Abstract

Gamma-aminobutyric acid (GABA) has many pharmacological functions including being a major inhibitory neurotransmitter. Two comparative methods for GABA production in rice grains as main food source in Thailand were investigated in this study. Fermentation and germination method were separately carried out using seven selected local grain cultivars in northern Thailand. Red yeast rice, obtained from the fermentation method, gave the higher GABA concentration than the germinated rice produced from the germination method in most rice cultivars. The highest GABA concentration was 28.37 mg/g at 3 weeks fermentation time of glutinous rice, O. sativa L. cv. Sanpatong 1 cultivars, while germinated rice from glutinous rice; O. sativa L. cv. Korkor6 (RD6) cultivars contained the highest GABA concentration of 3.86 mg/g. These results provide information for the basis of an appropriate method for GABA production. The fermentation produced higher GABA concentration but required longer production period and red yeast rice was obtained as product. On the other hand, the germination method yielded rice grains with lower GABA but in more suitable form for consumption. Both methods are considered to be economical and efficient methods to increase GABA in rice grains, providing alternative products with higher nutritional values.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Gamma-aminobutyric acid (GABA) is a non-protein amino acid compound (Shelp et al. 1999; Komatsuzaki et al. 2005; Huang et al. 2007; Park and Oh 2007). It is produced in plants, microorganisms and mammals by decarboxylation of glutamic acid via the glutamate decarboxylase (GAD) enzyme (Kono and Himeno 2000; Ueno 2000; Su et al. 2003; Komatsuzaki et al. 2007). It has pharmacological functions such as, as an antihypertension agent, as a diuretic, as well as having a tranquilizing effect and as being an inhibitory neurotransmitter in sympathetic brain functions (Su et al. 2003; Komatsuzaki et al. 2005, 2007; Huang et al. 2007). GABA can regulate blood pressure, heart rate, sensations of pain and anxiety (Kono and Himeno 2000), lipid levels in serum (Miura et al. 2006) and assist in insulin secretion to prevent diabetes (Huang et al. 2007). Recently, it has been reported that germinated brown rice could effectively reduce glucose levels in diabetic rats (Hagiwara et al. 2004). Moreover, consumption of GABA-enriched foods can inhibit cancer cell proliferation (Park and Oh 2007) and improve memory and the learning abilities in rats (Miura et al. 2006).

GABA is found widely in nature, such as in tea leaves (Aoki et al. 2003), bean sprouts (Komatsuzaki et al. 2007), soybean seedling (Oh and Choi 2001), rice germ (Zhang et al. 2007a, b; Xing et al. 2007) and in microorganisms such as Lactobacillus brevis (Huang et al. 2007), Lactobacillus paracasei (Komatsuzaki et al. 2005), Lactococus sp. and Lactobacillus sp. (Nomura et al. 1998), Monascus sp. (Su et al. 2003; Wang et al. 2003; Chen et al. 2006), Rhizopus sp. (Aoki et al. 2003). It is also found in fermented food products made from lactic acid bacteria, such as cheese (Nomura et al. 1998), Tempeh-like fermented soybean, Korean kimchi and yogurt (Aoki et al. 2003).

Many methods used in previous reports have attempted to increase GABA levels in rice, for example by using biotechnology methods such as transferring GAD genes for the higher GABA production (Park and Oh 2006), fermentation methods for the conversion of glutamic acid substrate to GABA (Kono and Himeno 2000; Su et al. 2003; Chen et al. 2006; Huang et al. 2007) and other methods which include rice germination (Oh and Choi 2001; Komatsuzaki et al. 2007; Xing et al. 2007).

Among the described methods, fermentation and germination methods have been common practices in Asian countries (Su et al. 2003; Wang et al. 2003; Chen et al. 2006; Komatsuzaki et al. 2007). The germinated rice was produced with the conventional germination method by soaking rice grains in water at controlled temperature to promote germination. Accumulation of GABA and effective components in germinated rice grains were found during this process (Varanyanond et al. 2005; Komatsuzaki et al. 2007).

