Abstract

High molecular weight bioemulsifiers are amphipathic polysaccharides, proteins, lipopolysaccharides, lipoproteins, or complex mixtures of these biopolymers, produced by a wide variety of microorganisms. They are characterized by highly structural diversity and have the ability to decrease the surface and interfacial tension at the surface and interface respectively and/or emulsify hydrophobic compounds. Emulsan, fatty acids, phospholipids, neutral lipids, exopolysaccharides, vesicles and fimbriae are among the most popular high molecular weight bioemulsifiers. They have great physic-chemical properties like tolerance to extreme conditions of pH, temperature and salinity, low toxicity and biodegradability. Owing their emulsion forming and breaking capacities, solubilization, mobilization and dispersion activities and their viscosity reduction activity; they possess great environmental application as enhancer of hydrocarbon biodegradation and for microbial enhanced oil recovery. Besides, they are applied in biomedical fields for their antimicrobial and anti-adhesive activities and involvement in immune responses.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

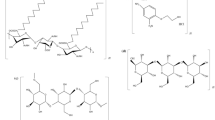

Today, synthetic emulsifiers are among the most produced compounds in the world as they are used in various industries like textile, paper, polymer, plastic, cosmetics, pharmaceuticals, food and machinery manufacture and in bioremediation (Kitamoto et al. 2002). However, they are highly toxic to environment and living organisms. So, microbial derived emulsifiers have particular interest and became widespread for potential use in diverse fields. They were firstly discovered as extracellular amphiphilic compounds in research into hydrocarbon fermentation, which started in the late 1960s (Kitamoto et al. 2002). They attracted attention as “alternative to chemical emulsifiers” due to their high biodegradability and environmental safety. They are mainly classified into four categories, i.e., (1) glycolipid type (4), (2) fatty acid type (5), (3) lipopeptide type (6) and (4) polymer type (7), based on the structure of their hydrophilic part. Among them, polymeric bioemulsifiers have attracted a great attention for biotechnological applications.

Generally, they are amphipathic polysaccharides, proteins, lipopolysaccharides, lipoproteins, fatty acids or complex mixtures of these biopolymers. Also, some whole bacterial cells, vesicles and fimbriae with complex structure are recognized as emulsifying agents. They can be produced from inexpensive raw materials that are available in large quantities, such as industrial wastes (Panilaitis et al. 2007) and oily byproducts including hydrocarbons (Kaeppeli and Finnery 1979; Leahy et al. 2003; Martinez-Checa et al. 2007; Arli et al. 2011) and vegetable oils (Liu et al. 2011). In many cases, they are produced by hydrocarbon degrading bacteria during their growth (Kaeppeli and Finnery 1979; MacDonald et al. 1981; Pines and Gutnick 1986; Peng et al. 2007; Sadouk et al. 2009). Furthermore, the production efficiency of the bioemulsifiers using microorganisms has been improved along with the progress of biotechnology by the amelioration of fermentation conditions (Doshi et al. 2010) and the optimization of production by means of the response surface methodology (Prapulla et al. 1992; Albuquerque et al. 2006; Su et al. 2009). Therefore, the yields of bioconversion are always so high that they permitted the retention of huge quantity of polymeric biosurfactants for diverse applications. They can be produced by a wide diversity of bacteria (Mousavian and Rahimi 2010; Burgos-Díaz et al. 2011; Franzetti et al. 2012), Actinomycete (Kokare et al. 2007; Maniyar et al. 2011), yeast (Walencka et al. 2007; Dikit et al. 2010) and fungus (Batrakov et al. 2001; Paraszkiewicz et al. 2002; Katemai et al. 2008). Generally, polymeric bioemulsifiers are released in the extracellular medium of the fermentation broth (Boyle and Reade 1983; Calvo et al. 1995). However, they can also be attached to the cell surface (Dikit et al. 2010; Huang et al. 2013).

Owing their structural diversity, interesting physic-chemical properties (great stability to drastic conditions of pH, salinity and temperature, low toxicity and biodegradability) and great functional properties (emulsification/de-emulsification, foaming, dispersing, hydrocarbon solubilizing …), they are potential candidates for bioremediation of hydrocarbon contaminated sites. Also, polymeric bioemulsifiers can be recognized for their antimicrobial and anti-adhesive activities and can be involved in several immune responses allowing their use in biomedical and therapeutic fields. This review deals with the latest research and development in polymeric type bioemulsifiers, including their structural diversity, surface activity, functional properties and potential applications in environmental and biomedical fields.

Polymeric bioemulsifiers: definition and classification

Numerous microorganisms are characterized by the synthesis of a wide variety of high- and low-molecular-weight bioemulsifiers. Generally, high molecular weight mass bioemulsifiers are proteins, polysaccharides, lipopolysaccharides, lipoproteins, or composite assortment of these biopolymers (Perfumo et al. 2010). The most studied polymeric bioemulsifiers are emulsan, alasan, liposan, mannoprotein and other polysaccharide protein complexes.

Emulsan family

Emulsan, an extracellular complex of acylated polysaccharide produced mainly by the gram-negative bacterium, Acinetobacter species, is among the most popular polymeric bioemulsifiers (Panilaitis et al. 2007). It’s composed of a polysaccharide backbone with O-acyl and N-acyl bound fatty acid side chains. The polysaccharide backbone consists of three amino sugars (d-galactosamine, d-galactosaminouronic acid, and a dideoxydiaminohexose) and the fatty acid side chains range in length from 10 to 20 carbons, and represent 5–23 % (w/w) of the polymer (Panilaitis et al. 2007). The emulsan amino groups are either acetylated or covalently linked by an amide bond to 3-hydroxybutyric acid (Panilaitis et al. 2007). The combination of hydrophilic anionic sugar main chain repeat units, along with the hydrophobic side groups leads to the amphipathic behavior of emulsan and, therefore, its ability to form stable oil-in-water emulsions (Panilaitis et al. 2007). In fact, emulsan is a very effective emulsifying agent for hydrocarbons in water even at concentration as low as 0.001–0.01 %.

Alasan, belonging to the emulsan family, is a high-molecular-weight complex of polysaccharide and protein synthetized generally by Acinetobacter species with a molecular weight of about 103 kDa (Navon-Venezia et al. 1998).However, the polysaccharide component of alasan is unusual in that it contains covalently bound alanine (Navon-Venezia et al. 1998). The purified polysaccharide and protein components have no emulsifying activity when used lonely. In fact, the protein component of alasan appears to play an important role in both the structure and the activity of the complex. However, the combination of the polysaccharide and the protein led to the reconstitution of the emulsifying activity (Toren et al. 2001).

In addition to emulsan family, a complex structure of polymeric bioemulsifiers consisting of a complex of lipids, proteins and polysaccharides, exopolysaccharides (EPS), proteins, glycoprotein compounds and glycolipoproteins can be found in the nature. Different examples of these compounds along with their producing strains and biological activities were presented in Table 1.

Fatty acids, phospholipids and neutral lipids

Large quantities of fatty acids, phospholipids or neutral lipids bioemulsifiers could be produced by several microorganisms when grown on n-alkanes. As suggested by Beeba and Umbreit (1971), the growth of Thiobacillus thiooxidans on sulfur particles is supported by the wetting of those particles by an heterogeneous mixture of neutral lipid and phospholipid, present in the medium, resulting from cellular disruption. Table 2 illustrated some examples of fatty acids, phospholipids and neutral lipids along with their microbial producing strains and biological activities.

Fatty acid biosurfactant

Generally, fatty acids produced by microorganisms might be simple straight-chain fatty acids or of complex nature containing OH groups and alkyl branches (Rahman and Gakpe 2008). They resulted from the microbial oxidation of alkanes and have gained great attention as surfactants. They were also known as lowering the surface and interfacial tensions. Among them, we distinguish mycolic acids and corynomucolic acid. Mycolic acids are long-chain; β-hydroxy fatty acids substituted at the α-carbon atom with a moderately long aliphatic chain and are primarily produced by Mycobacterium, Nocardia, Rhodococcus, and Corynebacterium species (Marrakchi et al. 2014). Corynomucolic acid is another example of a complex fatty acid containing OH groups and alkyl branches that are produced by R. erythropolis (Desai and Banat 1997). Fatty acids with chain length ranging from C9 to C22 (dicorynomycolates, monocorynomycolates and tetraester) produced by R. Erythropolis 3C-9 were shown to enhance the solubility of polycyclic aromatic hydrocarbons and the degradation rate of hexadecane (Peng et al. 2007).

Phospholipids biosurfactant

Phospholipids are known to be the key components of microbial membranes. When certain hydrocarbon-degrading bacteria or yeast are grown on alkane substrates, the level of phospholipid increases greatly. For instance, using hexadecane-grown Acinetobacter sp. HO1-N, phospholipids (mainly phosphatidylethanolamine) loaded vesicles were produced (Kaeppeli and Finnery 1979). Their effective surfactant properties are evidenced by their ability to generate optically clear micro-emulsions of alkanes in water (Ron and Rosenberg 2001). Moreover, they are recognized by their aptitude to reduce the surface and interfacial tension. Phosphatidyl ethanolamine produced by R. erythropolis grown on n-alkane resulted in the reduction of the interfacial tension between water and hexadecane at <1 mN/m with a Critical Micelle Concentration (CMC) of about 30 mg/L (Kretschmer et al. 1982).

