Abstract

The white-rot fungi Irpex lacteus KB-1.1 and Lentinus tigrinus LP-7 have been shown in previous studies to have high biobleaching activity in vivo. The aim of this study was to investigate the activities and stabilities of extracellular enzymes, prepared from I. lacteus and L. tigrinus culture grown in three types of economical media of agricultural and forestry wastes, for biobleaching of Acacia oxygen-delignified kraft pulp using kappa number reduction as an indicator of delignification. After 3 days of incubation, the extracellular enzymes preparations from I. lacteus and L. tigrinus cultures in media of Acacia mangium wood powder supplemented with rice bran and addition 1 % glucose (WRBG), resulted in significant decrease of 4.4 and 6.7 %, respectively. A slightly higher kappa number reduction (7.4 %) was achieved with the combine extracellular enzymes from I. lacteus and L. tigrinus. One of the strategies for reducing the cost of enzyme production for treatment processes in the pulp and paper industry is the utilization of agricultural and forestry waste. Thus, WRBG has potential as a culture medium for producing stable lignolytic enzymes simply and economically.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Enzymes from microorganisms have potential applications in the pulp and paper industry. These enzymes can reduce the use of chlorinated and other compounds utilized for chemical bleaching, as well as improving the quality of the pulp. Currently the most important application is the pre-bleaching of kraft pulp.

White-rot fungi have been recognized for their ability to completely degrade all ligninocellulosic materials to carbon dioxide and water (Boyle et al. 1992). The ability of some white-rot fungi to selectively degrade lignin has made them of increasing interest for biotechnological bleaching. The ability of white-rot fungi to degrade lignin is associated with their extracellular lignolytic enzymes, together with low-molecular-weight cofactors (Leonowicz et al. 1999). To date, four families of lignolytic enzymes are known to be involved in lignin degradation: manganese-dependent peroxidase (MnP), lignin peroxidase (LiP), manganese-independent peroxidase (MIP) and laccase (Lac). The activities of MnP, LiP and Lac have been correlated with increased brightness of kraft pulp (Katagiri et al. 1995). MIP was discovered in the white-rot fungus Bjerkandera sp. BOS55 (De Jong et al. 1992) and was shown to be potentially involved in biobleaching (Moreira et al. 2001).

Many researchers consider MnP to be most important lignolytic enzyme for kappa number reduction. A partial correlation between MnP activity and increased brightness has been found during the biobleaching process (Moreira et al. 1997). In addition, MnP-deficient mutants of Trametes versicolor are not able to cause bleaching and bleaching activity can be restored by the exogenous addition of MnP (Addleman et al. 1995). Consequently, research on MnP purification for biobleaching applications has intensified. Kondo et al. (1994) have reported that purified MnP can increase brightness in the presence of MnSO4, Tween 80, and sodium malonate with the continuous addition of H2O2. Harazono et al. (1996) purified MnP from the fungus Phanerochaete sordida YK-624 and were able to increase brightness in the presence of an organic acid such as oxalate. Thus, although MnP is a good enzyme for degrading residual lignin in pulp, it requires additional elements. A previous study has shown that the degradation of residual lignin in pulp is not due to MnP alone, but also to the present of Lac during the bleaching process (Reid and Paice 1994a). In addition, Westermark and Eriksson (1974) have reported that the degradation of lignin by white-rot fungi in nature is an interdependence system. Thus, all of the fungal enzymes cooperate to degrade wood components in nature. This must be considered when purifying specific lignolytic enzymes for biobleaching applications.

Reducing the cost of enzyme production is required for developing enzymatic treatment processes in the pulp and paper industry. The use of crude enzymes in biobleaching of loblolly pine kraft pulp has shown promising results (Re et al. 2008). This is because white-rot fungi produce hemicellulases (xylanase or mannanase) in addition to lignolytic enzymes and the medium also may include other proteins or factors that might stabilize the extracellular enzymes. However, nutrition also plays an important role in extracellular enzyme production. Commercial products such as malt extract, peptone, some vitamins, and minerals, are used in conventional fungal media and can be expensive if the enzymes are to be produced on a large scale. Residual agricultural and forestry wastes, such as rice bran and wood powder, could be used as sources of carbon, vitamins and minerals for producing extracellular enzymes and are accessible, easy-to-handle, and economical.

