Abstract

ANT is a commonly occurring polycyclic aromatic hydrocarbon (PAH) in natural eutrophic waters where Microcystis blooms break out usually. In this study, effects of ANT at different concentrations (0.02, 0.06, 0.18, 0.54, and 1.62 μg/mL) on the growth, microcystin-LR (MC-LR) production, and expression of three key mcy genes in Microcystis aeruginosa were investigated. The results showed that all the tested concentrations of ANT inhibited M. aeruginosa growth significantly except 0.02 μg/mL ANT in the early stage of the experiment. In the culture media, initially applied ANT concentrations decreased significantly after 3 days of incubation. ANT stimulated MC-LR production in a concentration-dependent manner. After exposure to ANT for 1 day, the expression of mcyB gene was inhibited and the inhibitory effects increased with ANT concentrations. ANT at higher concentrations (above 0.02 μg/mL) stimulated gene expression of mcyD (P < 0.05) and mcyH (P < 0.01) significantly, and 0.02 μg/mL of ANT inhibited their expression significantly (P < 0.01). With increasing culture time, 0.18 μg/mL of ANT inhibited mcyB gene expression first and then stimulated it while gene expressions of mcyD and mcyH were stimulated throughout the experiment. Our results suggested that ANT in natural waters could affect not only Microcystis growth but also MC production via modifying mcy gene expressions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Cyanobacterial blooms occur worldwide in eutrophic freshwater ecosystems, causing of water quality deterioration, aquatic animal mortality and illness, food web destabilization, and human health menace (Iredale et al. 2012; Zhang et al. 2013). The genus Microcystis, as a well-known main group of cyanobacterial blooms, is of major concern since many species (strains) of this genus can produce cyclic heptapeptide toxins called microcystins (MCs) (Wiedner et al. 2003). Although MCs can be produced by other cyanobacterial genera (e.g., Anabaena, Aphanizomenon, and Planktothrix) (Rantala et al. 2004; Fiore et al. 2009), Microcystis is the primary producer of MCs in eutrophic freshwater environments such as ponds, lakes, and reservoirs worldwide (Tanabe et al. 2009).

MCs are contained within healthy cells and only released upon lysis or when changes in cell wall permeability occur (Chen et al. 2014). They are chemically stable and slowly decomposed (Harada et al. 1996). The concentration of MCs during the period of Microcystis bloom outbreak can reach above 10 μg/L (Xu et al. 2008). As potent inhibitors of protein phosphatase type 1 and 2A and tumor promoters (Matsushima-Nishiwaki et al. 1992), MCs can pose a health hazard for humans as well as domestic animals and wildlife (Dittmann and Wiegand 2006; Hoeger et al. 2007). The growing concern regarding the acute and chronic effects of MCs has resulted in the World Health Organization (WHO) setting a guideline value of 1 μg/L for microcystin-LR (MC-LR) in drinking water. Certain environmental factors, such as temperature (Westhuizen and Eloff 1985), light (Wiedner et al. 2003; Renaud et al. 2011), nutritive salt (Downing et al. 2005), heavy metals (Gouvea et al. 2008), and zooplankton grazing (Mohamed and Al-Shehri 2013), can affect the MC production of Microcystis.

Polycyclic aromatic hydrocarbons (PAHs), a highly toxic and carcinogenic class of compounds characterized by fused aromatic rings, are typical persistent organic pollutants usually found in waters where Microcystis blooms breakout (Guo et al. 2011). Their solubility in water decreases with increases in their molecular weight (Nikolaou et al. 2009). Low molecular-weight PAHs can dissolve in waters directly, while PAHs with high molecular weight can be sorbed strongly by waterborne organic and inorganic particles and brought down to the bottom sediment as a sink in the aquatic system (Dong et al. 2012; Kafilzadeh 2015). The sorbed PAHs will be released to the water as an extended source to be absorbed and accumulated by algae (Hong et al. 2008). The presence of PAHs in the waters can affect the growth of M. aeruginosa (Zhu et al. 2012). However, effects of PAHs on MC production and its involved mechanism have not been reported. In this study, ANT, a commonly occurring PAH, was selected as representative to investigate effects of PAH on the production of MC-LR, which is the most common and potent isoform of MCs in M. aeruginosa. In addition, changes in the expression of three key mcy genes, including mcyB, mcyD, and mcyH, were investigated as well.