Neutral lipids biosurfactant

Triacylglycerols found in all eukaryotic cells (yeasts, molds, plants and animals) and esters produced by Acinetobacter sp. related bacteria such as Moraxelle and some eukaryotic algae are examples of neutral lipids biosurfactants (Desai and Banat 1997). They can be also produced by Nocardia erythropolis (Desai and Banat 1997) and A. calcoaceticus C42 (Bashetti et al. 2012).

Exopolysaccharides bioemulsifiers

Exopolysaccharides complex active extracellular biopolymers, are high molecular weight carbohydrate polymers. They could be produced by various marine microorganisms form a layer surrounding the cells helping them to withstand or resist to adverse and extreme environmental conditions offering a high structural diversity (Satpute et al. 2010). These compounds are important in microbial interaction and emulsification of various hydrophobic substrates (Maki et al. 2000; Yim et al. 2005). They are also known to increase the viscosity of solutions at low pH value and emulsify several hydrocarbon compounds (Guezennec et al. 1994; Calvo et al. 1998).

Particulate biosurfactants and whole bacterial cells

Numerous microbial strain release extracellular membrane vesicles, called particulate biosurfactants, that partition to hydrocarbons to form microemulsion which plays an important role in alkane uptake by microbial cells. Vesicles of Acinetobacter sp. strain HO1-N, composed of protein, phospholipid, and lipopolysaccharide and those of A. calcoaceticus are some examples (Desai and Banat 1997). Moreover, some other particulate biosurfactants could be synthesized and remain adhered to the cell surfaces. Therefore, the corresponding microbial cells are characterized by their highly hydrophobic surface having the capacity to adhere to hydrocarbons and they could be recognized as bio-emulsifying agents.

Main properties of polymeric bioemulsifiers

Emulsification capacity

Emulsification corresponds to a dispersion of one liquid into another (as microscopic droplets) leading to the mixing of two immiscible liquids. Generally, polymeric bioemulsifiers are recognized by their emulsification activity and are good emulsifiers for food and petrochemical industry.

A partially purified bioemulsifier produced by Acinetobacter sp. formed stable oil-in-water emulsions with plant oils with a maximum emulsification activity of about 400 EU/mL (Jagtap et al. 2010). Also, a Streptomyces sp. S22 strain produced a peptide glycol lipid bioemulsifier with a maximum emulsification activity of 320 EU/mL (Maniyar et al. 2011). A glycol lipoprotein bioemulsifier produced by Microbacterium sp. MC3B-10 microbactan emulsified aromatic hydrocarbons and oils to various extents with a higher emulsification index against motor oil of about 96 % with a higher stability (94 %) at 50 °C, pH 10 and 3.5 % NaCl content (Camacho-Chab et al. 2013). Moreover, mannoprotein extracted from the cell wall of the yeast Saccharomyces cerevisiae exhibited emulsion with the vegetable oils tested and showed emulsion activity of 65 % towards palm oil as oil-in-water with a critical emulsifier concentration of 20 g/l with similar emulsifying properties to the commonly used food emulsifiers gum arabic and lecithin (Dikit et al. 2010). The emulsion was stable over a wide range of pH, temperature and salinity showing a great potential for application in salad dressing. A complex of lipids, proteins and polysaccharids bioemulsifier produced by Candida lipolytica formed stable emulsions with hydrophobic natural compounds (Rufino et al. 2007). In addition, fatty acid esters produced by P. citronellolis KHA showed greater emulsifying properties with an E24 of 75 % at the end of the exponential growth phase permitting its use in the cleanup of the sites contaminated with hydrocarbons (Sadouk et al. 2009). Besides that, whole bacterial cells of Pseudomonas marginalis PD-14B (Burd and ward 1996) and Micrococcus luteus BN56 (Tuleva et al. 2009) were reported as interesting emulsifying agents. Furthermore, EPS of Alcaligens faecalis and Enterobacter sp. which were able to emulsify n-octane, toluene, xylene, mineral oils and crude oil, showed potential for bioremediation application (Toledo et al. 2008). Similarly, a Sphingomonas paucimobilis derived exopolysaccharide emulsified efficiently xylene, benzene, 2-methylnaphthalene, hexadecane, hexane, kerosene and paraffin oil as well as castor, coconut and olive oils when used at 1 mg/mL (Ashtaputre and Shah 1995). It stabilized the emulsions more efficiently than commercial gums such as arabic, tragacanth, karaya and xanthan and emulsions were stable for 6 months, from 4 to 40 °C and pH 4 to 10 and in the presence of NaCl up to 50 g/l (Ashtaputre and Shah 1995). A curdlan-like exopolysaccharide production by Cellulomonas flavigena UNP3 during growth on hydrocarbon substrates was able to emulsify hexadecane (Arli et al. 2011).

De-emulsification capacity

In addition to the emulsification capacity, polymeric bioemulsifiers are able to break down the formed emulsion; they are recognized as de-emulsifiers. De-emulsification is achieved by disturbing the thermodynamic conditions at the interface. It’s very useful for the petrochemical industry. In fact, every year, millions of tons of crude oil emulsions are generated by petroleum exploration and water–oil emulsions occur throughout oil production, pipeline transportation and processing. Problems associated with the presence of water in oil include corrosion, scale formation and sludge accumulation in storage tanks. These altered the viscosity of oil and the flow properties and reduced distillation efficiency (Mohebali et al. 2012). Before being transported and refined, crude oil emulsions should be demulsified to reduce water content and recover crude oil (de Souza Sobrinho et al. 2013).

In this aim, a demulsifying strain, Alcaligenes sp. S-XJ-1, was investigated to synthesize a biodemulsifier using waste frying oils as carbon source (Liu et al. 2011). Hou et al. (2013) reported the production of biodemulsifier by B. mojavensis XH-1 identified as extracellular proteins attached to the cells or secreted into the culture medium. The de-emulsification mechanism was dogged as solubilization and replacement process (Hou et al. 2013). Moreover, a carbohydrate–protein–lipid complex isolated from the cell surface of Alcaligenes sp. S-XJ-1 exhibited 67.5 % of the de-emulsification ratio for water-in-kerosene emulsions when used at an amount of 356 mg/L providing demulsifying capability of the strain.

Regarding literature reviews and studies, many bacterial strains are investigated to have bio-demulsification competence. As suggested by Nadarajah et al. (2002), microorganisms are believed to modify emulsion properties by using hydrophobic cell surfaces or the dual hydrophobic/hydrophilic nature of biosurfactants to displace or alter the emulsifiers that are present at the oil–water interface. In fact, whole bacterial cells of B. subtilis (Janiyani et al. 1994), Nocardia amarae (Lee and Lee 2000), Micrococcus sp. (Das, 2001) and Ochrobactrum anthropi were reported as de-emulsifying agents (Mohebali et al. 2012). Along with different experiments, mixed culture products were shown to exhibit high de-emulsifying activity as compared to the most effective pure culture of A. calcoaceticus (Nadarajah et al. 2002). In fact, a mixed culture of Acinetobacter sp., Pseudomonas sp. and Alcaligenes latus showed high de-emulsification activity with 96 % de-emulsification of a water-in-oil emulsion within 24 h. Mohebali et al. (2012) isolated a new de-emulsifying bacterium, O. anthropi strain RIPI5-1. The potential activity of this strain was also explained using a complex oil field emulsion and suggested a biodemulsification capacity of about 63 and 72 % when using the whole culture and whole cells of the bacteria, respectively (Mohebali et al. 2012). Also, the finding of Park et al. (2000) reported that aerial spores of Streptomyces sp. broke emulsions of low viscosity hydrocarbons such as kerosene and gasoline within 1 min, but after 3 min of contact they could demulsify <50 % of emulsion of high viscosity hydrocarbons diluted with kerosene.

Ability to reduce the surface and interfacial tension

Generally, polymeric bioemulsifiers are recognized by their emulsification activity. However, they were demonstrated to decrease the surface and interfacial tension and can be acknowledged as biosurfactants. According to Satpute et al. (2010), surfactant can have both surface tension reduction and emulsification activity. Table 3 enumerates some polymeric biosurfactants along with their producing strains and corresponding surface and interfacial tensions values.

Fatty acids resulting from the microbial oxidation of alkanes have gained great attention as surfactants and were reported to lower the surface and interfacial tensions (Ron and Rosenberg 2001). Some of these complex fatty acids, e.g., those produced by Candida ingensare are potent surfactants able to reduce greatly the surface tension of culture media (Amézcua-Vega et al. 2007). Also, emulsan and phospholipids were reported to reduce the surface and interfacial tension of the medium broth (Table 3).

