Abstract

Several studies related to zero-valent iron (ZVI), which is employed for water remediation, have been made during the last years. It was found in the literature that the tests made with ZVI in situ, especially for groundwater remediation, were performed using ZVI and nano zero-valent iron (nZVI) as well. Particles usually are used like a “trench-and-fill” installation. In this arrangement, ZVI or nZVI is disposed in the contaminated areas, applied alone or mixed with other materials. The aim of the current work is to evaluate the use of nZVI, which is synthesized in laboratory, for copper ion removal in aqueous solution. The present study will serve like a base focusing, in a future stage, on the use of nZVI on groundwater remediation. For this purpose, commercial ZVI particles were also tested in order to compare the removal behavior. During this study, a relation between the solution characteristic (pH, ion concentration) and the surface purity of the iron particles was found. This relation generally is not reported in the literature. Finally, the copper removal was satisfactory with ZVI and nZVI.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In the last decade, several studies have been performed in order to characterize and synthesize metal nanoparticles (NPs). Several NPs of noble metals like silver and gold are being synthesized and tested, due to its optical electronic, catalytic, and magnetic properties. These properties are very different if compared in the macro and the nano magnitudes. They are in the nanoscale magnitude. According to the literature, the uses of NPs of noble metals are focused on applications in several fields. For example, they have been tested in communication and microelectronics areas, as well as in medical fields, like diagnostic and therapeutic fields. For these uses, small amounts of NPs are needed and its success has a strong relation with their size and shape. Moreover, the NPs of non-noble metals, such as that of the zero-valent iron (ZVI), have also been widely studied, mainly for their application in the field of environmental remediation (O’Carroll et al. 2013). Thus, they have been tested for treating contaminated water sources and therefore for their application on a large scale. Furthermore, one technique in which ZVI is used for environmental remediation is the permeable reactive barrier (BPR) (Sasaki et al. 2008; Di Natale et al. 2008; Bennett et al. 2010). ZVI has been the most widely used reactive material in the BPRs, interacting with the contaminant and converting it to a nontoxic or immobilized form (Rao et al. 2009; Bennett et al. 2010; Li and Benson 2010; Matthew et al. 2008). Also, several studies have been made to elucidate the mechanism by which nano zero-valent iron (nZVI) interacts with contaminants. Focusing on the removal mechanism, numerous target compounds which are successfully removed have been evaluated, for example, Co2+, U, Al, Zn, Cd, Ni, Pb, and organochlorines, among others (Üzüm et al. 2008, 2009; Yang et al. 2010; Xiaoshu et al. 2012). nZVI could be synthesized in laboratory, and consequently, there are in this area also several studies which focused on the understanding of the mechanism by which the synthesized nZVI removes metal ions. Consequently, the goals of several works are the synthesis, characterization, and use of nZVI obtained using a chemical reduction method (Wang et al. 2010). By this method, a percentage of particles in the nanometer range is obtained, which varies according to the author and which could improve the removal properties of ions in aqueous solution if compared with the micrometer range (Yan et al. 2010). In kinetic studies, it has been suggested that the ion uptake can occur through redox reactions, adsorption phenomena, precipitation, and/or by complex formation (Shih et al. 2011; Li and Zhang 2006, 2007; Çelebi et al. 2007). Moreover, some of these works have shown evidence of the oxides present in its surface, as well as the presence of impurities (Yan et al. 2010; Li and Zhang 2006, 2007; Çelebi et al. 2007; Sun et al. 2006; Kanel et al. 2006). For example, Li and Zhang (2007) have suggested that the mechanism for the metal ion removal through nZVI depends on its respective redox potentials. Thus, they say that the mechanism can occur by electrochemical reduction or by adsorption, depending on whether the interaction also occurs in the fraction of the surface containing elemental iron or in the fraction of the surface formed by iron oxides. These conclusions have been reached by complete and detailed characterization of nZVI, which are well documented in the literature (Dickinson and Scott 2010; Yan et al. 2010). There is also corroboration about the adsorption properties of the iron oxides (Kairies et al. (2005). However, even with evidence of the presence of iron oxides in the nZVI surface, there are few studies which evaluated the adsorption mechanism possible among metal ions and the nZVI surface (Çelebi et al. 2007; Xiaoshu et al. 2012). There is also evidence in the literature that the metal ions can be absorbed by iron oxides (Boujelben et al. 2009). The adsorption equilibrium established between a liquid phase and a solid phase could be described through adsorption isotherms. Experimental data of metal ions adsorbed on iron oxides are usually fit with the Langmuir and Freundlich isotherms. According to Boparai et al. (2011), the Freundlich isotherm is appropriate to both monolayer (chemisorption) and multilayer adsorption (physisorption). The linear form of Freundlich equation is expressed as

