Abstract

Marine waste is a highly renewable resource for the recovery of several value added metabolites with prospective industrial applications. This study describes the production of enzymes on marine waste and their subsequent use for the extraction of antioxidants from marine waste. Microbispora sp. and Bacillus sp. were grown on colloidal chitin and marine waste for the production of chitinase and protease. Microbispora sp. could produce 10.2 U ml−1 chitinase, whereas Bacillus sp. could produce 38 U ml−1 chitinase and 3.39 U ml−1 protease. The production of antioxidants was optimized using statistical designs and 6.6 units of 35 kDa chitinase from Microbispora sp., 16 units of 25 kDa chitinase from Bacillus sp., 2.3 units of protease, 1.5% marine waste and 36 h incubation gave maximum antioxidant activity. Nearly 5.0 mg of compound with antioxidant activity could be recovered per gram of marine waste. This compound was purified by HPLC and characterized by TLC, FT-IR and proton-NMR as N,N′-diacetylchitobiose. It exhibited 53% superoxide radical scavenging activity, 57% hydroxyl radical scavenging activity and 28% lipid peroxidation inhibition activity. Scale up of the extraction of antioxidant from marine waste and its pharmacological studies can extend its use in medicine.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Oxidative stress is one of the major causes of concern for human health as it is speculated to contribute to the development of a wide range of diseases like Alzheimer’s disease (Christen 2000), Parkinson’s disease (Wood-Kaczmar et al. 2006), diabetes mellitus (Giugliano et al. 1996), rheumatoid arthritis (Hitchon and El-Gabalawy 2004), multiple sclerosis, acute lymphoblastic leukemia, chronic hepatitis, carcinoma of different tissues and neurodegeneration (Cooke et al. 2003). The protective constituents of oxidative damage are antioxidants which are chemically synthesized or naturally found. They scavenge the free radicals and can influence the peroxidation process through either simple or complex mechanisms including free-radical scavenging, divalent metal chelation and others. Several of these are marketed as food supplements and are used for the production of functional foods. Several promising antioxidants of plant (Valentao et al. 2002a, b) and animal (Qin et al. 2002) origin have been studied. But many antioxidants like vitamins are similar to and affect steroid hormones or they act like prohormones hence they can be incorporated in foods only in stringent concentrations. However, search for new and natural antioxidants is beneficial for the prevention of free radical induced diseases.

Oligosaccharides prepared from chitosan are reported to exhibit free radical scavenging properties and find potential applications in the treatment of inflammatory diseases (Dou et al. 2007), metastasis (Kim and Kim 2006) and some diseases caused by reactive oxygen species. Carboxylated chitooligosaccharides can also prevent oxidation of cellular biomolecules (Rajapakse et al. 2007). Some workers have demonstrated antioxidant activities of N-acetylchitooligosaccharides (Chen et al. 2003, 2005). Most of the literature is focused on the oligosaccharides from chitosan however studies on acetylated oligomers are limited. The marine industry generates significant amount of waste that can serve as a renewable resource. This waste is rich in several proteinaceous compounds, organic material and chitin. Disposal of marine waste presents a major problem due to objectionable odour, high nutrient content and disposal regulations. However, due to its affluence in valuable by-products marine waste attracts attention for development of technology and products. Being a prominent source of chitin, marine waste can be used for the extraction of the chitin oligomers with the possibility of development of antioxidant formulations. So far marine waste has been used for the production of chitinases, antifungal hydrolytic enzymes, metalloproteases, carotenoids, amino acids and lipases (Chang et al. 2007; Gimeno et al. 2007; Sachindra et al. 2007; Ben Rebah et al. 2008). Some workers have reported antioxidant activities in proteolytic hydrolysates from shrimp waste (Sachindra and Bhaskar 2008).

In the present study, Bacillus sp. and Microbispora sp. from our culture collection were grown on marine waste for the production of chitinases, to substitute commercial chitin. Antioxidant activity was detected in the broth besides proteolytic and chitinolytic activity. The antioxidant activity was enhanced by the action of cocktail of chitinase and protease on marine waste than chitinase or protease alone. The compound displaying antioxidant activity was purified and characterized. Extraction of chitin oligosaccharides directly from marine waste using protease and chitinase cocktail opens future avenues for extraction of value-added products from marine waste.