The production of various polymeric surfactants was known to increase seriously when several hydrocarbon-degrading bacteria or yeast are grown on alkane substrates and were demonstrated to decrease the surface tension. However, the amount of the decrease of the surface tension can depends on the nature of the carbon source (Chamanrokh et al. 2010). When ethanol was used as a carbon source, the surface tension was about 30, 30 and 32 (mN/m) for three strains of A. calcoaceticus PTCC 1318, Pay-4 and IL-1, respectively. Whereas surface tension was 28.2, 29 and 30 (mN/m) for A. calcoaceticus PTCC 1318, PAY-4and IL-1, respectively with soy oil as a sole source of carbon and energy. When Crude oil was used, the obtained surface tensions were 29, 29.2 and 31 (mN/m), respectively for the above-mentioned bacteria. Generally, this reduction of surface tension measurements indicated the production of surface-active compounds by the microbial culture, which has been shown to support the metabolism of the substrate and stimulate microbial growth (Chamanrokh et al. 2010).

Tolerance to extreme conditions of pH, temperature and salinity

Biosurfactants are reported stable at various temperature, pH and salinity (Salihu et al. 2009; Augustin and Tene Hippolyte 2012). The polymeric bioemulsifier synthesized by Microbacterium sp. MC3B-10 produced a highly stable emulsion (94 %) at 50 °C, pH 10 and 3.5 % NaCl content (Camacho-Chab et al. 2013). Exopolysaccharide polymeric bioemulsifiers are well known by their great stability and activity at extreme pH values. Halomonas eurihalina EPS were found to increase effectively the viscosity of solutions at low pH value and emulsify several hydrocarbon compounds (Calvo et al. 1998). Similarly, an extracellular polysaccharide produced by Volcaniella eurihalina was found to be able to form high viscous solutions, like a gel, at low pH values even in the presence of inorganic salts (Calvo et al. 1995). Also, polysaccharides namely PS 3a24 and PS 3a35 produced by marine bacteria have been shown to have high specific viscosity, pseudoplasticity, and stability over a wide range of pH in the presence of a variety of salts (Boyle and Reade 1983). A high molecular weight polysaccharides bioemulsifiers produced by Variovorax paradoxus were able to produce a thick stable oil/water emulsion and maintained the emulsification activity after boiling and at low temperatures (Franzetti et al. 2012). An exopolysaccharide derived from Paenibacillus macerans demonstrated a great stability at 121 °C for 20 min, over a pH range from 3 to 11, and in saline conditions (Liang et al. 2014).

Kokare et al. (2007) showed a good stability at room temperature (28 °C) of the bioemulsifier derived from Streptomyces sp. S1. Navon-Venezia et al. (1995) reported a maximum emulsification activity of an A. radioresistens derived alasan at acidic pH value along with an activation at high temperature. The emulsifying activity of a mannoprotein derived from S. cerevisiae was stable over broad range of conditions, from pH 2 to 11, with up to 5 % sodium chloride or up to 50 % ethanol in the aqueous phase (Cameron et al. 1988). Moreover, in the presence of a low concentration of various solutes, emulsions were stable to three cycles of freezing and thawing. Acinetobacter bioemulsifiers created a highly stable oil-in-water emulsion that maintained 90 % of its stability up to 6 days at 37 °C (Patil and Chopade 2001).

These interesting properties offer the opportunities for the polymeric bioemulsifiers to be investigated in extreme environment for microbial enhanced oil recovery and in situ biodegradation of oil sludge (Sen 2008). Moreover, they enable their use in industrial processes for food and pharmaceutics frequently involve exposure to extremes of temperature, pressure, pH and ionic strength.

Low toxicity and biodegradability

Owing their natural origins, microbial derived emulsifiers are recognized as low or non-toxic compounds. Munstermann et al. (1992) showed the reduced toxicity of microbial derived surface active compounds (Trehalose dicorynomycolate and Trehalose tetraester from R. erythropoli) towards different synthetic surfactants. Similarly, in a study conducted by Edwards et al. (2003) reporting a comparison of acute and chronic toxicity of three synthetic surfactants and three microbiological derived surfactants commonly used in oil spill remediation, emulsan was revealed among the least toxic. In another study, acute toxicity tests involving two species of marine larvae, Mysidopsis bahia (shrimp) and Menidia beryllina (fish), demonstrated low toxicity of the high molecular weight biosurfactant JE1058BS produced by Gordonia sp. (Saeki et al. 2009). Following an acute toxicity test conducted on mice, Ashtaputre and Shah (1995) confirmed the non-toxicity of an exopolysaccharide bioemulsifier produced by S. paucimobilis. Similarly, a mixture of high molecular weight polysaccharides produced by V. paradoxus did not show any toxic properties through different ecotoxicological tests (decrease in the bioluminescence of Vibrio fischeri; mortality of the crustacean Daphnia magna; seed germination and root elongation test was performed on Cucumis sativus, Lepidium sativum and Sorghum saccharatum and a contact acute toxicity test was performed on earthworms Eisenia foetida) (Franzetti et al. 2012). Moreover, respirometric tests showed that moderate biodegradability of the bioemulsifier occurred by soil bacterial inoculum (Franzetti et al. 2012). Also, Camacho-Chab et al. (2013) reported the non-toxicity of a glycolipoprotein bioemulsifier produced by Microbacterium sp. MC3B-10. Thus, reduced toxicity towards synthetic surfactants recognized as highly toxic (Song et al. 2012) and biodegradability makes biosurfactants more suitable for industrial and environmental applications such as bioremediation. In fact, Cappello et al. (2011) recommended the biodegradability of an exopolysaccharide biosurfactant.

Foaming capacity

A foaming agent is a compound that facilitates formation of foam. A surfactant, which, when present in small amounts, reduces surface tension of a liquid (reduces the work needed to create the foam) or increases its colloidal stability by inhibiting coalescence of bubbles leading to the formation of foam. Also, stable foams can be generated by a selective enrichment of hydrophobic bacteria in them by a process of flotation (Petrovski et al. 2011). Studies suggested that there is a great correlation between cell surface hydrophobicity, biosurfactant production and foam formation (Stratton et al. 2002).

As suggested by Lang and Philp (1998), Rhodococci strains have been involved in foaming incidents due to their filamentous growth, although other actinomycetes are clearly implicated. A R. rubra strain and its crude lipidic biosurfactant preparation, generated foams in the laboratory which were similar to those produced in full-scale AS plants (Lang and Philp 1998).

Dispersion property

A dispersant is an agent that reduces the cohesive attraction between similar particles. With this, it keeps insoluble particles in suspension and prevents their aggregations. This property has application in oil field chemistry as it can lead desorption of hydrophobic molecules from rock surfaces enhancing mobility and recovery. The dispersants enhance the rate of natural dispersion of oil and its removal from the contaminated surface (Saeki et al. 2009). In addition, the dispersants amplify surface area of oil accordingly to its dispersion into small droplets that is expected to stimulate its biodegradation via the activity of naturally occurring microorganisms (Saeki et al. 2009). Besides, dispersion properties can be investigated in several other fields. In fact, it’s suggested that production of emulcyan by Phormidium cells serves as a dispersal strategy by this non-hormogonia-producing cyanobacterium. As reported by Rosenberg et al. (1989) the use of biodispersan produced by Acinetobacter calcoaceticus A2 in paper manufacturing industries is one of the interesting approaches. Also, Elkeles et al. (1994) reported that biodispersan is an extracellular anionic polysaccharide produced by A. calcoaceticus A2 that changes the surface properties of limestone and acts both as a dispersant and as a grinding support. Its addition as filler along with paper and limestone improves the quality of paper and significantly reduces the time required for the grinding process (Elkeles et al. 1994).

Main application of polymeric biosurfactants

Application in environment

Viscosity reduction for cleaning potency and microbial enhanced oil recovery

The viscosity of a fluid is a measure of its resistance to gradual deformation by shear stress or tensile stress. For liquids, it corresponds to the informal notion of “thickness”. Because of the existence of colloid and asphaltene, the viscosity of thick oil is mostly so high. Nevertheless, crude oil often needs to be transported over long distances from the extraction fields to the refineries. Such viscosity of heavy oils can be reduced by using surfactants to increase mobility and to facilitate its transport. Microbial derived surface active compounds can lower the dense oil viscosity, helping therefore their transportation. The bioemulsifier emulsan derived from A. venetianus RAG-1, is undoubtedly the most powerful, yet others such as alasan and biodipersan produced by different Acinetobacter strains, have been extensively studied to facilitate crude oil transportation in pipeline (Bryant 1987).

As described by Planckaert (2005), a reservoir rock is like a sponge that entraps and expels oil. Classical production technologies, namely primary and secondary recovery, can only partially recover the oil present in the field, with an efficiency estimated at one-third to half the overall amount of oil available. In this aim, the decrease of oil viscosity can stimulated the oil recovery. In fact, microbial enhanced oil recovery by using microbial derived surface active compounds is a promising technology. Previous studies described the use of polymeric bioemulsifiers for microbial enhanced oil recovery. A bioemulsifier produced by B. licheniformis and containing substantial amount of polysaccharide, protein and lipid gave 43 ± 3.3 % additional oil recovery upon application to a sand pack column designed to simulate an oil reservoir (Suthar et al. 2008). Similarly, a polysaccharide-protein complex bioemulsifier produced by B. licheniformis increased the efficiency of the residual oil recovery increased by 22 % in a sand-pack model saturated with liquid paraffin (Dastgheib et al. 2008). Salehizadeh and Mohammadizad (2009) reported the potential use of an Alcaligenes faecalis derived emulsan for microbial enhanced oil recovery. Equally, an Aspergillus ustus derived glycolipoprotein can be a potential candidate for microbial enhanced oil recovery (Seghal Kiran et al. 2009).

