Abstract

In this work, a coal combustion ash (CCA) has been tested as an alternative low-cost sorbent to commercial activated carbons (GAC) for cadmium and zinc removal from polluted water. To this aim, the effect of pH and metal concentration on CCA adsorption capacity has been investigated, and a comparative analysis with GAC has been carried out in the same experimental conditions. Furthermore, in order to improve CCA adsorption capacity, two different activation treatments of raw CCA have been tested. In particular, the CCA was subjected to a gasification process conducted with steam and to different acidic treatments, conducted either with hydrochloric acid or nitric acid at different acid concentrations. Experimental results showed that all the acid treatments determined a substantial reduction of both cadmium and zinc adsorption capacity. Differently, the steam gasification determined a substantial increase in adsorption capacity with respect to raw CCA, in particular for zinc as its adsorption capacity resulted even higher than the correspondent of GAC. Finally, a thorough analysis of sorbent physical and chemical properties and of adsorption data allowed the individuation of the main cadmium/zinc adsorption mechanism both on CCA and activated carbon, adequately described by the Freundlich model.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Natural and industrial water pollution is a recognized worldwide concern, and heavy metals are considered among the most toxic substances both for environment and human beings (Weiner and Matthews 2003). Exposure to heavy metals such as cadmium, mercury, and arsenic has been linked with several pathologies and with the development of various cancers. They are persistent throughout the environment; hence, they can undergo to a series of long-range transport mechanisms that enhance their diffusion through the environmental phases. Water releases mainly derive from industrial activities, such as production and processing of metals, mineral industry, chemical industry, waste and water management, and energy-related sources associated with fuel combustion. Natural sources are present as well, and an alteration in particular of groundwater quality can derive from natural rocks leaching, leading to an endemic water contamination in many parts of the globe (Stumm and Morgan 1996; Babel and Kurniawan 2003).

Many international and EU actions have been stated in the last years to face up this concern, including the establishment of specific emission standards and environmental quality standards for natural and industrial waters, such as Water Framework Directive (2000/60/EC). The Directive on Integrated Pollution Prevention and Control (96/61/EC), specifically, aims to prevent or minimize pollution of water, air, and soil by industrial effluent; to this end, it requires the application of best available techniques in industrial installations to reduce emissions of heavy metals (European IPPC Bureau 2003).

The currently adopted technologies mainly include coagulation/co-precipitation, ion exchange, membrane technologies, and adsorption processes. However, considering the worldwide diffusion of heavy metal water contamination, depuration methods that can assure an equal worldwide diffusion should be characterized by good efficiency, high simplicity, low cost, and possibility to make use of local and easily accessible materials.

Following these indications, adsorption can be considered among the most interesting technologies, and many different materials can be used as sorbent. The typical adsorbents for heavy metals capture are mainly represented by activated carbons, metal oxides, and zeolites (Suzuki 1990; Benjamin 2002). As a general rule, these sorbents present high adsorption capacity coupled with high costs, and in most of the cases, the regeneration methods are scarcely efficient or economically not competitive. For these reasons, the use of low-cost materials represents a valid alternative for the challenge of a wider diffusion of accessible water treatment systems. Waste recycling and re-utilization are two energy-efficient processes that have gained popularity due to their environmental friendliness and cost-reductive advantages. An example of such processes is the utilization of waste by-products generated from different human activities, such as agricultural materials (Bansode et al. 2003; Mohan and Pittman 2007; Kurniawan et al. 2006; Mehrasbi et al. 2009); waste products (Dias et al. 2007; Bhatnagar and Sillanpaa 2010); biomass (de Pietrobelli et al. 2009); industrial by-products, mainly in the form of oxides/hydroxides (Babel and Kurniawan 2003; Kurniawan et al. 2006; Mohan and Pittman 2007); and fly ashes (Cho et al. 2005; Wang and Wu 2006; Mohan and Pittman 2007; Mohan and Gandhimathi 2009; Ahmaruzzaman 2010; Balsamo et al. 2010; Balsamo et al. 2011) or further alternatives materials such as natural zeolites, chitosan, clays, peat, etc. (Babel and Kurniawan 2003; Mohan and Pittman 2007). In particular, due to the ever-increasing energy generation demand and also considering that coal combustion provides approximately 40 % of world electricity generation, the production of coal combustion ash (CCA) is likely to further increase from the 600 million tons/year currently estimated (Montes-Hernandez et al. 2009). As an industrial by-product, nowadays CCA is mainly used as an additive in concrete industry, as building material and for soil amendment (Jala and Goyal 2006; Marroccoli et al. 2010). However, only a low percentage of CCA produced are currently employed in such applications, and since there are growing concerns about fly ash disposal, there is a pressing need to find alternative solutions. To this purpose, adsorption can be a very promising alternative; the determination of the adsorption mechanisms of heavy metals on CCA is the starting point, still not addressed in the pertinent literature, for a thoughtful use of this waste material and for its conversion to a valuable resource.