where k F and n are the Freundlich isotherm constants related to adsorption capacity and adsorption intensity, respectively, and C e is the equilibrium concentration (in milligrams per liter). Furthermore, the Langmuir isotherm assumes a monolayer adsorption. The Langmuir isotherm in the linear form is described as

where k L is the Langmuir constant and q m is the maximum adsorption capacity (in milligrams per gram). In metal ion removal with nZVI, there are also other relevant aspects to be considered, for example, the influence of the nZVI on the solution properties, such as the pH, the dissolution of iron, and the dissolution of boron. However, these behaviors are not further explored in the literature (Yan et al. 2010; Li and Zhang 2006, 2007; Çelebi et al. 2007; Sun et al. 2006; Nurmi et al. 2005; Kanel et al. 2006; Dickinson and Scott 2010; Yan et al. 2010; Kwon et al. 2010; Huang et al. 2007; Kanel et al. 2006; Sen et al. 2002). The objectives of the current work were to investigate the presence of impurities on the nZVI surface and how these impurities could affect the solution properties. The main properties observed in solution were the pH, the iron concentration, and the boron concentration. The iron oxide formation on the nZVI surface was observed also. For this regard, an experiment was conducted to observe the ion concentration and the pH with time. The particles were characterized before and after their use, and adsorption experiments were performed.

2 Experiment

2.1 Preparation of nZVI Called Simply Washed nZVI (SWnZVI)

All chemicals used in this work were reagent grade and water was deionized. NaBH4 (Vetec) and FeCl3·6H20 (Vetec) were used to prepare synthesized iron. The cation salt used for solution preparation was CuSO4·5H2O (Labsynth). The reagent 65 % HNO3 (Quimex) was used for cleaning purposes and ethanol (Vetec) was employed to rinse Fe particles. Granular commercial iron LAFAN (100 ± 10 μm) was used for comparison purposes and was called in the current work as microscale zero-valent iron (mZVI). In a typical synthesis, a NaBH4 (0.26 M) solution was added into a FeCl3·6H2O (0.04 M) solution in the ratio of 1:1 volume, at room temperature and atmospheric pressure. To facilitate a fast and uniform growing of iron particle crystal, an excessive concentration of borohydride was needed (Zhang 2003). Soon afterwards, Fe3+ was reduced and metallic iron was formed as a black powder, with a notorious gas evolution. The reaction synthesis could be expressed as follows:

The beaker containing the solution mixture was placed in a T500 Thornton-Inpec Eletrônica LTDA ultrasound equipment, at room temperature for 5 min. This equipment was used to minimize particle flocculation. As a preliminary result, the pH value in the reaction solution was obtained (water and products by reaction 3) and every time the value was around 9. Soon after, the obtained particles were separated with vacuum filtration. The product retained in the filter paper was washed first with water and then with alcohol, in order to remove impurities and to retard the oxidation of the iron, respectively. This washing procedure was called simple wash and the iron particles produced in this way were called SWnZVI. On the other hand, if reaction 3 is observed, the presence of boron compounds on the iron surface due to the remaining by-products could be expected. Therefore, for comparison purposes, another product called multiple washed nano zero-valent iron (MWnZVI) was also synthesized.

