Abstract

Ethanol fermentation from sweet sorghum juice containing 240 g/l of total sugar by Saccharomyces cerevisiae TISTR 5048 and S. cerevisiae NP 01 immobilized on low-cost support materials, corncob pieces, was investigated. In batch fermentation, S. cerevisiae TISTR 5048 immobilized on 6 × 6 × 6 mm3 corncobs gave higher ethanol production than those immobilized on 12 × 12 × 12 mm3 corncobs in terms of ethanol concentration (P), yield (Y p/s ) and productivity (Q p ) with the values of 102.39 ± 1.11 g/l, 0.48 ± 0.01 and 2.13 ± 0.02 g/l h, respectively. In repeated-batch fermentation, the yeasts immobilized on the 6 × 6 × 6 mm3 corncobs could be used at least eight successive cycles with the average P, Y p/s and Q p of 97.19 ± 5.02 g/l, 0.48 ± 0.02 and 2.02 ± 0.11 g/l h, respectively. Under the same immobilization and repeated-batch fermentation conditions, P (90.75 ± 3.05 g/l) and Q p (1.89 ± 0.06 g/l h) obtained from S. cerevisiae NP 01 were significantly lower than those from S. cerevisiae TISTR 5048 (P < 0.05), while Y p/s from both strains were not different. S. cerevisiae TISTR 5048 immobilized on the corncobs also gave significantly higher P, Y p/s and Q p than those immobilized on calcium alginate beads (P < 0.05).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ethanol, an alternative of petroleum-based fuels, can be produced from biomass, a plentiful renewable resource. In Thailand, the main raw materials used for ethanol production are sugarcane molasses and cassava, which are used as substrates for many industries as well. Regarding the 15 year plan and target of biofuel development (year 2008–2022) of the Thai Government, ethanol production is set at 3, 6.2 and 9.0 M l/day for short-term (by 2011), medium-term (by 2016) and long-term (by 2022), respectively (Silalertruksa and Gheewala 2010). Therefore, it is possible that Thailand may face a shortage of sugarcane molasses and cassava.

Sweet sorghum (Sorghum bicolor (L.) Moench) is a promising large-scale energy crop because its stalks contain a large amount of fermentable sugar, and its juice also contains many essential trace elements for microbial growth and ethanol production (Laopaiboon et al. 2009; Dajue 2010). Moreover, it can be cultivated at nearly all temperatures and tropical climate areas with the growing period of 120–150 days (Wu et al. 2010). In Thailand, the average yield of sweet sorghum cultivar KKU40, 90–100 days old, is about 15–25 dry ton ha−1 (Jaisil et al. 2009), which is comparable to the average yield (20–30 dry ton ha−1) reported by Wu et al. (2010).

Among many microorganisms that have been exploited for ethanol production, S. cerevisiae still remains a prime species both in laboratory and industrial scales (Bai et al. 2008; Siqueira et al. 2008). Under appropriate environmental and nutritional conditions, it can produce and tolerate high ethanol concentrations (Bafrncová et al. 1999; Reddy and Reddy 2006; Bai et al. 2008). Our previous study also showed that S. cerevisiae TISTR 5048 and S. cerevisiae NP 01 were high-ethanol-producing strains from sweet sorghum juice (Laopaiboon et al. 2007, 2008, 2009; Nuanpeng et al. 2011).