The present study evaluates the activities and stabilities of extracellular enzymes produced by Irpex lacteus KB-1.1 and Lentinus tigrinus LP-7 for biobleaching of Acacia oxygen-delignified kraft pulp (A-OKP). Our previous study with an in vivo system has shown that the biobleaching activities of I. lacteus and L. tigrinus greatly exceed those of the highly lignin-degradative fungi Phanerochaete chrysosporium and T. versicolor (Afrida et al. 2009). To our knowledge, this was the first use of I. lacteus for biobleaching and there have been only rare reports of biobleaching with L. tigrinus (Moreira et al. 1997).

Materials and methods

Fungal cultures

Irpex lacteus KB-1.1 and L. tigrinus LP-7 were maintained on agar slants at 30 °C. The medium was prepared with 0.2 % Acacia mangium wood powder, 0.01 % guaiacol and 1.6 % agar (Nishida et al. 1988). The pre-inoculum was obtained by incubating the fungi on potato dextrose agar (PDA) at 30 °C for 7 days.

Culture media and enzyme production

Extracellular enzyme production was carried out at 30 °C in shallow stationary liquid cultures (10 ml media in 100-ml Erlenmeyer flasks). The basal medium was 2 % A. mangium wood powder (40–60 mesh) and rice bran (3:2) in distilled water (WRB). The effect of replacing the distilled water with a 1 % aqueous solution of glucose (WRBG) was evaluated. To study the effect of manganese (Mn2+) in malonate buffer, 330 µM MnSO4.5H2O in 50 mM malonate buffer, pH 4.5, (WRBM) was substituted for distilled water. The flasks were inoculated with single plugs (6 mm diameter) from 1-week-old cultures grown on PDA and incubated without shaking at 30 °C. Every 3 days for 21 days, cultures were filtered and centrifuged at 10,000 rpm at 4 °C for 10 min and the supernatants were used for enzyme activity assays. The experiment was carried out in triplicate.

Enzyme activity assays

Enzyme activities were determined using a UV-1600 Shimadzu spectrophotometer. All the lignolytic enzymes, including MnP, Lac, LiP and MIP were assayed at 40 °C. The method of Hirai et al. (1994) was slightly modified to determine lignolytic activity. MnP, MIP and Lac activities were monitored by the oxidation of 2,6-dimethoxyphenol at A470. Reaction mixtures for MnP activity contained 1 mM 2,6-dimethoxyphenol, 0.2 mM H2O2 and 1 mM MnSO4, in 50 mM malonate buffer (pH 4.5). Reaction mixtures for MIP activity contained 1 mM 2,6-dimethoxyphenol, 0.2 mM H2O2 and 1 mM ethylenediaminetetraacetic acid (EDTA) in 50 mM malonate buffer (pH 4.5). Reaction mixtures for Lac activity contained 1 mM 2,6-dimethoxyphenol in 50 mM malonate buffer (pH 4.5). LiP activity was determined by monitoring the oxidation of veratryl alcohol at A310. Reaction mixtures contained 1.7 mM veratryl alcohol and 0.2 mM H2O2 in 20 mM succinate buffer (pH 3.0).

Analysis of organic acids

The extracellular fluid was collected from cultures with maximum MnP activity. Organic acids were analyzed by Capillary Electrophoresis System (Quanta 4000CE, Waters, Milford, MA, USA). The extracellular fluid was filtered with a membrane filter (pore size = 0.45 µm) and diluted 4 times with milliQ water. The standards, including citric acid, malic acid, tartaric acid, oxalic acid, succinic acid, malonic acid, and glycolic acid, were prepared with milliQ water at concentrations of 1 and 10 mM.