2.2 Preparation of nZVI Called MWnZVI

To obtain the MWnZVI particles, the same procedure for the SWnZVI particles was made, up to the filtration process. However, the SWnZVI particles retained in the paper filter were subjected to multiple washing procedures, i.e., they were washed several times with water and alcohol alternatively until a pH value near the neutrality was achieved. That pH value was established in the washing water and this procedure was called multiple wash. In this multiple wash procedure, the last washing was also done with ethanol to avoid iron oxidation. After the washing procedure, the MWnZVI particles such as SWnZVI were dried at 70 °C in an oven for 2 h. The particles (MWnZVI and SWnZVI) were stored as dry powder in capped containers.

2.3 Equipments

A CILAS 1064 laser particle size analyzer equipment was used to obtain the size distributions of the synthesized particles. This equipment contains two lasers in order to cover a wider range of particles from 0.04 to 500 μm. The measurement condition could be chosen by “The Size Expert” software whose graphical display shows a symbolic representation of the different particle size analyzing functions, including the laser, ultrasound, pumps (wet mode), and vibratory feeder (dry mode). In this work, the wet mode was used. Hence, particles are prepared by dispersing them in ethanol using ultrasounds.

Brunauer–Emmet–Teller (BET) surface areas were determined using the nitrogen adsorption method with a Quantachrome Instruments version 11.0 surface analyzer. These measurements were performed in the LASID laboratory of the Universidade Federal do Rio Grande do Sul (UFRGS) through the multipoint BET method. Prior to each measurement, samples were placed in an oven overnight, and afterwards, they were loaded in the equipment in a container and evacuated at 150 °C overnight.

X-ray diffraction (XRD) technique for characterization was done in the Geociences Institute of the UFRGS. Powder iron samples were analyzed with Cu Kα radiation using a Siemens-Bruker-AXS model D5000 diffractometer. Scanning started at 2° and finished at 72°, at a scan rate of 0.02° s−1.

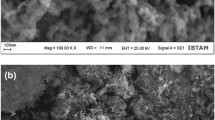

The dry metal particles were also observed by scanning electron microscopy (SEM). It was performed on a XL20 PHILIPS microscope, at the LAMEF Laboratory of the Metallurgic Department in the UFRGS. For the elemental analysis, an energy-dispersive spectrometer (EDS) coupled with the SEM instrument was used.

The concentration of the metal ions in the solutions was determined using inductively coupled plasma optical emission spectroscopy (ICP-OES). These measurements were performed in the laboratory of the Soil Department of the Faculty of Agronomy in the UFRGS. Iron and boron contents in the MWnZVI particles were determined using acid dissolution followed by ICP.

2.4 Experimental Procedure

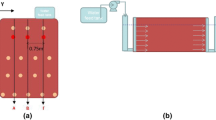

The copper uptake tendency was evaluated by a batch process. A typical batch reactor contained 200 mL of solution and 0.2 g of iron particles. Initial concentrations of copper sulfate were set to give 50 mg/L of Cu2+. At selected time intervals, the liquid sample was filtered with a syringe which was provided with a 0.45-μm Millipore membrane and the pH was measured. Afterwards, it was acidified and stored at −4 °C. The concentration of copper in the solution was determined by ICP-OES. Each experiment was made in duplicate.

The adsorption experiments were carried out in a batch process by using aqueous solution of copper ions. Standard solutions containing 10 to 500 mg/L of copper were prepared by dilution of a copper salt solution containing 1,000 mg/L of metal ion. All experiments were performed by using beakers of 200-mL capacity containing 0.2 g of iron particles. Adsorption experiments were done with SWnZVI, MWnZVI, and mZVI particles for comparison purposes. The suspensions (copper solutions and iron particles) were mixed at constant temperature (25 °C) in a Tecnal TE-420 shaker at 110 rpm for 3 h until equilibrium was reached. Aliquots of the suspensions were filtered with a syringe which was provided with a 0.45-μm Millipore membrane and the pH was measured. Afterwards, they were acidified and stored at −4 °C. The concentration of copper in the solution was determined by ICP-OES. Each experiment was carried out in duplicate.

