Abstract

Iron oxide magnetic particles (PMag) synthesized by microwave heating and irradiation were evaluated individually and loaded with laccases produced by the white-rot fungi Trametes villosa for removal of Acid Blue 277 and Acid Black 172 dyes. PMag were tested for the adsorption capacity and laccase enzymes were successfully immobilized on the surface of PMag, previously functionalized by APTES ((3-aminopropyl) triethoxysilane) and glutaraldehyde (Lac-PMag), for simultaneous adsorption and biodegradation of the dyes. PMag removed approximately 99.00% of Acid Blue 277 and 98.00% of Acid Black 172 from aqueous solutions at an initial dye concentration of 10 mg L−1. The immobilization yield of laccase enzymes was 99.85 ± 0.18%, and recovered activity was 46.18 ± 0.20%. In the simultaneous process of adsorption and biodegradation of dyes, Lac-PMag presented two-fold the removal efficiency of PMag at the highest initial concentration of the dyes. Lac-PMag removed 52.72 ± 1.23 and 57.47 ± 2.38 mg g−1 of Acid Blue 277 and Acid Black 172, respectively, both at an initial concentration of 300 mg L−1. Hence, the synthesized PMag was more effective in removing the dyes at the lowest initial concentrations in solution and Lac-PMag demonstrated efficiency in a simultaneous process of adsorption and biodegradation in higher concentrations of the dyes. Our results highlight the synergistic effect of adsorption and enzymatic degradation on dyes removal by Lac-PMag, which makes the technology even more efficient, ecofriendly, and economical.

Highlights

• PMag functionalization and silanization process improve particles adsorption.

• Laccase activity of Lac-PMag is stored for 8 months.

• Magnetic particles are easily recovered from the solution using a magnetic field.

• The simultaneous adsorption and biodegradation improve dye removal efficiency.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Effluents from industries in the textile sector currently represent a severe environmental problem. These industries are an essential part of the world economy and are responsible for high water consumption, with 20% of industrial water pollution resulting from this sector (Wong et al., 2019).

The main characteristic of these effluents is the coloring, resulting from the addition of dyes in the production process, which do not have complete fixation in the fiber, and thus are released into the industrial effluent (Khatri et al., 2015). Additionally, textile effluents have other characteristics such as high chemical oxygen demand (COD) and high biochemical oxygen demand (BOD), presence of salts and metals, toxicity, and, in some cases, mutagenicity, making them harmful not only to the environment as well as to humans (Chhabra et al., 2015; Yaseen & Scholz, 2019).

Dyes are complex organic molecules that are difficult to break down. Due to the intense coloring, the presence of these dyes in water bodies prevents the penetration of light, which results in the reduction of photosynthetic activity, inhibiting the growth of aquatic biota (Zhang et al., 2019).

To solve this problem, different physical–chemical methods are commonly used in the treatment of effluents containing dyes. However, these technologies are not always sufficient for the complete discoloration of the effluent. They also have essential disadvantages, such as high operating costs and increased energy demand (Chowdhury et al., 2011).

In this context, alternative technologies that are efficient and cost-effective from an economic and environmental point of view are desirable. The combination of physical–chemical and biological methods has been suggested as an essential alternative for developing sustainable treatment processes (Chhabra et al., 2015).

Biological processes using microorganisms or enzymes are alternatives with great potential. The laccase enzymes are polyphenoloxidases used in several enzymatic oxidative reactions to degrade various phenolic and non-phenolic compounds (Baldrian, 2006). These enzymes have been studied in several biotechnological applications. In the food industry, they can eliminate unwanted phenolic compounds in the processing of juices, wines, and beers. In the paper industry, they bleach paper. Furthermore, they degrade highly recalcitrant environmental pollutants and synthetic dyes (Cardoso et al., 2018; Morozova et al., 2007).

For industrial applications, the high cost of enzymes, the difficulty in separating them from the final product, and thermal and solvent inactivation often hinder their application. One of the main alternatives to make the process attractive is the immobilization of enzymes on an inert support. This process promotes an easy separation after the reaction, provides greater operational stability to the enzyme catalyst, and allows its reuse (Cao, 2005; Kopp et al., 2015).

Among the different supports used, magnetic particles are gaining prominence for presenting ideal characteristics for enzyme immobilization. These supports are attractive due to their strong magnetic properties, which facilitate separation under action of a magnetic field (Mohammed et al., 2017).

On the other hand, magnetic particles have the characteristic of being an essential class of ideal adsorbents. These particles receive wide attention due to their low cost, effortless control, non-toxicity, and, mainly, the magnetic response capacity that facilitates their recycling and reuse (H. Zhang et al., 2019).

In this context, the development of new materials and technologies for the treatment of effluents becomes essential. The simultaneous adsorption and biodegradation of textile dyes by laccase enzymes immobilized on magnetic supports with adsorbent characteristics are still poorly reported. Most studies only describe the biodegradation carried out by enzymes. Therefore, studies evaluating this simultaneous process of treating effluent containing dyes are still in an evolutionary phase. Thus, the present work aims to evaluate the removal of Acid Blue 277 and Acid Black 172 dyes from aqueous solutions by adsorption using magnetic iron oxide particles in comparison to a simultaneous process of adsorption and biodegradation after immobilization of laccase enzymes on the magnetic particles. The laccases used were produced from the fungus Trametes villosa and agro-industrial residue. Furthermore, kinetic studies were also carried out in order to elucidate the interaction between the dye and the particle.

2 Materials and Methods

2.1 Materials

The iron (II) sulfate heptahydrate (FeSO4.7H2O) (purity ≥ 99%) used to prepare Fe3O4 magnetic particles, (3-aminopropyl) triethoxysilane (APTES) (purity ≥ 99%) used to laccase immobilization, and 2,2′-azino-bis (3-ethylbenzothiazolin -6- sulfonic acid) (ABTS) (purity ≥ 98%) used to activity assay of laccase were purchased from Sigma-Aldrich (St. Louis, MO, USA). The other reagents and solvents used are all analytical grade. A textile industry located in Curitiba, PR, Brazil, kindly provided the samples of textile dyes.

2.2 Microorganism, Culture Conditions, and Enzyme Extraction

Trametes villosa was obtained from the Culture Collection of the Biotechnology Laboratory at the Federal University of Technology—Paraná, Curitiba, PR, Brazil. The fungus was cultured on potato dextrose agar (PDA) medium Petri dishes at 28 °C for 7 days.

The enzymatic extract was produced by semisolid cultivation in triplicate. The cultivation consisted of a semisolid fermentation containing the inoculum on 50 mL of culture medium. The inoculum was three plugs of fungal mycelium, measuring 10 mm in diameter. The semisolid culture medium was prepared to contain: 50 mL of glucose solution 10 g L−1; KH2PO4 3 g L−1; 0.50% peptone; agro-industrial waste as a carbon source (rice husk 1%; Bordô grape bagasse 0.50%; 2 g sugarcane bagasse) and metal ions as inducers (2 mL of MnSO4, CuSO4, FeSO4, ZnSO4 and MgSO at 25 mmol L−1) (Riedi 2019).

The culture medium was autoclaved for the fungus inoculation and was incubated at 28 °C for 7 days. After the incubation period, the medium was filtered (paper Framex, 11 cm in diameter) and centrifuged at 8000 rpm and 10 °C. The supernatant was used as the enzymatic extract.

2.3 Preparation of Magnetic Particles

The magnetic particles of iron oxide (PMag) were produced using 1 g of FeSO4.7H2O, dissolved in 100 mL of distilled water. A sodium hydroxide solution (NaOH, 1 mol L−1) was added slowly, with continuous stirring, until the pH reached a value range of 10 to 12. During this process, iron precipitates were formed, the volume was adjusted to 200 mL with distilled water and heated in a domestic microwave (Panassonic, NN5658BH-Manaus, AM, Brazil) at maximum power (1100 W) for 10 min (Pospiskova et al., 2013). The suspension of magnetic iron oxide particles formed was carefully washed with distilled water to neutralize the pH, using a magnetic field (magnet) to separate the supernatant particles. Subsequently, the particles were dried in an oven at 50 °C and scraped and crushed.

2.4 Laccase Immobilization

For the immobilization of laccases in PMag, the particles surface was functionalized with functional groups that facilitate the connection between the enzymes and the support. For that, we used the methodology adapted from Wang et al. (2018), where 25 mg of PMag were dispersed in a solution containing 5 mL of absolute ethyl alcohol PA, 0.1 mL of APTES, 0.5 mL of distilled water and were kept under stirring in a shaker incubator (Solab SL 222-Piracicaba, SP, Brazil) for 12 h, 28 °C, and 180 rpm.