The development of fermentation process has been very important for efficient ethanol production (Bai et al. 2004; Laopaiboon et al. 2007). In many distilleries, fermentation processes of ethanol production are conducted in batch or continuous modes (Alfenore et al. 2004; Tang et al. 2010). The batch process has many disadvantages, particularly when microorganisms are either slow growing or strongly affected by product inhibition (Najafpour et al. 2004). The continuous process does require a uniform substrate composition. In addition, the risk of mutation from outside contamination or internal adaptation is very high due to the long cultivation times, and the constant sterilization of the media can be expensive (Roehr 2001). Repeated-batch fermentation is the process that the portion of the fermentation broth is withdrawn at time intervals and the residual part of the broth is used as an inoculum for the next batch. This process aims to increase the productivity, and it is interesting due to several advantages compared with a conventional batch fermentation such as no new inocula requirement for each batch and long-term productivity (Anastassiadis and Rehm 2006). This operation also reduces time for cleaning and resterilization, and not much control is required compared to a continuous mode. Moreover, cell adaptation to very high osmotic pressure (e.g. high substrate or product concentration) may take place during the repeated-batch fermentation (Anastassiadis and Rehm 2006). In the repeated-batch process with free cell system, fermented broth is drained at appropriate amount and filled with fresh broth at the same volume to initiate the next cycle. This method causes the dilution of initial cell concentration in the broth, resulting in lower ethanol production efficiency. To avoid this problem, cell immobilization is introduced in the repeated-batch process. The immobilized cell system offers several advantages over the free cell fermentation operations, i.e., higher yeast cell concentration, intimate phase mixing, high fermentation rate, recycling utilization of the yeast and lower product inhibition (Tzeng and Fan 1991; Santos et al. 2008). Therefore, this system has been traditionally considered as an alternative to increase the process productivity and minimize the production cost (Santos et al. 2008).

The most widely used immobilization method is the cell entrapment on k-carrageenan or calcium (Ca)-alginate (Nigam 2000; Phisalaphong et al. 2007; Liu and Shen 2008). The main drawback of this system is the instability of Ca-alginate against phosphates, and the disruption of gel particles due to CO2 evolution during fermentation (Yu et al. 2007). In addition, the commercial materials, carrageen and alginate are expensive carriers for immobilization, which are not suitable for industrial purposes.

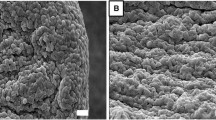

Corncob is the residues apart from stalks, leaves and husks. It can be used for producing heat, power, gas/liquid fuels, and a wide variety of chemical products (such as furfural, xylitol and activated carbon) as well as a source of fiber in fodder for ruminant livestock (Kaliyan and Morey 2010). The corn production in Thailand in year 2010 was 4,000,000 MT (United States Department of Agriculture 2011) and the cost of corncob in Thailand was USD 17–29/ton. The structure of the corncob is porous and honeycombed, and the bulk density of the whole corncob ranges from 160 to 210 kg/m3 (Kaliyan and Morey 2010), making good water retention capacity. For these reasons, this lignocellulosic material may be used as a potential low-cost support material for cell immobilization.

To our knowledge, this is the first report of using corncob as the support material for cell immobilization to produce bioethanol. The aims of this research were to study the ability of corncob pieces as the low-cost support materials for the immobilization of S. cerevisiae cells for ethanol fermentation and to investigate their stability in repeated-batch ethanol fermentation from sweet sorghum juice. The ethanol production efficiencies by two fermentative yeast strains immobilized on the corncob pieces and Ca-alginate beads were also compared.

Materials and methods

Microorganisms and inoculum preparation

Saccharomyces cerevisiae TISTR 5048 purchased from the culture collection of Thailand Institute of Scientific and Technological Research (TISTR), Bangkok, Thailand, and S. cerevisiae NP 01 isolated from Loog-pang (Chinese yeast cake for Thai rice wine making), Nakorn Panom province, Thailand (Laopaiboon et al. 2008), were used as fermentative yeasts for ethanol production. They were inoculated into 250 ml Erlenmeyer flasks containing 150 ml of yeast extract and malt extract (YM) medium. The medium consisted of yeast extract, 3 g/l; peptone, 5 g/l; malt extract, 3 g/l and glucose, 10 g/l. The flasks were incubated on a rotating shaker at 150 rev/min, 30°C for 24 h. The yeast suspension (approximately 3%) was transferred into 350 ml of the YM medium containing 20 g/l of glucose to give the initial cell concentration of approximately 5 × 106 cells/ml. The flasks were further incubated under the conditions as previously mentioned. After 15 h, the cells were harvested and used as an inoculum for cell immobilization.

Raw material and ethanol production medium

Sweet sorghum juice cv. KKU40 was obtained from the Department of Agronomy, Faculty of Agriculture, Khon Kaen University, Thailand. After extraction, the juice was kept at −18°C until use. To prepare ethanol production (EP) medium, the total soluble solids in the juice (18°Bx) were adjusted to 24°Bx by sucrose addition, which corresponded to the total sugar concentration of approximately 240 g/l. The EP medium was transferred into a 500 ml air-locked Erlenmeyer flask with a final working volume of 350 ml and autoclaved at 110°C for 15 min (Laopaiboon et al. 2009).

