Abstract

With rapid technology progress and cost reduction, clean hydrogen from water electrolysis driven by renewable powers becomes a potential feedstock for CO2 fixation by hydrogen-oxidizing bacteria. Cupriavidus necator (formally Ralstonia eutropha), a representative member of the lithoautotrophic prokaryotes, is a promising producer of polyhydroxyalkanoates and single cell proteins. This paper reviews the fundamental properties of the hydrogen-oxidizing bacterium, the metabolic activities under limitation of individual gases and nutrients, and the value-added products from CO2, including the products with large potential markets. Gas fermentation and bioreactor safety are discussed for achieving high cell density and high productivity of desired products under chemolithotrophic conditions. The review also updates the recent research activities in metabolic engineering of C. necator to produce novel metabolites from CO2.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

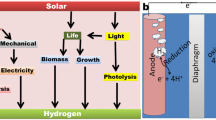

Carbon dioxide (CO2) from fossil fuel combustion has caused concerns over climate change and ocean acidification. Production of value-added products from CO2, especially those with large potential markets, could help reducing the greenhouse gas emission (Hunt et al. 2010). Hydrogen-oxidizing bacteria are primary biomass producers and play a role in the natural carbon cycle (Huber and Eder 2006). The chemolithotrophic prokaryotes use hydrogen (H2) as energy source to fix CO2 and produce value-added products including bioplastics, hydrogenases, animal feed additives, functional chemicals, liquid fuels, and so on. Clean hydrogen, in contrast to the hydrogen derived from fossil resources, is generated from water electrolysis driven by renewable powers (Ziogou et al. 2012). With rapid technology progress and cost reduction, clean hydrogen could be an inexpensive feedstock of a novel biorefinery that produces value-added products from CO2 (Nowotny et al. 2014).

Hydrogen-oxidizing bacteria (Knallgas bacteria) is a physiologically defined but phylogenetically diverse group of bacteria that can utilize H2 as electron donor and O2 as electron accepter for CO2 fixation (Aragno and Schlegel 1981). They are found in diverse habitats including marine sediments, hot springs and soils (Bae et al. 2001; Spear et al. 2005; Florentino et al. 2012). Synergistic relationship based on hydrogen exchange has been suggested to explain the presence of hydrogen-oxidizing bacteria in the environments (Florentino et al. 2012). Most of H2 produced in the anoxic habitats is immediately consumed and only little H2 gas enters the oxic environment where hydrogen-oxidizing bacteria thrive (Conrad 1996). The chemoautotrophs have therefore developed an ability to use the very little amount of hydrogen and become facultative to use organic carbon as the carbon and energy source.

Cupriavidus necator

Cupriavidus necator is a Gram-negative facultative hydrogen-oxidizing bacterium that populates soil and fresh water habitats at the aerobic-anaerobic interface and belongs to the class Betaproteobacteria, order Burkholderiales. The taxonomic position and the name of this taxon have been changed several times

Hydrogenomonas eutropha, Alcaligenes eutrophus, Ralstonia eutropha and Wautersia eutropha (Vandamme and Coeyne 2004). Ralstonia eutropha and C. necator are now used interchangeably. A type strain (H16) of C. necator was isolated from soil almost 60 years ago (Schlegel et al. 1961). Since then, it has become the most-studied hydrogen-oxidizing bacterium with the best characterized genome (Pohlmann et al. 2006). Proteomics and metabolomics analysis have been conducted under heterotrophic conditions (Lee et al. 2006; Schwartz et al. 2009; Peplinski et al. 2010), while less information is available under autotrophic conditions (Alagesan et al. 2018).

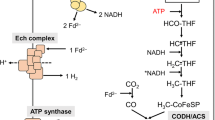

Cupriavidus necator H16 fixes CO2 via the Calvin–Benson–Bassham (CBB) cycle under aerobic conditions with hydrogen as the sole source of energy and reducing equivalents (Badger and Bek 2008). Genes for the CBB cycle are found in two operons located in chromosome 2 and megaplasmid (Bowien and Kusian 2002). The transcription of both cbb operons is controlled by a transcription regulator CbbR in response to the intracellular level of phosphoenolpyruvate as the carbon-state of the cell (Grzeszik et al. 2000). Under mixotrophic conditions, the carbon flux through the CBB cycle is affected by the organic substrates, ranging from complete repression in the presence of pyruvate and malate to a significant carbon flux in the presence of glycerol (Alagesan et al. 2018). A recent study reveals that the transcription control of both cbb operons appears to be more complex and, in addition to CbbR, involves transcription of regulator RegA as part of the global transcription regulation system (RegA/RegB) (Gruber et al. 2017).

