there are various image sensor solutions to realize the precision farming. According to leaf sensor based image solutions, this solution can analyze the plant stress effectively. In 2011, Seelye et al. [2] developed low cost colour sensors for monitoring leaf colour of plant tissues growing in a modified microprogation. In 2017, Thorat et al. [3] introduced an IoT based smart image sensor for leaf disease detection.

In 2018, Okamoto et al. developed plant growth estimation technologies by image analysis based on visible and thermography thermal images captured by cameras in real time and non-destructive leaf and root growth in lettuce hydroponic culture. The study shows that there is a correlation between the leaf area of the lettuce actually harvested and the area length of the root [4].

As discussed above, the image sensor solutions are considered as the external change solutions. These methods rely on the image information 2D or 3D information to analyze the plant stress. The image sensor solution is suitable for the stress that can analyze the leaf external information like leaf color, leaf area index (LAI), and leaf emotion and so on. The limitation of using the leaf external information is when these applies to analyze the root stress situation caused by high temperature root stress, the detection accuracy would be significantly decrease because the external change is so rough compared to plant transpiration and leaf temperature change. Thus internal change based leaf sensor methods have been introduced to be the best solutions for detecting and analyzing the plant stress caused by the internal change like root stress.

To detect the plant water status, a microwave method was introduced in 2006 as a novel method. The microwave sensor has been developed for precisely detecting plant water status or diagnosing water stress in plants. It is based on a microwave sensor, which contains a resonant cavity. Comparing to the methods introduced previously this method detects the plant water status more directly. It does not need a fusion sensor to measure more than one parameter to determine the plant water status. So it is more convenient and accurate than other methods. In 2016, an alternative solution of leaf sensor based on microwave sensor was presented by E. Pievanelli et al. The leaf wetness sensor is realized connecting the horn antenna to two transceivers by a 3-port circulator. Measuring the ratio between transmitted and received signal is possible to evaluate the reflector coefficients and consequently the wetness [5, 6].

Recently, remote sensing technologies have been presented for large area precision agricultures. Leaf area index (LAI) and leaf temperature have been introduced as the important biophysical parameters for estimating gas exchange, crop yields, and root stress for the precision agricultures.

Leaf area index (LAI) is an important vegetation biophysical parameter to estimate gas-vegetation exchange process. The airborne discrete-return light detection (LiDAR) based solution can estimate the LAI of low-statue vegetation, such as the maize [11]. However, the achievement of this technique has to complete with Beer-Lambert law and the algometric relationship. Thus, the LiDAR offers the possibility to characterize the 3-D variation of LAD over space [12]. In addition, the problem of LAI is that the saturation is possible to occur in the nadir direction, and vary with crop canopy structure and view zenith angles. To overcome this issue, the multi-angular remote sensing was presented to improve the monitoring accuracy and stability of VIs [13].

In 2017, Jin et al. developed a theoretical model based on physical energy balance equations and remote sensing data to evaluate heavy-metal stress in rice. Canopy temperature and LAI were used as the useful features to detect the heavy metal stress. Three extreme states of heavy-metal stress in rice were analyzed to be three states [7]. The hyperspectral based remote sensing method has been introduced for identifying of pathogen discrimination in coffee plants [14]. In [15], the simplified version of the boundary leaf resistance was presented to reduce the thickness of leaf lamina boundary layer so that the parasite population is rare filed.

Besides the remote sensing applications, the difference of leaf and air temperatures has been considered as the biophysical parameter for wireless sensor network (WSN) applications. In 2018, Daskalakis et al. develop the leaf sensor which used for the first time ambient backscattering over analog modulated (FM) signals. The leaf sensor is based on an ultra-low power microcontroller. Ambient backscattering has the potential to be the next new primitive approach for extremely low power communication [8].

The chlorophyll fluorescence (ChF) detection methods have been presented to be suitable for detecting the plant stress as an internal change principle. The principle of ChF method is very useful for detecting leaf stress especially nutrient stress and abiotic stress. The limitation of ChF method is that some techniques need the dark environment to analyze the plant stress. This is suitable as an alternative method [9, 10].

