Abstract

The degradation of methyl orange (MO) in aqueous solution by microwave irradiation in the presence of granular-active carbon (GAC) was investigated. It was found that a synergistic rather than an additive effect of microwave irradiation and GAC contributes to the high-degradation efficiency. The ultraviolet and visible spectrum (UV–vis), infrared spectroscopy (IR), and scanning electron microscopy (SEM) measurements were conducted to trace the MO degradation process. It was demonstrated that the decrease in performance of GAC after repetitive use is largely attributed to the adsorption of some intermediate products on the surface of GAC. The regeneration of the spent GAC under microwave radiation was also investigated. The results show that the activity of spent GAC can be effectively recovered by microwave radiation and 74.1 % of its initial activity remains after six reaction cycles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Azo dyes are the largest class of dyes commercially used in textile industry and have become one of the most widespread pollutants in the effluents (Türgay et al. 2011). It has been reported that some of these dyes are toxic, mutagenic, and carcinogenic compounds, which show resistance to biological and even chemical degradation, making them hazardous for the environment even at low concentration. Much effort has been devoted to finding effective and economical routes suitable for the removal of such a large number of pollutants derived from the textile effluents. As a result, a wide variety of advanced oxidation processes such as Fenton (Rodríguez et al. 2010), photo-Fenton (Macías-Sánchez et al. 2011), ozonation (Koch et al. 2002), and photocatalysis (Dong et al. 2012; Ahmed et al. 2011) have been investigated to treat the wastewater containing diverse synthetic dyes. Although these advanced oxidation processes have been proved to exhibit good performance for treatment of the dye-related chemicals, the complexity, high chemical consumption, and relatively high costs constitute major barriers for their large-scale applications.

Microwave irradiation can produce efficient internal heating by direct coupling of microwave energy with the molecules of solvents, reagents, or catalysts presented in the reaction mixture, making it an interesting alternative heating method in chemistry and industry. During the past decade, microwave has been experimentally tested to treat wastewater containing various organic pollutants either alone or coupled with different advanced oxidation processes (Remya and Lin 2011). Under microwave irradiation, the polar molecule dissolved in solution will rotate rapidly to bring about thermal effect; and consequently, selective heating, which could act only to the desired points, is feasible by means of microwave irradiation (Bosske et al. 1992). Additionally, microwave irradiation can change the thermodynamics function, weaken the chemical bond intensities of various molecules, and reduce the activation energy of reaction system (Quan et al. 2004).

Granular-active carbon (GAC) has high porosities, from macro to microporous structures, render them the most efficient adsorbents to trap dyes and other organic compounds (Pelekani and Snoeyink 2000; Wang et al. 2005). Being an excellent microwave absorber, GAC has recently been used as a catalyst for microwave-assisted degradation of wastewater. It has been demonstrated that the combination of microwave irradiation with activated carbon is highly effective for the degradation of phenolic compound (Polaert et al. 2005; Bo et al. 2006) and azo dyestuff-congo red in aqueous solution (Zhang et al. 2007). However, the stability and reusability of GAC during this combined process will need to be considered in order to determine its practicability for the treatment of the high volumes of wastewater. As was noticed in previous works (Cordero et al. 2008; Santos et al. 2005), some changes in the physicochemical properties of activated carbon have taken place during the wet oxidation process, which subsequently influenced the catalytic behavior of activated carbon. It was found that activated carbon exposed to oxygen can react and cause carbon loss during catalytic wet air oxidation process (Stüber et al. 2005). To date, few reports have been published concerning the cycling stability of GAC during the microwave-assisted degradation process.

In this work, methyl orange (MO) was selected as a model azo dye to examine the performance of GAC for organic pollutant degradation under microwave irradiation. The performance of repetitive use and regeneration of GAC will be investigated and analyzed.

2 Experimental

2.1 Chemicals

Commercial GAC (analytical grade, 1,055 m2/g of BET area) was purchased from Shenyang Chemical Co., China. Methyl orange (4-[4-(dimethylamino) phenylazo] benzenesulfonic acid) was purchased from Regent Chemicals. Sodium hydroxide was purchased from Tanjin Bodi Chemical Reagent. Sulfuric acid was purchased from Yantai Sanhe Chemical Reagent. All chemicals mentioned above are of analytical grade.