While, fermentation method was employed to produce red yeast rice with high GABA content using Monascus sp. Three traditional fermentation Monascus species, M. purpureus, M. ruber and M. pilosus, has been commonly used in food for thousands of years in East Asia (Hawksworth and Pitt 1983). Products derived from fermented rice with Monascus sp. present the deep-red color, therefore they have been called red-yeast rice or red-mold rice (Babitha et al. 2007).

Previous reports studied the different species of Monascus sp. and various rice cultivars as substrates for GABA production in red yeast rice (Hu et al. 2003; Su et al. 2003; Wang et al. 2003; Pattanagul et al. 2007; Sun et al. 2008). Su et al. (2003) screened Monascus sp. for the highest GABA production on solid state of steamed rice from local areas in Taiwan which contained sufficient carbon sources, added various nitrogen and inorganic salts sources. While, Wang et al. (2003) further improved GABA production in red yeast rice by adding Monascus purpureus NTU 601 to the culture medium supplemented with varying carbon sources, nitrogen sources, fatty acid and oil. For further study in Korea and China, Plackett-Burman Design (PBD) and Central Composite Design (CCD) were applied to seek for the crucial parameters that affect the production of GABA in red yeast rice by Monascus pilosus GM100 under solid state fermentation (Sun et al. 2008).

Rice plants are grown in almost every part of Thailand mainly for consumption and export. Polished rice which is prepared by removal of the outer shell of whole grains rice is used in cooking. However, the ordinary polished rice has less nutritional components, these biofunctional components exist mainly in the germ and bran layers which are removed by the polishing process (Champagne et al. 2004). It is interesting to add value to a variety of Thai rice by increasing GABA concentration.

Therefore, the objective of this study was to compare the conventional fermentation and germination methods for GABA production in Thai rice cultivars, based on the hypothesis that GABA can increase rice value, price and the income of farmers in Thailand. People can choose both methods to increase GABA levels in polished rice grains for both consumption and for use in the food industry. The product from both techniques will be monitored quantitatively and qualitatively by HPLC and LC–MS analysis, respectively. The relationship between GABA concentration and glutamic acid will also be studied.

Materials and methods

Materials

The seven cultivars of the polished form of normal rice; O. sativa L. cv. Kawdokmali 105 (KDML105), O. sativa L. cv. Supan 1 (SP1), O. sativa L. cv. Chainat 1 (CN1), O. sativa L. cv. Pitsanulok2 (PL2) and O. sativa L. cv. Patum1 (PT1). The second one is glutinous rice; O. sativa L. cv. Sanpatong 1 (SPT1), O. sativa L. cv. Korkor 6 (RD6) were purchased from a local market to be used in fermentation and the same seven cultivars of whole grain rice were obtained from Pitsanulok and Chiang Mai rice seed centers in Thailand, all of which were to be used for the germination experiments.

Gamma-aminobutyric acid (GABA) was purchased from Fluka, China and hydroxy-napthaldehyde (HN) was purchased from Aldrich, Germany. HPLC grade acetonitrile and ethanol were purchased from BDH Prolabo, EC. PDA agar was purchased from Difco, USA. Formic acid was purchased from Wako-Pure Chemical Industries, Japan. Buffer solutions were prepared from sodium tetraborate (borax) (1 M) and boric acid (1 M) which were purchased from MERCK, Germany.

Isolated Monascus purpureus strain CMU001 on PDA slant was obtained from the Department of Biology, Faculty of Science, Chiang Mai University.

Germination method

The seven cultivars of whole grain rice were washed with distilled water three times. They were then soaked in distilled water for 72 h, while the water was changed every 24 h and finally the water was decanted. Whole grain rice was allowed to germinate on moist paper in separate plastic boxes at 30°C. The germination process was completed by germination of the seeds under these conditions, and germinated rice samples were collected every 3 days during germination. The rice germ was removed by cutting and eliminating the bran layer by machine. Polished rice grains were obtained from this procedure and were dried at 70°C for 12 h, then ground by blender (Komatsuzaki et al. 2007; Xing et al. 2007). Ground samples were collected for GABA extraction and further analysis.