Materials and methods

Bacterial strains, culture conditions and pretreatment of marine waste

Microbispora sp. and Bacillus sp. used in this study were maintained on colloidal chitin agar and nutrient agar slopes respectively, at 4°C and as a suspension in 20% glycerol at −80°C. All the chemicals and reagents used were of analytical grade (Qualigens, Mumbai, India and Sigma Co., St. Louis, USA) and colloidal chitin was prepared from practical grade chitin flakes (SD-Fine Industries, Mumbai, India) by the method of Hsu and Lockwood (1975). Marine waste used in this study was mainly composed of shrimp and crab shells and was consistently obtained from processing units and local marine food suppliers through personal communication. The marine waste used in this study was grossly composed of 15.4% chitin, 9.4% protein, 12.7% lipids and 64.7% ash content. Marine waste was dried in the sun for 2 days and then ground in a mixer grinder to a fine powder. This fine powdered waste was directly used for microbial growth.

Enzyme activities

Production of chitinase for both the strains was carried out on 1% marine waste in water at pH 7.0, 40°C with shaking at 150 rpm and in colloidal chitin broth with g l−1 colloidal chitin 4, yeast extract 0.03, KH2PO4 0.3, (NH4)2SO4 0.25, MgSO4 0.5, K2HPO4 0.3 and FeSO4, ZnSO4 and MnCl210 mg l−1 each. The broth was centrifuged at 10,000g for 15 min and used for the determination of enzyme activity. Chitinase activity was determined by incubating 1.0 ml each of colloidal chitin and cell free broth at 40°C for Bacillus sp. and at 60°C for Microbispora sp. for 1 h. The mixture was centrifuged at 5,000g for 5 min and reducing sugars in the supernatant were estimated by DNS method. Chitinase activity was also determined using chromogenic derivatives p-nitrophenyl-β-d-N,N′-diacetylchitobiose and p-nitrophenyl-β-d-N,N′,N″-triacetylchitotriose as substrates (Nawani et al. 2002). One unit of chitinase activity is defined as the amount of enzyme required to release 1 μmol of N-acetylglucosamine (GlcNAc) or p-nitrophenol in 1 min under the described assay conditions. Protease activity was determined by mixing 0.5 ml of cell free broth with 0.5 ml of 2% casein in 0.05 M phosphate buffer, pH 7.0 and incubating at 37°C for 1 h. The reaction was stopped with 5.0 ml of 10% trichloroacetic acid and hydrolyzed products in the supernatant were measured by Lowry’s method (Lowry et al. 1951; Romaguera et al. 1992). One unit of protease activity was defined as the amount of enzyme required for giving an absorbance of 1.0 at 620 nm in 1 h. The enzymes in broth were concentrated by precipitation with ammonium sulfate and were used for preliminary studies. Chitinases from both the strains were purified as described below and further used for extraction of antioxidants from marine waste.

Purification of chitinase

Purification of chitinase from Bacillus sp. was carried out by HPLC on 5C18-AR-300 column (2.5 × 25 cm, Nacalai-Tesque, Japan) with an increasing linear gradient of 20–60% acetonitrile at a flow rate of 2.0 ml min−1. Purification of chitinases from Microbispora sp. was carried out as described previously (Nawani et al. 2002).

Fractions with chitinase activity were checked for purity by SDS–PAGE (Laemmli 1970) and enzyme activity was detected by electrophoresis on glycol chitin (Nawani and Kapadnis 2004).

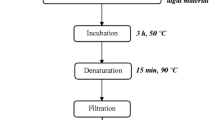

Optimization of production of antioxidants from marine waste

Crude chitinase and protease cocktail obtained from the culture broth of Bacillus sp. and Microbispora sp. was incubated in different proportions with marine waste powder and used for selection of variables for statistical optimization. The statistical optimization of production of antioxidants from marine waste was then carried out with pure chitinase and protease cocktail. Five variables viz., units of chitinase from Microbispora sp., chitinase from Bacillus sp., units of protease, concentration of waste and incubation period were used for making the design matrix. The coding of the variables was done as per the equation:

where x j is coded level, X j is real value, X cp is the real value of center point and Δx j is the value of step change of the variable. Table 1 gives the variables and their levels used for the design matrix having six central points (all variables set at zero or central point level) and ten axial points (one variable set at ±2 level and others at central point level).

