Abstract

Photocatalysis is one of environment-friendly and efficient methods for municipal wastewater disinfection. In this research, two pathogens, Staphylococcus aureus and fecal coliform, were chosen to investigate the disinfection effects of several TiO2 photocatalysts on sewage plant secondary treatment effluent, compared with UV disinfection. The results show that TiO2 species and concentrations, light intensity, light time, and pH all have significant influences on the pathogen deactivation. It was found that the optimum operation parameters were as follows: the P25 commercial TiO2 powder at the concentration of 0.5 g/L, the light intensity of 40 W, and the radiation duration of 20 min. The photocatalyst performed better at either acid or alkaline condition than neutral. The TiO2 photocatalytic deactivation to S. aureus was more effective than the UV.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Wastewater recycling is one of the effective solutions for water shortage in many water-salvage countries; however, waterborne pathogens limit the reusing by infecting the contacting people and threatening human health, especially for developing countries (Rincón and Pulgarin 2004). Pathogens in wastewater and referred disinfections have been severely concerned and comprehensively researched. However, current disinfection technologies are not always satisfied: chlorine disinfection is cheap and historical but generates carcinogenic by-product, such as trihalomethanes and carbon tetrachloride; ozone disinfection is too expensive and causes aldehyde and ketone problems; chlorine dioxide disinfection costs a lot and produces chlorite if overdosed; and UV light disinfection encounters pathogen resurrection. Safe and effective disinfection technology is urgent in wastewater reclamation. TiO2 photocatalysis, as a potential alternative disinfection, is cost-effective and stable without producing any disinfection by-product or secondary pollution. Aqueous TiO2 suspensions have been reported to detoxify pollutants since 1976 (Carey et al. 1976). UV/TiO2 disinfection has also been introduced for almost 20 years (Feitz 1998). This technology can eliminate microorganism and mineralize organic matter by producing hydroxyl (·OH), superoxide anion (O2 −), and other strong oxidizing agents under UV irradiation. However, it was still far from industrial application owing to the photocatalytic reaction kinetics and photoactivity ranges (Qu et al. 2013).

This research employed TiO2 photocatalysis to disinfect secondary effluent from sewage treatment plant. Since the crystal structure and composition of TiO2 affect the disinfection of pathogens, three kinds of TiO2 (P25, Sub-Seeley, TBD-A500) were studied in this research. Staphylococcus aureus and fecal coliform were used as indicators to investigate the optimum parameters of the pilot test. S. aureus is a type of Gram-positive bacteria with thick and tough cell membrane containing 15 to 50 layers of peptidoglycan and teichoic acid (Carneiro et al. 2012). S. aureus could secrete cytotoxic chemical, enterotoxin, causing vomiting, diarrhea, and abdominal pain (Han et al. 2011). Fecal coliform is a type of Gram-negative bacteria with loose cell membrane compromised of two to three layers of peptidoglycan, which is usually used as pathogen indicator reflecting the water quality (Elghniji et al. 2012; Hofer and Penner 2011). The different inactivation effect was also compared for both pathogens.

2 Materials and Methods

2.1 Instruments and Reagents

Incubator (SPX-100B-Z) was made by Far Right Instrument Co., Ltd. (Shanghai, China); portable electric pressure steam sterilizer (YXOG02) was manufactured by Andhra Medical Technology Co., Ltd. (Zibo, China); electronic balance (CP114) was manufactured by Ohaus Instrument Co., Ltd. (Shanghai, China); High-speed centrifuge (TG16-WS) was manufactured by Gordon-centrifuge machines Ltd. (Changsha, China); multipurpose pump circulating water (SHK-III) was manufactured by Elcoteq Experimental Equipment Co. (Zhengzhou, China); electromagnetic air compressor (ACO-388D) was made by Haley Group Co., Ltd (Chaozhou, China); optical microscope (XSP-4C) was manufactured by Miriam Round Optical Instrument Co. (Shanghai, China); spectrophotometer (UV-3200) was from the US Spectrum Up Instrument Co., Ltd. (Shanghai, China); filter (pore size of 0.45 μm, with a diameter of 50 mm) was purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China).