Fermentation method

The seven cultivars of purchased polished rice were used as a source of glutamic acid under the solid state fermentation. Ten gram of each polished rice cultivar were soaked in distilled water for 8 h and water was then removed. The soaked polished rice was separately steamed in a cooking pot for 20 min. After that, steamed polished rice was removed into a 250 ml Erlenmeyer flask and autoclaved at 120°C for 20 min. After being autoclaved the rice was cooled. M. purpureus CMU 001 spores were inoculated into the steamed rice and it was incubated at 30°C. GABA was produced after 1 week of fermentation and the red color resulting from the fermentation by-product was developed during the fermentation process. Sampling of red rice for GABA analysis was done every week and the rice was dried at 70°C in an oven (Su et al. 2003; Wang et al. 2003; Chen et al. 2006). Red rice was ground by a blender and the ground sample was collected for GABA extraction and analysis as described below.

GABA extraction

Two hundred and fifty milligram of ground samples were vigorously mixed in 800 μl of 70% ethanol by vortex mixer. The mixture was shaken for 30 min at room temperature and then centrifuged at 13,000g at 4°C for 10 min. The supernatant in the upper layer was collected and then 800 μl of 70% ethanol was added to the pellet, the extraction process was repeated three times. The supernatant was collected and combined with the first supernatant (Baum et al. 1996; Oh and Choi 2001; Komatsuzaki et al. 2007). The obtained crude extract containing GABA was then passed through the 0.45 μm filter and analyzed by HPLC and LC–MS techniques after 2-hydroxynaphthaldehyde (HN) derivatization.

Derivatization of GABA and standard curve

One millilitre of rice extract sample was added to 0.5 ml of borax buffer pH 8 and 0.5 ml of HN (0.3% w/v in methanol). The solution was heated in a water bath at 80°C for 10 min and was allowed to cool. The standard curve was constructed from five standard solutions of GABA (250, 125, 50, 25 and 10 ppm of GABA) analyzed by the modified procedure of Khuhawar and Rajper 2003.

Analysis of GABA by HPLC and LC–MS

GABA was determined to be present in the sample by HPLC (JASCO, Japan) which consisted of a pump (JASCO PU-980 intelligent HPLC pump), a variable wavelength UV detector (JASCO MD-2010 plus multiwavelength), degasser (JASCO DG-2080-53, 3 line degasser) and column ODS-80Ts, size 4.6 mm (I.D.) × 25.0 cm (L), (Tosoh Corporation, Japan). HPLC with pre-column derivatization with HN was done using the following conditions; UV detection at 330 nm with a flow rate of 1 ml/min. Mobile phase containing acetonitrile (mobile phase A):0.1% formic acid (mobile phase B) were applied. The elution gradient was evaluated using %mobile phase A; 35–40, 40–55, 55–35 at 0–5, 5–10 and 10–20 min, respectively. Glutamic acid was analyzed simultaneously during GABA analysis.

All samples containing GABA were analyzed by LC–MS (HP 1100 Binary/G1946A) to confirm the HPLC results. The mass spectrometer with an electrospray ionization (API-EI) source was operated in the positive ion mode. Mass spectrometry experiments were performed to isolate and fragment the targeted ions. The operation conditions of the MS detector were optimized with a solution of GABA standard with an abundance of m/z 258 [M+H]+ which was determined as follows; Fragmentation range: 70, Mass range: 100–1,000, Drying gas flow:12 l/min, Nebulizer pressure: 32 psig, Drying gas temperature: 350°C, and Capillary voltage: 3,000 V. Data were processed with data analysis software.

Results and discussion

GABA concentrations in rice grains using fermentation method

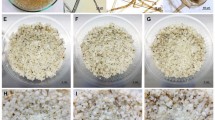

Change in the GABA concentrations in the seven cultivars of rice grains during fermentation was investigated. GABA was produced and increased every week after inoculating isolated M. purpureus CMU001 spores into the seven cultivars of steamed polished rice (Fig. 1c), while the control (no added M. purpureus spores) contained no GABA as shown in Fig. 1a. The control and fermented rice extract chromatograms are represented by PL2 cultivar, while the chromatograms of other cultivars are not shown. These results indicated that glutamic acid in steamed rice could be converted to GABA using the GAD enzyme from M. purpureus (Su et al. 2003; Wang et al. 2003).