The responses obtained in terms of antioxidant activity (superoxide radical scavenging activity) were subjected to non-linear regression analysis to obtain the coefficients. The final model incorporated estimates of the coefficients with levels higher than 95% (P = 0.05). The preparation of design matrix and statistical analysis was done using Design-Expert® 7.0 (Stat-Ease Inc., Minneapolis, USA). The equation generated using the final model can be used for the prediction of response. A response curve was also generated with Central composite design considering the most significant variables.

Determination of in vitro free radical scavenging activity

Antioxidants were produced by incubation of marine waste with the enzyme cocktail under the optimized conditions. Antioxidant activity in the mixture was determined after removal of solids by centrifugation at 5,000g for 5 min. Antioxidant activity was primarily determined by superoxide radical scavenging assay. Superoxide radical scavenging activity was determined by non-enzymatic method based on PMS/NADH system (phenazine methosulfate and NADH) and reduction of nitroblue tetrazolium (NBT). The reaction mixture had 160 μM NADH, 25 μM NBT in 100 mM sodium phosphate buffer, pH 7.4 and 200 μl of test sample. The reaction was initiated by addition of 20 μM PMS and incubated for 5 min at room temperature and the absorbance was read at 560 nm against reaction mixture without test sample and PMS. Reaction mixture with PMS but without test sample served as control. Percent superoxide radical scavenging activity was determined as

where A C is absorbance of control and A T is absorbance of test sample at 560 nm (Fernandes et al. 1999; Valentao et al. 2001).

For the purified antioxidant, additional assays for the determination of antioxidant activity were performed. Antioxidant activity was thus determined by inhibition of lipid oxidation as described by Wijewickreme and Kitts (1997) where 1.0 ml of test sample is added to mixture containing fish oil (twice the quantity of the test sample), 0.13 ml Tween 20, 10 ml 99% ethanol and 10 ml of 0.2 M sodium phosphate buffer pH 7.0 and total volume was made to 25 ml with deionized water. This mixture was incubated in dark and the degree of oxidation was measured by taking absorbance at 500 nm against 75% ethanol. An increase in absorbance indicates accumulation of lipid peroxides and a delay in the onset of lipid oxidation indicates inhibition of lipid peroxidation.

Hydroxyl (OH) radical scavenging activity was determined by the method of Elizabeth and Rao (1990). The reaction mixture had 2.8 mM deoxyribose, 100 μM FeCl3, 20 mM KH2PO4-KOH buffer pH 7.4, 100 μM EDTA, 1.0 mM H2O2, 100 μM ascorbic acid and 200 μl of test compound. The final volume was made to 1 ml and the mixture was incubated at 37°C for 1 h. To 0.5 ml of the mixture, 1.0 ml 2.8% TCA and 1.0 ml 0.6% aqueous solution of thiobarbituric acid (TBA) was added and heated at 95°C for 15 min. The absorbance of thiobarbituric acid reactive substances (TBARS) formed was measured at 532 nm against reagent blank without deoxyribose. Control sample was devoid of test compound and percent hydroxyl radical scavenging ability was calculated as described for superoxide radical scavenging assay. Ability to scavenge hydrogen peroxide was determined by method of Wei et al. (1993). The reaction mixture, 0.98 ml containing 200 μM phenol red, 10 μM H2O2 and 200 μl test compound was incubated at room temperature for 5 min and 10 μl of 10.0 U ml−1 horseradish peroxidase was added. This was further incubated for 5 min and the reaction was terminated by addition of 10 N NaOH. The purple coloration due to oxidation of phenol red was recorded at 610 nm against blank without horseradish peroxidase. Control was without test sample and percent hydrogen peroxide scavenging ability was calculated as described for superoxide scavenging assay. Metal chelation ability of the test compound was determined by measuring the absorption spectra of 50 μm CuSO4 in presence and absence of 5.0 mg of the test compound at pH 7.0, 30°C in the range of 200–300 nm (Chen et al. 2003).

