Abstract

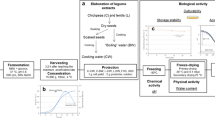

The quality of a fermented beverage (FSB) produced from seaweed (Gracilaria fisheri) was investigated after four different fermentation processes. 1, a normal fermentation as control (N-N); 2, batch with addition of an inoculum of an antiyeast starter culture, Lactobacillus plantarum DW3 (N-S); 3, a partial sterilization of the seaweed with 0.5% potassium metabisulfite (KMS) (P-N); and 4, a partial sterilization followed by an inoculum as for 2 (P-S). At the end of fermentation (60 days) and after storage for 3 months, all treatment sets passed the microbiological quality guidelines, as no bacterial indicators (total coliforms and Escherichia coli) or foodborne pathogens (Salmonella sp. Clostridium perfringens and Staphylococcus aureus) were detected. All treatments improved the availability of elements (Cu, Zn, and Fe) in the seaweed beverage and they were all below the recommended safety levels. Toxic compounds such as methanol, and the elements As and Pb were below either the detection or safety limits. The starter culture controlled yeast contamination and had inhibitory effects against foodborne pathogenic bacteria (Vibrio parahaemolyticus PSSCMI 0064 > Bacillus cereus ATCC 11778 > Salmonella typhi PSSCMI 0034 ∼ Staphylococcus aureus PSSCMI 0004 ∼ E. coli PSSCMI 0001). The inoculation set without pretreatment by KMS (N-S) was the treatment that produced the best FSB based on its antibacterial activity, reduction of contaminated yeasts, remaining probiotic LAB and organoleptic properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A fermented plant beverage (FPB) is a non-alcoholic beverage produced by lactic fermentation from different kinds of plants. There are three main components in the FPB: plant material, water and sugar (Kantachote et al. 2005a). Consumers believe that FPBs can promote good health and can also cure some diseases (Kantachote et al. 2005b) such as by having anticancer and anti-inflammatory properties (Hirazumi and Furusawa 1999; McClatchey 2002; McKoy et al. 2002). Consequently, the market for foods with health-promoting properties, so called ‘functional foods’, has shown a remarkable growth over the last few years (Leroy and De Vuyst 2004).

The seaweed Gracilaria fisheri is classified in the division Rhodophyta, class Rhodophyceae. It has long been consumed by people who live near the seashore. Antivirus and anticancer compounds have been extracted from this seaweed (Farfield 2007). Due to its abundance in the south of Thailand, its cheap price and high nutritional value, Gracilaria fisheri was selected for this study. However, although it has a high nutritional value, this seaweed depending on its source may be associated with high concentrations of heavy metals such as Fe, Cu and Zn so there is some concern in its use. Some heavy metals such as As and Pb are toxic elements even at very low concentrations (Holum 1983; Ferner 2001) therefore, their concentrations in fermented beverages need to be investigated.

Although FPBs are produced in many countries, such as Noni juice originally produced in Polynesia, EM-X Rice Bran Beverage (EM-X) from Japan, Vita Biosa, product from Denmark and many kinds of fermented plant beverage in Thailand, they have not yet been accepted by food-related organizations including the Thai FDA because scientific information and regulations about the FPBs are relatively low compared to the more popular beverages like wine. In addition, high numbers of yeasts found in the finished product seem to be of critical concern for the Thai FPB (Kantachote et al. 2005a).

To control contamination by yeasts, chemical methods are not considered to be an attractive way for functional foods because at present, consumers are mostly interested in healthy food, so the use of food additives is regarded as unnatural and unsafe. However, potassium metabisulfite (KMS) has long been used to reduce the numbers of native microbes in the raw materials used for making wine and plant products. For instance, a combination of blanching and 0.5% KMS for the production of dehydrated cauliflower was found to be the best method to use with regard to the nutritional and microbiological quality of the finished product (Kadam et al. 2005). In addition, physical treatments using for example heat for either pasteurization or sterilization may result in the loss of some nutrients and flavor that consumers would prefer to be preserved (Ray 1992; Kantachote et al. 2005a; Schnürer and Magnusson 2005).