This paper presents the IoTs based root stress detection system for lettuce cultures. The proposed detection algorithm is based on the leaf energy balance principle and transpiration patterns. Unlike image sensors based detection methods, transpiration patterns derived from a lettuce leaf are considered as the key features to address the lettuce root stress conditions. The challenge of detecting lettuce stress by using a leaf sensor is to estimate the non-linear function of stomatal conductance. This paper has clarified the concept of detecting lettuce root stress using the transpiration patterns as well.

2 Materials and Methods

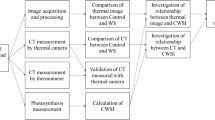

As discussed in the literatures, this section explains the details of the leaf sensor development. The concept of development starts with the overall precision detection system. Figure 1 shows the overall system of the IoT based root stress detection. In order to early detect the lettuce root health in real-time, the system consists of four parts (1) people, (2) cloud, (3) lettuce culture and (4) sensors. Lettuce is one kind of vegetable that consumes low levels of fertilizer. Its leaf thickness is not largely. Thus leaf sensors need to design as an infrared leaf sensor. We cannot attach any kind of disguised material to the leaf. Otherwise our sensors would be major cause of lettuce stress.

The sensor module as shown in Fig. 1 consists of internal change based sensor like infrared temperature sensor. Light intensity sensor is used to analyze the relationship among the heat radiation, internal change in lettuce plant and light intensity. The ChF sensor is an optional sensor to be a second opinion sensor for analyzing the other kinds of lettuce stress.

The communication of each module can be realized by WiFi connection via cloud platform.

2.1 The Concept of the Root Stress Detection by the Leaf Sensor

The principle of the proposed leaf sensor is based on energy balance principle as shown in Fig. 2. The net radiation Rn is balanced by sensible heat H and latent heat \(\uplambda {\text{E}}\) as expressed in Eq. (1). In Eq. (2), Qa is the radiative forcing, defined as the sum of absorbed solar radiation and incident longwave radiation. Longwave radiation is emitted by the leaf in proportion to its temperature (Tleaf, °C) raised to the fourth power. Sensible heat is exchanged between the leaf and air temperature (Tair, °C) in proportion to the temperature difference divided by a diffusion resistance (\(r_{H}\), sm−1). Similarly, latent heat is exchanged in relation to the vapor pressure deficit (VPD) between the leaf and the surrounding air divided by a diffusion resistance (\(r_{W}\), sm−1) [16].

The transpiration rate depends on the total resistance \(r_{W}\) (actually the sum of the stoma resistance and the boundary layer resistance) as expressed in Eq. (3). In Eq. (4), Vapor pressure deficit (VPD) can be calculated by the leaf temperature, the air temperature, and relative humidity RH [17]. The transpiration E can be expressed in function of VPD, and stomatal conductance gsw as in Eqs. (5) and (6).

where \(g_{sW}\) is the stomatal conductance, BP is the barometric pressure in kPa (101.3 at sea level).

Since stomatal conductance \(g_{sW}\) in Eq. (6) is a non-linear function, transpiration E is so difficult to determine the exact values, especially during plant stress. When a lettuce faces to temperature root stress caused by high net radiation, abscisic acid (ABA) hormones are generated and mixed into the water and nutrient via xylem as shown in Fig. 3. The ABA hormones affecting to the change of stomatal conductance, thus the latent heat decrease as well [18, 19]. Moreover, the change of stomatal conductance caused by the temperature root stress affects to the decrease of the latent heat according to Eq. (3). Thus the difference of leaf and air temperature DTLA, VPD, and E would also significantly change as well.

Figure 4 shows the patterns of transpiration and the difference of leaf and air temperature, DTLA. DTLA is the key features of the proposed leaf sensor to detect the root stress. In addition, the patterns of transpiration rate in different conditions of lettuce root would be a main feature for early detecting the root stress.