Purification and characterization of the antioxidant

Compounds in the marine waste and enzyme cocktail were purified by HPLC (Gilson, USA) on a Sugar-D column (2.5 × 25 cm, Nacalai-Tesque, Japan) using acetonitrile:water (70:30) as mobile phase at flow rate of 7.0 ml min−1. The fractions collected were concentrated and tested for free radical scavenging activity. The fractions displaying antioxidant activity were used for further identification and characterization of the compound. Purity of the preparation was confirmed by rechromatography on the above-mentioned column and by TLC on silica-gel plates (Merck silica gel 60 F254) with n-propanol:ethanol:water (7:1:2). The spots were detected by spraying the plate with aniline-diphenylamine reagent (1 ml aniline, 1 g diphenylamine, 50 ml acetone and 7.5 ml of 85% phosphoric acid) and baking at 180°C for 5–7 min. The end products were identified based on their R f values in comparison with the standard sugars and chitooligosaccharides (Seikagaku Kogyo Co., Japan) and were quantitated by HPLC and on DeSaga ver 2.0 densitometer by measurement of peak area. Antioxidant activity of the purified compound was determined as mentioned above. Functional groups in the purified compound were determined from FT-IR spectrum recorded on a Shimadzu 8400 FT-IR spectrometer using test compound and KBr pellets. Proton-NMR was determined on Varian Mercury YH-300 spectrometer using D2O as the solvent.

Results and discussion

Enzyme and antioxidant activities

During course of studies on using marine waste as a substitute to chitin for chitinase production, antioxidant activity was observed in the fermented broth. Antioxidant activity evaluated in terms of superoxide radical scavenging ability increased when enzymes harvested from the broth were incubated with marine waste depicting an enzyme-substrate reaction. The predominant enzymes in the broth were chitinases and protease. In case of Bacillus sp., 19.0 U ml−1 of chitinase was produced on marine waste and 16.7 U ml−1 on colloidal chitin after 5 days of incubation. Maximum chitinase activity (7.8 U ml−1) was seen for Microbispora sp. after 5 days incubation on colloidal chitin and negligible enzyme was produced on marine waste, as determined by DNS method. Chitinase activity was also determined with chromogenic derivatives as substrates as described in “Materials and methods” section, this gave 10.2 U ml−1 chitinase from Microbispora sp. (with p-nitrophenyl-β-d-N,N′-diacetylchitobiose) and 38 U ml−1 chitinase from Bacillus sp. (with p-nitrophenyl-β-d-N,N′,N″-triacetylchitotriose). Bacillus sp. produced 3.39 U ml−1 of protease on marine waste and 0.49 U ml−1 on colloidal chitin after incubation for 4 days. Microbispora sp. produced only 0.13 U ml−1 of protease activity in 7 days after which the activity declined.

Chitinase production was previously carried out on shrimp and crab shell powder medium (Wang et al. 1997) where the researchers observed that chemically treated shell powder significantly induced chitinase as compared to the untreated substrate. However, in the present study, chemically untreated marine waste gave a higher production of enzymes. We observed an equivalent induction of chitinolytic enzymes in case of Bacillus sp. on marine waste than pure chitin medium. This was not the case with Microbispora sp. which could produce higher amount of chitinases on colloidal chitin than marine waste. This could be due to the production of proteases by Bacillus sp. which made the chitinous material in the waste available for induction and growth. Studies on bioconversion of shrimp shell wastes by Bacillus subtilis demonstrate the production of 0.34 U ml−1 protease and 0.003 U ml−1 chitinase which is much lower than the amount of enzymes produced by strains used in this study (Wang and Yeh 2006). In the present study, the amount of enzymes produced were relatively higher and were produced on marine waste in water as the growth medium indicating the suitability of marine waste as the substrate for the production of chitinases and proteases. These enzymes were subsequently used for the production of antioxidants from marine waste.

Marine waste particularly squid pen is recently explored for the production of functional foods. Antioxidant activity was associated to ethyl acetate soluble extract where a strong correlation between antioxidant activity and phenolic content and free amino acids was observed in case of Serratia ureilytica TKU013 grown on squid pen (Wang et al. 2009a, 2010). Similarly, 1.3 mg ml−1 N-acetylglucosamine, 2.7 mg ml−1 N,N′-diacetylchitobiose and antioxidant activity was produced in culture supernatant of Serratia sp. TKU020 grown on squid pen. However no direct correlation between the antioxidant activity and N-acetylated chitooligosaccharides is reported (Wang et al. 2009b). DPPH radical scavenging ability was seen in the culture supernatant of Bacillus sp. TKU004 grown on squid pens (Wang et al. 2009d). Chitooligosaccharides reclaimed from squid pens have been evaluated for antitumor and antimicrobial activities indicating the potential of marine waste as a useful renewable resource for functional foods (Wang et al. 2008).