An alternative method may be to encourage more use of controlled starter cultures. Lactic acid bacteria (LAB) produce several antimicrobial compounds; for example, carbon dioxide, hydrogen peroxide, and organic acids such as lactic acid and acetic acid. These compounds can play a key role in reducing microbial contamination. Hence, selecting the best strains of starter cultures or co-cultures for the fermentation processes is necessary to guarantee the consistency of the desired properties of the product (Leroy and De Vuyst 2004). In our previous work (Prachyakij et al. 2007) studied the best way to control contamination by yeast strains in Thai fermented plant beverages and Lactobacillus plantarum DW3 was the most promising strain we isolated.

The aims of this study were to investigate the effect of using L. plantarum DW3 as a starter inoculum and comparing it with a partial sterilization process using KMS, on the quality of a fermented seaweed beverage, in terms of the reduction of yeast contamination, the microbiological quality, chemical properties, antibacterial activity and a sensory test.

Materials and methods

Seaweed fermentation

Lactobacillus plantarum DW3 was used as the starter inoculum in this study. The bacterium was inoculated into 100 ml MRS broth and incubated at 30°C until the culture reached the late log phase. The cells were harvested by centrifugation at 6000 rev/min for 15 min. The cell pellet was washed twice with 0.85% NaCl and then resuspended to approximately to 1.5 × 108 c.f.u./ml based on the McFarland number 0.5 for use as the inoculum.

Dried seaweed (Gracilaria fisheri) was purchased from a local market at Yor island, Songkhla province. The experimental design comprised four different treatments. Two sets of treatments used seaweed without pre-treatment by potassium metabisulfite (KMS). One set of these was inoculated with a 5% starter culture to obtain an initial cell density of approximately 7.5 × 106 c.f.u./ml (N-S). The other set, with no added starter (N-N) served as a natural fermentation control. In another two sets the seaweed was subjected to partial sterilization, by pre-treating with 0.5% KMS, overnight, followed by cleaning with tap water. One set was inoculated with 5% of the starter culture to provide 7.5 × 106 c.f.u./ml (P-S) and the last set had no added starter (P-N) to act as a negative control. The seaweed was well mixed with cane sugar and potable water in the ratio of 3:1:10 (w/w/v). The mixture had a total volume of 12 l in a 15-l plastic bucket and the starter was added to achieve an initial cell concentration as mentioned above. The space above the fermentation liquid was filled with a water-containing plastic bag and covered with the bucket’s lid (Kantachote and Charernjiratrakul 2008). All fermentation buckets were incubated at 30 ± 2°C for 60 days and were monitored to evaluate their chemical properties, role of microorganisms, microbiological quality, antimicrobial activity and a sensory test.

Microbial populations

Total bacterial counts (TBC) and lactic acid bacteria (LAB) were enumerated on Plate Count Agar (PCA) and De Man Rogosa Sharpe (MRS agar), respectively by the pour plate method, whereas yeasts were counted on Malt Extract Agar (MEA) by the spread plate technique (APHA 1995) at days 0, 1, 2, 4, 7, 14, 21, 30, 45 and 60.

Microbiological quality

Standard microbiological methods (APHA 1995) were used to enumerate microbes at days 0, 14, 30, 45 and 60. Additionally, microbiological quality after 3 months storage was investigated. Mold and yeast numbers were counted on MEA by the spread-plate method. Total coliform bacteria and E. coli were counted on Endo medium and EMB (Eosin Methylene Blue medium) using a membrane filter technique, while Salmonella sp., Stabphylococcus aureus and Clostridium perfringens were counted on Bismuth Sulfite agar (BS), Baird-Parker medium and Perfringens agar, respectively.