HPLC chromatograms of sample extraction containing GABA; in a Non-germinated grain (Control) and b Germinated rice extract of O. sativa L. cv. Pitsanulok2 (PL2) cultivar c Fermented rice (red yeast rice) extract of O. sativa L. cv. Pitsanulok2 (PL2) cultivar d GABA standard at a concentration of 250 ppm; Peak (1) GABA, (2) Glutamic acid and (3) excess HN, gradient eluent with acetonitrile: 0.1% formic acid; C-18 reverse phase condition

To confirm GABA composition in fermented rice, mass spectrometry was used to detect GABA based on the molecular weight of derivatives formed (GABA-HN) as shown in Fig. 2.

The results showed varying GABA concentrations, when using different rice cultivars. GABA concentrations were found at the intervals of 3.41–10.56, 3.17–8.61, 2.12–11.21, 2.27–9.45, 1.24–11.54, 4.44–17.53 and 3.11–28.37 mg/g of steamed rice in the cultivars of KDML105, CN1, PL2, PT1, RD6, SP1 and SPT1, respectively, (Fig. 3a). Previous reports suggested that nutrient composition, other components and culture conditions may affect the growth of fungi and GABA production (Wang et al. 2003).

SPT1 cultivar showed the highest GABA concentrations, with a maximum production of 28.37 mg/g at 3 weeks as shown in Fig. 3a. The results agree with the fact that SPT1 had a higher glutamic acid content (Fig. 3b), a substrate for GABA production, than the other cultivars.

Another reason was that this cultivar had a greater tendency under optimum conditions for M. purpureus fermentation than other cultivars. Because SPT1 is the glutinous rice which has a stickier appearance, a more glue-like texture and higher moisture content than the other cultivars. SP1, CN1, KDML105, PT1 and PL2 are considered to be normal rice, possessing the hard texture and there is no agglomeration of rice grains. In addition, GABA production is differently affected by environmental parameter, such as temperature and moisture content (Wang et al. 2003). Perhaps the moisture content of glutinous rice can promote the growth rate of Monascus sp. at fermentation condition of 30–35°C (Hu et al. 2003; Su et al. 2003; Wang et al. 2003; Sun et al. 2008; Pattanagul et al. 2007). The growth of Monascus fungi is a key indicator in the synthesis of pigments and other metabolites (Vignon et al. 1986). This result related with the previous report of Chairote et al. (2008) who found that the Thai glutinous rice seems to give more satisfactory amounts of secondary metabolites than non-glutinous rice.

GABA concentrations in rice grains using germination method

This study intended to increase GABA content in whole grain rice by the germination method. Germinated whole grain rice showed an initial small root with GABA production at 3 days (Fig. 4a). Over 9–12 days following germination, it had long roots and initiated its first leaf which possessed a higher GABA concentration than on the other days. In contrast, the control (non-germinated rice) (Fig. 1a) was found not to produce any GABA.

This result agreed with the previous reports which showed the higher GABA concentrations in rice (Komatsuzaki et al. 2007) and soybeans (Oh and Choi 2001) during germination than in non-germinated seed. The results indicated that during germination, hydrolytic enzymes were activated in grains and as a result starch, non-starch polysaccharides and proteins were decomposed leading to the increase of oligosaccharides and amino acids in the grains (Ohtsubo et al. 2005). According to the previous study, amino acids that are stored in grains as storage proteins are decomposed by water absorption during germination, and then changed into transportable amides, and supplied to the growing parts of the rice seedlings (Lea et al. 1990). Moreover, upon water absorption during soaking and germination, GAD enzyme is activated (Komatsuzaki et al. 2007). As a result, glutamic acid is effectively converted to GABA (Kono and Himeno 2000; Ueno 2000; Su et al. 2003; Komatsuzaki et al. 2007).

From the results in Fig. 4a, germinated whole grain rice showed different GABA concentration levels. It was found that the GABA concentrations varied in the intervals of 0.74–4.84, 1.43–5.09, 1.76–6.33, 1.55–5.65, 1.86–3.86, 1.71–6.31 and 2.79–3.27 mg/g in KDML105, CN1, PL2, PT1, RD6, SP1 and SPT1, respectively. Bautista et al. suggested that GAD activity was a more reliable index for the viability of different stored rice. This variation might be due to the different rice cultivars effect on the amount and pattern of GABA and GAD accumulations in this study.