In this work, the attention has been focused on the possible use of a fly ash, deriving from coal combustion, in an Italian thermoelectric power plant, as low-cost sorbent alternative to a commercial granular activated carbon (GAC), the Aquacarb 207EA™ provided by Sutcliffe Carbon. The adsorption of cadmium and zinc was adopted as term of comparison, as activated carbon represents the most popular sorbent for cadmium and zinc capture from polluted water (Gabaldon et al. 1996; Leyva-Ramos et al. 2001; Babić et al. 2002). To this end, the effect of pH and metal concentration on CCA adsorption capacity was investigated, as they are unanimously considered as the controlling parameters both for cadmium (Gupta et al. 2003; Srivastava et al. 2006; Papandreou et al. 2007) and zinc (Weng and Huang 2004; Cetin and Pehlivan 2007; Hong et al. 2009) adsorption on CCA. Simultaneously, a comparative analysis with GAC adsorption capacity was carried out in the same experimental conditions, in order to accurately define the field of CCA applications with environmental and economical convenience. Furthermore, in order to extend the investigation of activated carbon replaceability with CCA, two different activation treatments of raw CCA, aimed at increasing cadmium and zinc adsorption capacity, were tested. In particular, the CCA was subjected to a gasification process conducted with steam and to different acidic treatments, conducted either with hydrochloric acid or nitric acid, at different acid concentrations. Eventually, an attempt to highlight the adsorption mechanisms of the analyzed metals both on activated carbon and CCA samples was made by a critical analysis of experimental data.

2 Materials and Methods

2.1 CCA Physical/Chemical Characterization

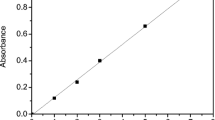

The coal combustion fly ash utilized in this work came from an Italian power plant operated by Enel, in which a bituminous coal is used as fuel. Laser granulometric analysis was performed by a Malvern Instrument Master Sizer 2000 granulometer, operating down to a minimum particle size of 0.02 μm. Porosimetric analysis was carried out by a CE Instruments Sorptomatic 1990 analyzer (N2, 77 K). CCA chemical characterization was obtained by performing X-ray diffraction (XRD; Philips PW1830) and proximate analysis. XRD analysis showed the presence of a significant silico-aluminous fraction, mainly represented by quartz (SiO2), mullite (3Al2O3 · 2SiO2), and calcium oxide (CaO) crystalline phases. In Fig. 1, the XRD pattern of the raw CCA has been reported, whereas in Table 1 the ash oxide composition has been summarized. Proximate analysis showed a moderate fixed carbon content, due to short mean residence times (and, therefore, limited carbon conversion degree) into the combustor. The evaluation of the pH of point zero charge (pHPZC) was made according to the Noh and Schwarz (1990) method, which showed that the CCA has a marked basic nature. Main CCA chemical and physical properties are reported in Table 2, where proximate analysis is provided on dry basis. A complete raw CCA characterization is reported in Balsamo et al. (2011).

Furthermore, the CCA sample was subjected to a batch leaching test to determine the ionic metallic releases, for a preliminary evaluation of its suitability for the proposed water treatment. To this end, 1 g of raw ash was put into contact, for 72 h and under stirring, with 100 ml of distilled water, and thereafter, the liquid solution was analyzed by ICP spectrophotometry (employing an Agilent 7500ce apparatus). The results showed a consistent Ca release and a moderate Si, Al, Na, and K release, while Zn and Cd releases in the leaching solution were negligible or absent, respectively.