Cupriavidus necator is one of the most prominent producer of poly-3-hydroxybutyrate (P3HB) from CO2 (Tanaka et al. 1995; Volova et al. 2013a). P3HB is a member of polyhydroxyalkanoates (PHAs) that are formed as inclusion bodies for carbon and energy storage as shown in Fig. 1. Under nutrient limitation such as nitrogen, C. necator has a strong ability to direct its carbon flow towards P3HB synthesis (Fig. 2). The biopolyester content can be up to 85% of the dry cell mass (DCM) under nutrient control (Volova et al. 2013a). The phbCAB operon encodes three key enzymes in P3HB synthesis: (i) β-ketothiolase (phaA) that condenses two molecules of acetyl-CoA to acetoacetyl-CoA, (ii) NADPH-dependent acetoacetyl-CoA (phaB) that reduces acetoacetyl-CoA to R(-)-3-hydroxyburyryl-CoA, and (iii) PHB synthase (phaC1) that catalyzes the polymerization of R(-)-3-hydroxybutyryl-CoA (Pohlmann et al. 2006). Induced by sufficient nutrients and limited carbon source, P3HB is hydrolyzed to 3-hydroxybutyrate by depolymerases and the stored carbon is returned to the main metabolism pathway as shown in Fig. 2 (Volova et al. 2013b).

Value-added products

Polyhydroxyalkanoates

P3HB is a homopolyester of R-(-)-3-hydroxybutyrate and a truly biodegradable polymer that can be completely utilized by microbial species in the environments. The weight-average molecular weight (Mw) of P3HB formed by C. necator on CO2 ranges from 600 to 900 kDa (Volova et al. 2013b). Because of the high stereoregularity in structure, P3HB has a high crystallinity (65–75%), resulting in a rigid plastic (Laycock et al. 2013). Its mechanical properties are similar to those of polypropylene, but with a relatively low ductility. The material ductility can be improved by introducing co-monomers such as 3-hydroxyvalerate (3HV), 3-hydroxyhexanoate (3HHx), 4-hydroxybutyrate (4HB) and 4-hydroxyvalerate (4HV) into the polyester backbones (Volova et al. 2013a; Park et al. 2014; Ghysels et al. 2018). The microbial cells, however, need organic precursors such as valeric acid, hexanoic acid and γ-butyrolactone to form copolymers under the mixotrophic conditions. Because of the excellent biodegradability, PHA bioplastics can find various environmentally friendly applications (Bugnicourt et al. 2014). The biomaterials may also find advanced medical applications, such as in drug delivery systems, wound management, and tissue repair (Luef et al. 2015). In situ and in vivo tests have demonstrated the biocompatibility and low toxicity of P3HB (Valappil et al. 2006).

Chemicals and liquid fuels derived from P3HB

P3HB is a platform material from which small functional chemicals can be derived such as 3-hydroxybutyric acid, crotonic acid, acetoacetic acid and 1,3-butanediol (Yu 2014). 3HB can be produced through catalytic hydrolysis of P3HB (Yu et al. 2005) and is an intermediate of lipid metabolism in human body. It may find potential applications in control of eating behavior and neuronal diseases (Laeger et al. 2010). 3HB is also a chemical chaperone capable of protecting enzymes such as lipase and lysozyme from adverse effects of high temperature and oxidation (Obruca et al. 2016). 3HB provides a better enzyme protection than the classical chaperones such as trehalose and hydroxyectoine. Crotonic acid or 3-methylacrylic acid can be obtained with a high yield (> 99 wt%) via catalytic degradation of P3HB (Ariffin et al. 2010). Crotonic acid is a key intermediate in catalytic refining of P3HB into a hydrocarbon oil (Kang and Yu 2015a). On a solid phosphoric acid catalyst, P3HB (87–98 wt% purity) was converted into hydrocarbons (C6–C16) through decarboxylation and deoxygenation in a one-pot reaction (Kang and Yu 2015b). Drop-in liquid fuels can be conveniently obtained from the high quality oil to replace gasoline and biodiesel. The liquid fuels have a very large market and hence benefit to greenhouse gas mitigation. The hydrocarbon oil contains primarily alkenes and benzenes from which organic solvents can be obtained (Kang and Yu 2015a).