Hydrocarbon dispersion, solubilization and mobilization capacities and enhancement of hydrocarbon biodegradation

Generally, the biodegradation of hydrocarbons is limited by their low bioavailability to the microorganisms, which is due to their hydrophobicity, low aqueous solubility and strong adsorptive capacity in soil (Amodu et al. 2013). Addition of synthetic surfactants or biosurfactants can increase the aqueous solubility of water-insoluble compounds (Pacwa-Plociniczak et al. 2011). The mechanism proposed for improving solubility of hydrophobic organic compounds includes their encapsulation in the hydrophobic core of the surfactant micelles (Pacwa-Plociniczak et al. 2011). In fact, at concentrations above the CMC, surfactant molecules associate to form micelles able to encapsulate insoluble molecules into their core (Pacwa-Plociniczak et al. 2011). The effects of such a process are the reduction of surface and interfacial tension and the enhancement of the bio accessibility of the hydrophobic contaminants for microbial attack (Perfumo et al. 2010). Several studies reported the efficiency of low and high molecular weight biosurfactants as hydrocarbon solubilizing agents (Perfumo et al. 2009). Also, at concentrations below the biosurfactant CMC, the mobilization mechanism can occurs. At such concentrations, biosurfactants reduce the surface and interfacial tension between air–water and soil–water systems. Due to the reduction of the interfacial force, contact of biosurfactants with a soil-oil system increases the contact angle and reduces the capillary force holding the oil and soil together leading to the release of oil into the aqueous phase (Perfumo et al. 2010). Therefore, biosurfactants increase the bioavailability of hydrophobic compounds resulting in enhanced growth of the degrading microorganism and the biodegradation of the contaminants. Numerous studies reported the enhancement of hydrocarbon biodegradation by the addition of high molecular weight biosurfactants.

High molecular weight biosurfactants are utilized as hydrophobic compounds solubilizers like alasan produced by A. radioresistens (Barkay et al. 1999) and an A. calcoaceticus derived bioemulsifier (Wong et al. 2010). Having the ability to solubilize hydrocarbons, alasan doubled the rate of fluoranthene mineralization and significantly increased the rate of phenanthrene mineralization by S. paucimobilis EPA505 (Barkay et al. 1999). Also, similar studies showed their efficiency in hydrocarbon solubilization towards synthetic ones. A thermostable polymeric biosurfactants produced by A. calcoaceticus BU03 improved, significantly, the apparent aqueous solubility of phenanthrene, pyrene and benzo (a) pyrene at a concentration of 25 times their CMC (Zhao and Wong 2009). At concentrations of 0.5 CMC and 1 CMC, the biosurfactant enhanced the biodegradation of phenanthrene by a consortium of polyaromatic hydrocarbon-degrading microrganisms (Zhao and Wong 2009). Also, Burd and Ward (1996) reported the beneficial effect of a high molecular weight biosurfactant containing protein and lipopolysaccharide in the degradation of polycyclic aromatic hydrocarbons by P. marginalis. Similarly, a free fatty acid produced by R. erythropolis strain 3C-9 was reported to enhance the hydrocarbons solubility and degradation (Peng et al. 2007). Also, Rosenberg et al. (1982) discussed the enhancement of hydrocarbons solubility and degradation by fimbriae of A. calcoaceticus RAG-1. Hanson et al. (1994) reported the potential involvement of an Acinetobacter sp. A3 derived protein in hydrocarbon degradation.

Moreover, numerous polymeric surfactants were investigated for their washing capacity. In this aim, Variovorax bioemulsifiers of polysaccharides nature showed significant removal of crude oil from the sandy soil making these compounds potentially suitable for removal of crude oil spill from sandy shorelines (Franzetti et al. 2012). Also, extracellular biosurfactant derived from A. calcoaceticus RAG-1 was efficient for the recovery of hexachtorobiphenyl from soil slurries (41.9 %) (Van Dyke et al. 1993). A complex of fatty acid and saccharide produced by Gordonia sp. was demonstrated to stimulate the degradation of weathered crude oil via the activity of the indigenous marine bacteria and stimulate the removal of crude oil from the surface of contaminated sea sand (Saeki et al. 2009).

Dispersant agents reduced the cohesive attraction between similar particles. With this, they prevent insoluble particles to form aggregations with each other. This property has application in oil field chemistry as it can lead desorption of hydrophobic molecules from rock surfaces enhancing mobility and recovery. The dispersants enhance the rate of natural dispersion of oils and their removal from the contaminated surface (Saeki et al. 2009). In addition, the dispersants increase surface area of oil as a result of its dispersion into small droplets that is expected to stimulate its biodegradation via the activity of naturally occurring microorganisms (Saeki et al. 2009). In fact, earlier works have shown that high molecular weight biosurfactants can work as efficient biodispersants of hydrophobic compounds. Biodispersan is an extracellular anionic polysaccharide produced by A. calcoaceticus A2 that changes the surface properties of limestone and acts both as a dispersant and as a grinding aid (Elkeles et al. 1994). Also, a complex of fatty acid and saccharide derived from Gordonia sp. showed great potential for application as an oil spill dispersant (Saeki et al. 2009). Pines and Gutnick (1986) reported the beneficial effect of emulsan in the dispersion of crude oil essential for the growth of the producing strain.

Use of biosurfactant for detergency and cleaning

A detergent is a surfactant or a mixture of surfactants with cleaning properties in dilute solutions. Owing diverse properties, biosurfactants and bioemulsifiers can act in similar way as that of detergents as well as in oil industry, laundry detergent formulation and cosmetic. According to Joshi-Navare et al. (2013), main properties enable the use of biosurfactants in detergent formulation, mainly, emulsifying, washing, wetting, foaming and dispersing capacities as well as the anti-microbial activity. This is specifically advantageous owing the biodegradability, ecofriendly, and nontoxic nature of biosurfactant.

In fact, biosurfactants are used as detergents in cleaning up hydrocarbon/crude oil storage tank. Chamanrokh et al. (2010) showed the efficiency of the bio-emulsifiers produced by autochthonous bacteria for cleaning hydrocarbonaceous residues at a like manner to emulsan produced by A. calcoaceticus PTCC 1318. Such cleanup process is highly desirable as it is economically rewarding and environmentally friendly. Moreover, a proteoglycan bioemulsifier with protein, polysaccharide and lipid moieties produced by Acinetobacter sp. formed stable emulsion oil-in-water emulsions with plant oils and displayed good cleaning property towards different oils (Jagtap et al. 2010). A high molecular weight, thermostable biopolymer produced by an alkaliphilic bacterium, Klebsiella sp. strain RJ-03, composed of sugar, uronic acid, protein and sulfate, showed an excellent oil removing efficiency from soil and cotton cloths as compared to chemical surfactants (Jain et al. 2012).

Biomedical and therapeutic applications

Biosurfactants are well known by their membrane permeabilization property as they can induce pore and ion channels formation in lipid bilayer membrane. So, they are able to destabilize membranes disturbing their integrity and permeability. Also, pore formation in membranes may cause trans-membrane ion influxes, including Na+ and K+, which result in membrane disruption and cell death. These structural fluctuations acting therefore on biological membrane integrity can explain the primary mode of the antibiotic action resulting in the important biological activities of biosurfactants including antibacterial; antifungal; antiviral; anti-mycoplasma and hemolytic activities (Fracchia et al. 2012). Therefore, high molecular weight bioemulsifiers are well known by their antibacterial activities against pathogenic bacteria. In fact, a novel biosurfactant isolated from Lactobacillus paracasei ssp. paracasei showed antimicrobial activity against several micro-organisms including the pathogenic Candida albicans, E. coli, Staphylococcus aureus, Staphylococcus epidermidis and Streptococcus agalactiae with a minimum inhibitory concentration and a minimum bactericidal concentration ranging from 25 to 50 mg/mL (Gudina et al. 2010). A fatty acid derivative produced by Halomonas sp. has a potent use as antimicrobial and anticancer drugs in biomedical field. It exhibited antimicrobial activity against a variety of human pathogenic bacteria (S. aureus, Klebsiella pneumonia, Streptococcus pyrogens and Salmonella typhi) and fungi (Trichophyton rubrum, Aspergillus niger, Aspergillus flavus and Fusarium sp.). It could also suppress the proliferation of mammary epithelial carcinoma cell by 46.77 % at 2.5 μg concentration (Donio et al. 2013).