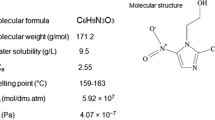

Malachite green, disodium hydrogen phosphate, citric acid, magenta, sodium sulfite, ethanol, and commercial TiO2 (P25, Sub-Seeley, TBD-A500) were purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). The average particle size of P25 was 21 nm (TiO2 > 99.5 %), consisted of 80 % of anatase and 20 % of rutile. The Sub-Seeley was a mixture of TiO2 crystals with the average particle diameter of 10 nm (TiO2 > 92 %). The TBD-A500 was anatase (TiO2 > 98.5 %) with the average particle diameter of 500 nm.

2.2 Experimental Methods

2.2.1 Photocatalytic Inactivation Experiments

The quality of the raw water is shown in Table 1, sampled from the second effluent from the water stations after sand filter at Shangdong Jianzhu University. Eight liters of raw water with certain amount of TiO2 was placed between the double layers of the reactor (shown in Fig. 1), and the UV lamp was set in the center of the cylinder. Compressor was started to aerate and mix before turning on the UV lamp for the photocatalytic reaction. The water was pumped from the bottom regularly and sampled from the outlets on the sidewall. If not specified, the concentration of TiO2 was 0.5 g/L, the UV light intensity was 40 W, the aeration rate was 0.18 L/h, and the type of TiO2 was TBD-A500.

2.2.2 Analytical Methods

Hydroxyl (·OH) was measured with malachite green method (Zeng et al. 2010); (Paz 2010); S. aureus was measured with Baird-Parker plate count method (Szczawiński et al. 2011); fecal coliform was measured with Quanti-Tray/2000 (IDEXX, USA) rapid method (Hernández-García et al. 2008).

3 Results and Discussions

3.1 Effect on the Generation of Hydroxyl

As shown in Fig. 2, the generation of ·OH was relatively high when the concentration of TiO2 were lower (0.01 or 0.05 g/L). It could attribute to the blockage of the ultraviolet light when the concentration of TiO2 was high. Ineffective penetration of the UV light source led to more electrons formed on the surface of TiO2 because of the overwhelming excitation (e−) than holes (h+) under this situation, resulting in the lower concentration of ·OH (Wang et al. 2008). Furthermore, the impurities in the raw water were adsorbed on the TiO2 and consumed much ·OH through the photocatalytic oxidation reaction. However, when the concentration of TiO2 was low, meaning of less surface area, the total ·OH could be insufficient to treat the large amount of wastewater. The production of ·OH, to some extent, fluctuated at the beginning 10 min but tended to be steady after then, indicating that the generation did not vary much when no microbes and pollutants existed along reaction time.

3.2 The Impact of Different Type of TiO2

The results of three kinds of TiO2 on fecal coliform sterilization are shown in Fig. 3, indicating that all removal efficiencies were more than 97 % with the highest of P25 and the lowest of TBD-A500. It has been reported that besides the crystallite size and specific surface area, the crystal structure and electron/hole distribution of TiO2 could influence the catalysis (Chong et al. 2010). Anatase was thought to be the most photocatalytically active modification (Hofer and Penner 2011). The anatase content in P25 was higher than that in Sub-Seeley, favoring the photocatalytical disinfection. Although TBD-A500 was also mostly composed of anatase, particle size was much larger than others, carrying out the lowest removal efficiency. However, due to the cheaper cost and easier recovery of larger crystallite, TBD-A500 was considered as the most potential sterilization catalyst for fecal coliform and used in the following tests of this research.

3.3 Effect of TiO2 Concentration

The concentration effect is shown in Fig. 4 for inactivation of both pathogens. The remaining number of S. aureus decreased sharply with the increasing dosing of TiO2 until 0.5 g/L when the remaining bacteria were minimum (11 colonies/mL) and rose slightly when overdosed. It was explained that the light could not be effectively utilized when less than 0.5 g/L, while the photons saturated the catalyst when more than 0.5 g/L, causing no significant change of active groups produced on the catalyst surface, and the UV light was scattered due to the increasing turbidity of solution, resulting in the slight decrease of the catalysis efficiency (Hu et al. 2007). The minimum remaining of fecal coliform seemed to appear at dosing of 0.5 g/L, but the sterilization efficiency did not significantly shift as S. aureus. For example, it was hard to differentiate the effect between dosing of 0.005 and 0.5 g/L, which demonstrated that fecal coliform was Gram-negative and sensitive to photolysis. In summary, 0.5 g/L of TiO2 was the optimum to deactivate both pathogens synchronously in this research.