Observation on the pattern of GABA production of germinated rice was shown in Fig. 4a. Even through amounts of GABA increased during germination, they began to decrease after 12 germination days of KDML105, CN1, RD6, SP1 and SPT1 cultivars. While, those in PL2 and PT1 still increased.

It might be that GABA is converted to succinic acid by GABA-aminotransferase and a succinic semialdehyde dehydrogenase enzyme in mitochondria further acted as a metabolizing compound in the TCA cycle (Shelp et al. 1999; Kono and Himeno 2000; Huang et al. 2007). Therefore, it is of interest to examine this activity and inhibit both enzymes during germination for higher GABA accumulation.

Comparison of the methods for GABA production in rice grains

According to the results shown in Figs. 3a and 4a the GABA concentration levels between fermentation and germination methods can be compared. The level of GABA in rice grains found in the fermentation method was significantly higher than that in the germination method. Beside these, changes of glutamic acid concentration were compared during germination and fermentation processes which are shown in Figs. 3b and 4b. It may be because rice in the fermentation method had higher glutamic acid concentration profiles at the initial time of fermentation in all cultivars (Fig. 3b). Secondly, the sources of the GAD enzyme for producing GABA in both methods were different. During fermentation, the GAD enzyme is secreted from M. purpureus CMU001, while germination uses GAD enzyme from whole grain rice during germination. However, previous reports suggested that GABA levels in plants can be enhanced during high stress conditions, such as by mechanical stimulation, hypoxia, cytosolic acidification, or by altering the conditions of water supply, darkness and water stress (Snedden and Fromm 1998).

Moreover, the relationship between glutamic acid and GABA content during germination of each cultivar was studied (Fig. 4a, b). The glutamic acid showed an inverse relationship with GABA production in most rice cultivars (CN1, PL2, RD6, SP1, PT1 and SPT1) except KDML105 during germination. At the 6 and 9 days of germination, a decrease in glutamic acid levels was observed in CN1, PL2, RD6 and PT1, respectively, whereas the levels of GABA were slightly increased during the same period. These reports suggested that a decrease of endogenous glutamic acid could be used as a substrate for GABA production in the subsequent days, suggesting that the GAD enzyme might be activated for GABA formation (Huang et al. 2007).

However, KDML105 cultivar showed a different result from the other cultivars. GABA content during germination increased, while glutamic acid content remained unchanged.

The result was the same as the previous reports of Komatsuzaki et al. 2007 who found the increase of glutamic acid during the germination of brown rice. Moreover, Duke et al. (1978) found high glutamic acid concentrations in both cotyledons and axes of soybean seedling after 5 days of germination at 10°C.

Moreover, glutamic acid concentrations were investigated during the fermentation method as shown in Fig. 3b. An increase in glutamic acid concentrations were found in all cultivars during 4 weeks of fermentation. The glutamic acid contents of these cultivars were 3.66–10.67, 3.64–23.37, 1.74–11.00 and 2.74–98.72 mg/g of KDML105, PL2, RD6 and SPT1, respectively.

The relationship profile between glutamic acid and GABA during fermentation (Fig. 3a, b) differ from those of germination (Fig. 4a, b). Most cultivars showed parallel changes between an increase of glutamic acid and the accumulation of GABA levels such as KDML 105, RD6 and PL2. It is worth mentioning that glutamic acid levels were found to be higher than GABA concentrations in all cultivars. These cultivars showed the increase level of glutamic acid in later weeks, although it was used to produce GABA. This result may be that, while the glutamic acid is used to produce GABA, it is synthesized by the glutamate syntheses (GOGAT) and glutamine syntheses (GS) cycles during GABA fermentation. The GS/GOGAT cycles play an important role in the anaerobic accumulation of GABA and alanine (Aurisano et al. 1995; Reggina et al. 2000). Therefore, fermentation is the method of choice to produce glutamic acid for subsequent GABA production.