Support material and cell immobilization

Corncobs cv. Sugar-75 were used as low-cost support materials. They were cut into two different particle sizes, approximately 6 × 6 × 6 and 12 × 12 × 12 mm3. The corncob pieces were autoclaved at 121°C for 15 min. The sterile 6 × 6 × 6 mm3 corncobs at 30% of the working volume were transferred into YM medium containing 2.0 × 108 cells/ml of the active yeasts. The immobilization was carried out at 30°C under static condition. After 24 h, the corncobs were washed with the sterile EP medium and transferred into the fresh EP medium, which were further used as an inoculum (immobilized cells) for ethanol production. The 12 × 12 × 12 mm3 corncobs at the same dry weight of the 6 × 6 × 6 mm3 corncobs were sterilized and performed in the same manner.

For the immobilization in alginate beads, the inoculum was added into the sterilized sodium alginate solution (2.0% w/v) to obtain the yeast cell concentration of 2.0 × 108 cells/ml. The mixture was thoroughly mixed and placed in a syringe. It was then added dropwise to gently stirred calcium chloride solution (0.1 M) at 0°C to form 3 mm-diameter beads. The beads were stored at 4°C in the fresh calcium chloride solution for 24 h prior to use.

Fermentation processes

Batch fermentation by immobilized cell and free cell systems

The immobilized yeast cells on the corncobs and the alginate beads were inoculated into the sterile EP medium. The batch fermentation was operated at 30°C under static condition. The samples were collected at time intervals for further analysis. Ethanol fermentation by free cell system was also performed with the active initial yeast cell concentration of 5 × 107 cells/ml in the sterile EP medium.

Repeated-batch fermentation

The repeated-batch fermentation was first carried out in batch mode as described above. When the total residual sugars in the broth had dropped slowly as found in the batch fermentation system, all fermented broth was withdrawn and only the support materials with immobilized cells retained in the flask. Then, the same amount of the sterile EP medium was immediately replaced to initiate the next cycle of cultivation. At least eight successive cycles were performed. During each cycle, the fermented broth was collected for analysis as performed in the batch process.

Analytical methods

The viable suspended yeast cell numbers and total soluble solids of the fermentation broth were determined by direct counting method using haemacytometer and hand-held refractometer, respectively (Zoecklein et al. 1995). The fermentation broth was centrifuged at 13,000 rev/min for 10 min. The supernatant was then determined for residual total sugar in terms of total carbohydrate by phenol sulfuric acid method (Mecozzi 1995). Ethanol concentration (P, g/l) was analyzed by gas chromatography (Shimadzu GC-14B, Japan, Solid phase: polyethylene glycol (PEG-20 M), carrier gas: nitrogen, 150°C isothermal packed column, injection temperature 180°C, flame ionization detector temperature 250°C; C-R7 Ae plus Chromatopac Data Processor) and 2-propanol was used as an internal standard (Laopaiboon et al. 2009). The ethanol yield (Y p/s , g/g) and volumetric ethanol productivity (Q p , g/l h) were also calculated (Laopaiboon et al. 2009).

Statistical analysis

All the experiments were performed in triplicate, and the results were expressed as mean ± SD. Statistical analysis was carried out using SPSS 15.0 for Windows.

Results and discussion

Batch ethanol production by immobilized cell and free cell systems

The main parameters in sweet sorghum juice during the batch ethanol fermentation by S. cerevisiae TISTR 5048 immobilized on the 6 × 6 × 6 and 12 × 12 × 12 mm3 corncobs are shown in Fig. 1. Ethanol production from the juice by the free cells of this strain was also carried out as a control treatment. The sugar consumption by the immobilized yeasts on both sizes of corncobs and by the free cells was not different (Fig. 1a) with the remaining total sugar of approximately 7 g/l. This result indicated that there was no substrate inhibition in the free cell system even though the initial sugar concentration in the juice was as high as 240 g/l. The opposite results was observed by Nikolić et al. (2010), who reported that substrate inhibition occurred at the sugar concentration of 176 g/l in free cell system.