Proteins, lipids and bio-oils derived from residual cell mass

Cupriavidus necator H16 was considered as a source of single cell protein in the 1970s (Calloway and Kumar 1969). Almost 93% of bacterial protein is digestible by animals and the concentrations of certain important amino acids are similar to those in casein. There is a renewed interest in using P3HB as a component of animal feed to increase the energy content (Defoirdt et al. 2009; Boon et al. 2010; Kunasundari et al. 2013). The animal feed containing whole bacterial cells and P3HB granules may modulate the gut flora by delivering 3-hydroxybutyric acids (Boon et al. 2010). The short chain fatty acids may be a type of new biocontrol agents for sustainable animal production (Defoirdt et al. 2009). The excretion of P3HB in the fecal pellets was a concern when the primary objective was to increase the energy content of animal feed. The animal digestion of residual cell mass (RCM) is suggested for recovery of P3HB from the bacterial cell mass (Kunasundari et al. 2013).

Cupriavidus necator H16 contains all genes necessary for the de novo fatty acid synthesis via the β-oxidation pathway (Brigham et al. 2010). Under chemolithotrophic conditions, the amount of total lipids is 7.8% of the RCM, excluding P3HB (Zhila et al. 2015). The fatty acid composition of cytoplasmic membrane changes as the cell growth shifts from an active phase to a stationary phase. The mass ratio of saturated FAs to unsaturated FAs increases from 0.8 to 4.9, resulting in a change of membrane fluidity (Zhila et al. 2015). After P3HB was removed from the DCM of C. necator growing on CO2, the RCM contained carbon (45.1 wt%), hydrogen (6.3 wt%), oxygen (27.8 wt%), nitrogen (12.9 wt%) and ash (8.0 wt%) (Kang and Yu 2015c). The RCM was liquefied in subcritical water (300 °C) into two groups of products: a crude oil that was recovered with methylene dichloride and hydrophilic compounds that were left in the aqueous solution. The bacterial crude oil was similar to the bio-crudes derived from microalgae biomass, and had a higher energy content than the bio-crude derived from cellulosic biomass (Kang and Yu 2015c). The hydrophilic hydrolysates solution contained a large amount of organic nitrogen and was found a good source of nutrients for C. necator growth under chemolithotrophic conditions.

Oxygen-resistant hydrogenases

Three physiologically different [NiFe]-hydrogenases have been identified in C. necator H16: membrane-bound hydrogenase (MBH), cytoplasmic soluble hydrogenase and cytoplasmic soluble regulatory hydrogenase (Burgdorf et al. 2005). They are good source of oxygen-resistant hydrogenases with potential applications in biofuel cells and biosensors (Mertens and Liese 2004). The soluble hydrogenase favors reversible hydrogen oxidation in vivo and its activity has been demonstrated on a polymyxin-coated electrode surface under a potential of 550 mV (Jugder et al. 2016). The enzymes can directly transfer electrons to or from electrodes to reduce the kinetic hindrance in the conventional mediated electron transfer (Rasmussen et al. 2016). The MBH from hydrogen-oxidizing bacteria is a distinctive oxygen-tolerant enzyme that can perform electrocatalytic H2-oxidation in a high oxygen atmosphere (Yoon et al. 2011).

Metabolic engineering for novel metabolites

The utilization of C. necator as a single cell factory is not limited to the synthesis of P3HB or derivatives thereof. The ability of the organism to assimilate CO2 to high cell density and direct the carbon flow to P3HB under nutrient control can be utilized to produce novel metabolites (Müller et al. 2013; Torella et al. 2015; Przybylski et al. 2015). A new host (H16 ΔphaCAB) was generated by deleting the PHA operon from parent strain C. necator H16, and a synthetic pathway was rationally designed and expressed in the C. necator mutant to efficiently divert carbon flux from P3HB to isopropanol production (Grousseau et al. 2014). Up to 216 mg/L of isopropanol was produced by the engineered strain from CO2 and H2 (Torella et al. 2015). With the development of genetic engineering tools in C. necator, the number of novel chemicals that can be produced from CO2 is increased, including: up to 3.2 g/L of 2-hydroxyisobutyric acid (Przybylski et al. 2015), 80 mg/L of methyl ketones (Müller et al. 2013), 4.4 mg/L of alkan(e)s (Crépin et al. 2016), and 100 mg/L of isobutanol with an electromicrobial conversion of CO2 (Li et al. 2012). One issue that has to be considered when producing the novel metabolites by engineered strains is the toxicity of the chemicals. In order to raise the isopropanol titer, for example, groESL chaperons were searched and identified. Overexpression of the native groEL and groES genes led to a better tolerance of the strains towards exogenous isopropanol (Marc et al. 2017).