2.2 Instruments

All ultraviolet and visible spectrum (UV–vis) absorption spectra were carried out using a spectrophotometer (UV752, Shanghai Yoke Instrument. Co., Ltd, China). Fourier transform infrared (FTIR) spectroscopy was carried out using a spectrometer (Tensor 27, Bruker, Germany). The morphology of the GAC was studied by scanning electron microscopy (SEM) (JSM 6700 F, JEOL, Japan) operating at 8 kV.

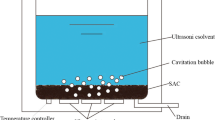

2.3 Degradation of Methyl Orange

The microwave-assisted degradation experiment was carried out in a modified microwave apparatus (MM721AC8-PW, Meide household electrical appliances group Co., Ltd., China) with a frequency of 2,450 MHz and a maximum output power of 700 W. All the experiments were conducted in batch mode. In a typical reaction, 50-mL MO aqueous solution (20 mg/L) and GAC were placed in a quartz beaker, which was then put into the microwave oven and subjected to microwave irradiation at varied power levels for 8 min. The pH of the reaction mixture was adjusted by adding 0.1-M HCl or 0.1-M NaOH solutions.

2.4 Analysis

After degradation experiment, the treated solution was filtered to remove the GAC. The MO concentration (C) in solution can be determined by measuring the absorbance (A) at 462 nm using a TU 1810 spectrophotometer. A calibration curve was obtained by using the standard MO solutions with known concentrations (A = 0.0024 + 0.07458C, R = 0.99991). The calibration curve of standard MO solutions was used to estimate the percentage of degradation = [(C 0 − C)/C 0] × 100 %, where C 0 and C are the initial and instant (at reaction time t) concentrations of MO, respectively.

3 Results and Discussion

3.1 Comparison of MO Degradation Efficiencies in Different Treatment Processes

To investigate the effects of microwave irradiation and GAC on the MO degradation efficiency, several contrastive experiments were carried out at the same reaction time of 8 min. Table 1 shows the MO degradation efficiency in these different treatment processes. It was found that negligible degradation efficiency was obtained when the MO aqueous solution was exposed to microwave irradiation, indicating that the energy of microwave at a frequency of 2.45 GHz is not enough to destroy any bonds of MO. A degradation efficiency of 14.7 % was gained after addition of GAC to the MO aqueous solution at ambient temperature as a result of adsorption of MO molecules on the surface of GAC. In the presence of GAC, the degradation efficiency of MO increased to 54.8 % by heating the system with electric jacket maintained at 90 °C, which is possibly ascribed to the speeding adsorption of MO molecules under high temperature. However, the microwave irradiation can induce much higher degradation efficiency than conventional heating. At microwave power of 539 W, this combined process can produce as high as 98.3 % degradation efficiency, suggesting a synergistic effect of microwave irradiation and GAC on the degradation of MO. It has been suggested that “hot spots” can form on the surface of GAC under microwave irradiation and thus promote the oxidation of organic pollutants (Zhang et al. 2007).

3.2 UV–vis Spectra of MO Solution

Figure 1 displays the UV–vis absorption spectra of the original and treated MO solutions (20 mg/L). As shown in Fig. 1a, the original MO aqueous solution gives two absorption peaks at 460 and 290 nm corresponding to azo band (−N = N−) and benzene rings in MO molecule, respectively. After degradation for 8 min, the peak at 460 nm almost totally disappeared, indicating the cleavage of azo band. The intensity of the peak centered at 290 nm significantly reduced but did not disappear, implying the benzene ring was hard to be destroyed. It was noted that a new band centered at 335 nm appeared. Some authors have proposed that five main possible degradation products containing benzene rings formed during photocatalytic degradation of MO (Fan et al. 2012). Therefore, the new band, centered at 335 nm, demonstrates the formation of benzene-containing intermediate products during the degradation process.