3.4 Effect of UV Light Intensity

Figure 5 shows the influence of different light intensity on the S. aureus. The results show that the inactivation increased with the illumination time and the remaining number of bacteria tent to zero after 40-min reaction. The disinfection favored 40-W intensities, meaning that either too high or low intensity could not assist the TiO2 photocatalytic reaction, which also matched the previous report (Kumar and Devi 2011). Usually, higher intensity means more photons contact with the catalyst, resulting in high-energy electron–hole pairs and improving photocatalysis efficiency (Li et al. 2006). The trend of the logarithmic curves could be explained as follows: at the beginning, the reaction rate between generated ·OH and the pathogen was accelerated because of the high concentration of S. aureus; as time goes, the reaction was slowed down due to the consumption of bacteria.

3.5 Effect of UV Light Time

As shown in Fig. 6, the S. aureus inactivation rate was 83 % after 0.5 min, 94 % after 1 min, 99 % after 8 min, and 99.91 % after 20 min, when the remaining bacteria number was only 3/mL, close to complete disinfection. For fecal coliform, the inactivation was 95 % after 1 min, 99.2 % after 5 min, and 99.9 % after 10 min, when the remaining bacteria number is less than 2/mL. Therefore, 20-min should be chosen as the disinfection time to completely inactivate both pathogens.

3.6 Effect of pH Value

The pH value can influence TiO2 photocatalysis in two ways: (1) affecting the catalysts surface properties and pollutant adsorption on the surface; (2) affecting the formation rate of active substances and the photocatalytic reaction (Michael et al. 2010). TiO2 is a kind of amphoteric oxide catalyst, with isoelectric point of approximately 6.6, which means that surface negative charge TiO2 − or positive charge TiO2 + forms when pH increases or decreases (Muneer et al. 2001).

As shown in Fig. 7, with 5-min irradiation, pH value affected fecal coliform more than S. aureus. The reason may attribute to the different structure of cell membrane. Both have different ability to attach ·OH under different pH values, but natural solution was not favored for either. Mechanisms for the bactericidal disinfection of TiO2 photocatalysis were reported that the radicals oxidize the lipid of cell membranes and, consequently, damage the cellular respiration and kill the bacteria (Blake et al. 1999).

3.7 Comparison Between TiO2 Photocatalysis and UV Disinfection

As shown in Fig. 8, TiO2 photocatalytic inactivation was better than UV disinfection for both pathogens. Dunford reported that the ·OH produced by TiO2 photocatalysis could directly damage DNA and penetrate the thick cell membrane, which could resist the irradiation of UV (Dunford et al. 1997). The thick cell membrane of S. aureus has certain resistance to direct UV irradiation, but not to the ·OH. Since fecal coliform belongs to Gram-negative bacteria with thin cell wall, the difference was not significant as S. aureus.

4 Conclusions

-

1.

TiO2 photocatalytic inactivation for S. aureus and fecal coliform can be affected by the kinds and concentrations of TiO2, UV light intensity, reaction time, and pH value. The results showed the optimum photocatalytic inactivation operation parameters in this research: TiO2 type P25, TiO2 concentration of 0.5 g/L, UV light intensity of 40 W, and reaction time of 20 min. For both pathogens, acidic and alkaline conditions were better than neutral for the photocatalysis disinfection.

-

2.

For Gram-positive bacteria such as S. aureus, UV disinfection needs longer reaction time to achieve the same inactivation effect as TiO2 photocatalysis.

References

Blake, D. M., Maness, P.-C., Huang, Z., Wolfrum, E. J., Huang, J., & Jacoby, W. A. (1999). Application of the photocatalytic chemistry of titanium dioxide to disinfection and the killing of cancer cells. Separation and Purification Methods, 28(1), 1–50.

Carey, J. H., Lawrence, J., & Tosine, H. M. (1976). Photodechlorination of PCB’s in the presence of titanium dioxide in aqueous suspensions. Bulletin of Environmental Contamination and Toxicology, 16(6), 697–701.

Carneiro, J. O., Teixeira, V., Azevedo, S., Fernandes, F., & Neves, J. (2012). Development of photocatalytic ceramic materials through the deposition of TiO2 nanoparticles layers. In Journal of Nano Research, 18, 165–176. Trans Tech Publ.

Chong, M. N., Jin, B., Chow, C. W. K., & Saint, C. (2010). Recent developments in photocatalytic water treatment technology: a review. Water Research, 44(10), 2997–3027.