Transpiration patterns of green oak lettuce a transpiration patterns in different stress conditions, b the difference of leaf temperature and air temperature (DTLA) in different stress conditions, c a green oak with root stress, d green oak with temperature root stress and e green oak with black root rot

During the normal condition (no root stress), the transpiration patterns, DTLA, and the lettuce image are shown in Fig. 4a–c, respectively. When the lettuce faces to root stress, the transpiration patterns, DTLA patterns, and the lettuce image become the line (b) in Fig. 4a, b, respectively. The lettuce image during root stress is shown in Fig. 4d. The black root rot situation, final stage of root stress, the transpiration pattern and DTLA become the line (c) as shown in Fig. 4a, b, respectively. The lettuce image with black root rot damaged by temperature root stress caused by high net radiation is shown in Fig. 4e. This is impossible to compensate back to the normal condition or even the stress condition.

2.2 The Detection Algorithm

After clarifying the concept of stress detection, the detection algorithm would be explained in this section. According to Eq. (6), the difference of leaf and air temperatures DTLA, light intensity LX, are used to be the inputs of the proposed detection algorithm. The LXA and LXB related to the saturated transpiration of green oak lettuce for tropical climates. In this paper, the LXA and LXB are set to be 20,000 lux and 73,000 lux, respectively [20]. The basic concept of the detection algorithm is to divide the patterns into three regions related to the amount of the net radiation. The light intensity LX is thresholded by LXA and LXB values as shown in Fig. 5b. Thus, there are three regions to be considered, R1, R2, and R3 as shown in Fig. 5c, d. These regions would be represented the region area of each part related to the different levels of net radiation. R1 is the region that the light intensity LX gradually increases. The latent heat and transpiration rate would also increase. When a lettuce is healthy (no temperature root stress), \(g_{sW}\) has no effect of ABA. Thus DTLA is the negative value. When LX is beyond LXB, the decrease of \(g_{sW}\) and E depends on the conditions of stress according to Fig. 4b. The change of \(g_{sW}\) caused by ABA hormones affecting to the change of latent heat, transpiration patterns, and DTLA inevitably. Figure 5a shows the flowchart of the detection algorithm. There are four steps (steps 1–4) of DTLA determination. The decision making is based on DTLA patterns according to Fig. 5e.

2.3 Sensor Implementation

The concept of the leaf sensor that can be able to detect the root stress is shown in Fig. 6. The infrared temperature sensor and the controller would be in the bottom side of the leaf sensor. The light intensity sensor and the display are on the top-side of the leaf sensor. In case of long time monitoring, the solar panel, battery charger and battery are employed as the DC power supply for the sensor system.

To realize the proposed concept for internal change detection, the concept of leaf sensor has been designed as shown in Fig. 7. Figure 7a is the tested circuit of IoT based leaf sensor. The prototype of the proposed leaf sensor is shown in Fig. 7b and 7c, respectively.

As shown in Fig. 7a, b, the prototype of leaf sensor has been designed with OLED display. Thus a user can use it as a portable sensor without WiFi connection to manually detect the lettuce root stress in field test as well. The lists of hardware components and software are shown in Tables 1 and 2, respectively.

3 Experimental Results

To evaluate the proposed root stress detection system, the experiments are set up to measure the difference of leaf temperature TL and air temperature TA at root temperature 30 °C, 40 °C, 50 °C and 60 °C. The ambient temperature is controlled to be between 28 °C and 32 °C. As discussed previously, the internal change of lettuce leaf would be able to detect with the proposed detection system. In Sect. 3.1, the difference of TL and TA vs light intensity (lux) are shown.

To realize the performance of the proposed root stress detection system, the samples of 24 hydroponic lettuces have been tested in different root temperatures. The weight per plant of green oak and red oak is 1.2 g and 1.0 g respectively. The reason of selecting the hydroponic lettuce is easy to evaluate lettuce root health. Root color based method is the alternative way to evaluate the temperature root stress conditions. The clear white, light brown and black represent no stress, temperature root stress, and black root rot, respectively. However the proposed detection methods can be applied to both organic and hydroponic cultures.

3.1 Difference of TL and TA (DTLA) Versus Light Intensity

The objective of this experiment is to show that the difference of leaf temperature TL and ambient temperature TA can be determined by using the proposed detection system. The TL and TA in different root stress conditions are compared to light intensity. The experimental results show that the internal changes in difference of TL and TA relate to the heat radiation affecting by sunlight. The representative of the heat radiation from sunlight is measured by using the light intensity sensor (lux).