3.3 FT-IR Analysis of GAC

Infrared spectroscopy can provide information on the chemical structure of the adsorbent and/or catalyst materials. To track the degradation behaviors of MO, the IR spectra of the original GAC and spent GAC were recorded (Fig. 2). The characteristic bands are observed within two ranges: 1,640–1,340 and 1,300–1,000 cm−1. The former indicates the presence of C–O- and N–O-containing structures. The peak centered at 1,553 cm−1 may be ascribed to highly conjugated C = O stretching, C–O stretching in carboxylic groups, and carboxylate moieties (El-Hendawy 2003). The broad band between 1,300 and 900 cm−1 in all the samples has a maximum at 1,100 cm−1, which can be assigned to C–O stretching and O–H bending modes of alcoholic, phenolic, and carboxylic groups (Lua and Guo 2001; Pradhan and Sandlea 1999). Shoulder bands at lower wavenumbers (790, 660 cm−1) may be related to out-of-plane bending modes. After MO adsorption, a strong absorption band was observed at around 3,400 cm−1 and this is assigned to carboxylic group O–H stretching (Fig. 2b). It was reported that the FTIR spectra of control MO display stretching vibrations of S = O at 624 and 1,202 cm−1, stretching vibration of C = C bond at 1,121 cm−1 and N = N stretching of azo group at 1,607 cm−1 (Goel et al. 2012). However, no characteristic peaks of MO were found in the IR spectrum of GAC experienced adsorption in MO solution possibly due to its concentration being too low to be detected using FTIR. The appearance of several new peaks centered at 1,387; 1,464; 1,735; 2,920; and 2,851 cm−1 after microwave degradation test indicates the generation of intermediates (see Fig. 2c). The peak appearing at 1,735 cm−1 is due to asymmetric stretching of N–H bond, while the peak appearing at 1,387 cm−1 is ascribed to N–O stretching vibration and N–H bending vibration (Liu and Sun 2007). Combined with FTIR measurement results, it is reasonable to speculate that various intermediate products can generate during the MO degradation process.

3.4 Repetitive Uses of GAC for Microwave Degradation of MO

To study the performance of GAC during long-term use, the effect of repetitive use on MO degradation efficiency was investigated under the optimal conditions. The spent AC was collected after the degradation test and utilized for the next reaction cycle under the same experimental conditions. It can be found from Fig. 3 that the performance of GAC decreases remarkably after several cycles of reaction and only 62.7 % of its initial activity was obtained after four cycles. Decreased adsorption capacities of GAC after repetitive uses have been reported in previous studies (Jou and Wu 2008). It is generally suggested that an adverse impact on the porous structure due to long-term exposure of GAC under microwave radiation and incomplete removal of the oxidation products contribute to the loss of adsorption capacities of GAC (Ania et al. 2004; Liu et al. 2007).

Figure 4 presents the surface morphology of GAC before and after MO degradation test. Compared with the original GAC (Fig. 4a, c), it could be seen that some adsorbate (mostly the intermediates) remained on the surface of spent GAC, leading to significant decrease in the number of pores (Fig. 4b, d). Obviously, the adsorption of residual intermediate products on the surface of GAC after degradation reaction will occupy some active sites and prevent the adsorption of MO in the next degradation test cycle, thus resulting in decreased activity.

3.5 Effect of Regeneration on the Performance of Spent GAC

To improve the repetitive performance of GAC, a regeneration procedure was adopted before the successive degradation reactions. In recent years, microwaves have been applied successfully for the regeneration of GAC (Yuen and Hameed 2009). However, the most researches are focused on the effect of microwave regeneration on the adsorption performance of exhausted GAC. Here, we investigate the influence of microwave regeneration on the performance of GAC for MO degradation. After each test cycle, the spent GAC was regenerated by immersing it in water and subsequently exposing to microwave irradiation at a power of 385 W for 2 min. It was noted that the performance of GAC can be effectively recovered through microwave regeneration treatment. As noted from Fig. 5, the MO degradation efficiency remains 72.9 % after six reaction cycles, corresponding to 74.1 % of its initial activity, this is higher than that exhibited by unregenerated GAC after two cycles. As shown in Fig. 2d, the IR characteristic peaks of intermediates disappear after regeneration by subjecting the spent GAC to microwave irradiation. It has been confirmed that the combination of microwave with GAC can generate hot-spot (high temperature) on the surface of GAC (Horikoshi et al. 2011; Remya and Lin 2011). Therefore, the higher degradation efficiency of organic pollutants during combined microwave and GAC process is due to high-temperature oxidation. Of course, the contribution of adsorption to the removal of MO cannot be excluded. Obviously, the residual intermediate species on the surface of GAC would be mostly oxidized by ambient oxygen at high temperature during microwave regeneration process. It was found that a considerable decrease in the specific surface area and specific pore volume occurred for the regenerated GAC samples due to the adverse impact of microwave radiation on the porous structure (Liu et al. 2012). In addition, the GAC can also become damaged to some extent during microwave degradation reaction. As a consequence, the decrease in performance of GAC for microwave degradation of MO is inevitable.