After silanization with APTES, the PMag was added in a glutaraldehyde solution (6.0%) and remained under stirring for 3 h at 28 °C and 180 rpm. Using a magnet, three washes were carried out with distilled water to remove excess glutaraldehyde (Q. Wang et al., 2018). After this process, functionalized magnetic particles (PMag-func) were obtained. For enzymatic immobilization, PMag-func (25 mg) was added to a solution (10 mL) containing laccase enzymes, under different conditions (0.1, 0.3, and 1.0 U mL−1) diluted in 50 mmol L−1 sodium acetate buffer pH 5, under stirring at 180 rpm and 28 °C for 3 h. Finally, the enzymes immobilized on the PMag-func (Lac-PMag) were magnetically separated from the supernatant and washed three times with the respective buffer to determine its enzymatic activity. The enzyme activity of the supernatant was also chosen to assess the amount of non-immobilized laccase.

2.5 Activity Assay of Laccase

Laccase activity was measured using a UV–visible spectrophotometer (UV-M51 BEL Engineering S.R.L—Monza, MB, Italy) at a fixed wavelength of 420 nm by monitoring the oxidation of ABTS. The methodology used was adapted from Hou et al. (2004), where 100 µL of the sample was added to a test tube with 1.7 mL of 50 mmol L−1 sodium acetate buffer pH 5 and 200 µL of a 10 mmol L−1 ABTS solution, remaining in a water bath for 5 min at 40 °C. Activity measures were performed in duplicate, and a unit of enzyme activity (U) was defined as the amount of enzyme required to oxidize 1 μmol of the ABTS substrate per minute.

2.6 Evaluation of Parameters of Immobilization

To describe the efficiency of enzymatic immobilization, the parameters immobilization yield (IY) (Eq. 1) and recovered activity (AR) (Eq. 2) were used:

where Ai = activity of the enzyme provided for immobilization (U); Af = activity of the enzyme in the supernatant (U); Ar = activity of the immobilized enzymes (U g−1); and At = total activity provided for immobilization (U g−1).

2.7 Stability of Free and Immobilized Laccase

The effect of pH on the activity of free and immobilized enzymes was determined using the ABTS assay at different pH values (3–7). The buffers used were 50 mmol L−1 sodium tartrate pH 3, 50 mmol L−1 sodium acetate pH 4–5, and 50 mmol L−1 sodium phosphate pH 6–7. To evaluate the operational stability of the immobilized enzymes, five consecutive active cycles of ABTS oxidation reaction were evaluated. After each reaction, the immobilized laccases were separated using a magnet and washed three times with 50 mmol L−1 sodium acetate buffer pH 5 before being reused. To determine storage stability, free and immobilized enzymes were stored in 50 mmol L−1 acetate buffer pH 5 in a refrigerator (-4 °C) for 30 days and 8 months. For all stability tests, the calculation of relative activity was used.

2.8 Characterization

The morphology and size of the particles were characterized by transmission electron microscope (TEM, Jeol, JEM 1200EX-II, Tokyo, Japan) and scanning electron microscope with coupled energy-dispersive X-ray spectrometry (SEM/EDS, Tescan, Vega3 LMU, Brno, Czech Republic). Mid-infrared spectra (MIR-ATR) were recorded within a wavenumber range from 4000 to 650 cm−1 on a MIR-ATR spectrometer (Varian, 640-IR Santa Clara, California) by the attenuated total reflection (ATR) method.

2.9 Removal of Textile Dyes

2.9.1 Adsorption of Dyes by Magnetic Particles

-

(a) Effect of pH and Temperature

The tests were performed containing 10 mL of the dye solution and 25 mg of PMag, incubated at 180 rpm. Initially, different initial pH conditions (3, 4, 5, 6, and 7) were evaluated at a fixed temperature of 30 °C, dye concentration of 50 mg L−1, and a reaction time of 4 h. The pH was adjusted using 0.1 mol L−1 hydrochloric acid solution (HCl) and 0.1 mol L−1 sodium hydroxide solution (NaOH). The initial conditions defined for the tests were adapted from Semião et al. (2020). All tests were performed in triplicate and with dye controls without the presence of PMag. The temperature effect was evaluated by varying the temperature (25, 35, 45, and 55 °C) of the adsorption process. For this purpose, the same initial conditions were used at the pH that obtained the best color removal results for each dye. The supernatant concentration of residual dyes was analyzed using a UV–visible spectrophotometer (UV-M51 BEL Engineering SRL-Monza, MB, Italy) at wavelengths 612 and 576 nm for Acid Blue 277 and Acid Black 172, respectively. To calculate the dye concentration present in the supernatant, calibration curves were performed with concentrations ranging between 10 and 200 mg L−1.

-

(b) Adsorption Kinetics

For adsorption tests, 25 mg of PMag were added in 10 mL of dye solution at pH 3 and a concentration of 50 mg L−1. The flasks were incubated at 180 rpm and temperature of 30 °C. In reaction times 0, 5, 30, 60, 90, 120, 150, 180, 210, 240, 270, and 300 min, using a magnet to separate, analyses of the concentration of residual dye in the supernatant were performed in a UV–visible spectrophotometer, as described in “Section 2.9.1.a.” The experimental tests were carried out in triplicate. The results obtained were adjusted to the pseudo-first and pseudo-second-order models, Elovich and intraparticle diffusion, aiming to demonstrate which model the data fit and, consequently, to evaluate which model best describes the process that occurred. The equations for the respective models are shown in Table 1 (Supplementary Information).

-

(c) Adsorption Isotherms.

After the equilibrium time was determined, studies of the adsorption isotherms were carried out from the kinetics data. Therefore, 25 mg of PMag were added in 10 mL of different dye solution concentrations (10, 25, 50, 75, 100, and 150 mg L−1) and incubated in a shaker at 180 rpm, 30 °C, until they reached equilibrium time. The concentration of residual dye in the supernatant was analyzed as described in “Section 2.9.1.a.” The experimental data obtained were adjusted to the Langmuir, Freundlich, Sips, and Temkin isotherm models. The equations of the respective models are also shown in Table 1 (Supplementary Information).

2.9.2 Simultaneous Adsorption and Biodegradation of Dyes by Laccases Immobilized on Magnetic Particles

The adsorption and simultaneous biodegradation tests were performed in a 50 mL Erlenmeyer, containing 10 mL of the dye solution and 25 mg of Lac-PMag (0.3 U mL−1 of laccase in 25 mg of particles) at 180 rpm in an incubator shaker. To assess the possible interferences of the enzymatic immobilization process in the removal of the dyes, all tests were also performed with PMag (magnetic particles), with PMag-func (magnetic particles after the process of functionalization with APTES, glutaraldehyde, and without the addition of enzymes), and with free enzymes (laccase enzyme extract) (0.3 U mL−1).

-

(a) Effect of pH and Temperature

The tests that evaluate the effect of pH and temperature on the simultaneous adsorption and biodegradation process were carried out for the different conditions described above, using the methodology described for PMag in “Section 2.9.1.a.”

-

(b) Effect of Reaction Time

The effect of time on removing dyes by adsorption and biodegradation were evaluated under the conditions described initially, at pH 3 and concentration of dyes of 50 mg L−1. The flasks were incubated in a shaker at 180 rpm and 30 °C. The flasks were removed at times 5, 30, 60, 90, 120, 150, 180, 210, 240, 270, and 300 min and then, using a magnet, analyses of the concentration of residual dyes in the supernatant were carried out in a spectrophotometer, according to “Section 2.9.1.a.” Experimental tests were performed in triplicate.

-

(c) Effect of Initial Concentration of Dyes

After the equilibrium time was determined, based on data from the study of the effect of reaction time on removing dyes, studies were carried out evaluating the interference of the initial concentration of dyes. The tests were carried out under the conditions described initially, assessing the different concentrations of dyes (5, 10, 25, 50, 75, 100, 125, 150, 200, and 300 mg L−1), and the pH adjusted to 3. The flasks were incubated in a shaker at 180 rpm and 30 °C until they reached equilibrium time. With the aid of a magnet, the particles were separated from the supernatant analyzed to assess the concentration of residual dye, in a UV–visible spectrophotometer, according to “Section 2.9.1.a.”