3 Results and Discussion

3.1 Diameter Distribution and Surface Area

Figures 1 and 2 show the particle size distribution of the SWnZVI and MWnZVI particles, respectively. A great span of size—ranging from 1 to 10 μm—can be seen. Furthermore, a fraction with a diameter in the interval of 200–300 nm could also be observed. However, it is smaller due to particle agglomeration.

The range of diameters found agrees with previous papers such as that of Sun et al. (2006) in which the diameters of NPs were in the range of 5 nm to 1,000 μm. The two regions shown in this work meet also the result of the distribution found by Kanel et al. (2006) who observed two groups with different diameters, assigning a region to individual particles and another region to aggregates. The MWnZVI particles have a distribution of diameters without gaps and do not have a significant frequency in the nanometer region (Fig. 2). This may indicate the loss of smaller particles in the successive washes. In addition, the surface area obtained by nitrogen BET of the SWnZVI and MWnZVI particles was 17 and 12 m2/g, respectively. The minor area obtained with MWnZVI also could be a result of the loss of smaller particles in the successive washes. The surface area of the mZVI particles was 0.15 m2/g.

3.2 Solution Behavior

The diameter distribution parameter such as the high surface area of the nZVI (synthesized by the tetrahydride method) has been associated with the high capacity of nZVI to remove cations in an aqueous solution. Besides that, a study such as that of Li and Zhang (2007) has associated the versatility of the nZVI particles with its electrochemical activity (attributed to elemental iron) and its adsorption capacity (attributed to its oxide layer). Moreover, the synthesis process itself can affect the composition of the obtained nZVI. In consequence, they can affect the properties of the solution in which they are contained. For example, in previous studies which were carried out with nZVI in aqueous solution, the dissolution of iron and boron ions has been observed (Wan et al. 2010). Then, in the present work, the values of pH and the concentrations of total iron (Fet), copper (Cu), and boron (B) were measured. These values obtained at the end of the test are shown in Table 1. The different systems tested were named Cu-SWnZVI, Cu-MWnZVI, and Cu-mZVI. They are related to the systems containing the copper ions (50 mg/L) in aqueous solution in contact with the SWnZVI, MWnZVI, and mZVI, respectively.

These values were reached at the end of each test, requiring a total time of ~75 h for both SWnZVI and MWnZVI and ~600 h for mZVI. As it can be seen, the copper removal was complete with SWnZVI while it was only 76 % with MWnZVI. This lower efficiency of MWnZVI can be attributed to the larger diameters and lower surface area with respect to SWnZVI in the same contact time. Additionally, the removal efficiency using mZVI was 100 %, which could suggest another factor besides the high superficial area, helping in the removal mechanism. The total removal of copper ions by mZVI could be attributed in part to the redox reactions of Cu and Fe. According to the redox potential values of Cu and Fe, the Cu2+ ions are electrochemically reduced by elemental iron. Therefore, the occurrence of a redox reaction on the entire surface of the particles would imply high iron dissolution. Then, it was noted in Table 1 that in any case, the dissolution of iron exceeds the concentration of 40 mg/L. This reasoning can be applied on “clean” surfaces like MWnZVI and mZVI where an interaction between the copper ions and the iron surface could exist. On the other hand, the SWnZVI particles showed an iron dissolution value of 500 orders of magnitude smaller. This result leads us to think that there is some impediment or physical barrier on the particles’ surface which prevents the iron dissolution. It should be made clear also that the iron concentration was kept in low values during all the experiment time indicating no dissolution and precipitation.

In Fig. 3, the two characteristic peaks of metallic iron can be seen. These spectrograms correspond to mZVI (a) and MWnZVI (b), before being used in the tests. Based on these figures, impurities are not observed in the spectrum corresponding to MWnZVI. However, the result of the acidic digestion of a determined mass of MWnZVI showed 1.1 % of boron. Consistent with this fact, the data in Table 1 indicate a concentration of 15 mg/L of boron at the end of the test. This result suggests that boron remains as impurity even after the multiple washing procedures, withdrawing the available sites of iron or iron oxides.