Dunford, R., Salinaro, A., Cai, L., Serpone, N., Horikoshi, S., Hidaka, H., et al. (1997). Chemical oxidation and DNA damage catalysed by inorganic sunscreen ingredients. FEBS Letters, 418(1), 87–90.

Elghniji, K., Soro, J., Rossignol, S., & Ksibi, M. (2012). A simple route for the preparation of P-modified TiO2: effect of phosphorus on thermal stability and photocatalytic activity. Journal of the Taiwan Institute of Chemical Engineers, 43(1), 132–139.

Feitz, A. J. (1998). Photocatalytic oxidation of a cyanobacterial toxin (microcystin-LR). University of New South Wales.

Han, C., Pelaez, M., Likodimos, V., Kontos, A. G., Falaras, P., O’Shea, K., et al. (2011). Innovative visible light-activated sulfur doped TiO2 films for water treatment. Applied Catalysis B: Environmental, 107(1), 77–87.

Hernández-García, H., López-Arjona, H., Rodríguez, J. F., & Enríquez, R. (2008). Preliminary study of the disinfection of secondary wastewater using a solar photolytic-photocatalytic reactor. Journal of Solar Energy Engineering, 130(4), 041004.

Hofer, M., & Penner, D. (2011). Thermally stable and photocatalytically active titania for ceramic surfaces. Journal of the European Ceramic Society, 31(15), 2887–2896.

Hu, C., Guo, J., Qu, J., & Hu, X. (2007). Photocatalytic degradation of pathogenic bacteria with AgI/TiO2 under visible light irradiation. Langmuir, 23(9), 4982–4987.

Kumar, S. G., & Devi, L. G. (2011). Review on modified TiO2 photocatalysis under UV/visible light: selected results and related mechanisms on interfacial charge carrier transfer dynamics. The Journal of Physical Chemistry. A, 115(46), 13211–13241.

Li, Y., Li, X., Li, J., & Yin, J. (2006). Photocatalytic degradation of methyl orange by TiO2-coated activated carbon and kinetic study. Water Research, 40(6), 1119–1126.

Michael, I., Hapeshi, E., Michael, C., & Fatta-Kassinos, D. (2010). Solar Fenton and solar TiO2 catalytic treatment of ofloxacin in secondary treated effluents: evaluation of operational and kinetic parameters. Water Research, 44(18), 5450–5462.

Muneer, M., Theurich, J., & Bahnemann, D. (2001). Titanium dioxide mediated photocatalytic degradation of 1, 2-diethyl phthalate. Journal of Photochemistry and Photobiology A: Chemistry, 143(2), 213–219.

Paz, Y. (2010). Application of TiO2 photocatalysis for air treatment: patents’ overview. Applied Catalysis B: Environmental, 99(3), 448–460.

Qu, X., Alvarez, P. J. J., & Li, Q. (2013). Applications of nanotechnology in water and wastewater treatment. Water Research, 47(12), 3931–3946.

Rincón, A.-G., & Pulgarin, C. (2004). Field solar E. coli inactivation in the absence and presence of TiO 2: is UV solar dose an appropriate parameter for standardization of water solar disinfection? Solar Energy, 77(5), 635–648.

Szczawiński, J., Tomaszewski, H., Jackowska-Tracz, A., & Szczawińska, M. (2011). Survival of Staphylococcus aureus exposed to UV radiation on the surface of ceramic tiles coated with TiO2. Polish Journal of Veterinary Sciences, 14(1), 41–46.

Wang, Y., Cui, J.-Y., Hu, L., Wang, J.-G., & Mu, K.-G. (2008). Photocatalytic degradation of organophosphorous pesticides over aqueous TiO2 suspensions [J]. Journal of China Agricultural University, 2, 015.

Zeng, Z., Peng, C., Hong, Y., Lu, Y., & Wu, J. (2010). Fabrication of a photocatalytic ceramic by doping Si−, P−, and Zr− modified TiO2 nanopowders in glaze. Journal of the American Ceramic Society, 93(10), 2948–2951.

Acknowledgments

Fundings for this work were provided by the National Natural Science Foundation of China (No. 21407097), the Shandong Science and Technology Development Program (No. 2011GSF11703), and the Shandong Natural Science Foundation (No. 2014ZRB01991).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Jia, P., Ding, N. et al. Photocatalytical Deactivation of Pathogens for Municipal Wastewater Reusing. Water Air Soil Pollut 226, 333 (2015). https://doi.org/10.1007/s11270-015-2619-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-015-2619-8