2.9.3 Statistical Analysis

The data obtained was expressed as mean ± standard deviation, and statistical analyses were performed using Origin ™ 8.5/2010 software. Tukey test was used to determine the significant differences in the sample means in a 95% confidence interval (p ≤ 0.05). The experimental data fitting to non-linear models was carried out using the Origin ™ 8.5/200 software, at he determination coefficient (R2) and chi-squared, SSR were used to define the best fit.

3 Results and Discussion

3.1 Production of Trametes villosa Laccase on Semisolid-State Fermentation

The laccase enzymes of Trametes villosa were produced under a semisolid-state fermentation, using an enriched culture medium previously studied by our group. Medium-induced laccase production with high enzymatic activity (17,000 U L−1) was used. This enriched medium, containing agro-industrial residues as carbon source and metal ions as inducers, provides nutrients similar to the natural growth medium of basidiomycetes, enabling the production of laccases with high enzymatic activity.

In addition to supplying the lignocellulosic substrates necessary for fungal fermentation and consequent induction of laccase enzyme production, the process adds value to these residues. This use minimizes the environmental impact caused by the disposal of residues in nature. Thus, this process uses a low-added value product to produce another with high-added value (laccase enzymes) (Akpinar & Ozturk, 2017; Alexandrino et al., 2007).

The use of trace elements in the culture medium to produce fungal laccases is also reported in the literature to increase enzyme activity. Knezevic et al. (2014) used the trace elements Mn2+, Cu2+, Zn2+, and Fe2+ to produce laccase enzymes from the fungus Trametes gibbosa. The authors report that at ideal concentrations, these elements stimulated an increase in laccase enzymatic activity. The authors also indicate that the positive impact on enzyme activity using some Mn2+ concentrations can be explained by the induction of gene transcription, which was also reported by Piscitelli et al. (2011).

3.2 Synthesis of Magnetic Particles and Laccase Immobilization

The color change of Fe solution after adjusting the pH to the range of 11–12 characterized Fe’ precipitation to form particles. After the microwave heat treatment, washing, and drying processes, the particles acquired magnetic properties, confirmed by the attraction using an applied magnetic field (magnet).

Bruce et al. (2004) report that iron oxides vary in color, and this can be used as an aid in their identification and purity in some cases. Thus, according to the black color, the magnetic particles (PMag) synthesized in this study were predominantly magnetite.

These characteristics of iron oxide particles, mainly the easy separation due to magnetic properties, make magnetic carriers suitable candidates for applications in the bioprocess industry, such as enzymatic immobilization (Kopp et al., 2015; Mohammed et al., 2017).

Before the immobilization of laccase enzymes, PMag was modified using APTES to add amino groups to the particle surface, a process called silanization. Silanization is a reaction of organosilane compounds with the surface of PMag. The general formula for silanes is Y (CH2)nSi(OR)3, Y being an organofunctional group (–CH = CH2, –Cl, –NH2 or –N = C = O), and OR an alkoxy group (–OCH3 or –OC2H5). The (OR)3 groups form a covalent bond between the silane molecules and the hydroxyls present on the surface of PMag, where these groups hydrolyze to form silanols groups (Si–OH) (Albuquerque et al., 2017).

APTES provided amino groups that reacted with the glutaraldehyde aldehydes (crosslinking agent added later) on the other side of the chemical bond. This connection formed a Schiff base with the groups from chemical amination and thus obtained PMag-func. A terminal aldehyde group was provided after these bonds, where laccase enzymes were attached (Wang et al., 2018), forming the Lac-PMag. This entire process is represented in Fig. 1.

PMag showed efficiency to immobilize laccase enzymes with better immobilization yield (IY) for the lowest initial enzyme conditions, 99.84 ± 0.18% when used 0.3 U mL−1 of laccase and 99.55 ± 0.20% when used 0.1 U mL−1 (Table 1). The increase of initial enzyme concentration on immobilization reduced the immobilization yield. This is probably due to the saturation of PMag binding sites. Some laccase molecules found free active sites to bind, and those that did not bind to the support remained in the supernatant. A similar condition has been reported in previous studies (Wu et al., 2019).

Although the IY presents statistically equal values for the two lowest initial laccase conditions, the condition of 0.3 U mL−1 was defined to assess the following immobilization tests. This condition was chosen by using a more significant amount of enzyme per gram of support without wasting laccase enzymes in the supernatant.

The recovered activity (AR) of immobilized enzymes was higher at the lowest initial enzyme concentrations. In several studies, the enzymatic immobilization process shows low laccase recovery. However, it generally presents improvements in operational stability and against denaturing agents (Fernández-Fernández et al., 2013).

The covalent bond, used in the laccase enzyme immobilization process to form Lac-PMag, generates strong bonds between the enzyme and the support, allowing easy manipulation and reuse without enzyme leaching (Moreira et al., 2017). However, this type of bond can present a modification of laccase structure, mainly at the immobilized enzyme active site, contributing to the low activity recovered (Fernández-Fernández et al., 2013).

Fortes et al. (2017) reports that the increase in activity recovered with the decrease in enzyme concentration indicates support saturation due to the excess of the enzyme in solution. Wang et al. (2013) and Jiang et al. (2009) who performed laccase immobilization studies on mesoporous silica nanoparticles and magnetic nanoparticles, respectively, also reported a decrease in activity recovered with an increase in the initial enzyme concentration. The authors describe that a barrier to limiting mass transfer may occur due to saturation, which leads to interactions between one protein and another and inhibits the flexibility of protein conformation.

The effect of pH on the activity of free and immobilized enzymes is shown in Fig. 2a. The optimal pH was 3 for both evaluated forms. Free and immobilized laccases showed a high reduction in enzymatic activity when the pH increased. The relative activity of the immobilized enzyme was lower than that of the free enzyme.

The decrease in relative activity may occur due to modifications in the enzyme structure during the immobilization process. At high pH values, enzymes can be denatured because the protein structure depends on the ionization of the amino acid side chains. Denaturation is a change in the dimensional form that can cause the loss of protein function. At extreme pH values, the net charge of proteins is altered, which causes an electrostatic repulsion and, consequently, hydrogen bonds break (Nelson, D. L., Cuchillo Foix, C. M., Lehninger, A. L., & Cox, M. M. 2005).

The operational stability of immobilized enzymes was evaluated through 5 consecutive operating cycles (Fig. 2b). The first cycle showed lower enzymatic activity due to the reaction that occurs with the chosen support for immobilization. PMag has adsorption capacity and, therefore, in the first cycle, the ABTS reaction product was adsorbed by the particles, resulting in less substrate degradation by immobilized enzymes. From the second operating cycle, the PMag-binding sites were saturated. Thus, the ABTS reaction product was not adsorbed, being released to the reaction medium, allowing the colorimetric reading to measure enzyme activity.

A gradual decline in the enzymatic activity of immobilized laccases was observed from the third cycle until the next two operating cycles. In the fifth cycle, the immobilized enzyme retained 41.00% of its initial activity. This decrease has already been observed in other studies and can be attributed to enzymes gradual denaturation. In this case, the immobilized enzymes desorption is discarded because the bonds between enzyme and support are covalent bonds, which characterizes substantial and irreversible bonds (Fortes et al., 2017).

Compared with other works, the Lac-PMag presented reasonable operational stability. Ladole et al. (2020) reported that laccase immobilized on peroxidase mimicking magnetic metal organic frameworks (MMOFs) can retain 89.00% of their initial activity after 10 cycles of reuse. In the study by Z. Li et al. (2020), laccases immobilized on Fe3O4@C-Cu2+ nanoparticles maintained 61.00% of their enzyme activity after 10 consecutive reuses. Other studies have also reported high stability after several operating cycles. The difference in the results reported in the literature can be related to the support and methods used in enzymatic immobilization, as well as the operational parameters used to carry out the different cycles.

For industrial applications, it is crucial that the immobilized laccase maintains high enzymatic activity for several operational cycles and, at the same time, that the process is easy to reuse (Wong et al., 2019). Thus, due to the practical reuse of the immobilized enzyme through the application of an external magnetic field and the possibility of using it during several cycles, this study demonstrates the high application potential of Lac-PMag.