2.2 CCA Activation Treatments

Activation by steam gasification is aimed at the conversion of the CCA unburnt carbon into gaseous product. It was conducted into an electrically heated tubular reactor (Nabertherm R60/750/13, i.d. = 60 mm), according to the well-known reactions C(s) + H2O(g) → CO(g) + H2(g) and, partially, CO(g) + H2O(g) → CO2(g) + H2(g). Samples (1 g) of CCA were charged into the reactor and kept in contact for 10 min with a steam stream generated by feeding liquid water (flow rate at room temperature equal to 60 ml h−1) through a pump (Stepdos 03RC) to the reactor that was kept at 850 °C. It is highlighted that steam flow rates at the operating temperature (850 °C) assume the value of about 300 l h−1. The steam gasified sample (CCA-G) was characterized with same techniques as raw CCA. XRD analysis for CCA-G sample (Fig. 1) showed an inorganic crystalline structure very similar to that of the raw CCA, testifying the occurrence of carbon gasification only. On contrary, the activation process determined a higher cumulative pore volume, as expected by gasification processes. The ash burn-off degree deriving from gasification, as the ratio between residual and initial carbon content, resulted to be 0.48, and the particle size diameter resulted to be smaller. Main CCA-G chemical and physical properties are reported in Table 2.

Starting from raw CCA, several acidic treatments were also tested, with the same aim of improving the adsorption properties of the sorbent. These treatments have an opposite effect on chemical CCA properties, as they have a direct influence on the inorganic fraction of the raw CCA. They were performed by immerging 1 g of raw CCA in 100 ml of either HCl or HNO3 solution, with acid concentration in the range 0.001–1 M. The temperature was kept constant at 20 °C for 72 h, under continuous stirring. The sample was then filtered and oven dried for 12 h at 105 °C, washed with distilled water until the pH of the washing solution resulted almost neutral, and dried again. In Table 2, the main chemical properties of the CCA treated with HNO3 at 0.001 M concentration (named CCA-A), which resulted the one with better adsorption properties among those acid-treated as will be discussed in the following, were reported. In Table 3, the metal releases for CCA-G and CCA-A, as determined for raw CCA, were reported, confirming that also for the beneficiated materials, Zn and Cd releases are absolutely compatible with the use of these samples as sorbents for water treatments.

2.3 Activated Carbon

A commercially available non-impregnated GAC was used for dedicated experimental tests (Aquacarb 207EATM, produced by Sutcliffe Carbon). This GAC has been produced starting from a bituminous coal and by steam activation. The textural properties of the sorbent have been studied by means of Brunauer–Emmett–Teller (BET) (Carlo Erba SORPTOMATIC 1900) and SEM (Environmental Scanning Electron Microscope Philips XL30) analyses. The BET surface area is 950 m2 g−1, and the average pore diameter is 24 Å. The chemical composition of the sorbent has been evaluated by elemental analysis (Perkin Elmer 2400 series—CHNS Analyser) which reveals high ash content (9.58 %). The chemical composition of the ashes has been evaluated by leaching 0.150 g of carbon in 7 ml of 65% (w/w) nitric acid and 2 ml H2O2 at 180 °C. The solution is then analyzed by ICP-MS (Agilent 7500 CE series).

The evaluation of the pHPZC is based on the Noh and Schwarz (1990) method, which shows that the activated carbon has a slightly basic nature as the pHPZC value is 8. In Table 2, the main activated carbon properties are reported. A complete list of chemical and physical characteristics can be found in Erto et al. (2010) and Di Natale et al. (2008), respectively.

2.4 Adsorption Tests

Adsorption tests addressed at adsorption capacity evaluation were carried out at T = 20 °C, in batch stirred reactors kept in a PID-controlled thermostatic oven. Experimental runs were conducted in model water solutions; stock solutions of cadmium and zinc were prepared by dissolving a given quantity of either Cd(NO3)2⋅4H2O or Zn(NO3)2⋅6H2O (Sigma Aldrich, 99.9 %), respectively, in double-distilled water. A constant mass of sorbent (1 g), either CCA, CCA-G, CCA-A, or GAC, is added to a 100 ml of metal solution. The initial metal concentrations used in each run were selected so that the equilibrium concentrations were in the typical range for contaminated wastewater. For test devoted to pH effect investigation, the initial solution pH was adjusted by addition of nitric acid (1 M) to the stock solutions, and it was not further altered during the experimental run.