Batch culture profiles of ethanol production from sweet sorghum juice by S. cerevisiae TISTR 5048: immobilized on the 6 × 6 × 6 mm3 corncobs (square symbols), 12 × 12 × 12 mm3 corncobs (circle symbols) and free cells (triangle symbols). a Total sugar (filled square, filled circle, filled triangle) and ethanol concentration (open square, open circle, open triangle), b log viable suspended cell concentration (filled square, filled circle, filled triangle) and pH (open square, open circle, open triangle)

The yeast cell concentrations in the free cell system increased in the first 12 h and were relatively constant throughout the experiments with the average value of 1.58 × 108 cells/ml (Fig. 1b). In the immobilized cell systems, the observed viable yeast cells in the broth or freely suspended cells at the beginning of the fermentation (about log 6.59–6.91 cells/ml) were the cells that detached from the corncobs. This indicated that the physical adsorption and the strength of cell bound to the carrier were not quite strong. This result was supported by Santos et al. (2008), who reported that cell immobilization on a solid carrier was carried out by physical adsorption due to electrostatic forces or by covalent binding between the cell membrane and the carrier. As there were no barriers between the cells and the solution, cell detachment and relocation was possibly occurred, resulting in an equilibrium between adsorbed and freely suspended cells. In our study, the detached cells grew well in the juice and the suspended cell numbers were similar to those of the free cell system within 12 h. High concentration of the freely suspended cells in the immobilized cell systems implied that sugar consumption and ethanol production were occurred by the activity of both immobilized and freely suspended cells in the system. The pH during the fermentation of all systems was decreased from 5 to about 4 within 24 h, but the pH of the free cell system was slightly higher than those of the immobilized cell systems after 12 h (Fig. 1b). However, they were in the optimum range for yeast growth and ethanol production (Narendranath and Power 2005).

Ethanol concentrations produced by the free cell system were slightly higher than those of the immobilized cell systems in the first 24 h (Fig. 1a). Lower ethanol production rate of the free cell system after 24 h might be due to product inhibition as the ethanol concentration (P) raised more than 80 g/l (Alfenore et al. 2004). The P value produced by the immobilized yeasts on 6 × 6 × 6 mm3 corncobs was maximum at 48 h, whereas those of the yeasts on 12 × 12 × 12 mm3 corncobs and the free cell system were gradually increased after 48 h and reached the maximum values at 54 and 72 h, respectively (Fig. 1a). However, the maximum P values of all systems were comparable.

Table 1 summarizes the ethanol production efficiencies of the batch fermentation at the time giving the highest P values by the immobilized cell and free cell systems. P and Y p/s obtained from all conditions were not different but Q p of the immobilized cells on 6 × 6 × 6 mm3 corncobs was the highest due to shorter fermentation time. The immobilized cell systems gave higher Q p than in the free cell system (Table 1). This result could be explained that the immobilized yeast cells for the bioethanol production might overcome the product inhibition, resulting in the improvement of the ethanol tolerance as reported by Nikolić et al. (2010).

Similar results were observed by Yu et al. (2007) who studied ethanol production using immobilized yeast on sorghum stalk from the fermentation medium containing 200 g/l of total sugar. They found that the ethanol productivity or Q p was decreased when the carrier size (5, 10 and 15 mm) increased. They explained that as the carrier size increased, the mass transfer at the inner part of the sorghum stalk would become more difficult, and finally influenced the fermentation productivity.

In our study, the total mass of the 6 × 6 × 6 and 12 × 12 × 12 mm3 corncobs for immobilization was equal. Considering the external surface area of the corncobs, the smaller size would have more surface area than the bigger one, resulting in the higher ethanol production efficiency by the yeasts immobilized on the 6 × 6 × 6 mm3 corncobs. Therefore, the 6 × 6 × 6 mm3 corncobs were selected to be the optimum size of the support material for cell immobilization in the subsequent experiments. The smaller sizes of corncobs (smaller than 6 × 6 × 6 mm3) were not tested due to the difficulty in preparation and inconsistency in size.