2 Materials and Methods

2.1 Algae Culture

M. aeruginosa FACHB-905 was provided by the Institute of Hydrobiology, Chinese Academy of Sciences. Algae were cultured in conical flasks containing sterilized BG11 medium under a 12 light/12 dark cycle with a light density of 60 μmol/m2 s at 25 °C. To reduce any effects related to minor differences in photon irradiance and maintain homogeneity, the flasks were shaken slightly four times each day and rearranged randomly. Cultures were used till algae were in exponential growth phase.

2.2 Experimental Design

Acetone was chosen to be the carrier solvent to prepare the stock solution of ANT (Sigma-Aldrich (Shanghai) Trading Co., Ltd.). Based on the inhibition of M. aeruginosa growth at different acetone concentrations, the 96-h NOEC value of acetone to M. aeruginosa was 0.5 % (v/v). Considering the NOEC value of acetone, the stock solution of ANT (1.0 mg/mL) was prepared. According to 96 h EC50 (3.36 μg/mL) evaluated previously, the final concentrations of ANT in the medium were set as follows: 0.02, 0.06, 0.18, 0.54, and 1.62 μg/mL. Each concentration was prepared in triplicate. Different volumes of stock solution were added to 3000-mL conical flasks containing 1500 mL of algal culture respectively, and the maximum volume of stock solution added was 2.43 mL, resulting in the highest final concentration of ANT (1.62 μg/mL). Acetone was supplemented to the same final volume of 2.43 mL in other ANT-exposed groups. Algal culture added with 2.43 mL of acetone was used as the control group. Samples were removed from the culture every 3 days (0, 3, 6, 9, and 12 days). In addition, samples were also removed after exposure to ANT for 1 day.

2.3 Determination of Cell Density and Relative Growth Rate

Algal cell density was tested using a blood counting chamber under a light microscope (×40). To reduce erroneous results, samples were taken 1 cm below the water surface with movement. The relative growth rate (RGT) of algae was calculated using the following formula:

where N 0 is the cell density at the beginning of a time interval, N T is the cell density at the end of a time interval, and △t is the length of the time interval in days (t T – t 0).

2.4 Monitoring of ANT Concentrations in the Culture Medium

Algal culture was poured through a 0.22-μm membrane to collect the culture medium, which was adjusted to pH 2.0. The culture medium was extracted twice, each with equal volume of dichloromethane in a separating funnel, and the extracted samples were combined and dried with anhydrous sodium sulfate, and then concentrated using a vacuum rotary evaporator (Eyela, Japan). The organic extract was transferred to sample bottle and diluted with dichloromethane to a constant volume of 1 mL.

The organic extracts were analyzed utilizing an HPLC system (SPD-M20A, Shimadzu, Japan) equipped with a C18 reversed-phase column (150 mm), using methanol/water (v/v, 85/15) at a flow rate of 1 mL/min, with the injection amount of 20 μL. ANT was extracted using the above method which yielded 78.6 and 110.9 % recovery.

2.5 Extraction of MCs

Eighty milliliterts of algal culture was centrifuged at 10,000 rpm for 10 min at 4 °C, and then the supernatant was discarded. The cell pellet was frozen (−20 °C) and thawed (4 °C) repeatedly for five times. After centrifugation, the supernatant I was collected and the cell pellet added with 20–30 mL of 5 % acetic acid was stirred for 20 min and then centrifuged at 10,000 rpm (4 °C; 10 min) to collect supernatant II. The left cell pellet dissolved with 30 mL of HPLC methanol was stirred for 20 min, and then centrifuged to collect supernatant III. The methanol left in supernatant III was removed using the rotary evaporation method. Supernatants I, II and III were mixed and filtered through a 0.22-μm membrane to prepare filtration for the subsequent solid phase extraction.

MCs were extracted on SPE C18 (Supelclean ENVI-18) cartridge as follows: C18 cartridge was firstly activated and cleaned with 10 mL of methanol and 15-mL distilled water in sequence, and then the filtration prepared was loaded and the flow rate was 8–12 mL/min. After washing with 10-mL distilled water and 20 % methyl alcohol solution in sequence, 40 mL of 60 % methyl alcohol solution containing 0.05 % trifluoroacetic acid (TFA) was used to elute MCs. The elute collected was rotary evaporated to dryness, redissolved in 1-mL 60 % methyl alcohol solution, and then filtrated through a 0.22-μm membrane. The filtration was applied to an HPLC system.