For all the tests conducted at neutral equilibrium pH and involving CCA, CCA-G, and all the acid-treated samples, including CCA-A, a pH adjustment of the initial solution was necessary as well. Preliminary tests, in fact, indicated that, in the presence of raw CCA or CCA-G, the equilibrium pH both for cadmium and zinc solutions equaled to 12. This strong alkaline character is likely related to calcium ions leaching from CCA, as reported in Balsamo et al. (2011). These operating conditions would strongly affect cadmium/zinc adsorption, since species such as Cd(OH)2 or Zn(OH)2 would likely precipitate, leading to unreliable adsorption data.

Conversely, the acid treatments determined a significant alteration of CCA properties resulting, as expected, in an acidification of the external surface. As a consequence, for these samples, the equilibrium pH was around 2, if no external pH modification was adopted.

For all these reasons, for all tests conducted with CCA and CCA-G, the initial cadmium/zinc solution pH was adjusted with HNO3 (0.1 M), while NaOH (0.025 M) solution was used in the case of all the acid treated and in particular for the CCA-A sample, in order to obtain an equilibrium pH around 7.

After equilibration, the reactors were sampled and the metal concentration both in solution and on the CCA/GAC surface was measured. To this purpose, the solution was filtered and analyzed for pH and metal concentration while the CCA/GAC was leached with 100 ml of nitric acid (1 M) for a complete extraction of the adsorbed metal. Finally, the extractive solution was analyzed for the metal uptake on the solid surface, and it was compared with the same quantity calculated through a metal mass balance, allowing a maximum error of 6 %. To assure the accuracy, reliability, and reproducibility of the collected data, all batch isotherm tests were recorded in triplicate and average values were only reported. Among each replica of a repeated test, the standard deviation in cadmium/zinc concentration is below the 7 % while that in the adsorption capacity is around 6 %. All the lab-ware used in the study was previously soaked in nitric acid (1 M), triply rinsed with distilled water, and oven dried. Analytical concentrations were measured by air/acetylene flame atomic absorption spectrophotometry by using a Varian SpectrAA-220 spectrophotometer, with metal standard solution provided by Sigma-Aldrich.

3 Experimental Results

The equilibrium pH plays a central role in the estimation of sorbent effectiveness for real wastewater treatment by adsorption (Benjamin 2002), and industrial effluent deriving from specific activities can be characterized by pH values ranging in a wide range. A complete comparative analysis between sorbents requires the determination of their adsorption capacity in the same pH range.

Hence, as a first approach, the effect of pH on Cd and Zn adsorption capacity both on CCA and GAC was evaluated and reported in Fig. 2, in which adsorption capacity was calculated in correspondence of a constant metal equilibrium concentration (i.e., C eq = 0.27 mmol/l and C eq = 0.60 mmol/l for cadmium and zinc, respectively), for a proper comparison. Adsorption tests were performed in the equilibrium pH range 2–7; as a matter of fact, at higher pH, the determination of reliable adsorption capacity is not possible, due to the precipitation of cadmium or zinc as hydroxide (Stumm and Morgan 1996).

Experimental results clearly show that adsorption capacity monotonically increases by increasing pH, for both metals and whatever is the sorbent considered. For the chosen equilibrium concentrations, CCA and GAC performances are always of the same order of magnitude and almost similar until pH = 7, where GAC shows higher adsorption capacity both for cadmium and zinc. Moreover, for cadmium tests and when equilibrium pH is lower than 4, CCA shows an adsorption capacity higher than GAC.

For an equilibrium pH near to neutrality, typical of most natural and industrial water, CCA adsorption capacity is comparable but lower with respect to GAC. Hence, a first attempt to improve its performances was made by treating the raw CCA with either HNO3 or HCl solution at different concentrations. After the treatment, the samples obtained were tested for both cadmium and zinc adsorption, and their performances were compared with those related to the raw material. To this aim, ten experimental runs were prepared with same volume (100 ml), sorbent mass (1 g), and initial cadmium or zinc concentration (C 0), using the different treated samples as sorbent. The results of adsorption tests are reported in Fig. 3, both for cadmium and zinc:

Cadmium/zinc adsorption capacity of CCA and CCA treated with different HCl/HNO3 solutions. \( C_{\mathrm{Cd}}^0={{{0.44\;\mathrm{mmol}}} \left/ {\mathrm{l}} \right.} \) (cadmium tests) and \( C_{\mathrm{Zn}}^0={{{0.76\;\mathrm{mmol}}} \left/ {\mathrm{l}} \right.} \) (zinc tests). T = 20 °C; equilibrium pH = 7.0 ± 0.3

As can be observed, all the treatments result in a substantial worsening of cadmium and zinc adsorption capacity by CCA. The sample treated with HNO3 at the lowest acid concentration (0.001 M) showed the highest adsorption capacity among the acid-treated samples, both for cadmium and zinc. This sample, named as CCA-A, was used for further adsorption tests, at different analyte concentrations, as reported below.