Gas fermentation

Gas mass transfer and uptake rates

One major goal of gas fermentation is to obtain high productivity of desired products, which often requires a high cell density (Tanaka et al. 2011). Because the gas substrates, especially hydrogen and oxygen, are poorly soluble in aqueous solution, the concentration of cell mass and/or products is very much dependent on the gas mass transfer rates, or volumetric mass transfer coefficients (kLa) of individual gases. Numerous correlations are available for the value of oxygen kLa (Garcia-Ochoa et al. 2010). In the same bioreactor, hydrogen has a higher kLa than oxygen because of its smaller molecular size and higher diffusivity in water. The ratio of hydrogen kLa to oxygen kLa is 1.47, very close to the square root of the ratio of two gas diffusion coefficients (Lu and Yu 2017b). With sufficient nutrients and little P3HB formation, the maximum DCM concentration of a C. necator strain increased with oxygen kLa: 9.5 gDCM/L at 180 h−1 and 18.5 gDCM/L at 400 h−1 (Lu and Yu 2017b). The DCM concentration was also dependent on the accumulation of P3HB under different nutrient control strategies. It was maximized to 48 g/L at a kLa of 450 h−1 with a very high P3HB content (85%) and a low RCM concentration (7.2 g/L) (Volova et al. 2013a). In a laboratory bioreactor with a basket-type agitator, the oxygen kLa could be increased up to 2970 h−1, generating 91 g/L DCM with 68% of P3HB (Tanaka et al. 1995).

During a gas fermentation, the cell density increased with time and one gas became the limiting substrate with its dissolved concentration approaching zero (dC ≈ 0), while the dissolved concentrations of other gases were kept relatively high (Lu and Yu 2017a). The microbes might be exposed to the conditions of oxygen limitation or hydrogen limitation, depending on the gas composition. Under oxygen limitation (dO2 ≈ 0), the hydrogen uptake rate reached a maximum level of 200 mmol H2 L−1 h−1, and the molar ratios of consumed gases H2/CO2 and O2/CO2 were 7.3 and 2.4, respectively. The numbers indicated that about 66% of H2 was oxidized for energy supply and 34% used as the reducing agents in CO2 fixation. The aerobic strain, however, suffered from oxygen limitation and its respiration activity declined quickly with time. Under hydrogen limitation (dH2 ≈ 0), the respiration activity was kept at the high level for quite long time, because of very high affinity of hydrogenases to hydrogen. However, the molar ratio of the consumed gases H2/CO2 was increased to ca. 10, indicating that more hydrogen was used for energy supply. It might reflect some adverse effect of high dissolved oxygen concentration on CO2 fixation efficiency (Yu et al. 2013). It is well known that the wasteful oxygenase activity of Rubisco results in a futile cleavage of Ru1,5P into 2-phosphoglycolate and formation of CO2 (Berg 2011).

Limitation of CO2 and other nutrients

Compared to H2 and O2, CO2 has a relatively high solubility in water. Its predominant form around pH 7, however, is bicarbonate (CO2 + H2O ↔ HCO3− + H+). Since free CO2 is the substrate of Rubisco, it may become the limiting substrate under a low partial pressure (1% mol CO2). Under CO2 limitation (dCO2 ≈ 0), the molar ratio of consumed gases H2/CO2 went up to ca. 20 (Lu and Yu 2017a), indicating that a large portion of hydrogen was wasted because of the lack of CO2 as the carbon source. The oxygenase activity of Rubisco might become predominant in the absence of dissolved CO2 (Badger and Bek 2008). C. necator uses carbonic anhydrase (CA) to catalyze the interconversion between carbon dioxide and bicarbonate. The genome of H16 strain contains four CA genes: can, can2, caa and cag (Pohlmann et al. 2006). One CA (Can) has been identified as being essential for growth under atmospheric concentration of CO2 (Kusian et al. 2002). A recent study reveals that Caa is an α-periplasmic CA and prefers CO2 as the substrate. Its location in the periplasm of a cell may play a role in transport of CO2 and supply of bicarbonate to the cell (Gai et al. 2014). Other CAs in cytoplasm prefer bicarbonate as their substrate and hence supply CO2 to Rubisco.