Stability and enzyme activity are naturally reduced throughout storage. In this study, free and immobilized laccase stability were evaluated, stored at − 4 °C for 30 days (Fig. 2c). The immobilized enzyme retained 94.28 ± 0.01% of its initial activity, while the free enzyme had 87.46 ± 0.01% of its initial activity after 30 days of storage. Thus, the immobilization did not reduce the stability of laccase enzymes. In the test performed with the immobilized enzyme stored for 8 months, high catalytic activity was maintained, with 91.00 ± 0.02% of the initial activity at the end of the test.

Chhabra et al. (2015) immobilized laccase enzymes in poly vinyl alcohol (PVA) based beads and obtained 80.00% activity of the laccase enzymes maintained after 4 months of storage. In the study by D. Zhang et al. (2017), laccases immobilized in Fe3O4 nanoparticles maintained 89.00% of the enzymatic activity after 40 days stored in a buffer. In this study, immobilized laccases also demonstrated advantages over free enzymes, which maintained 48.00% of the original activity.

Storage stability is a significant parameter for enzymatic biocatalysts applied in biotechnological processes (Fortes et al., 2017). According to the results obtained, Lac-PMag showed high storage stability, further elucidating their potential to degrade different compounds. In addition, the high storage stability of Lac-PMag could reduce costs for industrial applications.

3.3 Characterization of Magnetic Particles and Products Obtained After Laccase Immobilization

The morphology of PMag was evaluated using TEM. Figure 3a–b shows that the particles had heterogeneous nanometric and micrometric sizes and are agglomerated due to their magnetic properties. Thus, due to the state of aggregation and the heterogeneity in particle size, it is difficult to accurately measure the average size of PMag, so it was defined that a mixture of nanoparticles and microparticles was obtained.

TEM images of magnetic particles (PMag) with magnifications of 8000 × (a) and 40,000 × (b); SEM images of PMag with magnifications of 500 × (c); functionalized magnetic particles (PMag-func) with magnifications of 500x (d); PMag with magnifications of 5000 × (e), and PMag-func with magnifications of 5000 × (f)

SEM analysis (Fig. 3c–f) was used further to characterize the surface topography of the PMag and PMag-func. Comparing Fig. 3e and 3f, changes were observed in the surface of PMag after the treatment used for laccase immobilization. The functionalization process with glutaraldehyde and APTES modified the surface of the particles into a smoother surface.

Several methods are used to coat micro and nanoparticles to protect the iron oxide nuclei from corrosion and prevent particle agglomeration. Generally, chemical treatment or particle modification with polymers is carried out for the manufacture of magnetic materials (Zia et al., 2016). Studies report the conversion of particles surface with the addition of different types of functional groups, using reagents such as carboxylatopylar [5] arene (H. Zhang et al., 2019), 2-bromoisobutyryl bromide, and 3-aminopropyltriethoxysilane (Yang et al., 2019), N [3 (trimethoxysilyl) propyl] ethylenediamine (Sahoo et al., 2019), poly glycidyl methacrylate (Guo et al., 2019), and APTES (Cui et al., 2018). This is a considerable method to improve magnetic particle performance and extend their applications, both for enzymatic immobilization and to increase the adsorption of different compounds (H. Zhang et al., 2019).

EDS microanalysis provided qualitative analyses of chemical elements distributed on the particles surface (Table 2-Supplementary Information). The characterization by EDS confirmed the presence of iron (56.10%), oxygen (25.40%), carbon (17.40%), silicon (0.80%), manganese (0.20%), and sulfur (0.10%) in PMag, indicating that the production of Fe3O4 particles was successful. The presence of these elements was also confirmed in the Lac-PMag sample, except for manganese. These results indicated that the Fe3O4 structure was not affected or oxidized by the immobilization reactions. When comparing the PMag elements with the elements found in the Lac-PMag, the presence of chlorine (0.20%) and phosphorus (0.20%) was detected in the Lac-PMag sample. These elements result from the process and reagents used to immobilize the laccase enzymes in the magnetic particles.

MIR-ATR spectroscopy of PMag, PMag-func, and Lac-PMag (Fig. 4) was used to confirm the presence of the amino-terminal group in the particles after the functionalization process. Broadband is observed in the 3600–3000 cm−1 range in the PMag spectrum, which can be attributed to the stretching of a hydroxyl group (O–H) (Mate & Mishra, 2020). Also, the band at 1643 cm−1 is attributed to OH bending (Nalbandian et al., 2015). The bands at 2902 and 2836 cm−1 indicate the stretching vibrations of symmetrical and asymmetric elongation of C–H existing in CH2 and CH3 (Jiang et al., 2009). The band 1330 cm−1 is assigned to the C\N framework, the bands 892 and 1108 cm−1 represent the Si–O bond (Jiang et al., 2009).

After the functionalization process (PMag-func) and the immobilization of laccase enzymes (Lac-PMag), the bands described above were modified, decreasing their intensity. A band emerged at 1587 cm−1 that corresponds to the N–H vibration present in NH2 (Fortes et al., 2017; Kashefi et al., 2019). Therefore, it can be inferred that the binding of amino groups on particles’ surface to form PMag-func and Lac-PMag is confirmed.

3.4 Adsorption Experiment

3.4.1 Effect of Initial pH and Temperature

In adsorption, the pH of dye solution significantly influences the reaction due to its interference in the adsorbent surface properties and the ionization and dissociation of the dye molecules. The effect of pH on the adsorption of dyes by PMag is illustrated in Fig. 1a (Supplementary Information). For Acid Blue 277 dye, the removal efficiency decreases from 85.20 ± 1.70% to 4.70 ± 2.65% when the pH of the solution increased from 3 to 5. At pH 6 and 7, the dye was not removed from the solution. For Acid Black 172 dye, at pH 3, the discoloration was 94.80 ± 2.25%, gradually decreasing to 46.00 ± 1.86% at pH 7. The lower adsorption rate of dyes in alkaline medium occurs due to competition of the excess of OH ions with the anionic dye molecules for the adsorption sites (Wang et al., 2015).

The effect of temperature on the adsorption of dyes was evaluated for temperatures 25, 35, 45, and 55 °C (Fig. 1b-Supplementary Information). The adsorption of Acid Blue 277 by PMag showed better results at lower temperatures 25 and 35 °C, with 75.40 ± 1.03% and 78.00 ± 0.84% removal efficiency. For Acid Black 172 dye, there were no significant changes in dye removal for the different temperatures, ranging from 93.40 ± 0.50% at 25 °C to 96.00 ± 0.67% at 55 °C. To continue the tests, we chose to use 30 °C for both dyes. This temperature is the average temperature of 25 and 35 °C, which showed less variation for both dyes; moreover, it is an initial temperature used in the adsorption processes (Semião et al., 2020).

3.4.2 Adsorption Kinetics

The adsorption kinetics of Acid Blue 277 and Acid Black 172 dyes by PMag was investigated using 25 mg of adsorbent in 10 ml of dye solution at an initial concentration of 50 mg L−1. The adsorption capacity of both dyes increased rapidly until they reached the kinetic equilibrium time in 120 min of reaction. At this time, the removal efficiency for used conditions was 17.21 ± 0.06 mg g−1 (76.51 ± 0.26%) and 20.37 ± 0.11 mg g−1 (94.42 ± 0.50%) for Acid Blue 277 and Acid Black 172 dyes, respectively. The rapid adsorption at the beginning of the adsorption process is attributed to large functional groups present on the surface of the particles (Zheng et al., 2019a, 2019b).

Compared to some dye adsorbents reported in literature, such as magnetic chitosan microparticles (P. Wang et al., 2015; C. Zheng et al., 2019a, 2019b), nanocomposite (Y. Li et al., 2019), magnetic microparticles (Long et al., 2017), and polymer nanoparticles (Mohammadikish & Jahanshiri, 2020), PMag can achieve the kinetic equilibrium of adsorption in a similar or relatively shorter time. Thus, this adsorbent material has great potential for application in the treatment of effluents to remove dyes.

The adsorption kinetics was described using pseudo-first-order, pseudo-second-order, Elovich, and intraparticle diffusion. The relevant kinetic parameters and graphs are shown in Table 3 (Supplementary Information) and Fig. 2a-b (Supplementary Information), respectively.

The pseudo-second-order model presented coefficients of determination (R2) values close to 1, indicating that this model can correlate the adsorption kinetics data of both dyes. Using the intraparticle diffusion model, the adsorption data did not present a good fit, which means that the intraparticle diffusion was not the rate control step. The pseudo-second-order model describes that the rate-limiting phase can be characterized by chemical sorption involving valence forces through the sharing or exchange of electrons between the adsorbent material (PMag) and the adsorbate (dyes) (Wang et al., 2015).