Pulp treatment

A-OKP was provided by an industrial kraft pulp mill in Indonesia and had an International Standard Organization (ISO) brightness of 47.6 % and a kappa number of 9. The A-OKP was used to determine the biobleaching activity of extracellular enzymes secreted by I. lacteus and L. tigrinus on WRB, WRBG and WRBM. The extracellular enzymes were collected from cultures with maximum MnP activity, filtered and centrifuged at 10,000 rpm for 10 min at 4 °C. The A-OKP was sterilized (121 °C, 20 min) in 25-ml screw cap bottles and samples (equivalent to 1 g oven-dried weight) were added to 10 ml of extracellular enzymes. The stationary reactions were incubated at 40 °C for 1, 2, 3 and 4 days. Controls without extracellular enzymes were carried out in parallel. After treatment, the pulp samples were filtered and washed with distilled water. The pulp lignin oxidation was measured by the difference in kappa number reduction between the assays with extracellular enzymes and the parallel controls. All treatments were performed in triplicate.

To determine the optimal incubation temperature, A-OKP prepared as above, was treated with extracellular enzymes of I. lacteus and L. tigrinus, obtained from WBRG cultures with maximum MnP activity at 30, 40 and 50 °C.

The effect of the pulp pH on biobleaching was assessed at pH 9, 7 and 4.5. The initial pH of A-OKP was 9.0. This was reduced to pH 7 by washing extensively with distilled water until the filtrate was colorless. The washed pulp was submerged overnight into 50 mM malonate buffer, pH 4.5. The pulps of various pHs were treated at 40 °C for 1, 2 and 3 days with the extracellular enzymes from WRBG cultures with maximum MnP activity.

Analytical techniques

Pulp brightness was determined by using a colorimeter (Suga Test instruments Co., Ltd, Japan). This method measures the brightness of white, near-white and natural-colored pulp and paper using the directional reflectance factor at 457 nm (T 452 om-92, TAPPI 1996). The kappa number was determined according to the micro kappa number measurement (Berzins 1966). This can be used to determine the degree of pulp delignification and is the volume (in ml) of 0.1 N potassium permanganate solutions that is consumed by 1 g of moisture-free pulp under the appropriate conditions (T 236 cm-85, TAPPI 1996).

Results

Extracellular lignolytic activities

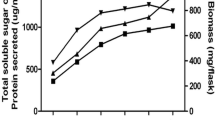

The time courses of lignolytic enzymes produced by I. lacteus and L. tigrinus grown on shallow stationary liquid cultures (WRB, WRBG and WRBM) were studied. Both strains produced MnP, MIP and Lac, but not LiP, in all culture media. Compared to L. tigrinus, I. lacteus showed lower production of lignolytic enzymes. As shown in Fig. 1, I. lacteus and L. tigrinus produced MnP as the dominant lignolytic enzyme activity. The peak lignolytic activities varied greatly according to the nutritional conditions. The lignolytic activities (MnP, MIP and Lac) increased significantly by about twofold to threefold in the present of Mn2+ in malonate buffer (WRBM), as compared to the basal medium (WRB). I. lacteus and L. tigrinus mycelial mats also grew better on WRBM than WRB (data not shown). In contrast, the culture medium containing glucose (WRBG) suppressed the production of extracellular lignolytic enzymes of I. lacteus and L. tigrinus by twofold as compared with WRB.

The maximum MnP activity produced by I. lacteus and L. tigrinus varied with the medium. Maximum MnP activity of L. tigrinus occurred after 12 days of incubation in all media (WRBM, 317 ± 42 µmol/L/min; WRB, 192 ± 21 µmol/L/min; WRBG, 99 ± 15 µmol/L/min) whereas I. lacteus showed maximum MnP activity after 6 days on WRBM (252 ± 24 µmol/L/min) and WRB (102 ± 21 µmol/L/min) and after 9 days on WRBG (39 ± 3 µmol/L/min) (Fig. 1).

The rapid acidification of WRB and WRBG cultures was observed during the growth of I. lacteus and L. tigrinus with the pH reaching a value close to 5 at 21 days (Fig. 2). However, the pH of WRBM cultures increased over the course of the incubation.