Under sufficient supply of CO2, H2, O2 and essential mineral nutrients, hydrogen-oxidizing bacteria including C. necator can grow to a high cell density with little P3HB accumulation. The limitation of dissolved oxygen (dO2 ≈ 0) does not trigger P3HB formation but brings down the overall metabolic activity (Lu and Yu 2017a). Among the essential nutrients for cell growth, including nitrogen, sulfur, phosphorus, potassium, and manganese, nitrogen is the most effective nutrient that can be controlled to direct carbon flow to P3HB synthesis (Volova et al. 2013a). Indeed, nitrogen is one of the major elements of RCM, accounting for 12–13 wt% of DCM (Kang and Yu 2015c).

Bioreactor and safety

Most studies on gas fermentation were conducted in conventional bioreactors with continuous bubbling of a gas stream of H2, O2 and CO2 through aqueous medium solution (Tanaka et al. 1995; Volova et al. 2013a; Garcia-Gonzalez et al. 2014). The exhaust gas was either discharged or recycled in a closed gas system. In the agitated bioreactors, a high gas mass transfer coefficient (kLa) was maintained with high mechanical power dispersion per liquid volume and high gassing rate in terms of gas volume per liquid volume per min (vvm) (Garcia-Ochoa et al. 2010). Recycling the hydrogen-rich exhaust gas is necessary for hydrogen waste minimization and process safety (Tanaka et al. 1995). The equipment and operation costs, however, could be very high, especially with a high gassing rate (1–2 vvm). In a packed bed bioreactor, oxygen kLa up to 400 h−1 could be maintained at a very low gassing rate (< 0.2 vvm) (Lu and Yu 2017b).

Hydrogen is a clean, odorless, non-toxic, but highly flammable gas. The lower and upper flammability levels of hydrogen in air are 4 and 75 vol%, respectively. In chemolithotrophic CO2 fixation, a molar ratio of H2/O2 is around 3 to provide a balanced supply of energy and reducing agents, but the gas composition lies in the explosion range (Takeshita and Ishizaki 1996). Several solutions have been proposed to solve the problem of gas explosion risk. The final electron acceptor O2 was replaced by nitrate (NO3−) that could be reduced to nitrite (NO2−). This replacement, however, resulted in a substantial decline of cell growth and yield (Tiemeyer et al. 2007). The lower explosion level of O2 in a hydrogen rich gas is estimated to range from 4.0 vol% (Schröder et al. 2004) to 6.9 vol% (Tanaka et al. 1995). Under a low O2 partial pressure (< 4 vol%), the dissolved oxygen concentration declines according to the Henry’s law. As a result, a low cell density was obtained, giving a low P3HB productivity (Garcia-Gonzalez et al. 2014). A bioreactor setup with a high gas mass transfer rate as well as hydrogen safety is a great technical challenge to industrial gas fermentation of hydrogen-oxidizing bacteria for CO2 fixation and carbon reuse.

References

Alagesan S, Minton NP, Malys N (2018) 13C-assisted metabolic flux analysis to investigate heterotrophic and mixotrophic metabolism in Cupriavidus necator H16. Metabolomics 14:9–19

Aragno M, Schlegel HG (1981) The hydrogen-oxidizing bacteria. In: Starr NP et al (ed) The prokaryotes. Springer, New York, pp 865–893

Ariffin H, Nishida H, Shirai Y et al (2010) Highly selective transformation of poly[R-3-hydroxybutyric acid] into trans-crotonic acid by catalytic thermal degradation. Polym Degrad Stab 95:1375–1381

Badger MR, Bek EJ (2008) Multiple Rubisco forms in proteobacteria: their functional significance in relation to CO2 acqusition by the CBB cycle. J Exp Bot 59:1525–1541

Bae S, Kwak K, Kim S et al (2001) Isolation and characterization of CO2-fixing hydrogen-oxidizing marine bacteria. J Biosci Bioeng 91(5):442–448