Repeated-batch ethanol fermentation by immobilized yeasts

To investigate the stability of the corncobs as support materials for cell immobilization and the ability of the immobilized cells for ethanol production, repeated-batch fermentation by S. cerevisiae TISTR 5048 immobilized on the 6 × 6× 6 mm3 corncobs was carried out. The changes of the main parameters in the broth during the ethanol production by the immobilized yeasts during repeated-batch fermentation are shown in Fig. 2. According to the optimum condition as illustrated previously in the batch process, the fermentation time of each cycle in the repeated-batch system was kept constant at 48 h. In the first cycle, the sugar was almost utilized and P, Q p and Y p/s were 98.25 ± 2.10 g/l, 2.05 ± 0.05 g/l h and 0.46 ± 0.01, respectively. In cycle 2–8, the residual sugar concentrations were approximately 15–43 g/l, while the P values were slightly fluctuated ranging from 92 to 106 g/l at 48 h (Fig. 2a, b). The initial sugar concentrations of fermentation broth in cycle 2–8 (222–238 g/l) were similar to that of cycle 1. The average P, Q p and Y p/s of cycle 1–8 are shown in Table 2. The initial concentrations of freely suspended cells of cycle 1–8 ranged from log 6.05 to log 6.48 cells/ml (Fig. 2c), indicating that the detachment of the yeast cells from the corncobs in each cycle was similar. In addition, some immobilized cells were detached into the broth and others grew and continuously attached in the support materials in each cycle. This implied that the corncobs containing active yeast cells acted as the source of inoculum for ethanol production. The number of freely suspended cells of cycle 1–8 increased to log 7.26–7.93 cells/ml in 24 h, indicating that the sweet sorghum juice adequately contained essential nutrients for yeast growth (Laopaiboon et al. 2009). Unfortunately, the amount of viable entrapped cells in the corncobs was not measured in this study. However, in repeated-batch ethanol production from sugarcane juice using immobilized S. cerevisiae on sugarcane pieces, the viable cells in the sugarcane pieces and in the fermentation broth of six successive cycles were about 5–15 × 1010 cells g−1 of the support and 4–15 × 107 cells/ml respectively (Liang et al. 2008), whereas ethanol concentrations (88.05–91.76 g/l) were approximately 7 g/l lower than those of our results.

Repeated-batch culture profiles of ethanol production from sweet sorghum juice by S. cerevisiae TISTR 5048 (filled circle) and S. cerevisiae NP01 (open triangle) immobilized on the 6 × 6 × 6 mm3 corncobs: a total sugar, b ethanol concentration and c log viable suspended cell concentration. The arrows indicate the start time of each cycle

The type of yeast strain is one of the main factors for the improvement of ethanol production efficiency (Breisha 2010). Laopaiboon et al. 2008 showed that the free cells of S. cerevisiae NP 01 grew well in the sweet sorghum juice and produced high ethanol concentration from the juice. Therefore, ethanol production by the two different yeast strains immobilized on the corncob pieces was compared in this study. Changes of total sugar, ethanol and viable suspended cells of the ethanol production from the juice by S. cerevisiae NP 01 immobilized on the 6 × 6 × 6 mm3 corncobs during the repeated batch fermentation (eight cycles) are shown in Fig. 2. The fermentation time of each cycle was controlled at 48 h, the same as that of the immobilized S. cerevisiae TISTR 5048. In the first cycle of the immobilized S. cerevisiae NP 01, the sugar remaining was 12 g/l and P, Q p and Y p/s were 97.02 ± 0.20 g/l, 2.02 ± 0.00 g/l h and 0.45 ± 0.00, respectively, which were not different from those of the immobilized S. cerevisiae TISTR 5048. In cycle 2–8, the higher residual sugar concentrations (49–58 g/l) and the lower P values (87–92 g/l) were detected at 48 h (Fig. 2a, b). Longer fermentation time might be required for the completion of sugar consumption and the increase in ethanol concentration. However, the longer fermentation time was, the lower productivity was obtained. The initial (log 6.02 to log 6.53 cells/ml) and the final suspended cell concentrations (log 7.25 to log 7.96 cells/ml) of NP 01 in cycle 1–8 were not different from those of TISTR 5048 (Fig. 2c). Comparison of the ethanol production efficiencies in the repeated-batch fermentation by both strains immobilized on the corncobs revealed that P and Q p of the immobilized S. cerevisiae TISTR 5048 were significantly higher than those of S. cerevisiae NP 01 (P < 0.05), while Y p/s was not different (P > 0.05; Table 2). These findings indicated that the rates of sugar consumption and ethanol production of the immobilized S. cerevisiae NP 01 in the repeated-batch fermentation were lower than those of S. cerevisiae TISTR 5048.