4 Conclusions

The high-efficient degradation of MO in aqueous solution was realized by microwave irradiation in the presence of GAC. After degradation, the azo linkage was almost totally cleaved but benzene group could only be partly decomposed, leading to the formation of some benzene-containing products. The adsorption of residual intermediate products on the surface of GAC after degradation reaction can occupy some active sites and prevent the adsorption of MO in the subsequent test cycle, thus resulting in the decreased repetitive performance. Using microwave radiation regeneration method, the activity of spent GAC can be effectively recovered, making it suitable to successive use. However, the deterioration in the repetitive performance of GAC is inevitable due to the structure damages under microwave irradiation during reaction and regeneration processes.

References

Ahmed, S., Rasul, M. G., Martens, W. N., Brown, R., & Hashib, M. A. (2011). Advances in heterogeneous photocatalytic degradation of phenols and dyes in wastewater: a review. Water, Air, & Soil Pollution, 215, 3–29.

Ania, C. O., Menendez, J. A., Parra, J. B., & Pis, J. J. (2004). Microwave-induced regeneration of activated carbons polluted with phenol. A comparison with conventional thermal regeneration. Carbon, 42, 1383–1387.

Bo, L. L., Quan, X., Chen, S., Zhao, H. M., & Zhao, Y. Z. (2006). Degradation of p-nitrophenol in aqueous solution by microwave assisted oxidation process through a granular ACP fixed bed. Water Research, 40, 3061–3068.

Bosske, J. H., Cooper, R. F., & Dobson, I. (1992). Mechanisms for nonthermal effects on ionic mobility during microwave processing of crystalline solids. Journal of Materials Research, 7, 495–501.

Cordero, T., Rodríguez-Mirasol, J., Bedia, J., Gomis, S., Yustos, P., García-Ochoa, F., et al. (2008). Activated carbon as catalyst in wet oxidation of phenol: effect of the oxidation reaction on the catalyst properties and stability. Applied Catalysis B: Environmental, 81, 122–131.

Dong, C. S., Zhong, M. L., Huang, T., Ma, M. X., Wortmann, D., Brajdic, M., et al. (2012). Photodegradation of methyl orange under visible light by micro-nano hierarchical Cu2O structure fabricated by hybrid laser processing and chemical dealloying. ACS Applied Materials & Interfaces, 3, 4332–4338.

El-Hendawy, A. A. (2003). Influence of HNO3 oxidation on the structure and adsorptive properties of corncob-based activated carbon. Carbon, 41, 713–722.

Fan, J., Hu, X. Y., Xie, Z. G., Zhang, K. L., & Wang, J. J. (2012). Photocatalytic degradation of azo dye by novel Bi-based photocatalyst Bi4TaO8I under visible-light irradiation. Chemical Engineering Journal, 179, 44–51.

Goel, A., Bhatt, R., & Rani, N. (2012). Removal of methyl orange, an azo dye, using oxidative degradation by hexacyanoferrate (III) ions. Discovery Science, 2, 32–36.

Horikoshi, S., Osawa, A., Abe, M., & Serpone, N. (2011). On the generation of hot-spots by microwave electric and magnetic fields and their impact on a microwave-assisted heterogeneous reaction in the presence of metallic Pd nanoparticles on an activated carbon support. Journal of Physical Chemistry C, 115, 23030–23035.

Jou, C. J., & Wu, C. R. (2008). Granular activated carbon coupled with microwave energy for treating pentachlorophenol-containing wastewater. Environmental Progress, 27, 111–116.

Koch, M., Yediler, A., Lienert, D., Insel, G., & Kettrup, A. (2002). Ozonation of hydrolyzed azo dye reactive yellow 84 (Cl). Chemosphere, 46, 109–113.

Liu, Y., & Sun, D. Z. (2007). Development of Fe2O3-CeO2-TiO2/γ-Al2O3 as catalyst for catalytic wet air oxidation of methyl orange azo dye under room condition. Applied Catalysis B: Environmental, 72, 205–211.