According to Fig. 8, Fig. 8a–d is the experimental results of green oak. When the root temperature increases, the different trends of TL and TA are higher (more positive). Figure 8e–h is the experimental results of red oak. Noticed that red oak is more sensitive than green oak comparing to the same level of root temperature. Tables 3, 4 and 5 shows experimental data used to plot Fig. 8.

3.2 The Comparison Between the Proposed Detection and the LAI Method

In order to evaluate the detection performance of the proposed detection system, the internal change detection and the external change detection would be explained in more details. Figure 9 shows the comparison of the internal change and external change. When the root temperature is at 60 °C, the difference of TL and TA (DTLA) has been significantly changed in different light intensity 500 lux, 3500 lux and 54,000 lux. This means that the lettuce root was affected by the temperature root stress. According to the external change feature, the red oak leaf was still fresh except two leaves in the dash circle that gradually started to wilt. Thus the external change features are more difficult to implement the early stage detection of lettuce root stress.

Figure 10 shows the experimental results of LAI based detection method with green oak by using Easy Leaf Area application for a smartphone. The LAI value of no stress green oak is 174.24 cm2 as shown in Fig. 10a. After facing temperature root stress at 55 °C, the LAI value of green oak significantly reduces by 20% (141.96 cm2), approximately. Table 6 shows the results of the LAI tests with 20 lettuces of green oak. The response detection time of the proposed method and the LAI method are 5 min and less than 60 s, respectively.

In practical, the response time of the detection system considerably affects to losing of crop yields. The response time of LAI method is equal to 5 min, approximately. This is not sufficient to early detect the temperature root stress. On the other side, the response time of the proposed detection system is less than 30 s. This is sufficient to early detect the temperature root stress for compensation in real-time.

4 Discussion

According to the experimental results, the difference of TL and TA in case of green oak and red oak in root temperature at 30 °C is very interested. Basically, the requirement of red oak in term of light intensity (lux) is lower than green oak. Normally, light intensity for green oak lettuce cultures is around 40,000–70,000 lux. The red oak cultures need only 30,000–50,000 lux approximately. This is the reason that red oak is more sensitive than green oak in term of root temperature increase. The comparison between green oak and red oak in term of root temperature is shown in Table 7. Figure 11 shows the internal change of red oak and green oak.

Figure 12 shows the detection error of the proposed root stress detection system. Basically, when the root temperature is at 60 °C, the difference of TL and TA should be close to zero or positive. In this case the difference of TL and TA is − 7.5. This is because of the limitation of the proposed detection system cannot effectively detect the leaf temperature when the leaf is wet. In practical, the lettuce cultures in tropical climate areas would compensate relative humidity RH by using foggy system. However, the foggy pressure and duration are recommended to be lower than 70% of RH. The measurement position of infrared temperature sensor should select a leaf in the vertical direction to avoid the dropped water on the leaf.

5 Conclusion

This paper presents the root stress detection system based on internal change detection using a novel leaf sensor system. The energy balance principle, stomatal conductance and lettuce leaf transpiration in different light intensity conditions are considered as the internal change features for detecting the lettuce root stress. The real-time detection system realized by IoT based controller has been implemented to monitor the internal change of lettuce culture. The experimental results show that the real-time monitoring of the TL and TA in different light intensity condition leads to effective detection for the lettuce root stress situation affected by root temperature increased. Moreover the internal change based root stress detection can be applied to different types of lettuce.

References

Roser, M., & Ortiz-Ospina, E. (2017). World population growth (online). https://ourworldindata.org/future-population-growth. Accessed 20 March 2019.

Seelye, M., Gupta, G. S., Bailey, D., & Seelye, J. (2011). Low cost colour sensors for monitoring plant growth in a laboratory. In IEEE international symposium on instrumentation and measurement technology (pp. 1–6).

Thorat, A., Kumari, S., Valakunde, N. D. (2017). An IoT based smart solution for leaf disease detection. In IEEE international conference on big data, IoT and data science (BID) (pp. 193–198).

