Abstract

The adsorption of As(III), As(V), Se(IV) and Se(VI) by seawater neutralized red mud and alum water treatment sludge was investigated and compared using the batch adsorption technique. For water treatment sludge, adsorption of As(V), Se(IV) and Se(VI), at equimolar concentrations of added metalloid, declined with increasing pH. The decline was rapid above pH 4.0 for Se(VI), above pH 5.0 for Se(IV) and above pH 6.0 for As(V). Adsorption of As(III) increased with increasing pH up to pH 9.0 and then declined. For red mud, adsorption of As(V), Se(IV) and Se(VI) showed a maximum at about pH 5.0 and for As(III) adsorption remained relatively constant over the pH range 2.0–10.0 after which it declined. Water treatment sludge removed 50 % or more of solution As(V) between pH 2.0 and 10.8, Se(IV) between 2.0 and 8.9, Se(VI) between 2.0 and 5.8 and As(III) between 8.4 and 10.9. By contrast, red mud showed less than 25 % adsorption of added Se(VI) and As(III) over the entire pH range tested (2.0–12.0) and reached 50 % or more for As(V) only over the pH range 4.0–6.9 and for Se(IV) between pH 4.3 and 5.6. At pH 5.0, adsorption of As(III) and Se(IV) was better described by the Langmuir than Freundlich equation but the reverse was the case for As(V) and Se(VI). Kinetic data for adsorption of all four oxyanions onto both adsorbents correlated well with a pseudo-second-order kinetic model suggesting the process involved was chemisorption. NaOH was more effective at removing adsorbed metals from both adsorbents than HNO3. Water treatment sludge maintained its As(III) and Se(IV) adsorption capability at greater than 70 % of that added over eight successive cycles of adsorption/regeneration using 0.5 M NaOH as a regenerating agent. By contrast, for red mud, As(V) adsorption capacity declined very rapidly after three adsorption/desorption cycles and that for Se(IV) it decreased progressively with increasing numbers of cycles. It was concluded that water treatment sludge is a suitable material to develop as a low-cost adsorbent for removal of heavy metal oxyanions from wastewater streams.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

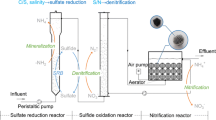

Adsorption has been shown to be an effective and economic technique for removing various pollutants from wastewater streams. Activated carbon has been the conventionally adopted adsorbent for removing heavy metal pollutants from waters but its use is restricted by the high cost and difficulties with regeneration (Gupta and Ali 2002). As a result, there is growing research interest in the use of waste products/by-products of industry as low-cost adsorbents (Babel and Kurniawan 2003). Two such materials are red mud and alum-derived drinking water treatment sludge (Zhou and Haynes 2010a, 2011).

During bauxite refining, Al-containing minerals are selectively extracted by dissolution in hot NaOH and the insoluble residue is known as red mud (Paramguru et al. 2005). It is mainly composed of Fe oxides. Untreated red mud has a high pH (11–12) and is also highly saline/sodic but it can be seawater neutralized to produce a commercial adsorbent material known as Bauxsol™ (Hanahan et al. 2004). This has been used successfully as an adsorbent for many heavy metal ions including Cr, Cu, Zn, Pb and Cd (Genc et al. 2003; Genc-Fuhrman et al. 2004; Zhou and Haynes 2011). Alum-derived water treatment sludge is produced during treatment of drinking water with alum. When added to water, alum polymerizes as hydroxyl-Al species and causes flocculation and coagulation of colloidal materials such as soluble organic matter and fine soil particles. The precipitated material is usually dewatered and transferred to waste disposal areas. Water treatment sludge has recently been shown to be a very effective adsorbent for heavy metal cations such as Cd(II), Cu(II), Pb(II), Zn(II) and Cr(III) (Zhou and Haynes 2010b). In addition, Zhou and Haynes (2011) found that water treatment sludge could be regenerated repeatedly using 0.10 M HNO3 as a desorbent, without significant loss of adsorption capacity for Pb(II) and Cd(II). By contrast, red mud showed a rapid decrease in adsorption capacity after only one adsorption/regeneration cycle. Because of its very high pH, red mud is less effective for adsorption of anions than cations but water treatment sludge has been shown to be an effective adsorbent of chromate [i.e. Cr(VI)] (Zhou and Haynes 2010b). Two toxic heavy metals which are often present in wastewaters as anions are arsenic and selenium.