Chemical properties

The following parameters were monitored in every FSB set at days 0, 1, 2, 3, 4, 5, 6, 7, 14, 21, 30, 45 and 60; pH (pH meter), total sugar as glucose (Dubois et al. 1956), total acidity as lactic acid (AOAC 2000). Amounts of ethanol, methanol, lactic acid and acetic acid were assayed at days 0, 14, 30, 45 and 60 by gas chromatography according to the method of Yang and Choong, (2001), whereas Cu, Zn, Fe, As and Pb were also analyzed at these times by inductively coupled plasma-atomic emission spectroscopy (ICP-AES) following the instructions provided by the company.

Antibacterial activity

Several foodborne pathogens were provided as target organisms by the Department of Microbiology, Faculty of Science, Prince of Songkla University as follows: Bacillus cereus ATCC 11778, Staphylococcus aureus PSSCMI 0004, Escherichia coli PSSCMI 0001, Salmonella typhi PSSCMI 0034 and Vibrio parahaemolyticus PSSCMI 0064. Antibacterial activity of the FSB (125 μl filtrate using a 0.45 μm Millipore filter) against foodborne pathogens was conducted by the agar well diffusion technique (Schillinger and Lucke 1989) at days 0, 60 and after storing for 3 months.

Sensory quality

For all four treatments, after day 60 of fermentation, the finished products were organoleptically evaluated by 30 panelists using the Hedonic-5-scale on the following factors: flavor, odor, color, clearness and overall acceptance by the modified method of Chambers and Wolf (1996).

Statistical analysis

All experiments were performed in duplicate, and the raw data for each parameter was analyzed using the multiple general linear model in order to establish whether the monitored parameters were affected by the variable conditions used for the fermentation. When the monitored factors did change they were further analyzed by Duncan’s method. The mean, standard deviation and least significant difference (LSD) values (0.05) are reported.

Results and discussion

Microbial populations

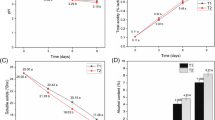

Significant differences in the numbers of total bacteria, LAB and yeasts were found in the four procedures (Fig. 1a–c). At the start of the fermentation sets, with no pre-sterilization and no starter inoculum of LAB (N-N), the TBC was approximately 3.6 log c.f.u./ml, and the LAB approximately 1.5 log c.f.u./ml, while after treatment with KMS the TBC was reduced to about 1.6 log c.f.u./ml and the LAB were not detectable. After addition of 7.5 × 106 LAB/ml starter, TBC increased by only about 4 log c.f.u./ml for both untreated (N-S) and partially sterilized seaweed (P-S) so only 4 log c.f.u./ml of LAB survived when plated on PCA medium. In contrast, after addition of the starter inoculum the LAB count measured on MRS agar was initially about 7 log c.f.u./ml on P-S and about 8 log c.f.u./ml on N-S. This shows that MRS agar is far more suitable for counting LAB than PCA agar.

In the early phase of the fermentation (days: 0–7), TBC, LAB and yeast levels in most treatments increased in a similar pattern with the highest number found at day 7, except that the N-N set peaked for TBC and LAB at day 4. The results did imply that LAB were initially the predominant bacteria in all the fermentations. After day 7 all counts decreased steadily to reach a steady low from day 30 onwards. At day 60 the TBC counts were mostly about 4 log c.f.u./ml except the N-S at about 5 log c.f.u./ml while the LAB counts of P-S and N-S were 4 and 4.73 log c.f.u./ml respectively whereas the LAB, N-N and P-N count was only 2.4 and 2.6 log c.f.u./ml, respectively the higher values presumably being due to the addition of KMS and continuing presence of the starter L. plantarum DW3.