2.6 Determination of MC-LR Concentration by HPLC

Standard MC-LR bought from Sigma (98 % purity) and extracted MC-LR were analyzed by HPLC (SPD-M20A, SHIMADZU, Japan) with a Shim-Pack VP-ODS column (250 mm × 4.6 mm). The column temperature was 40 °C. The mobile phase was 60 % (v/v) methyl alcohol-water solution containing 0.05 % (v/v) TFA. The flow rate was 1.0 mL/min and the injection amount was 20 μL. The detection wavelength was 238 nm. The limit of detection (LOD) was 0.1 μg/L. The calibration curve of MC-LR was created according to the peak area of 5 vol (4, 8, 12, 16, and 20 μL) of 10.0 μg/mL standard MC-LR solution. These standard MC-LR solutions were extracted on SPE C18 cartridge to determine its recovery rate of MC-LR.

2.7 RNA Extraction, Reverse Transcription and Real-Time Analysis

M. aeruginosa cells from the 120-mL algal culture were harvested by centrifuging at 7000 rpm for 5 min at 4 °C. The pelleted cells were suspended in a Trizol reagent (TOYOBO, Japan) and ground under liquid nitrogen. Total RNAs were extracted following the Trizol reagent manual (TOYOBO, Japan), then digested with RNase-free DNase (TOYOBO, Japan). For reverse transcription, 1 μg of total RNA was mixed with random primers p(dN)9 and reverse transcriptase according to the instructions of the reverse transcriptase kit (Generay, China).

The primers of mcyB, mcyD, and mcyH were referred from previous research report (Table 1). Real-time RT-PCR was performed with 25-μL THUNDERBIRD SYBR® qPCR Mix (TOYOBO, Japan), 1.5-μL forward primer and reverse primer (10 pmol/μL), respectively, 1-μL cDNA, and 21-μL distilled water to a final volume of 50 μL. The amplification reactions were performed by a MyiQ™ 5 real-time RT-PCR (Bio-Rad, USA) using the following conditions: 1 cycle at 94 °C for 2 min followed by 40 cycles at 94 °C for 10 s, 57 °C for 30 s, and 72 °C for 30 s. Gene expression data from real-time qPCR were evaluated using Ct value (Livak and Schmittgen 2001), and the 16S rRNA gene was used as the housekeeping gene to normalize the expression levels of the target gene since the expression of 16S rRNA is stable under various conditions. The induction ratio was calculated as under using 2−ΔΔCt (Livak and Schmittgen 2001), where ΔΔCt = (C t, target gene − C t, 16S rrn)stress − (C t, target gene − C t, 16S rrn)control.

2.8 Statistical Analysis

Statistical analysis was performed with SPSS 13.0. The resulting data were expressed as mean ± SD (n = 3). Differences among means were determined using one-way analysis of variance (ANOVA) and considered significant at P < 0.05 and remarkably significant at P < 0.01.

2.9 Results

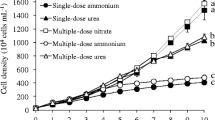

Figure 1 shows the effects of ANT on the growth and relative growth rate of M. aeruginosa. All the tested concentrations of ANT inhibited M. aeruginosa growth significantly (P < 0.05) except 0.02 μg/mL of ANT at day 3, which stimulated algal growth significantly (P < 0.05). With the prolongation of culture time, algal cell densities in 0.02 and 0.06 μg/mL ANT-exposed groups gradually increased, while cell densities of M. aeruginosa exposed to higher concentrations (above 0.06 μg/mL) of ANT decreased first at day 3 and then increased significantly at day 6. The specific growth rate of M. aeruginosa was markedly increased at day 6, exhibiting an overcompensatory growth response. ANT evoked overcompensatory growth in a concentration-related manner. Change of ANT concentrations in the culture medium is shown in Fig. 2. In the culture media, initially applied ANT concentrations decreased significantly in the early stage of experiment. After 3 days of incubation, ANT concentrations remaining in the culture media initially exposed to 1.62 μg/mL ANT and 0.02μg/mL ANT decreased to 0.090 and 0.006 μg/mL, respectively.