Biobleaching

The maximum activity of extracellular enzymes produced by I. lacteus and L. tigrinus on WRB, WRBG and WRBM were examined for their activity and stability in the biobleaching of Acacia kraft pulp (Fig. 3). Kappa number reduction occurred on 3 days of incubation with enzymes from I. lacteus grown on WRB and remained stable on 4 days. Meanwhile, kappa number reduction occurred on 2 and 4 days of incubation with enzyme from L. tigrinus grown on WRB. With enzymes from I. lacteus grown on WRBG, the kappa number was reduced on 1st day, decreased slightly on 2nd day, rose again on 3rd day, and remained stable on 4th day. With enzymes from L. tigrinus grown on WRBG, a kappa number reduction was detected on 1st day, decreased slightly on 2nd day, rose sharply on 3rd day and decreased on 4th day. Delignification by enzymes from I. lacteus and L. tigrinus grown on WRBM appeared on 1st day. However, on 2nd day and 3rd day, the kappa number increased with the enzymes from L. tigrinus. As shown on Fig. 3, enzymes from both I. lacteus and L. tigrinus grown on WRB and WRBM resulted in increased kappa number values. These increasing kappa numbers with A-OKP were also found with the extracellular enzymes from P. chrysosporium and T. versicolor grown on WRB and WRBM but not with the enzymes from the fungi on WRBG (data not shown). Three days of incubation appeared to be the proper amount of time for observing delignification. Although the extracellular enzyme activities were lower from WRBG cultures than from WRB and WRBM cultures, the A-OKP biobleaching activity and enzyme stabilities of both of the strains were better from WRBG. These results clearly illustrate that the lignolytic enzyme activities of the cultures are not indicative of their biobleaching abilities.

Following this preliminary study, we examined the effect of temperature on biobleaching. The kappa number reduction was not improved significantly by biobleaching at 30 or 50 °C as compared with 40 °C with the combine extracellular enzymes from I. lacteus and L. tigrinus (Fig. 4A). A slight increase in kappa number reduction of the pulp was observed after 3 days of incubation at 40 °C with the combined extracellular enzymes from I. lacteus and L. tigrinus cultures grown on WRBG. These results also indicate that delignification was more stable during incubation at 40 °C than at 30 or 50 °C since the kappa number values did not increase at 40 °C.

We also determined the brightness values during the course of this experiment (Fig. 4B). Unfortunately, the reduction in kappa number was accompanied by a 2–3 point decrease in pulp brightness as compared to controls without enzymes. The initial pH of A-OKP from the mill was 9.0. The addition of the extracellular enzymes lowered the pH of the pulp to about 6.0 and this pH remained stable during four days of biobleaching (data not shown). Washing the pulp to pH 7.0 or submerging the pulp in malonate buffer to pH 4.5 did not improve the biobleaching ability or stability of the extracellular enzymes (Fig. 5).

Organic acids

We determined the presence of organic acids in the culture media when MnP is maximal (Fig. 6). The concentration of organic acids secreted by I. lacteus and L. tigrinus were highest in culture media containing glucose. Malonate and oxalate were detected in the culture medium containing glucose, but only oxalate was found in WRB and WRBM cultures. Compared to L. tigrinus, I. lacteus showed higher production of malonate on WRBG cultures. However, L. tigrinus showed higher production of oxalate compared to I. lacteus on WRBG.

Discussion

The extracellular lignolytic enzymes of I. lacteus and L. tigrinus were examined on WRB, WRBG and WRBM media. During fungal growth, MnP was the major oxidative enzyme activity detected in the extracellular fluid with all media. As expected, manganese and organic acids such as malonate increased the secretion of lignolytic activity. Kuan and Tien (1993) reported that the oxalate content of the culture fluid correlates with MnP activity, presumably because of its ability to chelate manganese. Moreover, glycolate, malonate, glucuronate, gluconate and 2-hydroxybutyrate stimulate the production of MnP isoenzymes in the extracellular fluid (Mester and Field 1997). In addition, manganese is considered to be an inducer of MnP activity (Buswell et al. 1995; Fu et al. 1997; Papinutti and Forchiassin 2003) and the expression of the mnp gene in P. chrysosporium cultures is dependent on manganese (Brown et al. 1991). Moreover, Lac catalyzes the oxidation of manganese in the presence of the chelators oxalate and malonate (Scholosser and Höper 2002) and manganese may influence the availability of endogenous veratryl alcohol which is a known cofactor of LiP (Mester et al. 1995). Consequently, organic acids and manganese are important, directly or indirectly, for the secretion of lignolytic enzymes into the culture medium.