In the absence of added LAB without sterilization (N-N), yeast numbers increased rapidly from 3.5 log c.f.u./ml to about 6 log c.f.u./ml at day 7 and although treatment with KMS (P-N) reduced the yeast numbers to 0.7 log c.f.u./ml they rapidly increased to 4.68 log c.f.u./ml at day 7 in the absence of added LAB (Fig. 1c). Treatment with KMS without inoculation had reduced the yeast numbers by 2.8 log c.f.u./ml. In the presence of added LAB, in the non-sterilized preparation (N-S), over the first 4 days there was a decrease in yeast numbers from 3 log c.f.u./ml to 2.5 log c.f.u./ml followed by an increase to day 7 to 3.5 log c.f.u./ml whereas in the sterilized preparation (P-S) the numbers increased over the first 7 days from 1.5 log c.f.u./ml to 2.5 log c.f.u./ml. The presence of the added LAB was obviously inhibiting the growth of the yeast. After day 7, yeast numbers reduced at a uniform rate to 1.2 log c.f.u./ml in N-S and P-N and to 2.63 log c.f.u./ml in N-N but after sterilization and in the presence of LAB (P-S) the rate of loss was faster and yeast were not detected at all after day 45. The presence of the added LAB was obviously inhibiting the growth and survival of the yeast and at the end of the fermentation no yeast were detected. From these studies it appears that the most effective way to control yeast contamination is to use a suitable starter culture and to partially sterilize the raw material with 0.5% KMS (P-S). Based on Thai Microbiological Quality Guidelines, Section of Food Analysis, Division of Medical Science, Ministry of Public Health, yeast counts must not be more than 100 c.f.u./ml and therefore in the situations here only the natural fermentation set N-N did not pass the guideline. It also states that inoculating with an anti-yeast Lactobacillus or partial sterilization is required for achieving the goal to control yeast contamination.

Treatment with KMS certainly had a major effect on the normal LAB population. At the beginning of the fermentation (day 0), no LAB were detected (P-N) after treatment with 0.5% KMS and numbers did not show an increase until day 4 then reached a peak at only 3.6 log c.f.u./ml on day 7. In contrast, the N-N natural LAB grew quickly from day zero and the count increased from 1.34 log c.f.u./ml to 6.85 log c.f.u./ml on day 4. The behavior of the starter LAB cultures added to the N- and P- cultures was very similar from day zero except that the total LAB was always less in the P-S preparation (Fig. 1b).

Previously we have shown that L. plantarum DW3 was a probiotic strain (Duangjitcharoen 2006), the increased numbers of LAB as a result of the inoculation may make this supplemented fermented plant beverage a more attractive functional food as a source of nutrients, bioactive compounds, essential elements and probiotics.

The microbiological quality of all FSB treatments was also investigated. Bacterial indicators such as E. coli and coliforms including foodborne pathogenic bacteria such as S. aureus, B. cereus and C. perfringens were not detected throughout the fermentation process. Moreover, the finished products of the FSB after storing for 3 months passed the standard microbiological quality tests. Results indicate that lactic fermentation preserves raw materials and provides a safe fermented beverage for drinking.

Chemical properties

Changes in sugar concentrations, measured as glucose, were similar in all treatments. During the first 2 days sugar concentrations decreased at a rapid rate from 11.25–11.76% to about 9%, then the rate decreased until day 21 to a level of about 8%, accelerated again to a level of about 5% at day 45 and then changed very little until day 60 at 4.21–4.72% (Fig. 2a). As the dominant organisms in the seaweed fermentation were LAB, the end products of the sugar loss were acids and ethanol. Over the first 7 days acid production in all cases was low and almost identical from 0 to 0.1% but then there were significant changes (Fig. 2b). The fermentations inoculated with LAB, N-S and P-S produced identical rates of acid production from 0.1 at day 7 to 0.95 at day 60. The highest rate of acid production was by the preparation that had shown the highest rate of LAB production (N-N), (Fig 1b), but this rate decreased as the LAB count fell (Fig. 1b) to give a final acidity of 0.8%. On the other hand, the lowest rate of acid production and final acidity (0.63%) was found in (P-N). At the end of the fermentation (day 60), the pH value of all treatments was in a range of 2.9–3.1 (Fig. 2c). This profile is general in lactic fermentations, and similar to the findings of Ruiz-Barba et al. (1994) who used L. plantarum LPCO10, a bacteriocin producer, as a starter culture in a Spanish-style green olive fermentation.