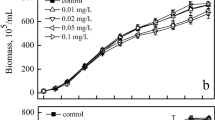

As shown in Fig. 3, the calibration curve of MC-LR was linear (y = 2.7477x − 0.1272) with the correlation coefficients (r 2 = 0.9985). The recovery rate of MC-LR on the SPE C18 cartridge was 0.7853. The concentrations of the sampled MC-LR were rectified with the recovery rate obtained. As shown in Fig. 4, ANT could stimulate MC-LR production in a concentration-dependent manner (P < 0.05). At the end of the experiment, MC-LR produced in M. aeruginosa exposed to 0.06 μg/mL ANT reached 6.16 μg/107 cells, which was significantly higher than that (5.20 μg/107 cells) in the control group (P < 0.05). The highest MC-LR production was observed in M. aeruginosa exposed to 1.62 μg/mL ANT. It was 1.32-fold of that in the control group, reaching 6.87 μg/107 cells.

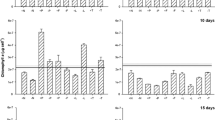

Figure 5 shows the expression of three key mcy genes in M. aeruginosa exposed to different concentrations of ANT for 1 day. ANT downregulated gene expression of mcyB and the inhibitory effects increased with ANT concentrations. ANT (0.02 μg/mL) inhibited gene expressions of mcyD and mcyH significantly (P < 0.01), while higher concentrations (above 0.02 μg/mL) of ANT stimulated gene expressions of mcyD (P < 0.05) and mcyH (P < 0.01) significantly. The effects of 0.18 μg/mL of ANT on the three key mcy genes expressions of M. aeruginosa at different culture times are shown in Fig. 6. With the prolongation of culture time, 0.18 μg/mL of ANT inhibited mcyB gene expression first and then stimulated it, while gene expressions of mcyD and mcyH were stimulated throughout the experiment.

3 Discussion

PAHs, as typical persistent organic pollutants usually found in eutrophic waters with common occurrence of Microcystis blooms (Guo et al. 2011), could affect the growth of M. aeruginosa. Naphthalene, phenanthrene, and pyrene were dominant PAHs in surface water (Li et al. 2010), and Zhu et al. (2012) found a solution that the mixture of these PAHs could markedly promote the growth of M. aeruginosa. ANT is also a commonly occurring PAH in natural aquatic environments. It has been included in the US Environmental Protection Agency’s Priority Pollutant List for its genotoxic and immunotoxic properties. In the early stage of the experiment, the lowest concentration (0.02 μg/mL) of ANT, which was selected considering ANT concentrations in lakes in China (Guo et al. 2012), could stimulate M. aeruginosa growth. Wong (2000) found that algal growth was stimulated by low concentrations of 2, 4-D and glyphosate and inhibited at high concentrations. Hormesis, the stimulatory effects caused by low levels of potentially toxic agents (Calabrese 2005), might be responsible for the stimulation of growth by the low level of ANT and other toxicants. High concentrations of ANT could inhibit M. aeruginosa growth in the first 3 days, and alga restored their growth after 6 days of incubation, which was accompanied with a rapid decrease of initial ANT concentrations in the culture media. It was impossible to maintain stable ANT concentrations in the culture media at different incubation times because of inevitable removal of ANT by algal adsorption and absorption, evaporation, and degradation (Hong et al. 2008). High initially applied ANT concentrations decreased significantly after 3 days of incubation, which resulted in algal growth inhibition in the first 3 days and growth restoration in the following incubation time.

It has been found that MCs played important role in enhancing and maintaining the Microcystis colony size by increasing the production of extracellular polysaccharides (Gan et al. 2012). The colony formation of Microcystis provided a competitive advantage over other phytoplankton species (Wu et al. 2007). Increased MC production could also be used as a defense device against zooplankton grazing by inhibiting feeding rate (DeMott 1999). In this study, we found ANT could stimulate MC-LR production in a concentration-dependent manner, suggesting that ANT could be a stimulus of MC production and ANT pollution in natural waters might contribute to the persistence of algal colonies and the dominance of Microcystis. Some previous studies found that there was a positive linear relationship between MC content and the growth of M. aeruginosa under stress (Long et al. 2001; Pan et al. 2008). However, according to our results, intracellular MC concentrations were higher under poorer growth conditions of M. aeruginosa in the early stage of ANT exposure. M. aeruginosa might have different growth responses to various stimulatory factors involved in MC production.