In the study by Zhang et al. (2019), the kinetics was also described by the pseudo-second-order model. Furthermore, the authors also obtained a faster adsorption rate than other magnetic adsorbents, 90.00% of the adsorption occurred within the first 5 min, identifying the adsorbent as a material with ultra-fast adsorption performance. In the present study, PMag removed more than 80.00% of the two dyes during the first 30 min, demonstrating that the adsorption capacity of PMag is also quite fast.

3.4.3 Adsorption Isotherms

To investigate the PMag adsorption performance for the two dyes, the adsorption equilibrium isothermal models using different initial dye concentrations were evaluated at 30 °C. These models describe the relationship between equilibrium adsorption capacity and equilibrium concentration.

The removal efficiency was higher at lower concentrations of dyes, which occurs due to the saturation of binding sites of PMag with the increase in the concentration of dye in the solution. At the initial concentration (10 mg L−1), the removal efficiency for Acid Blue 277 dye was 4.73 ± 0.12 mg g−1 (99.0 ± 2.41%) and for Acid Black 172 dye it was 4.77 ± 0.05 mg g−1 (98.0 ± 1.06%). The data obtained (Fig. 2c-d-Supplementary Information) was analyzed using Freundlich, Langmuir, Sips, and Temkin isothermal models.

As shown in Table 4 (Supplementary Information), the Sips model presented the highest determination coefficients (R2) to remove both dyes. This model offers a combination of Langmuir and Freundlich models, considering that at low concentrations of adsorbate, the adsorption behavior is described in the Freundlich model. In high concentrations of adsorbate, the adsorption occurs in the monolayer, which Langmuir isotherm describes. According to the Sips model, the maximum adsorption capacity was 20.142 mg g−1 for Acid Blue 277 dye and 36.702 mg g−1 for Acid Black 172 dye.

Studies report magnetic particles associated with other materials or pretreatment with greater dye adsorption capacities in literature. The maximum adsorption capacity for Food Yellow 3 and Acid Yellow 23 dyes using magnetic chitosan microparticles was 357.140 mg g−1 and 116.128 mg g−1, respectively (C. Zheng et al., 2019a, b). For Fe3O4 magnetic nanoparticles adsorbent modified with carboxylatopylar [5], the maximum adsorption capacity for Methylene Blue dye was 136.29 mg g−1 and for Crystal Violet dye was 140.26 mg g−1 (H. Zhang et al., 2019). However, the adsorbent evaluated in this study has a simple and easy-to-apply methodology compared to other magnetic adsorbents, presenting this advantage to be used in dye removal.

Adsorbent materials with reduced size are efficient in adsorption processes due to the large surface area, which provides a large surface area/volume ratio when compared to adsorbent materials on a macro scale. Consequently, smaller particles will have more active sites available, favoring the capacity for adsorption of dyes (Do Nascimento et al., 2014). Therefore, the PMag used in this study showed efficiency in the adsorption of acid dyes with more than 95.00% removal efficiency of dyes in their ideal conditions.

3.5 Simultaneous Adsorption and Biodegradation Experiment

3.5.1 Effect of Initial pH and Temperature

The effect of pH and temperature on the removal of dyes was evaluated to define the best conditions for simultaneous adsorption and biodegradation. In tests with Acid Blue 277, Lac-PMag and PMag-func showed low variation in removal efficiency for the pH conditions evaluated (Table 5-Supplementary Information). PMag only removed the dyes at pH 3, and free laccase showed a reduction of 15.00 and 21.00% at pH 6 and 7, respectively. The efficiency of Acid Black 172 removal by Lac-PMag, PMag, and PMag-func was higher at pH 3. The free laccase was more efficient at pH 4 and 5. Thus, pH 3 presented the best removal results for both dyes in the adsorption and biodegradation tests, so it was decided to carry out the following tests under this initial pH condition.

The removal tests of Acid Blue 277 and Acid Black 172 dyes, carried out at different temperatures (Table 5- Supplementary Information), showed little difference for all conditions evaluated. Therefore, according to adsorption tests carried out previously, 30 °C was defined as the reaction temperature.

The effects of pH and temperature on the adsorption and biodegradation of dyes showed greater removal using PMag-func and Lac-PMa compared to PMag and free laccase. This factor indicates that the functionalization of particles with APTES and glutaraldehyde improved the dye removal process, as PMag-func and Lac-PMag were functionalized. Silanization with APTES inserts amino groups on the surface of the particle, and glutaraldehyde forms a “crosslink,” improving the binding of the dye molecules in the magnetic particles (Costa et al., 2019). The literature points out that modifying the surface of magnetic particles on a nano- or micro-scale increases the particle-binding sites, which substantially favors the adsorption process of different compounds (H. Zhang et al., 2019).

3.5.2 Effect of Reaction Time

The effect of reaction time for removing dyes by simultaneous adsorption and biodegradation was evaluated to find an equilibrium time, where the removal of dyes reaches maximum capacity (Fig. 5).

For both dyes, the removal efficiency was higher when using PMag-func and Lac-PMag; in addition, the removal was more evident for the Acid Blue 277 dye. Dye removal was rapid in the first stage of the reaction, as shown in the slope of graph curves, and then gradually became linear. The equilibrium time for all evaluated conditions was determined to be 120 min. At this time, Acid Blue 277 dye was completely removed by PMag-func and Lac-PMag, while PMag and free laccase removed 45.49 ± 0.64% and 62.70 ± 6.61%, respectively. For the Acid Black 172 dye, the removal in 120 min was 88.58 ± 0.21, 75.25 ± 2.12, 40.95 ± 3.69, and 94.09 ± 1.35% for Lac-PMag, PMag, free laccase, and PMag-func, respectively.

Chhabra et al. (2015) obtained 70.00% decolorization of a synthetic effluent containing the Acid Violet 17 dye in 120 h, using laccase enzymes immobilized in PVA in a packed bed column. Compared with this result, the 120 min (2 h) obtained in this work as equilibrium time is significantly shorter, which facilitates the color removal process and reduces process costs, optimizing time and using less energy.

In PMag-func, removal occurred by adsorption of dyes and was better than adsorption by PMag, due to its functionalization process. The laccase enzymes immobilized on the particles (Lac-PMag) did not show significant differences in dye removal compared to PMag-func. Thus, it is inferred that the adsorption process was limiting for the removal of dyes under the conditions evaluated, with an initial dye concentration of 50 mg L−1.

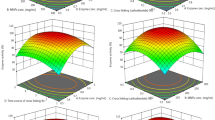

3.5.3 Effect of Initial Concentration of Dyes

The efficiency of adsorption and biodegradation simultaneous process was evaluated at different initial concentrations of dyes (Fig. 6). Using Lac-PMag, removal efficiency for Acid Blue 277 dye was 95.00% in 120 min at initial concentrations of 5, 10, 25, 50, and 75 mg L−1. From a concentration of 100 mg L−1, the removal of the dye gradually decreased until it reached 48.10 ± 1.12% at the initial concentration of 300 mg L−1.

For PMag-func the removal of Acid Blue 277 was similar. However, the removal in terms of the amount of dye removed per gram of particles used showed significant differences. At the highest initial dye concentrations, Lac-PMag demonstrated a greater ability to remove dyes per gram of Lac-PMag used. At concentrations of 200 and 300 mg L−1, Lac-PMag removed 44.60 ± 0.17 and 52.72 ± 1.23 mg g−1 of dye, respectively. PMag-func removed 38.71 ± 0.14 and 4.94 ± 0.83 mg g−1 for these same concentrations. When compared to PMag and free laccase, removal of Acid Blue 277 by Lac-PMag was also greater.

For Acid Black 172 dye, at lower concentrations, dye removal was more significant with the use of PMag. At the highest dye concentrations, Lac-PMag removed 46.24 ± 1.74, 52.03 ± 0.09, and 57.47 ± 2.38 mg g−1 for concentrations of 150, 200, and 300 mg L−1, respectively. The removal rates using PMag-func for these dye concentrations were 31.56 ± 0.12, 25.01 ± 0.77, and 21.32 ± 1.91 mg g−1.