Rüttiman-johnson et al. (1993) reported that the activities of Lac and MnP were higher in presence of high glucose (1 %) as compared to low glucose (0.1 %). However, in our study, the addition of 1 % glucose suppressed the lignolytic activity of I. lacteus and L. tigrinus as compared with the basal medium. In general, increasing concentrations of glucose in cultures increase the fungal biomass, but inhibit the synthesis of lignolytic enzymes (Yamanaka et al. 2008).

Previous studies have shown that MnP is correlated with delignification during biobleaching (Paice et al. 1993; Katagiri et al. 1995; Addleman et al. 1995). Therefore, MnP has an important role in the delignification of residual lignin in pulp. For this reason, we used the MnP maximum for collecting the extracellular enzymes for biobleaching. The extracellular enzymes from WRBG cultures seemed to be more stable than the extracellular enzymes from WRB or WRBM cultures for biobleaching A-OKP without increasing the kappa number. We suggest that this stability is due to the secretion of different natural co-factors in WRBG medium as compared with WRB and WRBM media. These natural co-factors are important for stabilizing the oxidized enzyme product and may include such organic acids. Important roles for organic acids in biobleaching systems have been discussed by Moreira et al. (1997, 1998, 1999, 2001) and include complexing Mn3+, stimulating production of extracellular lignolytic enzymes and secondary metabolites, and reducing oxygen radicals. The high concentrations of malonate and oxalate may correlate with activities and stabilitis of delignifying extracellular enzymes from WRBG cultures (Fig. 3). The malonate buffer in WRBM was converted by I. lacteus and L. tigrinus to oxalate (Fig. 5). The increasing pH of WRBM during the growth of both fungi (Fig. 2) may have been due to the conversion of malonate to oxalate. The acidification of the WRB and WRBG culture media was observed during the growth of I. lacteus and L. tigrinus. An association between acidification of the culture medium during fungal growth and organic acid production has been reported (Mäkelä et al. 2002; Hakala et al. 2005).

Our preliminary study shows potential for the application of extracellular enzymes of I. lacteus and L. tigrinus to biobleaching of A-OKP. However, in some cases we found an increase in the kappa number and a decrease in brightness after enzymatic treatment. We suggest that this may reflect possible lignin modification and/or repolymerization by the enzymes. Further study is necessary to elucidate these phenomena. There are some reports of lignin modification and decrease brightness after treatment with lignolytic enzymes (Arbeloa et al. 1992; Reid and Paice 1994b, 1998; Wong et al. 1999). Chakar and Ragauskas (1999) have reported that the loss in brightness may be attributable to quinone-type structures. Quinoids are known to be chromophores in lignin. Quinone residuals may be responsible for the darkening of pulp after enzymatic treatment and can be reversed with sodium borohydrate or repeated the enzyme treatments (Ehara et al. 1998).

The potential application of lignolytic enzymes in biotechnology will require large amounts of low-cost enzymes. One strategy is to stimulate the utilization of agricultural and forestry wastes. Wood powder and rice bran are commonly used as raw materials for culturing edible and medicinal mushrooms. Wood powder is a lignocellulosic material that is commonly used as a mushroom substrate and rice bran is an additive that can boost yield (Stamets 2000). Rice bran is known to be rich sources of carbohydrates (Hanmoungjai et al. 2000), proteins (Shih et al. 1999), lipids (Hemavathy and Prabhakar 1987), vitamins (Yasumoto et al. 1997; Diack and Saska 1994), and trace elements (Idouraine et al. 1996; Bergman et al. 1997). Cultures based on wood powder and rice bran can be used for the large-scale production of extracellular enzymes and are inexpensive, readily available and very simple. In contrast, Borràs et al. (2008) have evaluated the biotechnological cost of using T. versicolor and found that culturing with malt extract is too expensive to be considered. Production of lignolytic enzymes on agricultural and forestry wastes have been studied primarily by solid-state fermentation (Silva et al. 2005; Kachlishvili et al. 2006; Papinutti and Foarchiassin 2007).