Furthermore, the NaBH4 hydrolysis reaction (4) was proposed by Liendo et al. (2012). Consequently, the high concentration of boron found in solution could be due to the excess of the NaBH4 reagent remaining and to some by-products of reaction 4 as well. Moreover, the spectrogram of the fresh SWnZVI is shown in Fig. 4. The patterns indicate, besides the presence of metallic iron, the existence of Na2B4O7·5H2O and NaCl, confirming therefore the existence of impurities, which were derived from the SWnZVI synthesis method. This result agrees with Nurmi et al. (2005) who suggested that besides the presence of a layer of iron oxides in nZVI obtained with the same method used in the current work, there is a further outer layer that was predominantly formed by a sodium borate salt. In consequence, considering the by-products of reaction 4, the following reaction could be suggested:

The compound Na2B4O7·5H2O was confirmed by the fresh SWnZVI spectrogram shown in Fig. 4. Hence, in the used ZVI particles, iron oxide formation on the surface must be expected.

In addition, in systems with MWnZVI and SWnZVI, the dissolution of the sodium borate salts must be expected too. The XRD spectra for the MWnZVI, SWnZVI, and mZVI particles after their use are shown in Fig. 5 (a, b, and c, respectively). As expected, the presence of iron oxides in the three spectrograms is expected. The iron oxides formed in mZVI and MWnZVI were lepidocrocite and goetita, while SWnZVI produced metallic iron, hematite, lepidocrocite, and goetita. SWnZVI evidenced therefore more heterogeneity in relation to the surface composition. Furthermore, the absence of Na2B4O7·5H2O and NaCl is noted. This fact suggests the dissolution in the aqueous solution of both compounds. Besides that, through observing Table 1, it could be noted that a high pH value was established in the system containing the SWnZVI particles. The absence of copper could indicate that it is covered by the iron oxide layer.

Two facts could contribute to the rise in pH: the lowest dissolution of iron (which confers acidic character due to ferric ion hydrolysis) and the occurrence of reaction 4. The products formed in reaction 4, which include OH−, BO2−, and H2BO3 −, could be responsible for the alkaline character. Moreover, the lowest quantity of dissolved iron may be related to the passivating character of some boron compounds in aqueous solution.

These products may prevent or decrease the iron dissolution. Thus, the iron particles in the presence of boron compounds, i.e., SWnZVI, showed the lowest iron concentration value during the test duration (Martini and Muller 1999). Figures 6 and 7 represent respectively the SEM picture and the EDS spectrogram, after the SWnZVI particles were used in the tests. The presence of an oxide layer on the surface may be noted in Fig. 6, as these particles did not show oxidation before contact with the copper solution. It is inferred therefore that this layer has been formed during contact with the solution. In Fig. 7, corresponding to the EDS spectra of SWnZVI after their use, the presence of copper can be identified, although its oxidation state has not been identified.

It should be remembered that iron oxides have good adsorption properties of cations. Furthermore, the results of the copper ion adsorption tests, using MWnZVI, SWnZVI, and mZVI are discussed next.

3.3 Adsorption Isotherms

The results obtained in the adsorption experiments for Cu2+ in the different systems were adjusted with both isotherms, Freundlich and Langmuir. The resulting parameters corresponding to the adsorption on MWnZVI, SWnZVI, and mZVI are presented in Table 2. It can be noted from the regression factors (R 2) that the systems containing the synthesized particles fitted the Langmuir isotherm. However, the low value of the correlation coefficient obtained in the system with the SWnZVI equal to 0.8 is not satisfactory. The data system containing MWnZVI met the Langmuir isotherm, while mZVI met the Freundlich isotherm.

4 Conclusions

Copper uptake with nZVI occurs through a complex mixture of mechanisms. Besides the frequently mentioned mechanisms in the literature (redox, coprecipitation, adsorption), the existence of impurities on the particle surface must also be considered. These impurities could be dissolved during the solution–particle contact and therefore modify the properties of the solution and the surface properties as well. Therefore, in SWnZVI, metal iron is revealing in some points of the surface, whereas in other points, the surface remains composed of iron oxide. Due this phenomenon, nZVI could present a redox mechanism (iron metal), adsorption mechanism (iron oxide), and precipitation (presence of basic compounds that could rise the pH and then they could assist the ion precipitation). On the other hand, besides pH modification, iron concentration and boron concentration could vary according to the presence of impurities on the nZVI (SWnZVI) surface.