In order to improve the adsorption capacity, the raw CCA was subjected also to an alternative beneficiation treatment, namely steam gasification, and adsorption isotherms for both cadmium and zinc have been determined on the beneficiated material (CCA-G). Simultaneously, a more sensitive comparison among all the investigated sorbents was made by the determination of a complete adsorption isotherm at equilibrium pH = 7, for both analytes. In Fig. 4, the complete set of results is reported.

Experimental data on cadmium (Fig. 4a) show that, in the range of equilibrium concentration investigated, GAC shows the highest adsorption capacity. The CCA-G sample showed an adsorption capacity higher with respect to raw CCA, being steam gasification an effective beneficiation treatment of CCA for cadmium adsorption. For equilibrium concentration lower than 0.1 M, typical of natural polluted waters, the difference among GAC, CCA, and CCA-G became even negligible. For zinc tests (Fig. 4b), a different ranking among the sorbents can be defined. In particular, the CCA-G sample showed the highest adsorption capacity, even higher than GAC. The raw CCA sample shows an adsorption capacity comparable with GAC just in a little range of concentration (0–0.2 mmol/l), typical of regulation limits. Finally, the CCA-A sample confirmed to adsorb both cadmium and zinc at a less extent with respect to the raw CCA and all the other sorbents.

4 Discussion

For the interpretation of experimental data, a speciation analysis of cadmium/zinc solution at equilibrium was made, as adsorption phenomena are strictly dependent on ionic species distribution, as a function of solution pH (Benjamin 2002; Di Natale et al. 2009). Ionic speciation can be evaluated by using mass and electric charge balance equations in a system including the equations representative of chemical equilibria. Davies’ formula was used for the evaluation of the activity coefficients of the ionic species (Stumm and Morgan 1996; Benjamin 2002). In Table 4, the equilibrium reactions for Cd(II) and Zn(II) ions together with their equilibrium constants at 20 °C and the corresponding Gibbs’ free energy of reaction are reported.

In the investigated experimental conditions (i.e., pH 2–7), Cd++ and Zn++ resulted to be largely predominant in cadmium and zinc solution, respectively. Hence, the effect of solution pH on CCA and GAC adsorption capacity can be likely referred to the well-known competition phenomena among cadmium or zinc cations and H3O+ (Benjamin 2002; Di Natale et al. 2009). Coherently, the layout of pH–ω relationship (Fig. 2) has a similar exponential trend because an increase in pH results in orders of magnitude decrease of H3O+ concentration and, consequently, in the competition effect.

The initial solution pH also influenced the experimental runs when CCA and CCA-G were used as sorbent. In fact, by contacting 1 g of ash (containing about 0.0425 g of CaO) into 100 ml of aqueous solution, the complete hydration of CaO into Ca(OH)2 gives a Ca(OH)2 concentration equal to 0.56 g l−1, thus well below the solubility limit at room temperature. Then, the precipitation of Ca(OH)2 could be neglected. If a complete dissociation of Ca(OH)2 into Ca++ and OH- is assumed, a pH around 12 is obtained, in line with the experimental data. In order to obtain an equilibrium pH equal to neutrality during adsorption runs, a defined quantity of HNO3 was added to the cadmium/zinc solution. This quantity was optimized for each run and resulted proportional with the concentration of analyte in solution, i.e., a higher quantity was necessary for tests conducted at higher cadmium/zinc concentration. This result suggests an ion exchange mechanism for the adsorption of both cadmium/zinc on CCA and beneficiated samples, likely due to a substitution of cations originally present on ash surface and released in water (mainly represented by Ca++, see also Table 3) with Cd++ or Zn++ ions. It also means that the inorganic fraction of the ash is likely to be the active part for adsorption, the organic part contribution being negligible. Differently, adsorption on GAC is likely to occur on specific superficial functional groups (Di Natale et al. 2009), even if a minority contribution offered by the inorganic fraction cannot be neglected.