In the present study, antioxidant activity was evaluated initially in terms of superoxide radical scavenging ability. The superoxide radical scavenging activity of 29 and 24% could be detected in colloidal chitin broth cultured with Microbispora sp. and marine waste cultured with Bacillus sp., respectively. This was suggestive of a role of chitinases in the production of antioxidant compound. Thus enzyme-substrate reactions with marine waste as substrate, and cell free colloidal chitin broth (Microbispora sp.) and marine waste broth (Bacillus sp.) were carried out. The antioxidant activity in the enzyme-substrate reactions increased till 32 h and remained static with further incubation till 40 h. Superoxide scavenging ability of 33% was detected when the crude enzyme mixture from both strains was incubated with marine waste. After the identification of the factors influencing the production of antioxidants and purification of chitinases, optimization studies were carried out using statistical designs.

Optimization of production of antioxidants from marine waste

The 35 kDa chitinase from Microbispora sp. and 25 kDa chitinase from Bacillus sp. were used for the production of antioxidants from marine waste. Figure 1 shows the crude and purified chitinases from Bacillus sp. and Microbispora sp. used in this study. As described in the “Materials methods”, a central composite design was used to generate final model for optimization of antioxidant production from marine waste. The responses obtained in terms of antioxidant activity were statistically evaluated and variables with confidence levels above 95% (P < 0.05) were regarded significant. These were used to generate response curves as seen in Fig. 2A–D. The most significant factors were amount of chitinase, protease, concentration of marine waste and incubation period. As seen from the Fig. 2A and B, decreasing or increasing the amount of protease in the reaction mixture to a low and high level respectively reduces the antioxidant activity significantly. However, maximum antioxidant activity is seen near central point or zero level of protease. Presence of protease in the reaction mixture could be essential to make the marine waste facile to attack by chitinases. Yang et al. (2000) reported the deproteinization of marine waste with 20.2 U ml−1 protease which was higher than the amount of protease used in this study. Figure 2c shows a linear increase in the antioxidant activity with increase in chitinase from Bacillus sp. however, chitinase from Microbispora sp. gave nearly similar response in the chosen range. Figure 2d shows the quadratic effect of both marine waste and incubation time on antioxidant activity indicating the central levels to be more suitable for production of antioxidants. The final model equation is (in coded levels)

where A is units of chitinase from Microbispora sp., B is units of chitinase from Bacillus sp., C is units of protease, D is concentration of marine waste and E is incubation time in hours. The model generated has R 2 value of 0.94 indicating the model can explain 94% of total variation.

Chitinases from Microbispora sp. and Bacillus sp. used for the production of antioxidants from marine waste. Enzymes were purified as mentioned in “Materials and methods” and were detected by electrophoresis on glycol chitin gel. Lane 1: crude chitinases from Bacillus sp.; Lane 2: crude chitinases from Microbispora sp.; Lane 3: 25 kDa chitinase from Bacillus sp.; Lane 4: 35 kDa chitinase from Microbispora sp. and Lane M: standard protein molecular weight markers in kDa

Maximum antioxidant activity was seen with 6.6 units of chitinase from Microbispora sp., 16 units chitinase from Bacillus sp., 2.3 units of protease, 1.5% marine waste and 36 h incubation. Incremental addition of chitinase 2.0 units each, after every 8 h improved the production which otherwise reached a static value. This could be due to the action of protease on chitinase making it unavailable for further action on the substrate. Overall 47% superoxide scavenging ability was obtained after optimization and using pure enzymes which was higher than the activity displayed by crude enzymes. Incorporation of equivalent quantity of commercial protease did not significantly alter the yield of the antioxidants. The reaction of marine waste with protease alone gave not more than 20% antioxidant activity. We noticed negligible antioxidant activity when protease was incubated with marine waste which significantly increased upon addition of chitinase. The antioxidant activity was noticed in the cell free system, it was less likely that the antioxidant compounds were produced directly as a result of microbial growth.

Other chitinases from Microbispora sp. and Bacillus sp. did not yield more than 18% of the superoxide scavenging ability from marine waste, hence those were not used for any further reactions. Statistical optimization for the recovery of antioxidants improved the yield by nearly 42%. Recovery of carotenoids from shrimp waste was similarly optimized earlier by Sachindra et al. (2007) using statistical designs indicating the relative ease and perfection in the standardization despite the complexity of the raw material.