Arsenic may exist in −3, 0, +3 and +5 oxidation states with As(III) (arsenite; AsO 3−3 /AsO −2 ) and As(V) (arsenate; AsO 3−4 ) being the dominant species in wastewater streams (Smith et al. 1998). Arsenate is the most stable form under aerobic conditions while arsenite predominates in moderately reducing anaerobic conditions. The most important oxidation states of Se are −2, 0, 4 and 6 and Se(IV) (selenite; SeO 2−3 ) and Se(VI) (selenate; SeO 2−4 ) are the most common ions in wastewaters (Adriano 2002). The purpose of this study was to compare the effectiveness of water treatment sludge and seawater neutralized red mud (Bauxsol™) to adsorb arsenate, arsenite, selenate and selenite from aqueous solutions and their capacities for desorption and regeneration.

2 Materials and Methods

2.1 Sample Description

Water treatment sludge was collected from the Seqwater Mount Crosby water treatment station where treatment consists of addition of 5.5 mg L−1 of grade 2 alum. Seawater-neutralized red mud (Bauxsol™) was obtained from Virotec International Ltd (Australia). It originates from the Queensland Alumina Ltd Gladstone refinery. The materials were ground and sieved (<125 μm) prior to use.

Elemental composition of materials was measured by inductively coupled plasma–atomic emission spectroscopy (ICP-AES) after digestion in a microwave system with HNO3, HCl and HF. A standard reference material (SRM 2709) was digested and analysed at the same time with the samples for quality control. Materials were subjected to X-ray diffraction analysis to determine their mineralogy. Specific surface area of samples was determined by the BET/N2-adsorption method and point of zero charge (PZC) was determined using a Laser Zeta meter. Cation exchange capacity (CEC) of materials was determined at pH 7.0 using 1 M ammonium acetate and pH and electrical conductivity (EC) were measured in a 1:5 material/water ratio (Rayment and Higginson 1992). Residual alkalinity of materials was quantified in a 1:10 material/water slurry by titrating them from their natural pH down to pH 4.0 using 1 M HNO3. Cr, Cd, Pb, As and Se were extracted from wastes by the Toxicity Characteristic Leaching Procedure (TCLP; USEPA Method 1311; USEPA 1992) and metals were measured by ICP-AES.

2.2 Adsorption Experiments

Batch adsorption studies were performed to determine the extent of adsorption of each individual heavy metal ion at room temperature (25 °C). All experiments were carried out in triplicate at a constant ionic strength provided by 0.01 M NaNO3. Metal solutions, with the desired metal concentration, were prepared in 0.01 M NaNO3 using NaAsO2, Na2HAsO4, Na2SeO3 and Na2SeO4. A measured amount of sludge or red mud was weighed into 50-mL centrifuge tubes and 10 mL of 0.01 M NaNO3 was added. The mixture was shaken for 1 h and then adjusted to desired pH using HNO3 or NaOH. Once the pH had stabilized, 10 mL of an individual heavy metal solution (at twice the desired final metal concentration) was added and the pH was adjusted again. The mixture was shaken on an end-over-end shaker for desired time periods. During adsorption, the pH was checked and readjusted, if necessary, every half hour. The resulting solution was centrifuged (4,000 rpm for 10 min) and the filtered supernatant was analysed for the appropriate aqueous heavy metal by ICP-AES. The percentage of metal adsorbed was calculated from the difference between that added and that remaining in solution.

The effect of pH on adsorption was investigated over the pH range of 2 to 12 with an initial metal concentration of 1 mM and adsorbent dosage of 10 g L−1. To measure the adsorption isotherm, eight different initial concentrations of arsenite, arsenate, selenite and selenate ranging from 0.1 to 6 mM were used (at pH 5 and an adsorbent dosage level of 10 g L−1). Adsorption data (equilibrium metal concentration versus quantity adsorbed) were fitted to the Langmuir and Freundlich equations. The effect of contact time, varying from 15 to 360 min., was studied at pH 5, a dosage level of 10 g L−1 and an initial concentration of 1 mM. The data was fitted to pseudo-first-order and pseudo-second-order kinetic models.