This research investigated GABA accumulation and disappearance during germination and fermentation by using several well-known rice cultivars. Both methods can produce GABA in rice, especially the fermentation method which can produce GABA in higher concentrations than the germination method, but longer time would be needed. The data provide an idea for the effective uses of germinated rice and fermented rice products which contain higher GABA levels than commercial rice presently available in the market.

References

Aoki H, Uda I, Tagami K et al (2003) Production of a new Tempeh-like fermented soybean containing a high level of gamma-aminobutyric acid by anaerobic incubation with Rhizopus. Biosci Biotechnol Biochem 67:1018–1023

Aurisano N, Bertani A, Reggiani R (1995) Anaerobic accumulation of 4-aminobutyrate in rice seedlings: causes and significance. Phytochem 38:1147–1150

Babitha S, Soccol CR, Pandey A (2007) Solid-state fermentation for the production of Monascus pigments from jackfruit seed. Bioresour Technol 98:1554–1560

Baum G, Lev YS, Fridmann Y et al (1996) Calmodulin binding to glutamate decarboxylase is required for regulation of glutamate and GABA metabolism and normal development in plants. J EMBO 15:2988–2996

Chairote EO, Chaiote G, Niamsup H et al (2008) The presence and the content of Monacolin in Red Yeast rice prepared from Thai glutinous rice. World J Microbiol Biotechnol 24:3039–3047

Champagne ET, Wood DF, Juliano BO et al (2004) The rice grain and its gross composition. In: Champagne ET (ed) Rice chemistry and technology, 3rd edn. The American Association of Cereal Chemists, St. Paul, pp 77–80

Chen YL, Hwang I.E, Lin MC et al (2006) Monascus purpureus mutants and their use in preparing fermentation products having blood pressure lowering activity. US Patent 7067304:1–10

Duke SH, Schrader LE, Miller MG (1978) Low temperature effects on soybean (Glycine max IL.I Menr. cv.Wells) free amino acid pools during germination. Plant Physiol 62:642–647

Hagiwara H, Seki T, Ariga T (2004) The effect of pre-germinated brown rice intake on blood glucose and PAI-1 levels in streptozotocin-induced diabetic rats. Biosci Biotechnol Biochem 68:444–447

Hawksworth DL, Pitt JI (1983) A new taxonomy for Monascus species based on cultural and microscopical characters. Aust J Bot 31:51–61

Hu XQ, Shao YC, Xu P et al (2003) Analysis of Citrinin in Hongqu (Monascus spp.) product by TLC. J Food Sci 5:126–129

Huang J, Mei LH, Wu H et al (2007) Biosynthesis of gamma-aminobutyric acid (GABA) using immobilized whole cells of Lactobacillus brevis. World J Microbiol Biotechnol 23:865–871

Khuhawar MY, Rajper AD (2003) Liquid chromatographic determination of gamma-aminobutyric acid in cerebrospinal fluid using 2-hydroxynaphthaldehydeas derivatizing reagent. J Chromatogr B 788:413–418

Komatsuzaki N, Shima J, Kawamoto S et al (2005) Production of gamma-aminobutyric acid (GABA) by Lactobacillus paracasei isolated from traditional fermented foods. J Food Microbiol 22:497–504

Komatsuzaki N, Tsukahara K, Toyoshima H et al (2007) Effect of soaking and gaseous treatment on GABA content in germinated brown rice. J Food Microbiol 78:556–560

Kono I, Himeno K (2000) Change in gamma-aminobutyric acid content during beni-koji making. Biosci Biotechnol Biochem 64:617–619

Lea PJ, Robinson SA, Stewart GR (1990) The enzymology and metabolism of glutamine, glutamate and asparagines. In: Miflin BJ, Lea PJ (eds) The biochemistry of plants. Academic Press, San Diego, pp 121–159

Miura D, Ito Y, Mizukuchi A et al (2006) Hypercholesterolemic action of pre-germinated brown rice in hepatoma-bearing. Life Sci 79:259–264

Nomura M, Kimoto T, Someya Y et al (1998) Production of gamma-aminobutyric acid by cheese starters during cheese ripening. J Dairy Sci 81:1486–1491