Result of the analysis of elements in the final product showed that levels of Cu, Fe and Zn were less than the limitation required by the USFDA for drinking water (FDA 2003) and no toxic elements such as As and Pb were detected (Table 1). It is well recognized that Cu, Zn and Fe have their own bio-functions i.e. Cu and Zn are cofactors of superoxide dismutases, that protects oxygen-using cells against toxic reactive oxygen species produced as by-products of respiration, oxidative metabolites and radiation (Woodruff et al. 2004).

Iron deficiency is one major cause of anemia and a world-wide nutritional problem (WHO 2002). In this study we have found that the seaweed fermentation provides more soluble forms of elements, particularly Fe, which was not found at zero time but increased up to 0.16–0.18 mg/l in the drinkable end product. There was a positive relationship between soluble elements and total acidity (data not shown) and therefore the organic acids produced by LAB improve the availability of elements. This has been supported by Bergqvist et al. (2005) who reported that lactic acid fermentation strongly increases Fe solubility in carrot juice with the increase related to the levels of organic acids.

Methanol was less than the detectable level (0.003 g/l) in all treatments, while ethanol was present in a range of 0.78–1.84 g/l (Table 2). In general yeasts such as Saccharomyces cerevisiae produce ethanol from sucrose under oxygen limitation. This yeast is a common contaminant of FPBs (Prachayakij et al. 2007). It was not surprising therefore to find that the amount of ethanol detected was determined by the yeast count. The N-N set (natural fermentation) had the highest amount of yeast (Fig. 1c) and the highest amount of ethanol, while the P-S set had the lowest yeast numbers and the lowest ethanol content. This confirms that the ethanol in the FSB is produced by contaminating yeast.

Lactic acid is the dominant acid produced by LAB so it was not surprising that the amount of lactic acid in the final beverage (Table 2) in general reflected the numbers of LAB present during the fermentation (Fig. 1b). Those inoculated with LAB (N-S and P-S) had higher levels (7.48 and 6.22 g/l) than those (N-N and P-N) with natural LAB i.e. 3.72 and 5.86 g/l respectively. The only slight anomaly was the lowest level in the N-N sample but this also had the highest acetic acid level, so the rapid increase in the LAB count in this preparation was probably due to a different population. The acetic acid in the final beverage was probably mainly produced by bacteria that originated from raw materials, especially seaweed. Some of these could have been heterofermentative LAB. These were mostly removed by the treatment with KMS. However in some situations it is known that L. plantarum DW3 can be a facultative heterofermenter producing acetic acid.

Antibacterial activity

The inhibition of the FSB against foodborne pathogenic bacteria was evaluated at days 0, 60 and after storing for 3 months. As no antibacterial activity was found at day 0 the antagonistic activity in the final FSB was a result of the lactic fermentation. The inhibitory activity of the final FSB (60 days) from the inoculated preparations was much higher than the others. The order of inhibitory activities was N-S > P-S > P-N > N-N (Table 3) and this correlated with the amounts of lactic acid in the FSB (Table 2). In terms of overall sensitivities, B. cereus ATCC 11778 and V. parahaemolyticus PSSCMI 0064 were equally sensitive, followed by S. typhi PPSCMI 0034 > S. aureus PSSCMI 0004 > E. coli PSSCMI 0001. This confirms that L. plantarum DW3 was able to control contamination by yeasts and also to inhibit these foodborne pathogens. These antimicrobial activities are mainly associated with the level of total acidity mainly lactic acid (Fig. 2b and Table 2). The antibacterial activity of lactic acid and acetic acid has been documented (Doores 1993). Ethanol can also inhibit bacteria particularly S. typhi PSSCMI 0034 but even the largest amount detected (N-N set, 1.84 g/l) was probably below the concentration required for inhibition and this set had the lowest inhibitory activity but also the lowest lactic acid level. The inhibitory effects of the FSB against foodborne pathogenic bacteria were retained throughout 3 months of storage with only minor reductions (data not shown). A similar conclusion was reached from the finding that the inoculated treatment sets had a higher inhibiting activity than that in the uninoculated sets. The results demonstrate that LAB starter inoculants provided the best benefit to increase antibacterial activity of the fermented beverage and also partial sterilization supported a suitable condition for proliferation of LAB in seaweed fermentation (Fig. 1b).