These outcomes are confirmed when the experimental results concerning the beneficiation treatments are taken into account. In fact, the beneficiation conducted with different acid treatments reduced the ashes content and increased the fixed carbon (cf. Table 2). This effect is proportional with acid concentration, and coherently, adsorption capacity of both cadmium and zinc was lower for CCA treated with higher acid concentration (as shown in Fig. 3). Moreover, the release of cations from CCA-A in water resulted to be negligible (Table 3), as most of the superficial inorganic fraction were dissolved during the acid treatment. This implies that the hypothesized ion exchange mechanism for the adsorption on all the acid treated CCA is less active, and consequently, adsorption capacity is sensibly lower (Figs. 3 and 4). This result is also consistent with the results reported in Balsamo et al. (2011), in which a complete demineralization of CCA was carried out. The results reported in the cited work clearly showed that this treatment determined a total elimination of the inorganic fraction and a moderate decreasing in both contact surface and porosity. Under those operating conditions, the CCA adsorption capacity for cadmium resulted to be almost zero.

The beneficiation of CCA conducted by steam gasification determined opposite results both for sorbent final properties and adsorption capacity. The carbon content was sensibly reduced, testified by a 48 % burn-off degree, and the ash content resulted consequently higher. Simultaneously, slight differences in the physical properties were determined, represented by an increase in BET area and porosity, due to the gasification process itself characterized by the development of gaseous products. CCA-G adsorption capacity for cadmium resulted moderately higher than raw CCA, but the effect of gasification resulted very strong in terms of zinc adsorption, as adsorption capacity resulted doubled with respect to raw CCA, also exceeding substantially the correspondent value of GAC. These results confirmed that adsorption on CCA, CCA-A, and CCA-G is mainly influenced by the inorganic fraction. Furthermore, it can be observed that the different adsorption capacities of CCA, CCA-G, and GAC does not reflect the ranking of BET surface area (Table 2); hence, BET area is not key parameters for adsorption of cadmium and zinc on the investigated sorbents. Notwithstanding, a high BET surface area can represent a useful “support” to guest a great number of adsorption sites, thus determining the highest adsorption capacity, but the superficial composition is likely to be the main controlling parameter.

As a final comparison, from Fig. 4, it can be also observed that each sorbent shows a higher affinity toward zinc rather than cadmium. This evidence can be likely due to the smaller dimensions of zinc cations that result less affected by steric hindrance effects, even if some authors have related it to a higher number of active sites, of different types, potentially selective for zinc (Leyva-Ramos et al. 2001).

The hypothesized adsorption mechanisms for the different sorbents tested appear to be compatible with the base hypotheses of Freundlich model, as both inorganic fraction and superficial functional groups can show a defined adsorption energy distribution due to their heterogeneous nature. Coherently, the Langmuir model showed less accurate regression results, referred to all adsorption data set (not reported).

A regression analysis of experimental data for all the investigated sorbents, performed with Freundlich model, confirmed these results, as can be observed in Fig. 4. The results of regression analysis are reported in Table 5, together with the standard error of each parameter. The accuracy of the experimental data and the model appropriateness are testified by the low value of the standard errors, always an order of magnitude less than the correspondent parameter.

As a final remark, technical applicability and cost-effectiveness are the key factors that play the major roles in the selection of the most suitable adsorbent to treat polluted water. It can be concluded that CCA can be a valid alternative to commercial activated carbon as adsorption capacity is comparable, while no cost for material acquisition is present. Indeed, the unit cost of commercially available activated carbons, which are the most largely used in water and wastewater treatments, is usually higher than 1,000 euros/ton (Di Natale et al. 2008). Moreover, the gasification treatment conducted with steam is a very effective beneficiation treatment of CCA against a low cost for its realization due to low process time; the performances of such beneficiated material resulted comparable (for cadmium) or even higher (for zinc) than a commercial activated carbon.