Since Ca-alginate bead is the most widely used carrier for cell immobilization in laboratory scales (Santos et al. 2008), it is chosen as a control treatment in the present study. Changes of total sugar and ethanol concentration of the ethanol production from the juice by S. cerevisiae TISTR 5048 immobilized on the Ca-alginate beads during the repeated batch fermentation are shown in Fig. 3. The ethanol production efficiencies in the repeated-batch fermentation by S. cerevisiae TISTR 5048 immobilized on the corncobs (by physical adsorption) were compared with the values obtained from immobilization by entrapment on the Ca-alginate beads (Table 2). The T test method showed that the yeasts immobilized on the corncobs gave significantly higher P, Y p/s and Q p than those on the Ca-alginate beads (P < 0.05). In all conditions, the Y p/s values were lower than the theoretical value, indicating that part of the consumed sugar might be used for maintenance and/or being converted to byproducts (Zoecklein et al. 1995; Ozmichi and Kargi 2007). The results showed that the corncobs provided sufficient mechanical strength and stability for yeast cell immobilization. Any change or damage in the physical structure of the corncobs was not observed after eight cycles in the repeated-batch fermentation. In addition, the rates of sugar consumption and ethanol production of the eight successive cycles were relatively constant. These might imply the mechanical strength of the particles as the support material. In contrast, some breakage of the Ca-alginate beads was seen after cycle 3, and only 60% of the beads remained after eight successive cycles. The instability in shape when using Ca-alginate beads as immobilization supports in repeated-batch fermentation was also reported by Phisalaphong et al. (2007) and Ellaiah et al. (2004). Methods to improve the strength or the hardness of alginate beads were to increase the percentage of alginate and/or calcium chloride for immobilization. However, the nutrient and product diffusion were more difficult, resulting in the reduction of fermentation rate (Najafpour et al. 2004; Idris and Suzana 2006).

In some studies, lignocellulosic support materials such as sugarcane bagasse (Santos et al. 2008) and sugarcane stalks (Chandel et al. 2009) had to be pretreated with alkaline to increase the affinity of cells for immobilization. To minimize the step and the cost of immobilization, no pretreatment of the corncobs was carried out in the present study. No chemical pretreatment of sorghum bagasse as the support material for S. cerevisiae immobilization was also reported (Yu et al. 2007).

The use of the immobilized cells on corncobs to produce ethanol for a long period of time in the repeated-batch fermentation was successful. The results were also supported by the finding of Krisch and Szajani (1997) and Yu et al. (2007) who reported that immobilized cells contained significantly higher percentage of saturated fatty acids than those of free cells, leading to greater ethanol tolerance of the immobilized cells, and hence greater survival and productivity than those of the free cells. However, the fatty acid contents in both free and immobilized cells in our study were not determined.

Conclusions

It was clearly demonstrated that corncob could be used as an alternative, abundant, cheap and durable immobilization support. The immobilized S. cerevisiae TISTR 5048 could be efficiently used for ethanol production from sweet sorghum juice by repeated-batch fermentation. The yeasts immobilized on the 6 × 6 × 6 mm3 corncobs could be reused at least eight successive cycles without a significant decrease in ethanol production. The results obtained from this research would be beneficial for the application of ethanol fermentation by immobilized S. cerevisiae on corncobs from sweet sorghum juice or other sugary raw materials.