Berg IA (2011) Ecological aspects of the distribution of different autotrophic CO2 fixation pathways. Appl Environ Microbiol 77:1925–1936

Boon N, Defoirdt T, De Windt W et al (2010) Hydroxybutyrate and poly-hydroxybutyrate as components of animal feed or feed additives. US Patent 2010/0093860 A1

Bowien B, Kusian B (2002) Genetics and control of CO(2) assimilation in the chemoautotroph Ralstonia eutropha. Arch Microbiol 178:85–93

Brigham CJ, Budde CF, Holder JW et al (2010) Elucidation of β-oxidation pathways in Ralstonia eutropha H16 by examination of global gene expression. J Bacteriol 192:5454–5464

Bugnicourt E, Cinelli P, Lazzeri A et al (2014) Polyhydroxyalkanoate (PHA): review of synthesis, characteristics, processing and potential applications in packaging. Express Polym Lett 8:791–808

Burgdorf T, Lenz O, Buhrke T et al (2005) [NiFe]-hydrogenases of Ralstonia eutropha H16: modular enzymes for oxygen-tolerant biological hydrogen oxidation. J Mol Microbiol Biotechnol 10:181–196

Calloway DH, Kumar AM (1969) Protein quality of the bacterium Hydrogenomonas eutropha. Appl Microbiol 17:176–178

Conrad R (1996) Microorganisms as controllers of atmospheric trace gases (H2, CO, CH4, OCS, N2O, and NO). Microbiol Rev 60:609–640

Crépin L, Lombard E, Guillouet SE (2016) Metabolic engineering of Cupriavidus necator for heterotrophic and autotrophic alka(e)ne production. Metab Eng 37:92–101

Defoirdt T, Boon N, Sorgeloos P et al (2009) Short chain fatty acids and poly-beta-hydroxyalkanoates: (new) biocontrol agents for a sustainable animal production. Biotechnol Adv 27:680–685

Florentino LA, Jaramillo PMD, Silva KB et al (2012) Physiological and symbiotic diversity of Cupriavidus necator strains isolated from nodules of Leguminosae species. Sci Agric 69(4):247–258

Gai CS, Lu J, Brigham CJ et al (2014) Insights into bacterial CO2 metabolism revealed by the characterization of four carbonic anhydrases in Ralstonia eutropha H16. AMB Express 4:2–14

Garcia-Gonzalez L, Mozumder MSI, Dubreuil M et al (2014) Sustainable autotrophic production of polyhydroxybutyrate (PHB) from CO2 using a two-stage cultivation system. Catal Today 257(2):237–245

Garcia-Ochoa F, Gomez E, Santos V et al (2010) Oxygen uptake rate in microbial processes: an overview. Biochem Eng J 49:289–307

Ghysels S, Mozumder MSI, De Wever H et al (2018) Targeted poly(3-hydroxybutyrate-co-3-hydroxyvalerate) bioplastic production from carbon dioxide. Bioresour Technol 249:858–868

Grousseau E, Lu J, Gorret N et al (2014) Isopropanol production with engineered Cupriavidus necator as bioproduction platform. Appl Microbiol Biotechnol 98:4277–4290

Gruber S, Schwab H, Heidinger P (2017) CbbR and RegA regulate cbb operon transcription in Ralstonia eutropha H16. J Biotechnol 257:78–86

Grzeszik C, Jeffke T, Schäferjohann J et al (2000) Phosphoenolpyruvate is a signal metabolite in transcriptional control of the cbb CO2 fixation operons in Ralstonia eutropha. J Mol Microbiol Biotechnol 2:311–320

Huber R, Eder W (2006) Aquificales. In: Dworkin M et al (ed) The prokaryotes: a handbook on the biology of bacteria, vol 7, 3rd edn. Springer, New York, pp 925–928

Hunt AJ, Sin EHK, Marriott R et al (2010) Generation, capture, and utilization of industrial carbon dioxide. Chem Sus Chem 3:306–332

Jugder B-E, Lebhar H, Aguey-Zinsou K-F et al (2016) Production and purification of a soluble hydrogenase from Ralstonia eutropha H16 for potential hydrogen fuel cell applications. MethodsX 3:242–250