5 Conclusions

In this work, a CCA has been tested as a sorbent for cadmium and zinc removal from contaminated water. Adsorption tests have been carried out in order to investigate the effect of metal concentration and pH, and different activation treatments were carried out aimed at a beneficiation of the raw material. In particular, a steam gasification at 850 °C for 10 min, aimed at the conversion of the CCA unburnt carbon into gaseous product, and different acid treatments conducted either with HCl or HNO3 at different acid concentrations have been proposed in order to increase the adsorption capacity. Simultaneously, a comparative analysis with a commercially available GAC adsorption capacity has been carried out in the same experimental conditions. Experimental results showed that the raw CCA has a good adsorption capacity toward both cadmium and zinc, even if still lower than the corresponding of activated carbon, except for a narrow range of equilibrium concentration. For pH ranging between 2 and 7, both raw CCA and GAC showed adsorption capacity increasing with pH, due to competition phenomena between Cd++ and Zn++ ions and H3O+. The activation of CCA with acid (either nitric or hydrochloric) always resulted in a decrease of the adsorption capacity both for cadmium and zinc, likely due to the depleting of the inorganic fraction that is believed to be the active part of the solid in terms of adsorption.

The activation by steam gasification, conversely, resulted very effective as it always determined an increase in adsorption capacity with respect to the raw material. For zinc adsorption, in particular, the gasified sample showed the highest adsorption capacity, even higher than the correspondent of GAC. In conclusion, the CCA investigated in the present work can be considered as a valid alternative for the treatment of cadmium/zinc polluted waters, and the steam gasification treatment represents the best beneficiation treatment among those tested.

References

Ahmaruzzaman, M. (2010). A review on the utilization of fly ash. Progress in Energy and Combustion Science, 36, 327–363.

Babel, S., & Kurniawan, T. A. (2003). Low-cost adsorbent for heavy metals uptake from contaminated water: a review. Journal of Hazardous Materials, 97, 219–243.

Babić, B. M., Milonjić, S. K., Polovina, M. J., Čupić, S., & Kaludjerović, B. V. (2002). Adsorption of zinc, cadmium and mercury ions from aqueous solutions on an activated carbon cloth. Carbon, 40, 1109–1115.

Balsamo, M., Di Natale, F., Erto, A., Lancia, A., Montagnaro, F., & Santoro, L. (2010). Arsenate removal from synthetic wastewater by adsorption onto fly ash. Desalination, 263(1–3), 58–63.

Balsamo, M., Di Natale, F., Erto, A., Lancia, A., Montagnaro, F., & Santoro, L. (2011). Cadmium adsorption by coal combustion ashes-based sorbents—relationship between sorbent properties and adsorption capacity. Journal of Hazardous Materials, 187, 371–378.

Bansode, R. R., Losso, J. N., Marshall, W. E., Rao, R. M., & Portier, R. J. (2003). Adsorption of metal ions by pecan shell-based granular activated carbons. Bioresource Technology, 89, 115–119.

Benjamin, M. (2002). Water chemistry. New York: McGraw Hill.

Bhatnagar, A., & Sillanpaa, M. (2010). Utilization of agro-industrial and municipal waste materials as potential adsorbents for water treatment—a review. Chemical Engineering Journal, 157, 277–296.

Cetin, S., & Pehlivan, E. (2007). The use of fly ash as a low cost, environmentally friendly alternative to activated carbon for the removal of heavy metals from aqueous solutions. Colloids and Surfaces A: Physicochem. Eng. Aspects, 298, 83–87.

Cho, H., Oh, D., & Kim, K. (2005). A study on removal characteristics of heavy metals from aqueous solution by fly ash. Journal of Hazardous Materials, B127, 187–195.

de Pietrobelli, A. J. M. T., Módenes, A. N., Fagundes-Klen, M. R., & Espinoza-Quiñones, F. R. (2009). Cadmium, copper and zinc biosorption study by non-living Egeria densa biomass. Water, Air, and Soil Pollution, 202(1–4), 385–392.

Di Natale, F., Erto, A., Lancia, A., & Musmarra, D. (2008). Experimental and modelling analysis of As(V) ions adsorption on granular activated carbon. Water Research, 42, 2007–2016.

Di Natale, F., Erto, A., Lancia, A., & Musmarra, D. (2009). A descriptive model for metallic ions adsorption from aqueous solutions onto activated carbons. Journal of Hazardous Materials, 169(1–3), 360–369.

Dias, J. M., Alvim-Ferraz, M. C. M., Almeida, M. F., Rivera-Utrilla, J., & Sanchez-Polo, M. (2007). Waste materials for activated carbon preparation and its use in aqueous-phase treatment: a review. Journal of Environmental Management, 85, 833–846.

Erto, A., Andreozzi, R., Lancia, A., & Musmarra, D. (2010). Factors affecting the adsorption of trichloroethylene onto activated carbons. Applied Surface Science, 256, 5237–5242.