According to the results obtained, it is evident that adsorption is the most efficient step in removing both dyes. PMag-func has high dye adsorption potential, mainly due to these particles surface functionalization. However, when using Lac-PMag, it is inferred that by saturating the binding sites for dye adsorption, biodegradation of the remaining part of this dye present in the solution occurs. At this stage of the process, the action of laccase enzymes immobilized on the particles occurred, resulting in the simultaneous process of adsorption and biodegradation (Fig. 3-Supplementary Information). Another possible mechanism that may occur is the biodegradation by laccase enzymes of molecules adsorbed on the particles. In this case, the adsorption favors the access of the enzymes to these dye molecules, facilitating the contact of the dyes with the active site of the enzymes, so that biodegradation occurs. In future studies, this mechanism can be observed to better elucidate how the biodegradation process occurs, as well as what the products of this biodegradation are.

The authors Fan et al. (2017) evaluated adsorption and biodegradation of dye using the bacteria Pseudomonas putida linked to nanoparticles of Fe3O4. The evaluated dye concentration decreased rapidly at first, indicating that adsorption by Fe3O4 nanoparticles played a fundamental role, and those dye molecules were adsorbed from the solution. Subsequently, after an adsorption balance, dye biodegraded by the microorganism, complementing the dye removal process.

Simultaneous adsorption and biodegradation of dyes by laccases immobilized on support can promote dye molecules interaction with the active sites of laccases (Nguyen et al., 2016). Other studies have reported the immobilization of enzymes on supports with adsorption capacity. The authors emphasize that using these immobilized enzymes leads to more consistent performance for removing contaminants due to the combined adsorption and biodegradation (Nguyen et al., 2016; Xu et al., 2013).

Most studies that evaluated laccases for biodegradation of dyes used initial dye concentrations of up to 100 mg L−1 (Chen et al., 2017; Daâssi et al., 2014; Dai et al., 2016; Glam & Glam, 2016; Liu et al., 2016; Rong et al., 2017; Sathishkumar et al., 2014; Zheng et al., 2016). Therefore, the use of Lac-PMag to remove textile dyes, Acid Blue 277 and Acid Black 172, is significant when used in high concentrations (> 100 mg L−1) of dye, demonstrating the potential of Lac-PMag in adsorption and simultaneous biodegradation.

Antecka et al. (2018) evaluated the simultaneous process of adsorption and biodegradation of dyes using laccases immobilized on TiO2-ZrO2 and TiO2-ZrO2-SiO2 oxide systems. Under the ideal process conditions, the authors obtained 100%, 91%, and 77% removal of Alizarin Red S (ARS), Remazol Brilliant Blue R (RBBR), and Reactive Black 5 (RB5) dyes, respectively, with an initial dye concentration of 5 mg L−1. Comparing it with our study, we obtained similar removal results with much higher initial dye concentrations, demonstrating that Lac-PMag showed good results even at high dye concentrations.

Other studies reporting immobilized laccases as a material capable of adsorption and biodegradation of contaminants also obtained their best results at lower concentrations of contaminants. The results by D. Wang et al. (2021) showed the immobilized laccase on core–shell magnetic metal organic framework microspheres can remove 100% of octylphenol polyethoxylate (OPEO) and 98.16% of nonylphenol polyethoxylate (NPEO) in 200 min, with an initial concentration of 25 mg L−1. Wu et al. (2019) showed 87.00% removal of 2,4-dichlorophenol by immobilized laccase on amino-functionalized magnetic metal organic framework, using an initial concentration of 10 mg L−1. Despite these studies evaluating the removal of other types of contaminants, the comparison highlights that our study presents originality in evaluating and presenting good results in the adsorption and biodegradation in high initial concentrations of dyes.

Thus, at low dye concentrations, the degradation effect was relatively weak and the adsorption step was responsible for dye removal. For the highest concentrations, such as 300 mg L−1, the simultaneous adsorption and biodegradation process proved to be efficient. Another essential factor in this study is the ability of free laccase to biodegrade dyes. Biodegradation with free laccases when compared to dye biodegradation by Lac-PMag showed lower efficiency. However, although the efficiency was lower, the laccase enzymes used in this study are of low cost, as they are obtained in a non-commercial way and use agro-industrial residues in their production. The low cost, combined with the dye removal efficiency presented by Lac-PMag, presents a potential alternative for the treatment of textile effluents.

4 Conclusions

We studied the adsorption of textile dyes by magnetic particles and immobilization of laccase enzymes in these magnetic particles to evaluate the simultaneous process of adsorption and biodegradation. The PMag efficiently removed the dyes from the aqueous solutions in an equilibrium time of 120 min and pH 3.0. The immobilization yield of laccase enzymes was 99.84% after functionalization of the magnetic particles with APTES and glutaraldehyde. The immobilized enzymes showed operational and storage stability, with 41.29% of the initial enzymatic activity in the fifth cycle of reuse and 91.00% of the initial enzymatic activity after 8 months of storage. The removal of dyes by combined adsorption and biodegradation, using Lac-PMag, showed promising results when used in higher concentrations of the dyes. The results indicate a removal capacity of 52.72 and 57.47 mg L−1 for Acid Blue 277 and Acid Black 172, respectively, at dye initial concentration of 300 mg L−1. We concluded that Lac-PMag is an excellent alternative for the biotreatment of dyes present in aquatic environments.

Data Availability

The datasets supporting the conclusions of this articleare included within the article and its additional files.

References

Akpinar, M., & Ozturk, R. (2017). Induction of fungal laccase production under solid state bioprocessing of new agroindustrial waste and its application on dye decolorization. 3 Biotech, 7(2), 1–10. https://doi.org/10.1007/s13205-017-0742-5

Albuquerque, I. L. T., Santos, P. T. A., Cornejo, D. R., Bicalho, S. M. C. M., Oliveira, L. S. C., Federal, U., et al. (2017). Modificação da superf í cie de nanocompósitos de Fe 2 O 3 / Fe 3 O 4 visando seu uso para imobilização da glicose oxidase 63 244–252.

Alexandrino, A. M., De Faria, H. G., Giatti, C., Souza, M. . De., & Peralta, R. M. (2007). Aproveitamento do resíduo de laranja para a produção de enzimas lignocelulolíticas por. Pleurotus ostreatus (Jack: Fr), 27(2), 364–368.

Antecka, K., Zdarta, J., Siwińska-Stefańska, K., Sztuk, G., Jankowska, E., Oleskowicz-Popiel, P., & Jesionowski, T. (2018). Synergistic degradation of dye wastewaters using binary or ternary oxide systems with immobilized laccase. Catalysts, 8(9). https://doi.org/10.3390/catal8090402

Baldrian, P. (2006). Fungal laccases-occurrence and properties. FEMS Microbiology Reviews, 30(2), 215–242. https://doi.org/10.1111/j.1574-4976.2005.00010.x

Beatriz, A., Capítulo, V., & Capítulo, C. T. (n.d.). Equipe de tradução.

Bruce, I. J., Taylor, J., Todd, M., Davies, M. J., Borioni, E., Sangregorio, C., & Sen, T. (2004). Synthesis, characterisation and application of silica-magnetite nanocomposites. Journal of Magnetism and Magnetic Materials, 284(1–3), 145–160. https://doi.org/10.1016/j.jmmm.2004.06.032

Cao, L. (2005). Immobilised enzymes : science or art ?, 217–226. https://doi.org/10.1016/j.cbpa.2005.02.014

Cardoso, B. K., Linde, G. A., Colauto, N. B., & do Valle, J. S. (2018). Panus strigellus laccase decolorizes anthraquinone, azo, and triphenylmethane dyes. Biocatalysis and Agricultural Biotechnology, 16, 558–563. https://doi.org/10.1016/j.bcab.2018.09.026

Chen, J., Leng, J., Yang, X., Liao, L., Liu, L., & Xiao, A. (2017). Enhanced performance of magnetic graphene oxide-immobilized laccase and its application for the decolorization of dyes. https://doi.org/10.3390/molecules22020221

Chhabra, M., Mishra, S., & Sreekrishnan, T. R. (2015). Immobilized laccase mediated dye decolorization and transformation pathway of azo dye acid red 27. Journal of Environmental Health Science and Engineering, 13(1), 1–9. https://doi.org/10.1186/s40201-015-0192-0

Chowdhury, S., Mishra, R., Saha, P., & Kushwaha, P. (2011). Adsorption thermodynamics, kinetics and isosteric heat of adsorption of malachite green onto chemically modified rice husk. Desalination, 265(1–3), 159–168. https://doi.org/10.1016/j.desal.2010.07.047