Rufino et al. (2011) have demonstrated the antimicrobial property of the crude biosurfactant isolated from C. lipolytica UCP0988 against several pathogenic bacteria suggesting the possibility of the use of this biosurfactant as an alternative antimicrobial agent in the medical field. Moreover, this biosurfactant showed anti-adhesive activity against most of the microorganisms tested (Rufino et al. 2011). Similarly, the surface-binding protein derived from Lactobacillus fermentum RC-14 inhibited adhesion of Enterococcus faecalis (Heinemann et al. 2000).

Having the ability to alter the cell surface hydrophobicity, adsorption of biosurfactant on solid surfaces can inhibit the bioadhesion of pathogenic bacteria (Cao et al. 2009). It’s very interesting for medical and food applications to preserve food from pathogenic bacteria spoilage and to protect biomedical material from nosocomial infections and biofilm formation (Cao et al. 2009). A surface active agent, mannoprotein, derived from S. cerevisiae may be used as inhibitor of S. aureus and S. epidermidis biofilm development for potential application in pharamaceutical industry (Walencka et al. 2007). A lactobacillus acidophilus derived surlactin was proved to inhibit the adhesion of biofilm formed by P. aeruginosa to surfaces up to 60 %. So, it showed an ability to treat the infection in rabbits’ eyes inoculated with P. aeruginosa (Ismaeel et al. 2013). Two homologs of phospholipids biosurfactants produced by P. putida were also shown to inhibit the bacterial adhesion by 23–72 % and that of C. albicans by 96–98 % (Janek et al. 2013).

In addition to the antibacterial potency and the anti-adhesive properties, polymeric biosurfactants are reported as useful as potent adjuvant and were also described as involved in immune responses. The partially degraded lipopolysaccharides of Burkholderia cepacia and the ornithine-containing lipids were purified from some bacteria, having weak toxicity and a great ability to activate the immune systems of the living body, were developed as complex lipid adjuvants (Kawai et al. 2002). The typical bacterial ornithine-containing lipid, exhibited strong interleukin-1- and prostaglandin E2-inducing activities, and further, it induced the production of high IgG anti-tetanus toxoid antibodies in mice is expected to be utilized as a nontoxic, potent adjuvant (Kawai et al. 1999). In a study conducted by Panilaitis et al. (2002), it was demonstrated that emulsan activates macrophages in a dose-dependent manner and this significant immunopotentiation demonstrated by this complex polymer establishes emulsan as an exciting new candidate adjuvant. Seo et al. (2008) demonstrated the involvement of bacterial lipoteichoic acid in inducing immune responses to gram-positive bacteria and its role in inducing inflammatory responses. Moreover, bacterial fimbriae derived from Porphyromonas gingivalis and their peptides activate human gingival epithelial cells through Toll-Like Receptor 2 (Asai et al. 2001). Besides that, researchers developed the potential use of polymeric bioemulsifiers as anticancer agents such as the outer membrane vesicles of Actinobacillus actinomycetemcomitans (Demuth et al. 2003).

Conclusion

In the past 30 years, several different polymeric biosurfactants have been discovered and numerous producing strains have been isolated and characterized. Microbial derived polymeric biosurfactants showed many interesting functional properties such as the ability to reduce the surface and interfacial tension, the emulsification and de-emulsification capacities, the foaming potency, the dispersing capacity, the solubilization and mobilization abilities and the pore-forming capacities. These permitted their applications in environmental field as great enhancers of hydrocarbons solubility, mobility and biodegradation. They are also potential candidates in biomedicine and therapeutics for their great antimicrobial, anti-adhesive and immune-modulating. Owing these fascinating properties and wide spectrum applications besides awareness of the importance of social development and environmental sustainability has aroused, polymeric biosurfactants became replacers of the synthetic surfactants. So, great efforts are needed in their production and purification at industrial scale.

References

Albuquerque CDC, Filetti AMF, Campos-Takaki GM (2006) Optimizing the medium components in bioemulsifiers production by Candida lipolytica with response surface method. Canad J Microbiol 52:575–583

Amézcua-Vega C, Poggi-Varaldo HM, Esparza-García F, Ríos-Leal E, Rodríguez-Vázquez R (2007) Effect of culture conditions on fatty acids composition of a biosurfactant produced by Candida ingens and changes of surface tension of culture media. Bioresour Technol 98(1):237–240

Amodu OS, Ojumu TV, Obed Ntwampe SK (2013) Bioavailability of high molecular weight polycyclic aromatic hydrocarbons using renewable resources. Environmental biotechnology—new approaches and prospective applications, Chapter 8 http://dx.doi.org/10.5772/54727

Arli SD, Trivedi UB, Patel KC (2011) Curdlan-like exopolysaccharide production by Cellulomonas flavigena UNP3 during growth on hydrocarbon substrates. World J Microbiol Biotechnol 27:1415–1422

Asai Y, Ohyama Y, Gen K, Ogawa T (2001) Bacterial fimbriae and their peptides activate human gingival epithelial cells through toll-like receptor 2. Infect Immun 69(12):7387–7395

Ashtaputre AA, Shah AK (1995) Emulsifying property of a viscous exopolysaccharicle from Sphingomonas paucimobilis. World J Microbiol Biotecbnol 11:219–222

Augustin M, Tene Hippolyte M (2012) Screening of biosurfactants properties of cell-free supernatants of cultures of Lactobacillus spp. isolated from a local fermented milk (Pendidam) of Ngaoundere (Cameroon). Int J Eng Res Appn 2(5):974–985

Avila-Calderon ED, Lopez-Merino A, Jain N, Peralta H, Lopez-Villegas EO, Sriranganathan N, Boyle SM, Witonsky S, Contreras-Rodriguez A (2011) Characterization of outer membrane vesicles from Brucella melitensis and protection induced in mice. Clin Develop Immunol. doi:10.1155/2012/352493

Barkay T, Navon-Venezia S, Ron EZ, Rosenberg E (1999) Enhancement of solubilization and biodegradation of polyaromatic hydrocarbons by the bioemulsifier alasan. Appl Environ Microbiol 65:2697–2702

Bashetti SP, Palande PP, Mankar SG, Bhuyan SS, Chopade BA, Mujumdar SS (2012) Studies of bioemulsifier production by Acinetobacter Caalcoaceticus C42 islated from rhizosphere of corn. Int J Inst Pharm Life Sci 2(3):2249–6807

Batrakov SG, Konova IV, Sheichenko VI, Esipov SE, Galanina LA (2001) Two unusual glycerophospholipids from a filamentous fungus, Absidia corymbifera. Biochim Biophys Acta 1531:169–177

Beeba JL, Umbreit WW (1971) Extracellular lipid of Thiobacillus thiooxidans. J Bacteriol 108:612–615

BonillaM Olivaro C, Corona M, Vazquez A, Soubes M (2005) Production and characterization of a new bioemulsifier from Pseudomonas putida ML2. J Appl Microbiol 98(2):456–463

Boyle CD, Reade AE (1983) Characterization of two extracellular polysaccharides from marine bacteria. Appl Environ Microbiol 46:392–399

Bryant R (1987) Potential use of microorganisms in petroleum recovery technology. Proc Okla Acad Sci 67:97–104

Burd G, Ward OP (1996) Involvement of a surface-active high molecular weight factor in degradation of polycyclic aromatic hydrocarbons by Pseudomonas marginalis. Can J Microbiol 42:791–797

Burgos-Díaz C, Pons R, Espuny MJ, Aranda FJ, Teruel JA, Manresa A, Ortiz A, Marqués AM (2011) Isolation and partial characterization of a biosurfactant mixture produced by Sphingobacterium sp. isolated from soil. J Colloid Interf Sci 361:195–204

Calvo C, Ferrer MR, Martinez-Checa F, Be Jar B, Quesada E (1995) Some rheological properties of the extracellular polysaccharide produced by Volcaniella eurihalina F2-7. Appl Biochem Biotechnol 55:45–54

Calvo C, Martinez-Checa F, Mota A, Bejar V, Quesada E (1998) Effect of cations, pH and sulfate content on the viscosity and emulsifying activity of the Halomonas eurihalina exopolysaccharide. J Ind Microbiol Biotechnol 20:205–209

Camacho-Chab JC, Guézenne J, Chan-Baca MJ, Ríos-Leal E, Sinquin C, Muñiz-Salazar R, De la Rosa-García S, Del C, Reyes-Estebanez M, Ortega-Morales BO (2013) Emulsifying activity and stability of a non-toxic bioemulsifier synthesized by Microbacterium sp. MC3B-10. Int J Mol Sci 14:18959–18972

Cameron DR, Cooper DG, Neufeld RJ (1988) The mannoprotein of Saccharomyces cerevisiae is an effective bioemulsifier. Appl Environ Microbiol 54(6):1420–1425

Cappello S, Crisari A, Denaro R, Crescenzi F, Porcelli F, Yakimov MM (2011) Biodegradation of a bioemulsificant exopolysaccharide (EPS2003) by marine bacteria. Wat Air Soil Poll 214:645–652

Castro GR, Panilaitis B, Kaplan DL (2008) Emulsan, a tailorable biopolymer for controlled release. Bioresour Technol 99:4566–4571