References

Alfenore S, Cameleyre X, Benbadis L, Bideaux C, Uribelarrea JL, Goma G, Molina-Jouve C, Guillouet SE (2004) Aeration strategy: a need for very high ethanol performance in Saccharomyces cerevisiae fed-batch process. Appl Microbiol Biotechnol 63:537–542

Anastassiadis S, Rehm HJ (2006) Citric acid production from glucose by yeast Candida oleophila ATCC 20177 under batch, continuous and repeated batch cultivation. Electron J Biotechnol 9:26–39

Bafrncová P, Šmogrovičová D, Sláviková I, Pátková J, Dömény Z (1999) Improvement of very high gravity ethanol fermentation by media supplementation using Saccharomyces cerevisiae. Biotechnol Lett 21:337–341

Bai FW, Chen LJ, Zhang Z, Anderson WA, Moo-Young M (2004) Continuous ethanol production and evaluation of yeast cell lysis and viability loss under very high gravity medium conditions. J Biotechnol 110:287–293

Bai FW, Anderson WA, Moo-Young M (2008) Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnol Adv 26:89–105

Breisha GZ (2010) Production of 16% ethanol from 35% sucrose. Biomass Bioenerg 34:1243–1249

Chandel AK, Narasu ML, Chandrasekhar G, Manikyam A, Rao V (2009) Use of Saccharum spontaneum (wild sugarcane) as biomaterial for cell immobilization and modulated ethanol production by thermotolerant Saccharomyces cerevisiae VS3. Bioresour Technol 100:2404–2410

Dajue L (2010) Sweet sorghum. In: Bassam NE (ed) Handbook of bioenergy crops: a complete reference to species, development and applications. Earthscan, London, pp 324–330

Ellaiah P, Prabhakar T, Ramakrishna B, Thaer Taleb A, Adinarayana K (2004) Production of lipase by immobilized cells of Aspergillus niger. Process Biochem 39:525–528

Idris A, Suzana W (2006) Effect of sodium alginate concentration, bead diameter, initial pH and temperature on lactic acid production from pineapple waste using immobilized Lactobacillus delbrueckii. Process Biochem 41:1117–1123

Jaisil P, Pakdee P, Pothisoong T, Lertprasert-rat K (2009) Production cost of sweet sorghum (Sorghum bicolor (L.) Moench) and syrup production for ethanol plant. J Nat Res Counc Thail (Energy). Special issue for 50th anniversary of NRCT, pp 148–156

Kaliyan N, Morey RV (2010) Densification characteristics of corn cobs. Fuel Process Technol 91:559–565

Krisch J, Szajani B (1997) Ethanol and acetic acid tolerance in free and immobilized cells of Saccharomyces cerevisiae and Acetobacteraceti. Biotechnol Lett 19:525–528

Laopaiboon L, Thanonkeo P, Jaisil P, Laopaiboon P (2007) Ethanol production from sweet sorghum juice in batch and fed-batch fermentations by Saccharomyces cerevisiae. World J Microbiol Biotechnol 23:1497–1501

Laopaiboon L, Nuanpeng S, Srinophakun P, Klanrit P, Laopaiboon P (2008) Selection of Saccharomyces cerevisiae and investigation of its performance for very high gravity ethanol fermentation. Biotechnology 7:493–498

Laopaiboon L, Nuanpeng S, Srinophakun P, Klanrit P, Laopaiboon P (2009) Ethanol production from sweet sorghum juice using very high gravity technology: effects of carbon and nitrogen supplementations. Bioresour Technol 100:4176–4182

Liang L, Zhang YP, Zhang L, Zhu MJ, Liang SZ, Huang YN (2008) Study of sugarcane pieces as yeast supports for ethanol production from sugarcane juice and molasses. J Ind Microbiol Biotechnol 35:1605–1613

Liu R, Shen F (2008) Impacts of main factors on bioethanol fermentation from stalk juice of sweet sorghum by immobilized Saccharomyces cerevisiae (CICC 1308). Bioresour Technol 99:847–854

Mecozzi M (1995) Estimation of total carbohydrate amount in environmental samples by the phenol-sulphuric acid method assisted by multivariate calibration. Chemom Intell Lab Syst 79:84–90

Najafpour G, Younesi H, Ismail KSK (2004) Ethanol fermentation in an immobilized cell reactor using Saccharomyces cerevisiae. Bioresour Technol 92:251–260

Narendranath NV, Power R (2005) Relationship between pH and medium dissolved solids in terms of growth and metabolism of Lactobacilli and Saccharomyces cerevisiae during ethanol production. Appl Environ Microbiol 71:2239–2243

Nigam JN (2000) Continuous ethanol production from pineapple cannery waste using immobilized yeast cells. J Biotechnol 80:189–193