MCs are synthesized non-ribosomally by the thiotemplate function of a large, modular enzyme complex encoded within the 55-kb mcy gene cluster (Pearson et al. 2004). The product of the mcy gene cluster is a large multienzyme complex of mixed polyketide synthase (PKS) and non-ribosomal peptide synthetase (NRPS) modules (Kaebernick et al. 2000; Noguchi et al. 2009).The gene cluster spans 55 kb and comprises ten genes arranged in two gene clusters that are divergently transcribed, mcyA to mcyJ, encoding three peptide synthetases (mcyA, mcyB, and mcyC), a modular polyketide synthase (mcyD), two hybrid enzymes comprising peptide synthetase and polyketide synthase modules (mcyE and mcyG), and enzymes putatively involved in the tailoring (mcyJ, mcyF, and mcyI) and transport (mcyH) of MCs (Tillett et al. 2000). In this study, mcyB and mcyD were chosen as representatives of the microcystin NRPS and PKS genes, respectively. Transporter gene mcyH involved in the intra (or extra)cellular transportation of MCs was also investigated with respect to expression in cells exposed to different concentrations of ANT. This is the first genetic study focusing on the effects of PAHs upon the transcriptional regulation of genes responsible for MC synthesis. The gene expression of mcyB was downregulated by all the tested concentrations of ANT, while gene expressions of mcyD and mcyH were upregulated by higher concentrations (above 0.02 μg/mL) of ANT. We proposed that ANT could affect, eventually modified, the expression of mcy genes, and their transcriptions required different thresholds of ANT to initiate and upregulate. Throughout the experiment, expressions of three key mcy genes in M. aeruginosa were stimulated except mcyB gene expression at day 1. ANT might stimulate MC production via upregulating mcy gene expressions.

In summary, ANT exposure could not only affect the growth of M. aeruginosa but also stimulate MC-LR production by modifying mcy gene expressions. The presence of ANT pollution in natural waters might play a subtle role in the breakout of Microcystis blooms.

References

Calabrese, E. J. (2005). Paradigm lost, paradigm found: the reemergence of hormesis as a fundamental dose response model in the toxicological sciences. Environ Pollut, 138(3), 378–411.

Chen, X. G., Xiang, H. Y., Hu, Y., Zhang, Y., Yang, L. O., & Gao, M. Y. (2014). Fates of Microcystis aeruginosa cells and associated microcystins in sediment and the effect of coagulation process on them. Toxins, 6(1), 152–167.

DeMott, W. R. (1999). Foraging strategies and growth inhibition in five daphnids feeding on mixtures of toxic cyanobacterium and a green alga. Freshw Biol, 42, 263–274.

Dittmann, E., & Wiegand, C. (2006). Cyanobacterial toxins-occurrence, biosynthesis and impact on human affairs. Mol Nutr Food Res, 50(1), 7–17.

Dong, C. D., Chen, C. F., & Chen, C. W. (2012). Determination of polycyclic aromatic hydrocarbons in industrial harbor sediments by GC-MS. Int J Environ Res Public Health, 9(6), 2175–2188.

Downing, T. G., Sember, C. S., Gehringer, M. M., & Leukes, W. (2005). Medium N:P ratios and specific growth rate comodulate microcystin and protein content in Microcystis aeruginosa PCC7806 and M. aeruginosa UV027. Microb Ecol, 49(3), 468–473.

Fiore, M. F., Genuario, D. B., da Silva, C. S. P., Shishido, T. K., Moraes, L. A. B., Cantusio Neto, R., et al. (2009). Microcystin production by a freshwater spring cyanobacterium of the genus Fischerella. Toxicon, 53, 754–761.

Gan, N. Q., Xiao, Y., Zhu, L., Wu, Z. X., Liu, J., Hu, C. L., et al. (2012). The role of microcystins in maintaining colonies of bloom-forming Microcystis spp. Environ Microbiol, 14(3), 730–742.

Gouvea, S. P., Boyer, G. L., & Twiss, M. R. (2008). Influence of ultraviolet radiation, copper, and zinc on microcystin content in Microcystis aeruginosa (Cyanobacteria). Harmful Algae, 7(2), 194–205.