Kang S, Yu J (2015a) Reaction routes in catalytic reforming of poly(3-hydroxybutyrate) into renewable hydrogen carbon oil. RSC Adv 5:30005–30013

Kang S, Yu J (2015b) A gasoline-grade biofuel formed from renewable polyhydroxybutyrate on solid phosphoric acid. Fuel 160:282–290

Kang S, Yu J (2015c) Hydrophobic organic compounds from hydrothermal liquefaction of bacterial biomass. Biomass Bioenergy 74:92–95

Kunasundari B, Murugaiyah V, Kaur G et al (2013) Revisiting the single cell protein application of Cupriavidus necator H16 and recovering bioplastic granules simultaneously. PLoS ONE 8(10):e78528. https://doi.org/10.1371/journal.pone.0078528

Kusian B, Sültemeyer D, Bowien B (2002) Carbonic anhydrase is essential for growth of Ralstonia eutropha at ambient CO2 concentrations. J Bacteriol 184:5018–5026

Laeger T, Metges CC, Kuhla B (2010) Role of β-hydroxybutyric acid in the central regulation of energy balance. Appetite 54:450–455

Laycock B, Halley P, Pratt S et al (2013) The chemomechanical properties of microbial polyhydroxyalkanoate. Prog Polym Sci 38:536–583

Lee S-E, Li QX, Yu J (2006) Proteomic examination of Ralstonia eutropha in cellular responses to formic acid. Proteomics 6(15):4259–4268

Li H, Opgenorth PH, Wernick DG et al (2012) Integrated electromicrobial conversion of CO2 to higher alcohols. Science 335:1596–1596

Lu Y, Yu J (2017a) Comparison analysis on the energy efficiencies and biomass yields in microbial CO2 fixation. Process Biochem 62:151–160

Lu Y, Yu J (2017b) Gas mass transfer with microbial CO2 fixation and poly(3-hydroxybutyrate) synthesis in a packed bed bioreactor. Biochem Eng J 122:13–21

Luef KP, Stelzer F, Wiesbrock F (2015) Poly(hydroxy alkanoate)s in medical applications. Chem Biochem Eng Q 29:287–297

Marc J, Grousseau E, Lombard E et al (2017) Over expression of GroESL in Cupriavidus necator for heterotrophic and autotrophic isopropanol production. Metabolic Eng 42:74–84

Mertens R, Liese A (2004) Biotechnological applications of hydrogenases. Curr Opin Biotechnol 15:343–348

Müller J, MacEachran D, Burd H et al (2013) Engineering of Ralstonia eutropha H16 for autotrophic and heterotrophic production of methyl ketones. Appl Environ Microbiol 79(14):4433–4439

Nowotny J, Bak T, Chu D et al (2014) Sustainable practices: solar hydrogen fuel and education program on sustainable energy systems. Int J Hydrog Energy 39:4151–4157

Obruca S, Sedlacek P, Mravec F et al (2016) Evaluation of 3-hydroxybutyrate as an enzyme-protective agent against heating and oxidative damage and its potential role in stress response of poly(3-hydroxybutyrate) accumulating cells. Appl Microbiol Biotechnol 100:1365–1376

Park I, Jho EH, Nam K (2014) Optimization of carbon dioxide and valeric acid utilization for polyhydroxyalkanoates synthesis by Cupriavidus necator. J Polym Environ 22:244–251

Peplinski K, Ehrenreich A, Döring C et al (2010) Genome-wide transcriptome analyses of the Knallgas bacterium Ralstonia eutropha H16 with regard to polyhydroxyalkanoate metabolism. Microbiology 156:2136–2152

Pohlmann A, Fricke WF, Reinecke F et al (2006) Genome sequence of the bioplastic-producing “Knallgas” bacterium Ralstonia eutropha H16. Nat Biotechnol 24:1257–1262

Przybylski D, Rohwerder T, Dilßner C et al (2015) Exploiting mixtures of H2, CO2, and O2 for improved production of methacrylate precursor 2-hydroxyisobutyric acid by engineered Cupriavidus necator strains. Appl Microbiol Biotechnol 99:2131–2145

Rasmussen M, Abdellaoui S, Minteer SD (2016) Enzymatic biofuel cells: 30 years of critical advancements. Biosens Bioelectron 76:91–102

Schlegel HG, Gottschalk G, Von Bartha R (1961) Formation and utilization of poly-[beta]-hydroxybutyric acid by Knallgas bacteria (Hydrogenomonas). Nature 191:463–465