Cao X-H, Liao Z-Y, Wang C-L, Yang W-Y, Lu M-F (2009) Evaluation of a lipopeptide biosurfactant from Bacillus natto TK-1 as a potential source of anti-adhesive, antimicrobial and antitumor activities. Braz J Microbiol 40:373–379

Chamanrokh P, Mazaheri Assadi M, Amoabediny Gh, Rashedi H (2010) Cleaning oil-contaminates vessel by emulsan producers (authochthonous bacteria). Iran J Environ Health Sci Eng 7(3):209–222

Choma A, Komaniecka I (2002) Analysis of phospholipids and ornithine-containing lipids from Mesorhizobium spp. Syst Appl Microbiol 25:326–331

Cirigliano MC, Carman GM (1985) Purification and characterization of liposan, a bioemulsifier from Candida lipolytica. Appl Environ Microbiol 50:846–850

Das M (2001) Characterization of de-emulsification capabilities of a Micrococcus species. Bioressour Technol 79:15–22

Dastgheib SMM, Amoozegar A, Elahi E, Asad Sand Banat M (2008) Bioemulsifier production by a halothermophilic Bacillus strain with potential applications in microbially enhanced oil recovery. Biotechnol Lett 30:263–270

de Souza Sobrinho HB, de Luna JM, Rufino RD, Lúcia A, Porto F, Sarubbo LA (2013) Assessment of toxicity of a biosurfactant from Candida sphaerica UCP 0995 cultivated with industrial residues in a bioreactor. Elect J Biotechnol. doi:10.2225/vol16-issue4-fulltext-4

Dehghan-Noudeh G, Moshafi MH, Sharififar F, Masoumi MA (2007) Studies of biosurfactant production by Acinetobacter calcoaceticus (PTCC 1318). Jundish J Nat Pharm Prod 2(2):116–123

Demuth DR, James D, Kowashi Y, Kato S (2003) Interaction of Actinobacillus actinomycetemcomitans outer membrane vesicles with HL60 cells does not require leukotoxin. Cell Microbiol 5(2):111–121

Desai JD, Banat IM (1997) Microbial production of surfactants and their commercial potential. Am Soc Microbiol 61:47–64

Deshmukh C, Jagtap CB, Titus S, Kumar P (2012) Isolation and characterization of fatty acid esters and hosphatidylethanolamine surfactants from a consortium of marine bacteria. Ind J Geo-Mar Sci 41(5):398–404

Dikit P, Maneerat S, Musikasang H, H-kittikun A (2010) Emulsifier properties of the mannoprotein extract from yeast isolated from sugar palm wine. Sci Asia 36:312–318

Donio MBS, Ronica FA, Viji VT, Velmurugan S, Adlin Jenifer JSC, Michaelbabu M, Dhar P, Citarasu T (2013) Halomonas sp. BS4, a biosurfactant producing halophilic bacterium isolated from solar salt works in India and their biomedical importance. Springer Plus 2:149

Doshi DV, Maniyar JP, Bhuyan SS, Mujumdar SS (2010) Studies on bioemulsifier production Actinopolyspora sp. A18 isolated from garden soil. Ind J Biotechnol 9:391–396

Duvnjak Z, Kosaric N (1985) Production and release of surfactant by Corynebacterium lepus in hydrocarbon and glucose media. Biotechnol Lett 7:793–796

Duvnjak Z, Cooper DG, Kosaric N (1982) Production of surfactant by Arthrobacter paraffineus ATCC19558. Biotechnol Bioeng 24:165–175

Edwards SG, Seddon B (2001) Mode of antagonism of Brevibacillus brevis against Botrytis cinerea in vitro. J Appl Microbiol 91(4):652–659

Edwards KR, Lepo JE, Lewis MA (2003) Toxicity comparison of biosurfactants and synthetic surfactants used in oil spill remediation to two estuarine species. Mar Pollut Bull 46(10):1309–1316

Elkeles A, Rosenberg E, Ron EZ (1994) Production and secretion of the polysaccharide biodispersan of Acinetobacter calcoaceticus A2 in protein secretion mutants. Appl Environ Microbiol 60:4642–4645

Fattom A, Shilo M (1985) Production of emulcyan by Phormidium J-1: its activity and function. FEMS Microbiol Lett 31(1):3–9

Fracchia L, Cavallo M, Martinotti MG, Banat IM (2012) Biosurfactants and bioemulsifiers biomedical and related applications—present status and future potentials, biomedical science, engineering and technology, Prof. Dhanjoo N. Ghista (Ed.), ISBN: 978-953-307-471-9

Franzetti A, Gandolfi I, Raimondi C, Bestetti G, Banat IM, Smyth TJ, Papacchini M, Cavallo Fracchia ML (2012) Environmental fate, toxicity, characteristics and potential applications of novel bioemulsifiers produced by Variovorax paradoxus 7bCT5. Bioresour Technol 108:245–251

Garduno RA, Phipps BM, Kay WW (1995) Physical and functional s-layer reconstitution in Aeromonas salmonicida. J Bacteriol 177:2684–2694

Geske T, Vom Dorp K, Dörmann P, Hölzl G (2013) Accumulation of glycolipids and other non-phosphorous lipids in Agrobacterium tumefaciens grown under phosphate deprivation. Glycobiol 23:69–80

Gudina EJ, Rocha V, Teixeira JA, Rodrigues LR (2010) Antimicrobial and antiadhesive properties of a biosurfactant isolated from Lactobacillus paracasei ssp. paracasei A20. Lett Appl Microbiol 50:419–424

Guezennec JG, Pignet P, Raguenes G, Deslandes E, Lijour Y, Gentric E (1994) Preliminary chemical characterization of unusual eubacterial exopolysaccharides of deep-sea origin. Carbohydr Polym 24:287–294

Gutiérrez T, Mulloy B, Black K, Green DH (2007) Glycoprotein emulsifiers from two marine Halomonas species: chemical and physical characterization. J Appl Microbiol 103:1716–1727

Haggar A, Hussain M, Lönnies H, Herrmann M, Norrby-Teglund A, Flock JI (2003) Extracellular adherence protein from Staphylococcus aureus enhances internalization into eukaryotic cells. Infect Immun 71(5):2310–2317

Hanson KG, Kale VC, Desai AJ (1994) The possible involvement of cell surface and outer membrane proteins of Acinetobacter sp.A3 in crude oil degradation. FEMS Microbiol Lett 122:275–280

Heinemann C, van Hylckama Vlieg JET, Janssen DB, Busscher HJ, van der Mei HC, Reid G (2000) Purification and characterization of a surface-binding protein from Lactobacillus fermentum RC-14 that inhibits adhesion of Enterococcus faecalis 1131. FEMS Microbiol Lett 190(1):177–180

Hisatsuka K, Nakahara T, Yamada K (1972) Protein-like activator for n-alkane oxidation by Pseudomonas aeruginosa S7B1. Agric Biol Chem 36:1361–1369

Hisatsuka K, Nakahara T, Minoda Y, Yamada K (1977) Formation of protein-like activator for n-alkane oxidation and its properties. Agric Biol Chem 41:445–450

Hou N, Li D, Ma F, Zhang J, Xu Y, Wang J, Li C (2013) Effective biodemulsifier components secreted by Bacillus mojavensis XH-1 and analysis of the demulsification process. Biodegr. doi:10.1007/s10532-013-9679-5

Ismaeel M Ch, Ibrahim KM, Al-Malikey M Kh (2013) The effect of surlactin produced by Lactobacillus acidophilus on eye infectious bacteria in rabbits. J Baghdad Sci 10(1):133–143

Jagtap S, Yavankar S, Pardesi K, Chopade B (2010) Production of bioemulsifier by Acinetobacter species isolated from healthy human skin. Ind J Exp Biol 48:70–76

Jain RM, Mody K, Mishra A, Jha B (2012) Physicochemical characterization of biosurfactant and its potential to remove oil from soil and cotton cloth. Carbohydr Polym 89:1110–1116

Janek T, Łukaszewicz M, Krasowska A (2013) Identification and characterization of biosurfactants produced by the Arctic bacterium Pseudomonas putida BD2. Colloids Surf B Biointerf. doi:10.1016/j.colsurfb.2013.05.008

Janiyani KL, Purohit HJ, Shanker R, Khanna P (1994) Deemulsification of oil-in-water emulsions by Bacillus subtilis. World J Microbiol Biotechnol 10:445–452

Johnson V, Singh M, Saini VS, Adhikari DK, Sista V, Yadav NK (1992) Bioemulsifier production by an oleaginous yeast Rhodotorulaglutinis IIP-30. Biotechnol Lett 14(6):487–490

Joshi-Navare K, Khanvilkar P, Prabhune A (2013) Jatropha oil derived sophorolipids: production and characterization as laundry detergent additive. Biochem Res Int. doi:10.1155/2013/169797

Kaeppeli O, Finnery WR (1979) Partition of alkane by an extracellular vesicle derived from haexdecane-grown Acinetobacter. J Bacteriol 140(2):707–712

Katemai W, Maneerat S, Kawai F, Kanzaki H, Nitoda T, H-Kittikun A (2008) Purification and characterization of a biosurfactant produced by Issatchenkia orientalis SR4. J Gen Appl Microbiol 54:79–82