Purification of the antioxidants

Figure 3 shows the HPLC fractionation profile of the products obtained from reaction of enzyme cocktail with marine waste under optimized conditions. Fractions eluting at 13–16 min (indicated by arrow) exhibited superoxide radical scavenging activity and were concentrated. The purity of fractions was verified by HPLC under the same conditions. Thin layer chromatography of the purified compound revealed a single spot detected by aniline-diphenylamine reagent as seen in Fig. 4. R f value of the compound was 0.72.

Thin layer chromatograph of the purified antioxidant, approximately 5.0 mg of the compound was obtained per gram of marine waste as estimated by average of densitometry analysis and quantitative HPLC. Lane A and B: 15 and 20 μg of the pure compound; Lane S: Standard N-acetylglucosamine (GlcNAc), N,N′-diacetylchiobiose (GlcNAc)2, N,N′,N″-triacetylchiotriose (GlcNAc)3, N,N′,N″,N′′′-tetraacetylchiotetraose (GlcNAc)4, Pentaacetyl-chiopentaose (GlcNAc)5, Hexaacetyl-chiohexaose (GlcNAc)6; (GlcNAc)4 was not clearly detected

Determination of in vitro free radical scavenging activity

Table 2 gives the free radical scavenging activity of the purified antioxidant using different scavenging assays. The compound exhibited maximum hydroxyl radical scavenging activity. Figure 5 shows the absorption spectra of copper sulphate in presence and absence of the antioxidant to evaluate metal chelation ability of the compound. As seen the spectrum of CuSO4 significantly changed in presence of the test compound indicating the possibility of metal chelation. Thus the antioxidant primarily exhibited lipid peroxidation inhibition, superoxide radical and hydroxyl radical scavenging abilities but could not scavenge H2O2.

Characterization of the antioxidant

The pure compound displaying antioxidant activity was characterized by FT-IR and proton NMR. The FT-IR spectrum is depicted in Fig. 6 which exhibited characteristic signals at ν 3294.5, 2895.2, 1660.7, 1645.3, 1566.2, 1550.8, 1429.3, 1375.2, 1313.5, 1114.8, 1049.3 cm−1. 1H NMR data was [300 MHz NMR (D2O)] δ 2.0 (d, 6H), 3.2–3.8 (m, 16H), 4.4 (d, 1H), 4.6 (d, 1H), 4.7 (d, 4H). From the biological data and spectral analysis the compound could be characterized as N,N′-diacetylchitobiose, i.e., 2-(acetylamino)-4-O-[2-(acetylamino)-2-deoxy-β-d-glucopyranosyl]-2-deoxy-d-glucopyranose. TLC was also carried out with the standard mixture of chitin oligosaccharides and R f value of the antioxidant purified in this study correlated with the R f value of N,N′-diacetylchitobiose as seen in Fig. 4. Nearly 5.0 mg of the compound could be recovered per gram of marine waste indicating a 0.5% recovery.

Production of chitooligomers from acetylated or deacetylated chitin has been carried earlier where a low yield of 0.17 mmol l−1 was reported from α-chitin (Laura et al. 2006). 0.13 mg ml−1 of chitobiose was produced from colloidal chitin using crude enzymes from Paenibacillus illinoisensis (Jung et al. 2007) and 415 mg of chitobiose was synthesized from DMSO treated chitin using Vibrio furnissi chitinase (Yoon 2005). But to the best of our knowledge, acetylated chitin oligosaccharides have not been recovered directly from marine waste except as reported by Wang et al. (2009b). Observations on antioxidant activity of lactic culture fermented shrimp waste were made by Sachindra and Bhaskar (2008). They have demonstrated 80% hydroxyl radical scavenging activity and 40% DPPH scavenging ability. Besides, they expected the association of antioxidant activity with peptides and amino acids in the shrimp waste hydrolysate. However in the present study the antioxidant did not exhibit DPPH radical scavenging ability and is not a peptide suggesting it to be different than that reported by Sachindra and Bhaskar (2008).

Thus a recovery of 0.5% of N,N-diacetylchitobiose from marine waste can be scaled up to develop a low cost technology for the production of chitobiose and other higher chitin oligomers. Although we could not detect the presence of other high molecular weight chitooligosaccharides in the marine waste treated with chitinase and protease, but their production can be studied with an alteration in reaction conditions.