Reducing the cost of enzyme production is necessary for developing enzymatic treatment processes in the pulp and paper industry. Therefore average cost of producing the extracellular enzymes in this study was evaluated. In addition to the cost of raw materials, simplicity, ease-of-handling and stability of the enzymes should be taken into consideration. We found that a medium such as WRBG, which is appropriate for extracellular enzyme production, can be obtained from agricultural waste including wood sawdust, rice bran and glucose. Cost of raw materials was used in this study including wood sawdust (US < $0.50/Kg), rice bran (US $1.00/Kg), and glucose (US $20.00/Kg). The calculated cost for 1 L of WRBG medium is US $0.21. Therefore, for biobleaching, if one ton pulp without water is treated with WRBG, the cost is US $2,100. However, if cost of WRBG is compared with malt extract (ME) known as general medium for culturing fungi, cost for 1 L ME is US $5.37 and US $53,700 to treat one ton pulp without water. Therefore, the use of WRBG for producing extracellular lignolytic enzymes may offer an economic advantage over a conventional medium such as ME. The present study is the first to examine the production of lignolytic enzymes using wood-powder-supplemented bran in shallow stationary liquid cultures.

References

Addleman K, Dumonceaux T, Paice MG, Bourbonnais R, Archibald FS (1995) Production and characterization of Trametes versicolor mutants unable to bleach hardwood kraft pulp. Appl Environ Microbiol 61(10):3687–3694

Afrida S, Tamai Y, Watanabe T, Osaki M (2009) Screening of white rot fungi for biobleaching of Acacia oxygen-delignified kraft pulp. World J Microbiol Biotechnol 25:639–647

Arbeloa M, Lesseleus J, Goma G, Pommier JC (1992) An evaluation of the potential of lignin peroxidase to improve pulps. Tappi J 75:215–221

Bergman CJ, Gualberto DG, Weber CW (1997) Minerals capacity of dephytinized insoluble fiber from extruded wheat, oat, and rice bran. Plant Food Hum Nutr 51:295–310

Berzins V (1966) Micro kappa number. Pulp Pap Mag Can 1996:T206–T208

Borràs E, Blànquez P, Sarrà M, Caminal G, Vicent T (2008) Trametes versicolor pellests production: low-cost medium and scale-up. Biochem Eng J 42:61–66

Boyle CD, Bradley RK, Reid ID (1992) Solubilization and mineralization of lignin by white rot fungi. Appl Environ Micribiol 58(10):3217–3224

Brown JA, Alic M, Gold MH (1991) Manganese peroxidase gene transcription in Phanerochaete chrysosporium: activation by manganese. J Bacteriol 173:4101–4106

Buswell JA, Chai Y, Chang S-T (1995) Effect of nutrient nitrogen and manganese on manganese peroxidase production by Lentinula (Lentinus) edodes. FEMS Microbiol Lett 128:81–88

Chakar FS, Ragauskas AJ (1999) The effect of oxidative alkaline extraction stages after laccaseHBT and laccaseNHAA treatments-an NMR study of residual lignins. Institute of Paper Science and Technology Atlanta, Georgia IPTS Technical Paper Series Number 822

De Jong E, Field JA, de Bont JAM (1992) Evidence for a new extracellular peroxidase: manganese inhibited peroxidase from the white rot fungi Bjerkandera sp BOS55. FEBS Lett 299:107–110

Diack M, Saska M (1994) Separation of vitamin E and γ-oryzanols from rice bran by normal-phase chromatography. JAOCS 17:1211–1217

Ehara K, Tsutsumi Y, Nishida T (1998) Structural changes of residual lignin in softwood kraft pulp treated with manganese peroxidase. J Wood Sci 44:327–331