European IPPC Bureau (2003). Reference document on best available techniques in common waste water and waste gas treatment/management systems in the chemical sector—European Commission—on-line version at http://eippcb.jrc.es/

Gabaldon, C., Marzal, P., Ferrer, J., & Seco, A. (1996). Single and competitive adsorption of Cd and Zn onto a granular activated carbon. Water Research, 30(12), 3050–3060.

Gupta, V. K., Jain, C. K., Imran, A., Sharmaa, M., & Sainia, V. K. (2003). Removal of cadmium and nickel from wastewater using bagasse fly ash—a sugar industry waste. Water Research, 37, 4038–4044.

Hong, J. K., Ho, Y. J., & Yun, S. T. (2009). Coal fly ash and synthetic coal fly ash aggregates as reactive media to remove zinc from aqueous solutions. Journal of Hazardous Materials, 164, 235–246.

Jala, S., & Goyal, D. (2006). Fly ash as a soil ameliorant for improving crop production—a review. Bioresource Technology, 97(9), 1136–1147.

Kurniawan, T. A., Chan, G. Y. S., Lo, W., & Babel, S. (2006). Comparisons of low-cost adsorbents for treating wastewaters laden with heavy metals. Science of the Total Environment, 366, 409–426.

Leyva-Ramos, R., Bernal-Jacome, L. A., Guerrero-Coronado, R. M., & Fuentes-Rubio, L. (2001). Competitive adsorption of Cd(II) and Zn(II) from aqueous solution onto activated carbon. Separation Science and Technology, 36(16), 3673–3687.

Marroccoli, M., Pace, M. L., Telesca, A., Valenti, G. L., & Montagnaro, F. (2010). Utilization of coal combustion ashes for the synthesis of ordinary and special cements. Combustion Science and Technology, 182, 588–599.

Mehrasbi, M. R., Farahmandkia, Z., Taghibeigloo, B., & Taromi, A. (2009). Adsorption of lead and cadmium from aqueous solution by using almond shells. Water, Air, and Soil Pollution, 199(1–4), 343–351.

Mohan, S., & Gandhimathi, R. (2009). Removal of heavy metal ions from municipal solid waste leachate using coal fly ash as an adsorbent. Journal of Hazardous Materials, 169, 351–359.

Mohan, D., & Pittman, C. U., Jr. (2007). Arsenic removal from water/wastewater using adsorbents—a critical review. Journal of Hazardous Materials, 142, 1–53.

Montes-Hernandez, G., Perez-Lopez, R., Renard, F., Nieto, J. M., & Charlet, L. (2009). Mineral sequestration of CO2 by aqueous carbonation of coal combustion fly-ash. Journal of Hazardous Materials, 161, 1347–1354.

Noh, J. S., & Schwarz, J. A. (1990). Effect of HNO3 treatment on the surface acidity of activated carbons. Carbon, 28(5), 675–682.

Papandreou, A., Stournaras, C. J., & Panias, D. (2007). Copper and cadmium adsorption on pellets made from fired coal fly ash. Journal of Hazardous Materials, 148, 538–547.

Srivastava, V. C., Mall, I. D., & Mishra, I. M. (2006). Equilibrium modelling of single and binary adsorption of cadmium and nickel onto bagasse fly ash. Chemical Engineering Journal, 117, 79–91.

Stumm, W., & Morgan, J. J. (1996). Aquatic chemistry. New York: Wiley.

Suzuki, M. (1990). Adsorption engineering. Amsterdam: Elsevier.

Wang, S., & Wu, H. (2006). Environmental-benign utilisation of fly ash as low-cost adsorbents. Journal of Hazardous Materials B, 136, 482–501.

Weiner, R. A., & Matthews, R. A. (2003). Environmental engineering (4th ed.). Amsterdam: Butterworth-Heinemann.

Weng, C. H., & Huang, C. P. (2004). Adsorption characteristics of Zn(II) from dilute aqueous solution by fly ash. Colloids and Surfaces A: Physicochem. Eng. Aspects, 247, 137–143.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Erto, A., Giraldo, L., Lancia, A. et al. A Comparison Between a Low-Cost Sorbent and an Activated Carbon for the Adsorption of Heavy Metals from Water. Water Air Soil Pollut 224, 1531 (2013). https://doi.org/10.1007/s11270-013-1531-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-013-1531-3