Schröder V, Emonts B, Janβen H et al (2004) Explosion limits of hydrogen/oxygen mixtures at initial pressures up to 200 bar. Chem Eng Technol 27:847–851

Schwartz E et al (2009) A proteomic view of the facultatively chemolithoautotrophic lifestyle of Ralstonia eutropha H16. Proteomics 9(22):5132–5142

Spear JR, Walker JJ, McCollom TM et al (2005) Hydrogen and bioenergetics in the Yellowstone geothermal ecosystem. Proc Natl Acad Sci 102(7):2555–2560

Takeshita T, Ishizaki A (1996) Influence of hydrogen limitation on gaseous substrate utilization in autotrophic culture of Alcaligenes eutrophus ATCC 17697T. J Ferment Bioeng 81:83–86

Tanaka K, Ishizaki A, Kanamaru T et al (1995) Production of poly(D-3-hydroxybutyrate) from CO2, H2, and O2 by high cell density autotrophic cultivation of Alcaligenes eutrophus. Biotechnol Bioeng 45:268–275

Tanaka K, Miyawaki K, Yamaguchi A et al (2011) Cell growth and P(3HB) accumulation from CO2 of a carbon monoxide-tolerant hydrogen-oxidizing bacterium, Ideonella sp. O-1. Appl Microbiol Biotechnol 92:1161–1169

Tiemeyer A, Link H, Weuster-Botz D (2007) Kinetic studies on autohydrogenotrophic growth of Ralstonia eutropha with nitrate as terminal electron acceptor. Appl Microbiol Biotechnol 76:75–81

Torella CJ, Gagliardi JS, Chen DK et al (2015) Efficient solar-to-fuels production from a hybrid microbial/water-splitting catalyst system. Proc Natl Acad Sci USA 112:2337–2342

Valappil S, Misra SK, Boccaccini AR et al (2006) Biomedical applications of polyhydroxyalkanoates, an overview of animal testing and in vivo responses. Expert Rev Med Devices 3(6):853–868

Vandamme P, Coeyne T (2004) Taxonomy of the genus Cupriavidus: a tale of lost and found. Int J Syst Evol Microbiol 54:2285–2289

Volova TG, Kiselev EG, Shishatskaya EI et al (2013a) Cell growth and accumulation of polyhydroxyalkanoates from CO2 and H2 of a hydrogen-oxidizing bacterium, Cupriavidus eutrophus B-10646. Bioresour Technol 146:215–222

Volova TG, Zhila NO, Kalacheva GS et al (2013b) Effects of intracellular poly(3-hydroxybutyrate) reserves on physiological biochemical properties and growth of Ralstonia eutropha. Res Microbiol 164:164–171

Yoon K-S, Fukuda K, Fujisawa K et al (2011) Purification and characterization of a highly thermostable, oxygen-resistant, respiratory [NiFe]-hydrogenase from a marine, aerobic hydrogen-oxidizing bacterium Hydrogenovibrio marinus. Int J Hydrog Energy 36:7081–7088

Yu J (2014) Bio-based products from solar energy and carbon dioxide. Trends Biotechnol 32(1):5–10

Yu J, Plackett D, Chen LXL (2005) Kinetics and mechanism of the monomeric products from abiotic hydrolysis of poly[(R)-3-hydroxybutyrate] under acidic and alkaline conditions. Polym Degrad Stab 89:289–299

Yu J, Dow A, Pingali S (2013) The energy efficiency of carbon dioxide fixation by a hydrogen-oxidizing bacterium. Int J Hydrog Energy 38:8683–8690

Zhila N, Kalacheva G, Volova T (2015) Fatty acid composition and polyhydroxyalkanoates production by Cupriavidus eutrophus B-10646 cells grown on different carbon sources. Process Biochem 50:69–78

Ziogou C, Ipsakis D, Stergiopoulos F et al (2012) Infrastructure, automation and model-based operation strategy in a stand-alone hydrolytic solar-hydrogen production unit. Int J Hydrog Energy 37:16591–16603

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, J. Fixation of carbon dioxide by a hydrogen-oxidizing bacterium for value-added products. World J Microbiol Biotechnol 34, 89 (2018). https://doi.org/10.1007/s11274-018-2473-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-018-2473-0