Fu SY, Yu H-S, Buswell JA (1997) Effect of nutrient nitrogen and manganese peroxidase and laccase production by Pleurotus sajor-caju. FEMS Microbiol Lett 147:133–137

Hakala TK, Lundell T, Galkin S, Maijala P, Kalkkinen N, Hatakka A (2005) Manganese peroxidase, laccase and oxalic acid from the selective white rot fungus Physisporinus rivulosus grown on spruce wood chips. Enzym Microb Technol 36:461–468

Hanmoungjai P, Pyle L, Niranjan K (2000) Extraction of rice bran oil using aqueous media. J Chem Technol Biotechnol 75:348–352

Harazono K, Kondo R, Sakai K (1996) Bleaching of hardwood kraft pulp with manganese peroxidase from Phanerochaete sordida YK-624 without addition of MnSO4. Appl Envrion Microbiol 62(3):913–917

Hemavathy J, Prabhakar JV (1987) Lipid composition of rice (Oryza sativa L.) bran. JAOCS 64:1016–1019

Hirai H, Kondo R, Sakai K (1994) Screening of lignin-degrading fungi and their ligninolytic enzyme activities during biological bleaching of kraft pulp. Mokuzai Gakkaishi 40:980–986

Idouraine A, Khan MJ, Weber CW (1996) In vitro binding capacity of wheat bran, rice bran, and oat fiber for Ca, Mg, Cu, and Zn alone and its different combinations. J Agric Food Chem 44:2067–2072

Kachlishvili E, Penninckx MJ, Tsiklauri N, Elisashvili V (2006) Effect of nitrogen sources on lignocellulotic enzyme production by white-rot basidiomycetes under solid-state cultivation. World J Microbiol Biotechnol 22:391–397

Katagiri N, Tsutsumi Y, Nishida T (1995) Correlation of brightening with cumulative enzyme activity related to lignin biodegradation during biobleaching of kraft pulp by white rot fungi in the solid-state fermentation system. Appl Environ Microbiol 61(2):617–622

Kondo R, Harazono K, Sakai K (1994) Bleaching of hardwood kraft pulp with manganese peroxidise secreted from Phanerochaete sordida YK-624. Appl Environ Microbiol 60(12):4359–4363

Kuan I-C, Tien M (1993) Stimulation of Mn peroxidase activity: a possible role for oxalate in lignin degradation. Proc Natl Acad Sci 90:1242–1246

Leonowicz A, Matuszewska A, Luterek J et al (1999) Biodegradation of lignin by white rot fungi. Fungal Genet Biol 27:175–185

Mäkelä M, Galkin S, Hatakka A, Lundell T (2002) Production of organic acids and oxalate decarboxylase in lignin-degrading white rot fungi. Enzym Microb Technol 30:542–549

Mester T, Field JA (1997) Optimization of manganese peroxidase production by the white rot fungus Bjerkandera sp. BOS55. FEMS Microbiol Lett 155:161–168

Mester T, Jong ED, Field JA (1995) Manganese regulation of veratryl alcohol in white rot fungi and its indirect effect on lignin peroxidase. Appl Environ Microbiol 61:1881–1887

Moreira MT, Feijoo G, Sierra-Alveraz R, Lema J, Field JA (1997) Biobleaching of oxygen delignified kraft pulp by several white rot fungal strains. J Biotechnol 53:237–251

Moreira MT, Feijo G, Mester T, Mayorga P, Sierra-Alvarez R, Field J (1998) Role of organic acids in the manganese-independent biobleaching system of Bjerkandera sp. strain BOS55. Appl Environ Microbiol 64(7):2409–2417

Moreira MT, Feijoo G, Sierra-Alvarez R, Field JA (1999) Reevaluation of the manganese requirement for the biobleaching of kraft pulp by white rot fungi. Bioresour Technol 70:255–260

Moreira MT, Sierra-Alvarez R, Lema JM, Feijoo G, Field JA (2001) Oxidation of lignin in eucalyptus kraft pulp by manganese peroxidase from Bjerkandera sp. strain BOS55. Bioresour Technol 78:71–79