Sensory evaluation

In the sensory evaluation, there were no significant differences in the overall acceptance and flavor (Table 4). Assuming that a high value reflects a better acceptance then the most acceptable overall (adding together the values in each row in Table 4) was the sterilized seaweed preparation inoculated with L. plantarum DW3, but the differences were only small (P > 0.05). However, the overall acceptance indicates that all beverages were only moderately acceptable (3.00–3.43). The characteristics of the FSB were; the solution was a clear yellow color, tasted a little sweet with sour flavor and a small amount of seaweed odor (data not shown). Based on personal communication after the sensory test, the main points were flavor and odor although evaluation of color produced the lowest score in almost all treatments, except a P-S set (Table 4). In addition, total acidity in the beverages (0.63–0.95%) (Fig. 2b) was the main cause of the sour flavor while some seaweed odor was still retained. Generally, odor, color and clarity mainly depend on the types of plant used and sugar added (Kantachote et al. 2005a). Indeed, the beverages are not ready to drink unless they are diluted when they achieve higher scores. Further study will be required to prove the results of this sensory test of the FSB.

Conclusions

This study has proved that the fermented seaweed beverage produced by lactic fermentation is an attractive way to provide more available essential elements such as iron. The beverage with no detectable yeast was the partially sterilized preparation inoculated with the probiotic LAB (P-S) whereas the one with the strongest antibacterial activity, the highest level of probiotic LAB and a level of yeast below the maximum allowed by the Thai Microbiological Quality Guideline, Section of Food Analysis, Division of Medical Science, Ministry of Public Health was the inoculated non-sterilized preparation (N-S). Clearly inoculation with L. plantarum DW3 provides advantages and does not disturb the organoleptic properties of the beverage.

References

AOAC (2000) Official methods of analysis of the association of official analytical chemist, 17th edn. The Association of Official Analytical Chemist, Inc., USA

APHA (1995) American public health association standard methods for the examination of water and wastewater, 19th edn. Washington DC, USA

Bergqvist SW, Sandberg AS, Carlsson NG, Andlid T (2005) Improved iron solubility in carrot juice fermented by homo- and hetero-fermentative lactic acid bacteria. Food Microbiol 22:53–61

Chambers EIV, Wolf MB (1996) Scaling. In: Chambers EI, Wolf MB (eds) Sensory testing methods. ASTM, Philadelphia, USA, pp 38–53. ISBN 0803120680

Doores S (1993) Organic acids. In: Davidson MP, Branen LA (eds) In antimicrobials in foods, 2nd edn. Marcel Dekker, Inc., New York, pp 95–136. ISBN 0824789067

Duangchitchareon Y (2006) Selection of probiotic lactic acid bacteria from some pickles and biologically fermented plant products. Master degree, Chiang Mai University, Thailand

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Phenol-sulfuric total sugar. Anal Chem 28:350–356

FDA (2003) Requirements for specific standardized beverages, Sec. 165.110 Bottled water. http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?FR=165.110&st=drinking%20 water. Cited September 2007

Farfield K (2007) Red marine algae and herbs. http://www.herpes.com/redmarinealgae.shtml, Cited September 2007