Kawahara H, Hirai A, Minabe T, Obata H (2013) Stabilization of astaxanthin by a novel biosurfactant produced by Rhodotorula mucilaginosa KUGPP-1. Biocontrol Sci 18(1):21–28

Kawai Y, Nakagawa Y, Matuyama T, Akagawa K, Itagawa K, Fukase K, Kusumoto S, Nishijima M, Yano I (1999) A typical bacterial ornithine-containing lipid Nα-(D)-3-(hexadecanoy-loxy)hexadecanoyl]-ornithine is a strong stimulant for macrophages and a useful adjuvant. FEMS Immunol Med Microbiol 23:67–73

Kawai Y, Watanabe M, Matsuura M, Nishijima M, Kawahara K (2002) The partially degraded lipopolysaccharide of Burkholderia cepacia and ornithine-containing lipids derived from some gram-negative bacteria are useful complex lipid adjuvants. EMS Immunol Medical Microbiol 34:173–179

Khandelwal P, Banerjee-Bhatnagar N (2003) Insecticidal activity associated with the outer membrane vesicles of Xenorhabdus nematophilus. Appl Environ Microbiol 169(4):2032–2037

Kitamoto D, Isoda H, Nakahara T (2002) Functions and potential applications of glycolipids biosurfactants–from energy–saving materials to gene delivery carriers. J Biosci Bioeng 94:187–201

Kokare CR, Kadam SS, Mahadik KR, Chopade BA (2007) Studies on bioemulsifier production from marine Streptomyces sp. S1. Ind. J Biotechnol 6:78–84

Kretschmer A, Bock H, Wagner F (1982) Chemical and physical characterisation of interfacial-active lipids from Rhodococcus erythropolis grown on n-alkanes. Appl Environ Microbiol 44:864

Lang S, Philp JC (1998) Surface-active lipids in rhodococci. Antonie Van Leeuwenhoek 74:59–70

Leahy JG, Khalid ZM, Quintero EJ, Jones-Meehan JM, Heidelberg JF, Batchelor PJ, Colwell RR (2003) The concentrations of hexadecane and inorganic nutrients modulate the production of extracellular membrane-bound vesicles, soluble protein, and bioemulsifier by Acinetobacter venetianus RAG1 and Acinetobacter sp. strain HO1-N. Canad J Microbiol 49(9):569–575

Lee JC, Lee KY (2000) Emulsification using environmental compatible emulsifiers and de-emulsification using DC field and immobilized Nocardia amarae. Biotechnol Lett 22:1157–1163

Liang T-W, Wu C-C, Cheng W-T, Chen Y-C, Wang C-L, Wang I-L, Wang S-L (2014) Exopolysaccharides and antimicrobial biosurfactants produced by Paenibacillus macerans TKU029. Appl Biochem Biotechnol 172:933–950

Liu J, Peng J, Huang X, Lu L, Cheng H, Yang D, Zhou Q, Deng H (2011) Application of waste frying oils in the biosynthesis of biodemulsifier by a demulsifying strain Alcaligenes sp. S-XJ-1. J Environ Sci 23(6):1020–1026

Lukondeh T, Ashbolt NJ, Rogers PL (2003) Evaluation of Kluyveromyces marxianus FII 510700 grown on a lactose-based medium as a source of a natural bioemulsifier. J Ind Microbiol Biotechnol 30:715–720

Ly MH, Naïtali-Bouchez M, Meylheuc T, Bellon-Fontaine M-N, Le Mai T, Belin J-M, Waché Y (2006) Importance of bacterial surface properties to control the stability of emulsions. Int J Food Microbiol 112:26–34

Macdonald CR, Cooper DG, Zajic JE (1981) Surface-active lipids from Nocardia erythropolis grown on hydrocarbons. Appl Environ Microbiol 41(1):117–123

Maki JS, Ding L, Stokes J, Kavouras JH, Rittschof D (2000) Substratum/bacterial interactions and larval attachment: films and exopolysaccharides of Halomonasmarina (ATCC 25374) and their effect on barnacle cyprid larvae, Balanus amphitrite Darwin. Biofouling 16:159–170

Maneerat S, Bamba T, Harada K, Kobayashi A, Yamada H, Kawai F (2006) A novel crude oil emulsifier excreted in the culture supernatant of a marine bacterium Myroides sp. Strain SM1. Appl Microbiol Biotechnol 70:254–259

Maniyar JP, Doshi DV, Bhuyan SS, Mujumdar SS (2011) Bioemulsifier production by Streptomyces sp. S22 isolated from garden soil. Ind J Exp Biol 49:293–297

Marrakchi H, Lanéelle M-A, Daffé M (2014) Mycolic acids: structures, biosynthesis, and beyond. Chem Biol 21(1):67–85

Martinez-Checa F, Toledo FL, El Mabrouki K, Quesada E, Calvo C (2007) Characteristics of bioemulsifier V2-7 synthesized in culture media added of hydrocarbons: chemical composition, emulsifying activity and rheological properties. Bioresour Technol 98:3130–3135

Mohebali G, Kaytash A, Etemadi N (2012) Efficient breaking of water/oil emulsions by a newly isolated de-emulsifying bacterium, Ochrobactrum anthropi strain RIPI5-1. Colloids Surf B Biointerf 98:120–128

Mousavian SS, Rahimi KY (2010) Eumsan production by Acinetobacter calcoaceticus RAG-1 ATCC-31012. Iran J Food Sci Technol 7(3):117–125

Munstermann B, Poremba K, Lang S, Wagner F (1992) Studies on environmental compatibility: influence of (bio) surfactants on marine microbial and enzymatic systems. In Proceedings of the international symposium on soil decontamination using biological processes p. 414–420, 6–9, Karlsruhe, Germany. Frankfurt: Dechema

Nadarajah N, Singh A, Owen P (2002) Evaluation of a mixed bacterial culture for de-emulsification of water-in-petroleum oil emulsions. World J Microbiol Biotechnol 18:435–440

Navon-Venezia S, Zosim Z, Gottlibe A, Leggman R, Carmeli S, Ron EZ, Rosenberg E (1995) Alsan, a new bioemulsifier from Acinetobacter redioresistens. Appl Environ Microbiol 61:3240–3244

Navon-Venezia S, Banin E, Ron EZ, Rosenberg E (1998) The bioemulsifier alasan: role of protein in maintaining structure and activity. Appl Microbiol Biotechnol 49:382–384

Oloke JK, Glick BR (2005) Production of bioemulsifier by an unusual isolate of salmon/red melanin containing Rhodotorula glutinis. Afr J Biotechnol 4(2):164–171

Orsod M, Joseph M, Huyop F (2012) Characterization of exopolysaccharides produced by Bacillus cereus and Brachybacterium sp. Isolated from Asian Sea Bass (Lates calcarifer). Malays. J Microbiol 8(3):170–174

Pacwa-Plociniczak M, Plaza GA, Piotrowska-Seget Z, Cameotra SS (2011) Environmental applications of biosurfactants: recent advances. Int J Mol Sci 12:633–654

Panilaitis B, Johri A, Blank W, Kaplan DL, Fuhrman J (2002) Adjuvant activity of emulsan, a secreted lipopolysaccharide from Acinetobacter calcoaceticus. Clin Diagn Lab Immunol 9:1240–1247

Panilaitis B, Castro GR, Solaiman D, Kaplan DL (2007) Biosynthesis of emulsan biopolymers from agro-based feedstocks. J Appl Microbiol 102:531–537

Paraszkiewicz K, Kanwal A, Długonski J (2002) Emulsifier production by steroid transforming filamentous fungus Curularia lunata. Growth and product characterization. J Biotechnol 92:287–294

Park SH, Lee J-H, Ko S-H, Lee D-S, Lee HK (2000) Demulsifcation of oil-in-water emulsions by aerial spores of a Streptomyces sp. Biotechnol Lett 22:1389–1395

Patil JR, Chopade BA (2001) Studies on bioemulsifier production by Acinetobacter strains isolated from healthy human skin. J Appl Microbiol 91:290–298

Patrick S, McKenna JP, O’Hagan S, Dermott E (1996) A comparison of the haemagglutinating and enzymic activities of Bacteroides fragilis whole cells and outer membrane vesicles. Microb Pathog 20:191–202

Peng F, Liu Z, Wang L, Shao Z (2007) An oil-degrading bacterium: Rhodococcus erythropolis strain 3C-9 and its biosurfactants. J Appl Microbiol 102(6):1603–1611

Perfumo A, Smyth TJP, Marchant R, Banat IM (2009) Production and roles of biosurfactants and bioemulsifiers in accessing hydrophobic substrates: microbiology of hydrocarbons, oils, lipids, and derived compounds. In: Timmis KN (ed). Springer, UK (in press)

Perfumo AS, Smyth TJP, Marchant R, Banat I (2010) Production and roles of biosurfactants and bioemulsifiers in accessing hydrophobic substrates: In handbook of hydrocarbon and lipid microbiology. In: Timmis K.N (ed). Chap. 47. 2(7):1501–1512