Guo, G. H., Wu, F. C., He, H. P., Zhang, R. Q., & Li, H. X. (2012). Spatial distribution of ecological risk of polycyclic aromatic hydrocarbons in the surface waters of Lake Taihu (in Chinese). Zhong Guo Huan Jing Ke Xue, 32(6), 1032–1039.

Guo, W., Pei, Y. S., Yang, Z. F., & Chen, H. (2011). Historical changes in polycyclic aromatic hydrocarbons (PAHs) input in Lake Baiyangdian related to regional socio-economic development. J Hazard Mater, 187(1-3), 441–449.

Harada, K. I., Tsuji, K., Watanabe, M. F., & Kondo, F. (1996). Stability of microcystins from cyanobacteria-III. Effect of pH and temperature. Phycologia, 35, 83–88.

He, E. Q., Niu, W. M., Wu, Q. G., Zhou, W. J., Yan, L., Zhang, Y. Z., et al. (2011). Establishment of taqMan real-time fluorescence PCR of gene McyA of toxin-producing Microcystis spp (in Chinese). Huan Jing Ke Xue Yu Ji Shu, 34(12), 66–70.

Hoeger, S. J., Schmid, D., Blom, J. F., Ernst, B., & Dietrich, D. R. (2007). Analytical and functional characterization of microcystins [Asp3] MC-RR and [Asp3, Dhb7] MC-RR: consequences for risk assessment. Environ Sci Technol, 41(7), 2609–2616.

Hong, Y. W., Yuan, D. X., Lin, Q. M., & Yang, T. L. (2008). Accumulation and biodegradation of phenanthrene and fluoranthene by the algae enriched from a mangrove aquatic ecosystem. Mar Pollut Bull, 56(8), 1400–1405.

Iredale, R. S., McDonald, A. T., & Adams, D. G. (2012). A series of experiments aimed at clarifying the mode of action of barley straw in cyanobacterial growth control. Water Res, 46(18), 6095–6103.

Kaebernick, M., Neilan, B. A., Börner, T., & Dittmann, E. (2000). Light and the transcriptional response of the microcystin biosynthesis gene cluster. Appl Environ Microbiol, 66(8), 3387–3392.

Kafilzadeh, F. (2015). Distribution and sources of polycyclic aromatic hydrocarbons in water and sediments of the Soltan Abad River, Iran. The Egyptian Journal of Aquatic Research, 41(3), 227–231.

Li, J. W., Shang, X., Zhao, Z. X., Tanguay, R. L., Dong, Q. X., & Huang, C. J. (2010). Polycyclic aromatic hydrocarbons in water, sediment, soil, and plants of the Aojiang River waterway in Wenzhou, China. J Hazard Mater, 173, 75–81.

Livak, K. J., & Schmittgen, T. D. (2001). Analysis of relative gene expression data using real-time quantitative PCR and the 2-△△CT method. Methods, 25, 402–408.

Long, B. M., Jones, G. J., & Orr, P. T. (2001). Cellular microcystin content in N-limited Microcystis aeruginosa can be predicted from growth rate. Appl Environ Microbiol, 67(1), 278–283.

Mohamed, Z. A., & Al-Shehri, A. M. (2013). Grazing on Microcystis aeruginosa and degradation of microcystins by the heterotrophic flagellate Diphylleia rotans. Ecotoxicol Environ Saf, 96, 48–52.

Nikolaou, A. D., Kostopoulou, M., Lofrano, G., & Meric, S. (2009). Determination of PAHs in marine sediments: analytical methods and environmental concerns. Global NEST Journal, 11(4), 391–405.

Matsushima-Nishiwaki, R., Ohta, T., Nishiwaki, S., Suganuma, M., Kohyama, K., Ishiwaka, T., et al. (1992). Liver tumor promotion by the cyanobacterial cyclic peptide toxin microcystin-LR. J Cancer Res Clin Oncol, 118(6), 420–424.

Noguchi, T., Shinohara, A., & Nishizawa, A. (2009). Genetic analysis of the microcystin biosynthesis gene cluster in Microcystis strains from four bodies of eutrophic water in Japan. J Gen Appl Microbiol, 55(2), 111–123.

Pan, X. J., Chang, F. Y., Kang, L. J., Liu, Y. D., Li, G. B., & Li, D. H. (2008). Effects of gibberellin A3 on growth and microcystin production in Microcystis aeruginosa (Cyanophyta). J Plant Physiol, 165(16), 1691–1697.