Ferner DJ (2001) Toxicity, heavy metals. Med J 2(5):1

Hirazumi A, Furusawa E (1999) An immunomodulatory polysaccharide-rich substance from the fruit juice of Morinda citrifolia (noni) with anti-tumor activity. Phytother Res 13:380–387

Holum JR (1983) Elements of general and biological chemistry. John Wiley and Sons, New York

Kadam DM, Vijay LD, Samuel K, Pandey AK (2005) Influence of different treatments on dehydrated cauliflower quality. Int J Food Sci Technol 40:849–856

Kantachote D, Charernjiratrakul W, Asavaroungpipop N (2005a) Characteristics of fermented plant beverages in southern Thailand. Songklanakarin J Sci Technol 27:601–615

Kantachote D, Ongsakol M, Charernjiratrakul W, Chaiyasut C, Poosaran N (2005b) Fermented plant beverages and their application. In: Abstracts of proceedings of the 1st international conference on natural products for health and beauty from local wisdom to global marketplace, Maha Sarakham University, Thailand, 17–21 October 2005

Kantachote D, Charernjiratrakul W (2008) Effects of initial air removal methods on microorganisms and characteristics of fermented plant beverages. Pak J Biol Sci 11(2):173–180

Leroy F, De Vuyst L (2004) Lactic acid bacteria as functional starter cultures for the food fermentation industry. Trends Food Sci Technol 15:67–78

McClatchey W (2002) From polyesian healers to health food stores: changing ethnopharmacology of Morinda. J Integr Cancer Ther 1:110–120

McKoy M, Thomas E, Simon O (2002) Preliminary investigation of the anti-inflammatory properties of an aqueous extract from Morinda citrifolia (noni). Proc West Pharmacol Soc 45:76–78

Prachyakij P, Schnürer J, Charernjiratrakul W, Kantachote D (2007) Selection and identification of lactic acid bacteria with ability to inhibit contaminated yeast in fermented plant beverages. Songklanakarin J Sci Technol 29(Suppl 2):211–218

Ray B (1992) The need for food biopreservation. In: Ray B, Daeschel M (eds) Food biopreservatives of microbial origin. CRC Press, Boca Raton, Florida, pp 1–23

Ruiz-Barba LJ, Cathcart PD, Warner JP, Jimenez-Aiaz (1994) Use of lactobacillus plantarum LPCO10, a bacteriocin producer, as a starter culture in Spanish-style green olive fermentation. Appl Environ Microbiol 60:2059–2064

Schillinger U, Lucke FK (1989) Antibacterial activity of Lactobacillus sake isolated from meat. Appl Environ Microbiol 55:1901–1906

Schnürer J, Magnusson J (2005) Antifungal lactic acid bacteria as biopreservatives. Trends Food Sci Technol 16:70–78

WHO (2002) Micronutrient deficiencies. Battling iron deficiency anemia. WHO 2002. http://www.who.int/nut/ida.htm

Woodruff RC, Phillip JP, Hilliker AJ (2004) Increased spontaneous DNA damage in Cu/Zn superoxide dismutase (SOD1) deficient Drosophila. Genome 47(6):1029–1035

Yang MH, Choong YM (2001) A rapid gas chromatographic method for direct determination of short-chain (C2–C12) volatile organic acids in foods. Food Chem 75:101–108

Acknowledgements

This study was fully supported by the National Science and Technology Development Agency (NSTDA) in the program year of 2006, project no. CO-B-22-2C-18-4801, and partly supported by Graduate School, Prince of Songkla University, Thailand. We thank Dr. Brian Hodgson for his critical reading of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prachyakij, P., Charernjiratrakul, W. & Kantachote, D. Improvement in the quality of a fermented seaweed beverage using an antiyeast starter of Lactobacillus plantarum DW3 and partial sterilization. World J Microbiol Biotechnol 24, 1713–1720 (2008). https://doi.org/10.1007/s11274-008-9662-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-008-9662-1