Petrovski S, Dyson ZA, Quill ES, McIlroy SJ, Tillett D, Seviour RJ (2011) An examination of the mechanisms for stable foam formation in activated sludge systems. Water Res 45:2146–2154

Pines O, Gutnick D (1986) Role for emulsan in growth of Acinetobacter calcoaceticus RAG-1 on crude oil. Appl Environ Microbiol 51(3):661–663

Planckaert M (2005) Oil reservoirs and oil production. Petroleum microbiology. ASM Press, Washington

Post FJ, Collins NF (1982) A preliminary investigation of the membrane lipid of Halobacterium halobium as a food additive. J Food Biochem 6(1):25–38

Prapulla SG, Jacob Z, Nagin C, Rajalakshmi R, Karanth NG (1992) Maximization of lipid production by Rhodotorula gracilis CFR-1 using response surface methodology. Biotechnol Bioeng 40:965–970

Rahman KSM, Gakpe E (2008) Productioncharacterization and applications of biosurfactants-review. Biotechnol 7(2):360–370

Rhee CH, Park HD (2001) Three glycoproteins with antimutagenic activity Identified in Lactobacillus plantarum KLAB21. Appl Environ Microbiol 67(8):3445–3449

Rodrigues RL, Teixeira AJ, van der Mei CH, Oliveira R (2006) Physicochemical and functional characterization of a biosurfactant produced by Lactococcus lactis 53. Colloids Surf B Biointerf 49:79–86

Ron E, Rosenberg E (2001) Natural roles of biosurfactants. Environ Microbiol 3:229–236

Rosenberg E, Ron EZ (1999) High- and low-molecular-mass microbial surfactants. Appl Microbiol Biotechnol 52:154–162

Rosenberg M, Bayer EA, Delarea J, Rosenberg E (1982) Role of thin fimbriae in adherence and growth of acinetobacter calcoaceticus RAG-1 on hexadecane. Appl Environ Microbiol 44(4):929–937

Rosenberg E, Schwartz Z, Tenenbaum A, Rubinovitz C, Legmann R, Ron EZ (1989) Microbial polymer that changes the surface properties of limestone: effect of biodispersan in grinding limestone and making paper. J Dispers Sci Technol 10:241–250

Rufino RD, Sarubbo LA, Campos-Takaki GM (2007) Enhancement of stability of biosurfactant produced by Candida lipolytica using industrial residue as substrate. World J Microbiol Biotechnol 23(5):729–734

Rufino RD, de Luna JM, Sarubbo LA, Marona Rodrigues LR, Teixeira JAC, de Campos-Takaki GM (2011) Antimicrobial and anti-adhesive potential of a biosurfactants produced by Candida Species. Practical applications in biomedical engineering; Chapter 10; doi: 10.5772/52578

Sadouk Z, Tazerouti A, Hacene H (2009) Biodegradation of diesel oil and production of fatty acid esters by a newly isolated Pseudomonas citronellolis KHA. World J Microbiol Biotechnol 25:65–70

Saeki H, Sasaki M, Komatsu K, Miura Matsuda H (2009) Oil spill remediation by using the remediation agent JE1058BS that contains a biosurfactant produced by Gordonia sp. strain JE-1058. Bioresour Technol 100:572–577

Salehizadeh H, Mohammadizad S (2009) Microbial enhanced oil recovery using biosurfactant produced by Alcaligenes faecalis. Iran J Biotechnol 7(4):216–223

Salihu A, Abdulkadir I, Almustapha MN (2009) An investigation for potential development on biosurfactants. Biotechnol Mol Biol Rev 3(5):111–117

Sarubbo LA, de Luna JM, de Campos-Takaki GM (2006) Production and stability studies of the bioemulsifier obtained from a new strain of Candida glabrata UCP 1002. Elect J Biotechnol 9(4):400–406

Satpute SK, Banat IM, Dhakephalkar PK, Banpurkar AG, Chopade BA (2010) Biosurfactants, bioemulsifiers and exopolysaccharides from marine microorganisms. Biotechnol Adv 28:436–450

Seghal Kiran G, Hema TA, Gandhimathi R, Selvin J, Anto Thomas T, Rajeetha Ravji T, Natarajaseenivasan K (2009) Optimization and production of a biosurfactant from the sponge-associated marine fungus Aspergillus ustus MSF3. Colloids Surf B Biointerf 73(2):250–256

Sen R (2008) Biotechnology in petroleum recovery: the microbial EOR. Prog Energy Combust Sci 34:714–724

Seo HS, Michalek SM, Nahm MH (2008) Lipoteichoic Acid Is Important in Innate Immune Responses to Gram-Positive Bacteria. Infect Immun 76(1):206–213

Sharma A, Novak EK, Sojar HT, Swank RT, Kuramitsu HK, Genco RJ (2000) Porphyromonas gingivalis platelet aggregation activity: outer membrane vesicles are potent activators of murine platelets. Oral Microbiol Immunol 15:393–396

Song H-Y, Kim Y-H, Seok S-J, Gil H-W, Yang J-O, Lee E-Y, Hong S-Y (2012) Cellular toxicity of surfactants used as herbicide additives. J Korean Med Sci 27:3–9

Stratton HM, Brooks PR, Griffiths PC, Seviour RJ (2002) Cell surface hydrophobicity and mycolic acid composition of Rhodococcus strains isolated from activated sludge foam. J Ind Microbiol Biotechnol 28:264–267

Su W-T, Chen W-J, Lin Y-F (2009) Optimizing emulsan production of A. venetianus RAG-1 using response surface methodology. Appl Microbiol Biotechnol 84:271–279

Suthar H, Hingurao K, Desai A, Nerurkar A (2008) Evaluation of bioemulsifier mediated microbial enhanced oil recovery using sand pack column. J Microbiol Methods 75:225–230

Tahara Y, Yamada Y, Kondo K (1976) A new lipid; the ornithine and taurine-containing ‘cerilipin’. Agric Biol Chem 40:243–244

Toledo FL, Gonzalez-Lopez J, Calvo C (2008) Production of bioemulsifier by Bacillus subtilis, Alcaligenes faecalis and Enterobacter species in liquid culture. Bioresour Technol 99:8470–8475

Toren A, Navon-Venezia S, Ron EZ, Rosenberg E (2001) Emulsifying activities of purified alasan proteins from Acinetobacter radioresistens KA53. Appl Environ Microbiol 67:1102–1106

Trindade JR, Freire MG, Amaral PFF, Coelho MAZ, Coutinho JAP, Marrucho IM (2008) Aging mechanisms of oil-in-water emulsions based on a bioemulsifier produced by Yarrowia lipolytica. Colloids Surf A Physicochem Eng Aspects 324:149–154

Tuleva B, Christova N, Cohen R, Antonova D, Todorov T, Stoineva I (2009) Isolation and characterization of trehalose tetraester biosurfactants from a soil strain Micrococcus luteus BN56. Process Biochem 44:135–141

Van Dyke M, Gulley S, Lee H, Trevors J (1993) Evaluation of microbial surfactants for recovery of hydrophobic compounds in soil. J Ind Microbiol Biotechnol 11:163–170

Vesper SJ (1987) Production of pili (fimbriae) by Pseudomonas fluorescens and correlation with attachment to corn roots. Appl Environ Microbiol 53(7):1397–1405

Walencka E, Wieckowska-Szakiel M, Rozalska S, Sadowska B, Rozalska B (2007) A surface-active agent from Saccharomyces cerevisiae influences staphylococcal adhesion and biofilm development. Z Naturforsch C 62(5–6):433–438

Wong JWC, Zhao Z, Zheng G (2010) Biosurfactants from Acinetobacter calcoaceticus BU03 enhance the bioavailability and biodegradation of polycyclic aromatic hydrocarbons. Proceedings of annual international conference on soils, sediments, water and energy

Huang X-f, Peng K, Feng Y, Liu J, Lu L (2013) Separation and characterization of effective demulsifying substances from surface of Alcaligenes sp. S-XJ-1 and its application in water-in-kerosene emulsion. Bioresour Technol 13:257–264

Yim JH, Ahn SH, Kim SJ, Lee YK, Park KJ, Lee HK (2005) Production of novel exopolysaccharide with emulsifying ability from marine microorganism, Alteromonas sp. strain 00SS11568. Key Eng Mat 277(279):155–161

Zhang Q, He G, Wang J, Cai W, Xu Y (2009) Mechanisms of the stimulatory effects of rhamnolipid biosurfactant on rice straw hydrolysis. Appl Energy 86:233–237

Zhao Z, Wong JWC (2009) Biosurfactants from Acinetobacter calcoaceticus BU03 enhance the solubility and biodegradation of phenanthrene. Environ Technol 30(3):291–299

Acknowledgments

This work has been supported by grants from ‘‘Tunisian Ministry of Higher Education, Scientific Research and Technology”.

Conflict of interest

The authors report no declaration of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mnif, I., Ghribi, D. High molecular weight bioemulsifiers, main properties and potential environmental and biomedical applications. World J Microbiol Biotechnol 31, 691–706 (2015). https://doi.org/10.1007/s11274-015-1830-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-015-1830-5