References

Bennett, P., He, F., Zhaob, D., Aiken, B., & Feldman, L. (2010). In situ testing of metallic iron nanoparticle mobility and reactivity in a shallow granular aquifer. Journal of Contaminant Hydrology, 116, 35–46.

Boparai, H., Joseph, M., & O’carroll, D. (2011). Kinetics and thermodynamics of cadmium ion removal by adsorption onto nano zerovalent iron particles. Journal of Hazardous Materials, 186, 458–465.

Boujelben, N., Bouzid, J., & Elouear, Z. (2009). Adsorption of nickel and copper onto natural iron oxide-coated sand from aqueous solutions: study in single and binary systems. Journal of Hazardous Materials, 163, 376–382.

Çelebi, O., Üzüm, Ç., Shahwan, T., & Erten, H. N. (2007). A radiotracer study of the adsorption behavior of aqueous Ba2+ ions on nanoparticles of zero-valent iron. Journal of Hazardous Materials, 148, 761–767.

Di Natale, F., Di Natale, M., Greco, R., Lancia, A., Laudante, C., & Musmarra, D. (2008). Groundwater protection from cadmium contamination by permeable reactive barriers. Journal of Hazardous Materials, 160, 428–434.

Dickinson, M., & Scott, T. B. (2010). The application of zero-valent iron nanoparticles for the remediation of a uranium-contaminated waste effluent. Journal of Hazardous Materials, 178, 171–179.

Huang, Y., Hsueh, C., Cheng, H., Su, L., & Chen, C. (2007). Thermodynamics and kinetics of adsorption of Cu(II) onto waste iron oxide. Journal of Hazardous Materials, 144, 406–411.

Kairies, C. L., Capo, C. L., & Watzlaf, G. R. (2005). Chemical and physical properties of iron hydroxide precipitates associated with passively treated coal mine drainage in the bituminous regions of Pennsylvania and Maryland. Applied Geochemistry, 20, 1445–1460.

Kanel, S. R., Grenèche, J., & Choi, H. (2006). Arsenic(V) removal from groundwater using nano scale zero-valent iron as a colloidal reactive barrier material. Environmental Science & Technology, 40, 2045–2050.

Kwon, J., Yun, S., Lee, J., Kim, S., & Jo, H. (2010). Removal of divalent heavy metals (Cd, Cu, Pb, and Zn) and arsenic(III) from aqueous solutions using scoria: kinetics and equilibria of sorption. Journal of Hazardous Materials, 174, 307–313.

Li, L., & Benson, C. H. (2010). Evaluation of five strategies to limit the impact of fouling in permeable reactive barriers. Journal of Hazardous Materials, 181, 170–180.

Li, X. Q., & Zhang, W. X. (2006). Iron nanoparticles: the core−shell structure and unique properties for Ni(II) sequestration. Langmuir, 22, 4638–4642.

Li, X. Q., & ZHang, W. X. (2007). Sequestration of metal cations with zerovalent iron nanoparticles—a study with high resolution X-ray photoelectron spectroscopy (HR-XPS). Journal of Physical Chemistry C, 111, 6939–6946.

Liendo, M. A., Hidalgo, G. N., Sampaio, C. H., & Heck, N. C. (2012). Synthesis of ZVI particles for acid mine drainage reactive barriers: experimental and theoretical evaluation. Journal of Materials Research and Technology, 1, 75–79.

Martini, E. M., & Muller, I. L. (1999). Passivation of iron in solutions containing borate using rotating ring-disc measurements. Journal of the Brazilian Chemical Society, 10, 505–511.

Matthew, B. J., Ptacek, C. J., Blowes, D. W., & Gould, W. D. (2008). Zero-valent iron and organic carbon mixtures for remediation of acid mine drainage: batch experiments. Applied Geochemistry, 23, 2214–2225.