Liu, X. T., Yu, G., & Han, W. Y. (2007). Granular activated carbon adsorption and microwave regeneration for the treatment of 2,4,5-trichlorobiphenyl in simulated soil-washing solution. Journal of Hazardous Materials, 147, 746–751.

Liu, Q. S., Wang, P., Zhao, S. S., & Zhang, W. (2012). Treatment of an industrial chemical waste-water using a granular activated carbon adsorption-microwave regeneration process. Journal of Chemical Technology and Biotechnology, 87, 1004–1009.

Lua, A. C., & Guo, J. (2001). Microporous oil-palm-shell activated carbon prepared by physical activation for gas-phase adsorption. Langmuir, 17, 7112–7117.

Macías-Sánchez, J., Hinojosa-Reyes, L., Guzmán-Mar, J. L., Peralta-Hernández, J. M., & Hernández-Ramírez, A. (2011). Performance of the photo-Fenton process in the degradation of a model azo dye mixture. Photochemical & Photobiological Sciences, 10, 332–337.

Pelekani, C., & Snoeyink, V. L. (2000). Competitive adsorption between atrazine and methylene blue on activated carbon: the importance of pore size distribution. Carbon, 38, 1423–1436.

Polaert, I., Estel, L., & Ledoux, A. (2005). Microwave-assisted remediation of phenol waste water on activated charcoal. Chemical Engineering Science, 60, 6354–6359.

Pradhan, B. K., & Sandlea, N. K. (1999). Effect of different oxidizing agent treatments on the surface properties of activated carbons. Carbon, 37, 1323–1332.

Quan, X., Liu, X. T., Bo, L. L., Chen, S., Zhao, Y. Z., & Cui, X. Y. (2004). Regeneration of acid orange 7-exhausted granular activated carbons with microwave irridiation. Water Research, 38, 4484–4490.

Remya, N., & Lin, J. G. (2011). Current status of microwave application in wastewater treatment—a review. Chemical Engineering Journal, 166, 797–813.

Rodríguez, A., Ovejero, G., Sotelo, J. L., Mestanza, M., & García, J. (2010). Heterogeneous Fenton catalyst supports screening for mono azo dye degradation in contaminated wastewaters. Industrial & Engineering Chemistry Research, 49, 498–505.

Santos, A., Yustos, P., Cordero, T., Gomis, S., Rodríguez, S., & García-Ochoa, F. (2005). Catalytic wet oxidation of phenol on active carbon: stability, phenol conversion and mineralization. Catalysis Today, 102–103, 213–221.

Stüber, F., Font, J., Fortuny, A., Bengoa, C., Eftaxias, A., & Fabregat, A. (2005). Carbon materials and catalytic wet air oxidation of organic pollutants in wastewater. Topics in Catalysis, 33, 3–50.

Türgay, O., Ersöz, G., Atalay, S., Fross, J., & Welander, U. (2011). The treatment of azo dyes found in textile industry wastewater by anaerobic biological method and chemical oxidation. Separation and Purification Technology, 79, 26–33.

Wang, S., Zhu, Z. H., Coomes, A., Haghseresht, F., & Lu, G. Q. (2005). The physical and surface chemical characteristics of activated carbons and the adsorption of methylene blue from wastewater. Journal of Colloid and Interface Science, 284, 440–446.

Yuen, F. K., & Hameed, B. H. (2009). Recent developments in the preparation and regeneration of activated carbons by microwaves. Advances in Colloid and Interface Science, 149, 19–27.

Zhang, Z. H., Shan, Y. B., Wang, J., Ling, H. J., Zang, S. L., Gao, W., et al. (2007). Investigation on the rapid degradation of congo red catalyzed by activated carbon powder under microwave irradiation. Journal of Hazardous Materials, 7, 325–333.

Acknowledgments

The work was supported by Shandong Provincial Natural Science Foundation, China (no. ZR2012EEM029).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, D., Cheng, F., Zhang, Y. et al. Degradation of Methyl Orange in Aqueous Solution by Microwave Irradiation in the Presence of Granular-Activated Carbon. Water Air Soil Pollut 225, 1983 (2014). https://doi.org/10.1007/s11270-014-1983-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-014-1983-0