Costa, J. B., Lima, M. J., Sampaio, M. J., Neves, M. C., Faria, J. L., Morales-torres, S., et al. (2019). Enhanced biocatalytic sustainability of laccase by immobilization on functionalized carbon nanotubes / polysulfone membranes. Chemical Engineering Journal, 355, 974–985. https://doi.org/10.1016/j.cej.2018.08.178

Cui, J., Ren, S., Lin, T., Feng, Y., & Jia, S. (2018). Shielding e ff ects of Fe 3 + -tannic acid nanocoatings for immobilized enzyme on magnetic Fe 3 O 4 @ silica core shell nanosphere. Chemical Engineering Journal, 343, 629–637. https://doi.org/10.1016/j.cej.2018.03.002

Daâssi, D., Rodríguez-couto, S., Nasri, M., & Mechichi, T. (2014). International biodeterioration & biodegradation biodegradation of textile dyes by immobilized laccase from Coriolopsis gallica into Ca-alginate beads. International Biodeterioration & Biodegradation, 90, 71–78. https://doi.org/10.1016/j.ibiod.2014.02.006

Dai, J., Wang, H., Chi, H., Wang, Y., & Zhao, J. (2016). Engineering immobilization of laccase from Pleurotus ostreatus on magnetic separable SiO 2 support and excellent activity towards azo dye decolorization. Journal of Environmental Chemical, 4(2), 2585–2591. https://doi.org/10.1016/j.jece.2016.04.037

Do Nascimento, R. F., De Lima, A. C. A., Vidal, C. B., Melo, D. de Q., & Raulino, G. S. C. (2014). Livro sobre adsorção. https://doi.org/10.13140/RG.2.1.4340.1041

Em, P. D. E. P., Tecnologia, C. E., & Riedi, H. D. E. P. (2019). PURIFICAÇÃO , CARACTERIZAÇÃO E IMOBILIZAÇÃO DE LACASES DE BASIDIOMICETOS E SEU USO NA DEGRADAÇÃO SIMULTÂNEA PURIFICAÇÃO , CARACTERIZAÇÃO E IMOBILIZAÇÃO DE LACASES.

Fan, J., Chen, D., Li, N., Xu, Q., Li, H., He, J., & Lu, J. (2017). SC. ECSN, 100. https://doi.org/10.1016/j.chemosphere.2017.10.042

Fernández-Fernández, M., Sanromán, M. Á., & Moldes, D. (2013). Recent developments and applications of immobilized laccase. Biotechnology Advances, 31(8), 1808–1825. https://doi.org/10.1016/j.biotechadv.2012.02.013

Fortes, C. C. S., Daniel-da-Silva, A. L., Xavier, A. M. R. B., & Tavares, A. P. M. (2017). Optimization of enzyme immobilization on functionalized magnetic nanoparticles for laccase biocatalytic reactions. Chemical Engineering and Processing: Process Intensification, 117(March), 1–8. https://doi.org/10.1016/j.cep.2017.03.009

Glam, S. S. A., & Glam, N. S. A. (2016). Immobilization of laccase onto a porous nanocomposite : Application for textile dye degradation, 262–276. https://doi.org/10.3906/kim-1504-63

Guo, S., Huang, L., Li, W., Wang, Q., Wang, W., & Yang, Y. (2019). Willow tree-like functional groups modified magnetic nanoparticles for ultra-high capacity adsorption of dye. Journal of the Taiwan Institute of Chemical Engineers, 101, 99–104. https://doi.org/10.1016/j.jtice.2019.04.041

Hou, H., Zhou, J., Wang, J., Du, C., & Yan, B. (2004). Enhancement of laccase production by Pleurotus ostreatus and its use for the decolorization of anthraquinone dye. Process Biochemistry, 39(11), 1415–1419. https://doi.org/10.1016/S0032-9592(03)00267-X

Jiang, Y., Guo, C., Xia, H., Mahmood, I., Liu, C., & Liu, H. (2009). Enzymatic magnetic nanoparticles supported ionic liquids for lipase immobilization : Enzyme activity in catalyzing esterification. Journal of Molecular Catalysis B, 58, 103–109. https://doi.org/10.1016/j.molcatb.2008.12.001

Kashefi, S., Borghei, S. M., & Mahmoodi, N. M. (2019). Covalently immobilized laccase onto graphene oxide nanosheets: Preparation, characterization, and biodegradation of azo dyes in colored wastewater. Journal of Molecular Liquids, 276, 153–162. https://doi.org/10.1016/j.molliq.2018.11.156

Khatri, A., Peerzada, M. H., Mohsin, M., & White, M. (2015). A review on developments in dyeing cotton fabrics with reactive dyes for reducing effluent pollution. Journal of Cleaner Production, 87(1), 50–57. https://doi.org/10.1016/j.jclepro.2014.09.017

Kne, A., Staji, M., Vukojevi, J., & Milovanovi, I. (2014). I The effect of trace elements on wheat straw degradation by Trametes gibbosa nternational. Biodeterioration & Biodegradation, 96, 152–156. https://doi.org/10.1016/j.ibiod.2014.10.004

Kopp, W., Silva, F. A., Lima, L. N., Masunaga, S. H., Tardioli, P. W., Giordano, R. C., et al. (2015). Synthesis and characterization of robust magnetic carriers for bioprocess applications. Materials Science and Engineering B: Solid-State Materials for Advanced Technology, 193(C), 217–228. https://doi.org/10.1016/j.mseb.2014.12.002

Ladole, M. R., Pokale, P. B., Patil, S. S., Belokar, P. G., & Pandit, A. B. (2020). Laccase immobilized peroxidase mimicking magnetic metal organic frameworks for industrial dye degradation. Bioresource Technology, 317(August), 124035. https://doi.org/10.1016/j.biortech.2020.124035

Li, Y., Bi, H., Liang, Y., Mao, X., & Li, H. (2019). A magnetic core-shell dodecyl sulfate intercalated layered double hydroxide nanocomposite for the adsorption of cationic and anionic organic dyes. Applied Clay Science, 183(April), 105309. https://doi.org/10.1016/j.clay.2019.105309

Li, Z., Chen, Z., Zhu, Q., Song, J., Li, S., & Liu, X. (2020). Improved performance of immobilized laccase on Fe3O4@C-Cu2+ nanoparticles and its application for biodegradation of dyes. Journal of Hazardous Materials, 399(April), 123088. https://doi.org/10.1016/j.jhazmat.2020.123088

Liu, Y., Yan, M., Geng, Y., & Huang, J. (2016). Laccase immobilization on poly ( p -phenylenediamine )/ Fe 3 O 4 nanocomposite for Reactive Blue 19 dye removal. Applied Sciences. https://doi.org/10.3390/app6080232

Long, Y., Xiao, L., & Cao, Q. (2017). Co-polymerization of catechol and polyethylenimine on magnetic nanoparticles for efficient selective removal of anionic dyes from water. Powder Technology, 310, 24–34. https://doi.org/10.1016/j.powtec.2017.01.013

Mate, C. J., & Mishra, S. (2020). Synthesis of borax cross-linked Jhingan gum hydrogel for remediation of Remazol Brilliant Blue R ( RBBR ) dye from water : Adsorption isotherm, kinetic, thermodynamic and biodegradation studies. International Journal of Biological Macromolecules, 151, 677–690. https://doi.org/10.1016/j.ijbiomac.2020.02.192

Mohammadikish, M., & Jahanshiri, D. (2020). Rapid adsorption of cationic and anionic dyes from aqueous solution via metal-based coordination polymers nanoparticles. Solid State Sciences, 99, 106063. https://doi.org/10.1016/j.solidstatesciences.2019.106063

Mohammed, L., Gomaa, H. G., Ragab, D., & Zhu, J. (2017). Magnetic nanoparticles for environmental and biomedical applications: A review. Particuology, 30, 1–14. https://doi.org/10.1016/j.partic.2016.06.001

Monte Blanco, S. P. D., Scheufele, F. B., Módenes, A. N., Espinoza-Quiñones, F. R., Marin, P., Kroumov, A. D., & Borba, C. E. (2017). Kinetic, equilibrium and thermodynamic phenomenological modeling of reactive dye adsorption onto polymeric adsorbent. Chemical Engineering Journal, 307, 466–475. https://doi.org/10.1016/j.cej.2016.08.104

Moreira, M. T., Moldes-diz, Y., & Feijoo, G. (2017). Formulation of laccase nanobiocatalysts based on ionic and covalent interactions for the enhanced oxidation of phenolic compounds. Applied Sciences. https://doi.org/10.3390/app7080851

Morozova, O. V, Shumakovich, G. P., Shleev, S. V, Yaropolov, Y. I. (2007). Laccase – mediator systems and their applications : A review 43(5), 523–535. https://doi.org/10.1134/S0003683807050055

Nalbandian, L., Patrikidou, A., Hatzidaki, E., & Papandreou, C. N. (2015). Magnetic nanoparticles in medical diagnostic applications : Synthesis , characterization and proteins conjugation, (December). https://doi.org/10.2174/1573413712666151210230002

Nguyen, T. A., Fu, C., & Juang, R. (2016). Effective removal of sulfur dyes from water by biosorption and subsequent immobilized laccase degradation on crosslinked chitosan beads. Chemical Engineering Journal. https://doi.org/10.1016/j.cej.2016.06.102

Piscitelli, A., Giardina, P., Lettera, V., Pezzella, C., Sannia, G., & Faraco, V. (2011). Induction and transcriptional regulation of laccases in fungi, 104–112.