Thus marine waste can serve as a potential substrate for the recovery of medicinally useful compounds. Biological extraction of these compounds ensures good quality of the compounds and makes the process environmental friendly and economically feasible. Large scale production of these compounds from marine waste can lead to the development of low-cost technologies with great demand in medicine and neutraceuticals.

References

Ben Rebah F, Frikha F, Kamoun W, Belbahri L, Gargouri Y, Miled N (2008) Culture of Staphylococcus xylosus in fish processing by-product-based media for lipase production. Lett Appl Microbiol 47:549–554

Chang WT, Chen YC, Jao CL (2007) Antifungal activity and enhancement of plant growth by Bacillus cereus grown on shellfish chitin wastes. Bioresour Technol 98:1224–1230

Chen AS, Taguchi T, Sakai K, Kikuchi K, Wang MW, Miwa I (2003) Antioxidant activities of chitobiose and chitotriose. Biol Pharm Bull 26:1326–1330

Chen AS, Taguchi T, Sakai K, Matahira Y, Wang MW, Miwa I (2005) Effect of chitobiose and chitotriose on carbon tetrachloride-induced acute hepatotoxicity in rats. Biol Pharm Bull 28:1971–1973

Christen Y (2000) Oxidative stress and Alzheimer disease. Am J Clin Nutr 71S:621S–629S

Cooke MS, Evans MD, Dizdaroglu M, Lunec M (2003) Oxidative DNA damage: mechanisms, mutation and disease. FASEB J 17:1195–1214

Dou J, Tan C, Du Y, Bai X, Wang K, Ma X (2007) Effects of chitooligosaccharides on rabbit neutrophiles in vitro. Carbohydr Polym 69:209–213

Elizabeth K, Rao MNA (1990) Oxygen radical scavenging activity of curcumin. Int J Pharm 58:237–240

Fernandes E, Borges F, Milhazes N, Carvalho FD, Bastos ML (1999) Evaluation of superoxide radical scavenging activity of gallic acid and its esters. Toxicol Lett 109:42

Gimeno M, Ramirez-Hernandez JY, Martinez-Ibarra C, Pacheco N, Garcia-Arrazola R, Barzana E, Shirai K (2007) One-solvent extraction of astaxanthin from lactic acid fermented shrimp wastes. J Agric Food Chem 55:10345–10350

Giugliano D, Ceriello A, Paolisso G (1996) Oxidative stress and diabetic vascular complications. Diabetes Care 19:257–267

Hitchon C, El-Gabalawy H (2004) Oxidation in rheumatoid arthritis. Arthritis Res Ther 6:265–278

Hsu SC, Lockwood JL (1975) Powdered chitin agar as a selective medium for enumeration of actinomycetes in water and soil. Appl Environ Microbiol 29:422–426

Jung WJ, Souleimanov A, Park RD, Smith DL (2007) Enzymatic production of N-acetyl chitooligosaccharides by crude enzyme derived from Paenibacillus illinoisensis KJA-424. Carbohydr Polym 67:256–259

Kim M, Kim S (2006) Chitooligosaccharides inhibit activation and expression of matrix metalloproteinase-2 in human dermal fibroblasts. FEBS Lett 580:2661–2666

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Laura RC, Maria MC, Sergio H, Sergio R, Shirai K (2006) Enzymatic hydrolysis of chitin in production of oligosaccharides using Lecanicillum fungicola chitinases. Process Biochem 41:1106–1110

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Nawani NN, Kapadnis BP (2004) Production dynamics and characterization of chitinolytic system of Streptomyces sp. NK1057, a well equipped chitin degrader. World J Microbiol Biotechnol 20:487–494

Nawani NN, Kapadnis BP, Das AD, Rao AS, Mahajan SK (2002) Purification and characterization of a thermophilic and acidophilic chitinase from Microbispora sp. V2. J Appl Microbiol 93:965–975

Qin C, Huang K, Xu HJ (2002) Protective effect of polysaccharide from the loach on the in vitro and in vivo peroxidative damage of hepatocyte. J Nutr Biochem 13:592–597

Rajapakse N, Kim MM, Mendis E, Kim SK (2007) Inhibition of free radical-mediated oxidation of cellular biomolecules by carboxylated chitooligosaccharides. Bioorg Med Chem 15:997–1003

Romaguera A, Menge U, Breves R, Diekmann H (1992) Chitinases of Streptomyces olivaceoviridis and significance of processing for multiplicity. J Bacteriol 174:3450–3454