Nikolić S, Mojović L, Pejin D, Rakin M, Vukašinović M (2010) Production of bioethanol from corn meal hydrolysates by free and immobilized cells of Saccharomyces cerevisiae var. ellipsoideus. Biomass Bioenerg 34:1449–1456

Nuanpeng S, Laopaiboon L, Srinophakun P, Klanrit P, Jaisil P, Laopaiboon P (2011) Ethanol production from sweet sorghum juice under very high gravity conditions: batch, repeated-batch and scale up fermentation. Electron J Biotechnol 14:1–12

Ozmichi S, Kargi F (2007) Ethanol fermentation of cheese whey powder solution by repeated fed-batch operation. Enzyme Microb Tech 41:169–174

Phisalaphong M, Budiraharjo R, Bangrak P, Mongkolkajit J, Limtong S (2007) Alginate-loofa as carrier matrix for ethanol production. J Biosci Bioeng 104:214–217

Reddy LVA, Reddy OVS (2006) Rapid and enhanced production of ethanol in very high gravity (VHG) sugar fermentations by Saccharomyces cerevisiae: role of finger millet (Eleusine coracana L.) flour. Process Biochem 41:726–729

Roehr M (2001) The biotechnology of ethanol: classical and future applications. Wiley-VCH, Weinheim

Santos DT, Sarrouh BF, Rivaldi JD, Converti A, Silva SS (2008) Use of sugarcane bagasse as biomaterial for cell immobilization for xylitol production. J Food Eng 86:542–548

Silalertruksa T, Gheewala SH (2010) Security of feedstocks supply for future bio-ethanol production in Thailand. Energ Policy 38:7476–7486

Siqueira PF, Karp SG, Carvalho JC, Sturm W, Rodriguez-Leon JA, Tholozan JL, Singhania RR, Pandey A, Soccol CR (2008) Production of bio-ethanol from soybean molasses by Saccharomyces cerevisiae at laboratory, pilot and industrial scales. Bioresour Technol 99:8156–8163

Tang YQ, An MZ, Zhong YL, Shigeru M, Wu X-L, Kida K (2010) Continuous ethanol fermentation from non-sulfuric acid-washed molasses using traditional stirred tank reactor and the flocculating yeast strain KF7. J Biosci Bioeng 109:41–42

Tzeng JW, Fan LS (1991) Ethanol fermentation using immobilized cells in a multistage bed bioreactor. Biotechnol Bioeng 38:1253–1258

United States Department of Agriculture (2011) Thailand corn production by year. Index Mundi. http://www.indexmundi.com/agriculture/?country=th&commodity=corn. Accessed 30 Jan 2011

Wu X, Staggenborg S, Propheter JL, Rooney WL, Yu J, Wang D (2010) Features of sweet sorghum juice and their performance in ethanol fermentation. Ind Crop Prod 31:164–170

Yu J, Zhang X, Tan T (2007) An novel immobilization method of Saccharomyces cerevisiae to sorghum bagasse for ethanol production. J Biotechnol 129:415–420

Zoecklein BU, Fugelsang KC, Gump BH, Nury FS (1995) Wine analysis and production. Chapman & Hall, New York

Acknowledgments

This research was financially supported by the National Research Council of Thailand (NRCT), Thailand. We would like to thank Assistant Prof. Dr. Paiboon Danviruthai, Faculty of Technology, Khon Kaen University (KKU) for providing the NP 01 strain, Associate Prof. Dr. Prasit Jaisil, Faculty of Agriculture, KKU for providing sweet sorghum juice, and Associate Prof. Dr. Aroonwadee Chanawong, Faculty of Associated Medical Sciences, KKU and Dr. Preekamol Klanrit, Faculty of Technology, KKU for their internal reviews of this paper and helpful suggestions. We also thank to our students, Mr. Suttipong Sak-Ubol, Ms. Sucheera Louwcharoen, Ms. Amornrat Siripan, Mr. Aroon Chanamarn and Mr. Pongthep Ariyajarearnwong for their technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Laopaiboon, L., Laopaiboon, P. Ethanol production from sweet sorghum juice in repeated-batch fermentation by Saccharomyces cerevisiae immobilized on corncob. World J Microbiol Biotechnol 28, 559–566 (2012). https://doi.org/10.1007/s11274-011-0848-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-011-0848-6