Pospiskova, K., Prochazkova, G., & Safarik, I. (2013). One-step magnetic modification of yeast cells by microwave-synthesized iron oxide microparticles. Letters in Applied Microbiology, 56(6), 456–461. https://doi.org/10.1111/lam.12069

Rong, J., Zhang, T., Qiu, F., & Zhu, Y. (2017). Preparation of efficient, stable, and reusable laccase − Cu 3 (PO 4 ) 2 hybrid microspheres based on copper foil for decoloration of Congo Red, 3. https://doi.org/10.1021/acssuschemeng.7b00820

Sahoo, J. K., Paikra, S. K., Mishra, M., & Sahoo, H. (2019). Amine functionalized magnetic iron oxide nanoparticles: Synthesis, antibacterial activity and rapid removal of Congo red dye. Journal of Molecular Liquids, 282, 428–440. https://doi.org/10.1016/j.molliq.2019.03.033

Sathishkumar, P., Kamala-kannan, S., Cho, M., Su, J., Hadibarata, T., Razman, M., & Oh, B. (2014). Enzymatic Laccase immobilization on cellulose nanofiber : The catalytic efficiency and recyclic application for simulated dye effluent treatment. Journal of Molecular Catalysis. B, Enzymatic, 100, 111–120. https://doi.org/10.1016/j.molcatb.2013.12.008

Semião, M. A., Windson, C., Haminiuk, I., & Maciel, G. M. (2020). Residual diatomaceous earth as a potential and cost e ff ective biosorbent of the azo textile dye Reactive Blue 160. Journal of Environmental Chemical Engineering, 8(1), 103617. https://doi.org/10.1016/j.jece.2019.103617

Wang, D., Lou, J., Yuan, J., Xu, J., Zhu, R., Wang, Q., & Fan, X. (2021). Laccase immobilization on core-shell magnetic metal-organic framework microspheres for alkylphenol ethoxylate compound removal. Journal of Environmental Chemical Engineering, 9(1), 105000. https://doi.org/10.1016/j.jece.2020.105000

Wang, H., Zhang, W., Zhao, J., Xu, L., Zhou, C., Chang, L., & Wang, L. (2013). Rapid decolorization of phenolic azo dyes by immobilized laccase with Fe 3 O 4 / SiO 2 Nanoparticles as Support, 2–8.

Wang, P., Ma, Q., Hu, D., & Wang, L. (2015). Removal of Reactive Blue 21 onto magnetic chitosan microparticles functionalized with polyamidoamine dendrimers. Reactive and Functional Polymers, 91–92, 43–50. https://doi.org/10.1016/j.reactfunctpolym.2015.04.007

Wang, Q., Yuan, T., Liu, S., Fu, X., Yang, G., Chen, J., et al. (2018). Synthesizing magnetic support for laccase immobilization for the purification of pre-hydrolysis liquor. BioResources, 13(1), 1885–1894. https://doi.org/10.15376/biores.13.1.1885-1894

Wong, J. K. H., Tan, H. K., Lau, S. Y., Yap, P. S., & Danquah, M. K. (2019). Potential and challenges of enzyme incorporated nanotechnology in dye wastewater treatment: A review. Journal of Environmental Chemical Engineering, 7(4), 103261. https://doi.org/10.1016/j.jece.2019.103261

Wu, E., Li, Y., Huang, Q., Yang, Z., Wei, A., & Hu, Q. (2019). Laccase immobilization on amino-functionalized magnetic metal organic framework for phenolic compound removal. Chemosphere, 233, 327–335. https://doi.org/10.1016/j.chemosphere.2019.05.150

Xu, R., Chi, C., Li, F., & Zhang, B. (2013). Immobilization of horseradish peroxidase on electrospun microfibrous membranes for biodegradation and adsorption of bisphenol A. Bioresource Technology, 149, 111–116. https://doi.org/10.1016/j.biortech.2013.09.030

Yang, H., Zhang, J., Liu, Y., Wang, L., Bai, L., Yang, L., et al. (2019). Rapid removal of anionic dye from water by poly(ionic liquid)-modified magnetic nanoparticles. Journal of Molecular Liquids, 284, 383–392. https://doi.org/10.1016/j.molliq.2019.04.029

Yaseen, D. A., & Scholz, M. (2019). Textile dye wastewater characteristics and constituents of synthetic effluents: A critical review. International Journal of Environmental Science and Technology (Vol. 16). Springer Berlin Heidelberg. https://doi.org/10.1007/s13762-018-2130-z

Zhang, D., Deng, M., Cao, H., Zhang, S., & Zhao, H. (2017). Laccase immobilized on magnetic nanoparticles by dopamine polymerization for 4-chlorophenol removal. Green Energy and Environment, 2(4), 393–400. https://doi.org/10.1016/j.gee.2017.04.001

Zhang, H., Wu, J. R., Wang, X., Li, X. S., Wu, M. X., Liang, F., & Yang, Y. W. (2019). One-pot solvothermal synthesis of carboxylatopillar[5]arene-modified Fe3O4 magnetic nanoparticles for ultrafast separation of cationic dyes. Dyes and Pigments, 162, 512–516. https://doi.org/10.1016/j.dyepig.2018.10.061

Zheng, C., Zheng, H., Wang, Y., Sun, Y., An, Y., Liu, H., & Liu, S. (2019a). Modified magnetic chitosan microparticles as novel superior adsorbents with huge “force field” for capturing food dyes. Journal of Hazardous Materials, 367(January), 492–503. https://doi.org/10.1016/j.jhazmat.2018.12.120

Zheng, F., Cui, B., Wu, X., Meng, G., Liu, H., & Si, J. (2016). Immobilization of laccase onto chitosan beads to enhance its capability to degrade synthetic dyes. International Biodeterioration & Biodegradation, 110(4), 69–78. https://doi.org/10.1016/j.ibiod.2016.03.004

Zheng, X., Zheng, H., Xiong, Z., Zhao, R., Liu, Y., Zhao, C., & Zheng, C. (2019). Novel anionic polyacrylamide-modify-chitosan magnetic composite nanoparticles with excellent adsorption capacity for cationic dyes and pH-independent adsorption capability for metal ions. Chemical Engineering Journal, 123706. https://doi.org/10.1016/j.cej.2019.123706

Zia, M., Phull, A. R., & Ali, J. S. (2016). Challenges of iron oxide nanoparticles, 49–67.

Acknowledgements

We would like to thank the Laboratório Multiusuário de Análises Químicas (LAMAQ) and Laboratório Multiusuários de Equipamentos e Análises Ambientais (LAMEAA) situated at Universidade Tecnológica Federal do Paraná (UTFPR), Campus Curitiba, Brazil; Centro de Microscopia Eletrônica (CME) situated at Universidade Federal do Paraná (UFPR), Campus Curitiba, Brazil, for provide the infrastructure.

Funding

We would like to thank Universidade Tecnológica Federal do Paraná (UTFPR), Campus Curitiba, Brazil; Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) (Process 1551249/2015–9) and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) for C.W.I. Haminiuk research productivity scholarship (Grant number 304722/2019-7) for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Modkovski, T.A., Maciel, G.M., Brugnari, T. et al. Simultaneous Removal of Textile Dyes by Adsorption and Biodegradation Using Trametes villosa Laccase Immobilized on Magnetic Particles. Water Air Soil Pollut 232, 512 (2021). https://doi.org/10.1007/s11270-021-05451-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-021-05451-2