2.3 Desorption and Regeneration

The adsorption was carried out at pH 5 for 2 h with 1 mM initial metal concentration and 10 g/L adsorbent dosage as described above. Water treatment sludge and red mud were separated from the solutions by centrifugation at 4,000 rpm for 10 min. The metal concentration in the supernatant was analysed by ICP-AES. After being washed three times with distilled water, the metal-loaded materials were then suspended in seven different desorption agents which were (1) 0.01 M NaNO3; (2) 0.01, 0.1 or 0.5 N HNO3; and (3) 0.01, 0.1 or 0.5 M NaOH. The mixture was shaken on an end-over-end shaker for 1 h and centrifuged. The supernatant was decanted and metal concentration in the solution was measured. The residue was washed again and resuspended in the desorption agent and the desorption procedure was repeated twice more. Prior to each desorption event, centrifuge tubes were weighed and final results corrected for the initial quantity of entrained solution present. The percentage of metal desorbed was calculated from the difference between that adsorbed and that removed by the desorption agents.

For regeneration, the metal-loaded materials were shaken in 0.5 M NaOH for 1 h to remove the adsorbed metal. The resulting adsorbents were washed three times with distilled water to remove the remaining alkali and were then used for the next adsorption/desorption cycle as described above. The adsorption/desorption cycles were repeated eight times under identical conditions.

2.4 Statistical Analysis

Standard errors of the means were calculated for all adsorption data and these are presented along with the data in Figs. 1, 2, 3, 4, 5 and 6.

Relative sorption (percent of added metal adsorbed) of As(V) and Se(IV) during eight successive adsorption/regeneration cycles using 0.5 M NaOH as the regenerating agent (temperature = 25 °C, pH = 5.0, dosage = 10 g L−1, equilibrium period = 2 h, initial metal concentration = 1 mM). Standard errors of the means shown

3 Results and Discussion

3.1 Properties of the Materials

The elemental and mineralogical composition of water treatment sludge and red mud are shown in Table 1 and, as expected, the main metallic element present in water treatment sludge was Al although some Fe was also present. X-ray diffraction analysis revealed it consisted of poorly crystalline amorphous material although small amounts of gehlenite (Ca2Al2SiO7) were also present. Once alum dissolves in water, Al3+ exists in aqueous solution as aluminohexahydronium ions (Al·6H2O)3+ and these dissociate sequentially as pH increases (leaving OH in place of OH2) to form species such as [Al(H2O)5OH]2+ and [Al(H2O)4(OH)2]+. These species polymerize to form positively charged polynuclear complexes which form a gel-like substance that adsorbs and coagulates colloidal materials such as soluble organic matter and fine soil particles. Adsorption of inorganic and organic anionic species to the hydroxyl-Al polymers is thought to inhibit their crystallization to [Al(OH)3] (Zhou and Haynes 2010b) and as shown here, water treatment sludge exists as a relatively stable amorphous material with a slightly acidic pH (6.8) and a very high surface area (97.31 m2g−1; Table 2). This large surface area is obviously a positive attribute when it is being used as adsorbent.

The elemental content of red mud was dominated by Fe and significant amounts of Na, Si and Al were also present (Table 1). Its mineralogy was composed of hematite and sodalite with gibbsite being subdominant (Table 1). Untreated red mud has a high pH (11–12) due to the presence of residual NaOH (giving it a high residual alkalinity). Seawater “neutralization” causes precipitation of Mg, Ca and Al hydroxide and carbonate minerals and results in a residue with a pH of about 8–10 (Hanahan et al. 2004). As shown in Table 2, the neutralized red mud was still alkaline (pH = 10.7) and had a high value for residual alkalinity. It is well documented that the high pH/surface alkalinity of red mud favours both adsorption and precipitation of heavy metal cations (Zhou and Haynes 2011) but the same properties are likely to hinder anion adsorption. The surface area of red mud (14.24 m2 g−1) was considerably smaller than that obtained for water treatment sludge (97.31 m2 g−1), but greater than that reported for other waste adsorbents such as coal fly ash (2–8 m2 g−1) (Wang et al. 2006). Both materials had relatively high CEC values and red mud had a higher pH, PZC and EC than water treatment sludge.