Oh SH, Choi WG (2001) Changes in the levels of gamma-aminobutyric acid and glutamate decarboxylase in developing soybean seedlings. J Plant Res 114:309–313

Ohtsubo K, Suzuki K, Yasui Y et al (2005) Bio-functional components in the processed pre-germinated Brown rice by a twin-screw extruder. J Food Compost Anal 18:303–316

Park KB, Oh SH (2006) Enhancement of gamma-aminobutyric acid production in chungkukjang by applying a Bacillus subtilis strain expressing glutamate gecarboxylase from Lactobacillus brevis. Biotechnol Lett 28:1459–1463

Park KB, Oh SH (2007) Production of yogurt with enhanced levels of gamma-aminobutyric acid and valuable nutrients using lactic acid bacteria and germinated soybean extract. Bioresour Technol 98:1675–1679

Pattanagul P, Pinthong R, Phianmongkhol A et al (2007) Review of Angkak production (Monascus purpureus). Chiang Mai J Sci 34:319–328

Reggina R, Nebuloni V, Brambilla I (2000) Anaerobic accumulation of amino acids in rice roots: role of the glutamine synthetase/glutamate synthase cycle. Amino Acids 18:207–217

Shelp BJ, Bown AW, McLean MD (1999) Metabolism and functions of gamma-aminobutyric acid. Trends Plant Sci 4:447–451

Snedden WA, Fromm H (1998) Calmodulin, calmodulin related proteins and plant responses to the environment. Trends Plant Sci 3:299–304

Su YC, Wang JJ, Lin TT et al (2003) Production of the secondary metabolites gamma-aminobutyric acid and monacolin K by Monascus. J Ind Microbiol Biotechnol 30:41–46

Sun BS, Zhou LP, Jia XQ, Sung CK (2008) Response surface modeling for gamma-aminobutyric acid production by Monascus pilosus GM100 under solid-state fermentation. Afr J Biotechnol 7(24):4544–4550

Ueno H (2000) Enzymatic and structural aspect on glutamate decarboxylase. J Mol Catal B 10:67–79

Varanyanond W, Tungtrakul P, Surojanametakul V et al (2005) Effect of water soaking on gamma-aminobutyric acid (GABA) in germ of different Thai rice varieties. J Kasetsart (Nat. Sci) 39:411–415

Vignon C, Plassard C, Mousain D et al (1986) Assay of fungal chitin and estimation of mycorrhizal infection. Physiol Veg 24:201–207

Wang JJ, Lee CL, Pan TM (2003) Improvement of monacolin K, gamma-aminobutyric acid and citrinin production ratio as a function of environmental conditions of Monascus purpureus NTU 601. J Ind Microbiol Biotechnol 30:669–676

Xing SG, Jun YB, Hua ZW et al (2007) Higher accumulation of gamma-aminobutyric acid induced by salt stress through stimulating the activity of diamine oxidase in Glycine max (L.) Merr.roots. J Ind Microbiol Biotechnol 45:560–566

Zhang H, Yao HY, Chen F et al (2007a) Purification and characterization of glutamate decarboxylase from rice germ. Food Chem 101:1670–1676

Zhang H, Yao HY, Chen F et al (2007b) Some molecular properties of glutamate decarboxylase from rice germ. Food Chem 105:65–71

Acknowledgments

We gratefully acknowledge the full financial support from the Office of the Higher Education Commission, Thailand for financial support by grant under the program Strategic Scholarships for Frontier Research Network for the Ph.D. Program Thai Doctoral degree for this research. As well as partial support from Rachabhut Pibulsongkram University, Pitsanulok, Thailand and The Center of Excellence for Innovation in Chemistry for Postgraduate Education and Research Program in Chemistry (PERCH-CIC), Thailand and Graduate School, Chiang Mai University, Thailand.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jannoey, P., Niamsup, H., Lumyong, S. et al. Comparison of gamma-aminobutyric acid production in Thai rice grains. World J Microbiol Biotechnol 26, 257–263 (2010). https://doi.org/10.1007/s11274-009-0168-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-009-0168-2

(3 weeks) and

(3 weeks) and  (4 weeks)

(4 weeks)

(15 days)

(15 days)