Nishida T, Kashino Y, Mimura A, Takahara Y (1988) Lignin biodegradation by white rot fungi I. Screening of lignin-degrading fungi. Mokuzai Gakkaishi 34(6):530–536

Paice MG, Reid ID, Bourbonnais R, Archibald FS, Jurasek L (1993) Manganese peroxidise, produced by Trametes versicolor during pulp bleaching, demethylates and delignifies kraft pulp. Appl Environ Microbiol 59(1):260–265

Papinutti VL, Foarchiassin F (2007) Lignocellulolytic enzymes from Fomes schlerodermeus growing in solid-state fermentation. J Food Eng 81:54–59

Papinutti VL, Forchiassin F (2003) Optimization of manganese peroxidase and laccase in the South American fungus Fomes schlerodermeus (Lév.) Cke. J Ind Microbiol Biotechnol 30:536–541

Re VD, Papinutti L, Villalba L, Forchiassin F, Levin L (2008) Preliminary studies on the biobleaching of loblolly pine kraft pulp with Trametes versicolor. Enzym Microb Technol 43:164–168

Reid ID, Paice MG (1994a) Biological bleaching of kraft pulps by white-rot fungi and their enzymes. FEMS Microbiol Rev 13:369–376

Reid ID, Paice MG (1994b) Effect of residual lignin type and amount on bleaching of kraft pulp by Trametes versicolor. Appl Environ Microbiol 60(50):1395–1400

Reid ID, Paice MG (1998) Effect of manganese peroxidase on residual lignin of softwood kraft pulp. Appl Environ Microbiol 64(6):2273–2274

Rüttiman-johnson C, Salas L, Vicuńa R, Kirk TK (1993) Extracellular enzyme production and synthetic lignin mineralization by Ceriporiopsis subvermispora. Appl Environ Microbiol 59:1792–1797

Scholosser D, Höper C (2002) Laccase-catalyzed oxidation of Mn2+ in the presence of natural Mn3+ chelators as a novel sources of extracellular H2O2 production and its impact on manganese peroxidase. Appl Environ Microbiol 68:3514–3521

Shih FF, Champagne T, Daigle K, Zarins Z (1999) Use of enzymes in the processing of protein product from rice bran and rice flour. Nahrung 43:14–18

Silva EM, Machuca A, Milagres AMF (2005) Effect of cereal brans on Lentinula edodes growth and enzyme activities during cultivation on forestry waste. Lett Appl Microbiol 40:283–288

Stamets P (2000) Growing gourmet and medicinal mushrooms. Teen Speed Press, Berkeley

Technical Association of the Pulp and Paper Industry (TAPPI) (1996) TAPPI test methods 1996–1997. TAPPI Press, Atlanta

Westermark U, Eriksson KE (1974) Carbohydrate-dependent enzymatic quinine reduction during lignin degradation. Acta Chem Scand B28:204–208

Wong KKY, Anderson KB, Kibblewhite RP (1999) Effect of the laccase-mediator system on the handsheet properties of two high kraft pulps. Enzym Microb Technol 25:125–131

Yamanaka R, Soares CF, Matheus DR, Machado KMG (2008) Lignolytic enzyme produced by Trametes vilosa CCB176 under different culture condition. Brazilian J Microbiol 39:78–84

Yasumoto K, Tsuji H, Iwami K, Mitsuda H (1997) Isolation from rice bran of a bound form of vitamin B6 and its identification as 5′-O-(β-D-Glucopyranosyl) pyridoxine. Agric Biol Chem 41:1061–1067

Acknowledgments

We thank JSPS’s Core University Program for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Afrida, S., Tamai, Y., Watanabe, T. et al. Biobleaching of Acacia kraft pulp with extracellular enzymes secreted by Irpex lacteus KB-1.1 and Lentinus tigrinus LP-7 using low-cost media. World J Microbiol Biotechnol 30, 2263–2271 (2014). https://doi.org/10.1007/s11274-014-1647-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-014-1647-7