Pearson, L. A., Hisbergues, M., Börner, B., Dittmann, E., & Neilan, B. A. (2004). Inactivation of an ABC transporter gene, mcyH, results in loss of microcystin production in the cyanobacterium Microcystis aeruginosa PCC 7806. Appl Environ Microbiol, 70(11), 6370–6378.

Rantala, A., Fewer, D. P., Hisbergues, M., Rouhiainen, L., Vaitomaa, J., Börner, T., et al. (2004). Phylogenetic evidence for the early evolution of microcystin synthesis. Proc Natl Acad Sci U S A, 101(2), 568–573.

Renaud, S. L., Pick, F. R., & Fortin, N. (2011). Effect of light intensity on the relative dominance of toxigenic and nontoxigenic strains of Microcystis aeruginosa. Appl Environ Microbiol, 77(19), 7016–7022.

Song, R. F., Wang, G. X., Xu, Y., Shao, J. H., Wang, Z. J., Liu, Y., et al. (2011). Transcriptional response of microcystin biosynthesis gene cluster of Microcystis aeruginosa PCC7806 under Daphnia stress using real-tmie RT-PCR technique (in Chinese). Hu Po Ke Xue, 23(1), 150–154.

Tanabe, Y., Sano, T., Kasai, F., & Watanabe, M. M. (2009). Recombination, cryptic clades and neutral molecular divergence of the microcystin synthetase (mcy) genes of toxic cyanobacterium Microcystis aeruginosa. BMC Evol Biol, 9, 115.

Tillett, D., Dittmann, E., Erhard, M., von Döhren, H., Börner, T., & Neilan, B. A. (2000). Structural organization of microcystin biosynthesis in Microcystis aeruginosa PCC7806: an integrated peptide-polyketide synthetase system. Chem Biol, 7(10), 753–764.

Westhuizen, A. J., & Eloff, J. N. (1985). Effect of temperature and light on the toxicity and growth of the blue-green alga Microcystis aeruginosa (UV-006). Planta, 163(1), 55–59.

Wiedner, C., Visser, P. M., Fastner, J., Metcalf, J. S., Codd, G. A., & Mur, L. R. (2003). Effects of light on the microcystin content of Microcystis strain PCC 7806. Appl Environ Microbiol, 69(3), 1475–1481.

Wong, P. K. (2000). Effects of 2, 4 - D, glyphosate and paraquat on growth, photosynthesis and chlorophyll-a synthesis of Scenedesmus quadricauda Berb 614. Chemosphere, 41, 177–182.

Wu, Z. X., Gan, N. Q., Huang, Q., & Song, L. R. (2007). Response of Microcystis to copper stress - do phenotypes of Microcystis make a difference in stress tolerance? Environ Pollut, 147(2), 324–330.

Xu, Q. J., Chen, W. M., & Gao, G. (2008). Seasonal variations in microcystin concentrations in Lake Taihu, China. Environ Monit Assess, 145(1-3), 75–79.

Zhang, C., Yi, Y. L., Hao, K., Liu, G. L., & Wang, G. X. (2013). Algicidal activity of Salvia miltiorrhiza bung on Microcystis aeruginosa—towards identification of algicidal substance and determination of inhibition mechanism. Chemosphere, 93, 997–1004.

Zhu, X. Z., Kong, H. L., Gao, Y. Z., Wu, M. F., & Kong, F. X. (2012). Low concentrations of polycyclic aromatic hydrocarbons promote the growth of Microcystis aeruginosa. J Hazard Mater, 237–238, 371–375.

Acknowledgments

The financial supports provided by the National Natural Science Foundation of China (Grant No. 31300393), China Postdoctoral Science Foundation (Grant No. 2015T80212, 2014M551013), Project of Tianjin Municipal Science and Technology (Grant No. 16JCYBJC29900, 15ZCZDNC00230), and Modern Aqua-ecology and Health Aquaculture Innovation Team of Tianjin (Grant No. TD12-5018) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bi, X., Dai, W., Zhou, Q. et al. Effect of Anthracene (ANT) on Growth, Microcystin (MC) Production and Expression of MC Synthetase (mcy) Genes in Microcystis aeruginosa . Water Air Soil Pollut 227, 259 (2016). https://doi.org/10.1007/s11270-016-2956-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-016-2956-2