Okamoto, T., et al. (2018). An image analysis method for lettuce leaf and root growth analysis in hydroponic culture. In IEEE international conference on region 10 (TENCON2018) (pp. 467–470).

Wang, W., Huang, M., Yang, J., & Zong, R. (2006). Precise diagnosis of water stress in plants based on microwave sensor. In IEEE international conference on information acquisition (pp. 1163–1167).

Pievanelli, E., Stefanelli, R., & Trinchero, D. (2016). Microwave-based leaf wetness detection in agricultural wireless sensor networks. In IEEE international conference on sensors applications symposium (SAS) (pp. 1–4).

Jin, M., & Lui, X. (2017). Evaluating heavy-metal stress levels in rice using a theoretical model of canopy-air temperature and leaf area index based on remote sensing. IEEE Transactions on Selected Topics in Applied Earth Observations and Remote Sensing, 10(7), 3232–3242.

Daskalakis, S. N., et al. (2018). A uW backscatter-morse-leaf sensor for low-power agricultural wireless sensor networks. IEEE Transactions on Sensors Journal, 18(19), 7889–7898.

Gull, C., Minkov, M. T., Pereira, E. G., & Nacif, J. A. (2016). A low-cost chlorophyll fluorescence sensor system. In IEEE conference on Brazillian symposium on computing systems engineering (SBESC) (pp. 186–191).

Puengsungwan, S., & Jirasereeamornkul, K. (2018). IoT based detection for organic lettuce farms using chlorophyll fluorescence (ChF). In The 6th global wireless summit (GWS-2018) (pp. 354–357).

Nie, S., et al. (2016). Estimating leaf area index of maize using airborne discrete—return LiDAR data. IEEE Transactions on Selected Topics in Applied Earth Observations and Remote Sensing, 9(7), 3259–3266.

Dutta, D., et al. (2017). Characterizing vegetation canopy structure using airborne remote sensing data. IEEE Transactions on Geoscience and Remote Sensing, 55(2), 1160–1178.

Xie, Q., et al. (2016). Estimating winter wheat leaf area index from ground and hyperspectral observations using vegetation indices. IEEE Transactions on Selected Topics in Applied Earth Observations and Remote Sensing, 9(2), 771–780.

Martins, G. D., et al. (2017). Detecting and mapping root-knot nematode infection in coffee crop using remote sensing measurements. IEEE Journal of Selected Topics in Applied Earth Observations and Remote Sensing, 10(12), 5395–5403.

Makhlouf, S., et al. (2016). Hot wire sensor-based data acquisition system for controlling the laminar boundary layer near plant leaves within a greenhouse. IEEE Transactions on Sensors, 16(8), 2650–2657.

Bonan, G. B. (2008). Ecological climatology concepts and applications (pp. 229–236). Cambridge: Cambridge University Press.

Pipitsunthonsan, P., et al. (2018) Leaf sensor for stomata transpiration monitoring using temperature and humidity. In IEEE international conference on wireless personal multimedia communications (pp. 252–255).

Kitano, M., et al. (1995). Evaluation of leaf boundary layer conductance of a whloe plant by application of abscisic acid inhibiting transpiration. Journal of Biotronics, 24, 51–58.

Hartung, W., Sauter, A., & Hose, E. (2002). Abscisic acid in the xylem: Where does it come from, where does it go to? IEEE Transactions on Experimental Botany, 53(366), 27–32.

He, J., Lee, S. K., & Dodd, I. C. (2001). Limitations to photosynthesis of lettuce grown under tropical conditions: Alleviation by root-zone cooling. IEEE Transactions on Experimental Botany, 12, 1323–1330.

Acknowledgements

This paper would not have accomplished without the assistance, support and guidance of so many people who have contributed in making this research possible especially Hydroinhome Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Puengsungwan, S., Jirasereeamornkul, K. IoT Based Root Stress Detection for Lettuce Culture Using Infrared Leaf Temperature Sensor and Light Intensity Sensor. Wireless Pers Commun 115, 3215–3233 (2020). https://doi.org/10.1007/s11277-020-07219-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11277-020-07219-z