Sachindra NM, Bhaskar N (2008) In vitro antioxidant activity of liquor from fermented shrimp biowaste. Bioresour Technol 99:9013–9016

Sachindra NM, Bhaskar N, Siddegowda GS, Sathisha AD, Suresh PV (2007) Recovery of carotenoids from ensilaged shrimp waste. Bioresour Technol 98:1642–1646

Valentao P, Fernandes E, Carvalho F, Andrade PB, Seabra RM, Bastos ML (2001) Antioxidant activity of Centaurium erythraea infusion evidenced by its superoxide oxidase inhibitory activity. J Agric Food Chem 49:3476–3479

Valentao P, Fernandes E, Carvalho F, Andrade PB, Seabra RM, Bastos ML (2002a) Studies on the antioxidant activity of Lippia citfiodora infusion: scavenging effect on superoxide radical, hydroxyl radical and hypochlorous acid. Biol Pharm Bull 25:1324–1327

Valentao P, Fernandes E, Carvalho F, Andrade PB, Seabra RM, Bastos ML (2002b) Antioxidant activity of Hypericum androsaemum infusion: scavenging activity against superoxide radical, hydroxyl radical and hypochlorous acid. Biol Pharm Bull 25:1320–1323

Wang SL, Yeh PY (2006) Production of a surfactant- and solvent-stable alkaliphilic protease by the bioconversion of shrimp shell wastes fermented by Bacillus subtilis TKU007. Process Biochem 41:1545–1552

Wang SL, Chiou SH, Chang WT (1997) Production of chitinase from shellfish waste by Pseudomonas aeruginosa K-187. Proc Natl Sci Counc Repub China B 21:71–78

Wang SL, Lin HT, Liang TW, Chen YJ, Yen YH, Guo SP (2008) Reclamation of chitinous material by bromelain for the preparation of antitumor and antifungal materials. Bioresour Technol 99:4386–4393

Wang SL, Lin CL, Liang TW, Liu KC, Kuo YH (2009a) Conversion of squid pen by Serratia ureilytica for the production of enzymes and antioxidants. Bioresour Technol 100:316–323

Wang SL, Liou JY, Liang TW, Liu KC (2009b) Conversion of squid pen by using Serratia sp. TKU020 fermentation for the production of enzymes, antioxidants and N-acetylchitooligosaccharides. Process Biochem 44:854–861

Wang SL, Liu KC, Liang TW, Kuo YH, Wang CY (2010) In vitro antioxidant activity of liquor and semi-purified fractions from fermented squid pen biowaste by Serratia ureilytica TKU013. Food Chem 119:1380–1385

Wang SL, Wu PC, Liang TW (2009d) Utilization of squid pen for the efficient production of chitosanase and antioxidants through prolonged autoclave treatment. Carbohydr Res 344:979–984

Wei H, Wei L, Frenkel K, Bowen R, Barnes S (1993) Inhibition of tumor promoter-induced hydrogen peroxide formation in vitro and in vivo by genistein. Nutr Cancer 20:1–12

Wijewickreme AN, Kitts DD (1997) Influence of reactions on the oxidative behavior of model Maillard reaction products. J Agric Food Chem 45:4571–4576

Wood-Kaczmar A, Gandhi S, Wood N (2006) Understanding the molecular causes of Parkinson’s disease. Trends Mol Med 12:521–528

Yang JK, Shih IL, Tzeng YM, Wang SL (2000) Production and purification of protease from a Bacillus subtilis that can deproteinize crustacean wastes. Enzyme Microb Technol 26:406–413

Yoon JH (2005) Enzymatic synthesis of chitooligosaccharides in organic cosolvents. Enzyme Microb Technol 37:663–668

Acknowledgments

This work was supported by the grant received from the Department of Science and Technology and Department of Biotechnology, Government of India. The authors are thankful to Department of Microbiology, University of Pune and Dr. D. Y. Patil Biotechnology and Bioinformatics Institute for providing the necessary infrastructural facilities for this work. The authors also thank Dr. Renu Vyas, Dr. D. Y. Patil Biotechnology and Bioinformatics Institute for spectral analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nawani, N.N., Prakash, D. & Kapadnis, B.P. Extraction, purification and characterization of an antioxidant from marine waste using protease and chitinase cocktail. World J Microbiol Biotechnol 26, 1509–1517 (2010). https://doi.org/10.1007/s11274-010-0327-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-010-0327-5