Nurmi, J. T., Tratnyek, P. G., Sarathy, V., Baer, D. R., Amonette, J. E., Pecher, K., et al. (2005). Characterization and properties of metallic iron nanoparticles: spectroscopy, electrochemistry, and kinetics. Environmental Science & Technology, 39, 1221–1230.

O’Carroll, D., Sleep, B., Krol, M., Boparai, H., & Kocur, C. (2013). Nanoscale zero valent iron and bimetallic particles for contaminated site remediation. Advances in Water Resources, 51, 104–122.

Rao, P., Mak, M. S., Liu, T., Lai, K. C., & Lo, I. M. (2009). Effects of humic acid on arsenic(V) removal by zero-valent iron from groundwater with special references to corrosion products analyses. Chemosphere, 75, 156–162.

Sasaki, K., Blowes, D. W., Ptacek, C. J., & Gould, W. D. (2008). Immobilization of Se(VI) in mine drainage by permeable reactive barriers: column performance. Applied Geochemistry, 23, 1012–1022.

Sen, T. K., Mahajan, S., & Khilar, K. (2002). Adsorption of Cu2+ and Ni2+ on iron oxide and kaolin and its importance on Ni2+ transport in porous media. Colloids and Surfaces A: Physicochem. Engineering Aspects, 211, 91–102.

Shih, Y., Hsu, C., & Su, Y. (2011). Reduction of hexachlorobenzene by nanoscale zero-valent iron: kinetics, pH effect, and degradation mechanism. Separation and Purification Technology, 76, 268–274.

Sun, Y. P., Li, X. Q., Cao, J., Zhang, W. X., & Wang, H. P. (2006). Characterization of zero-valent iron nanoparticles. Advances in Colloid and Interface Science, 120, 47–56.

Üzüm, Ç., Shahwan, T., Eroğlu, A. E., Lieberwirth, I., Scott, T. B., & Hallamc, K. R. (2008). Application of zero-valent iron nanoparticles for the removal of aqueous Co2+ ions under various experimental conditions. Chemical Engineering Journal, 144, 213–220.

Üzüm, Ç., Shahwan, T., Eroğlu, A., Hallam, K., Scott, T., & Lieberwirth, I. (2009). Synthesis and characterization of kaolinite-supported zero-valent iron nanoparticles and their application for the removal of aqueous Cu2+ and Co2+ ions. Applied Clay Science, 43, 172–181.

Wang, Q., Qian, H., Yang, Y., Zhang, Z., Naman, C., & Xu, X. (2010). Reduction of hexavalent chromium by carboxymethyl cellulose-stabilized zero-valent iron nanoparticles. Journal of Contaminant Hydrology, 114, 35–42.

Xiaoshu, L., Jiang, X., Guangming, J., Jie, T., & Xinhua, X. (2012). Highly active nanoscale zero-valent iron (nZVI)–Fe3O4 nanocomposites for the removal of chromium(VI) from aqueous solutions. Journal of Colloid and Interface Science, 369, 460–469.

Yan, W., Herzing, A., Kiely, C., & Zhang, W.-X. (2010). Nanoscale zero-valent iron (nZVI): aspects of the core-shell structure and reactions with inorganic species in water. Journal of Contaminant Hydrology, 118, 96–104.

Yang, J., Cao, L., Guo, R., & Jia, J. (2010). Permeable reactive barrier of surface hydrophobic granular activated carbon coupled with elemental iron for the removal of 2,4-dichlorophenol in water. Journal of Hazardous Materials, 184, 782–787.

Zhang, W. X. (2003). Nanoscale iron particles for environmental remediation: an overview. Journal of Nanoparticle Research, 5, 323–332.

Acknowledgments

We gratefully acknowledge the financial support we received from CNPq, FAPERGS, and CAPES.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liendo, M.A., Navarro, G.E. & Sampaio, C.H. Nano and Micro ZVI in Aqueous Media: Copper Uptake and Solution Behavior. Water Air Soil Pollut 224, 1541 (2013). https://doi.org/10.1007/s11270-013-1541-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-013-1541-1