For their use as adsorbents, it is essential that materials are considered as non-toxic wastes. For that reason, the two materials were subjected to TCLP leaching test. The values for all metals tested are extremely low and well below regulatory guidelines for toxic wastes (Table 2) (USEPA 1992). However, there was a significant amount of Cr leached from the red mud and this is probably due to inadequate leaching during seawater neutralization. TCLP extractions demonstrated both water treatment sludge and red mud can be readily used as adsorbents for heavy metals without the prospect of further contaminating the wastewater with metals.

3.2 Effect of pH on Adsorption

The surface charge on water treatment sludge and red mud arises from deprotonation and protonation of potential determining MOH 0.5+2 and MOH0.5− groups on their amphoteric surfaces and as pH is raised, the surface charge becomes increasingly negative. This results in greater electrostatic repulsion between metalloid anions and the adsorbent surface thus disfavouring adsorption. Above the PZC (5.6 for water treatment sludge and 6.5 for red mud), surfaces carry a net negative charge. Nonetheless, as pH is raised, hydrolysis of metalloid ions occurs and this also greatly affects adsorption behaviour. The interaction between these two factors can be seen in the adsorption envelopes for As and Se on water treatment sludge (Fig. 1). For example, for arsenious acid (H3AsO3), the pK 1 is at 9.2 so that as the pH is raised the proportion of As(III) present as H2AsO −3 increases up to pH 9.2. Since As(III) is preferentially adsorbed as the oxyanion H2AsO −3 , maximum adsorption of As(III) occurs at about pH 9.2. Above that value, the effect of increasing negative surface charge predominates and electrostatic repulsion causes a pronounced decrease in adsorption with increasing pH. By contrast, for arsenic acid (H3AsO4), the pK 1 and pK 2 are at 2.2 and 6.8, respectively. As a result, between pH 2.2 and 6.8 As(V) is already present predominantly as the oxyanion H2AsO −4 but the proportion of the more strongly adsorbed H2AsO 2−4 is increasing so the decline in adsorption is slow. With increasing pH above 6.8, electrostatic repulsion results in a more pronounced decrease in adsorption of As(V). Similarly the pK 1 and pK 2 for selenious acid (H2SeO3) are at 2.5 and 8.0 and adsorption of Se(IV) showed a broadly similar pattern as that for arsenate with a steeper decline in adsorption above pH 8.0. The pK 1 for selenic acid is 1.9 so it is present in solution predominantly as SeO 2−4 . Adsorption of Se(VI) declined slowly between pH 2.0 and 4.0 and then very rapidly with further rises in pH. Similar patterns of As(III), As(V), Se(IV) and Se(VI) adsorption with increasing pH have been recorded onto the surfaces of pure oxides and clay minerals (Hingston et al. 1972; Goldberg 2002; Duc et al. 2006; Masue et al. 2007; Chan et al. 2009).

The pattern of adsorption of As and Se onto red mud differed appreciably from that onto red mud (cf Fig. 1a and b). That is, between pH 2 and 5, adsorption of As(V), Se(IV) and Se(VI) was unexpectedly low. As noted previously by Raven et al. (1998), who studied adsorption of arsenite and arsenate to ferrihydrite, the reductions in adsorption below pH 4.0 are attributable to increased solubility of Fe oxides at extremely low pH resulting in release of adsorbed ions back into solution. The decline in adsorption as pH was increased above pH 5.0 for As(V), Se(IV) and Se(VI) was much steeper and more pronounced for red mud than for water treatment sludge suggesting that with increasing pH the effect of increasing negative charge, and thus electrostatic repulsion, was the dominant mechanism operative. At pH values above about 5.5, As(V) and Se(IV) are evidently much more strongly adsorbed to surfaces of water treatment sludge than red mud (Fig. 1).

Over the pH range 2.0–9.0 for water treatment sludge, and 4.0–7.0 for red mud, adsorption of As(V) was markedly greater than that for As(III). This demonstrates the difficulty of removing both ions from wastewaters simultaneously by adsorption. For water treatment sludge, similar adsorption of the two oxyanions occurred at about pH 10.0 and at this pH value removal amounted to about 60 % of that initially added in solution. However, for red mud similar adsorption occurred at pH 2.8 and 7.8 and only 19–21 % of the solution As was removed. Indeed, red mud removed less than 25 % of the added solution Se(VI) and As(III) over the entire pH range tested (2.0–12.0) and only removed 50 % or more of solution As(V) over the pH range 4.0–6.9 and for Se(IV) only between pH 4.3 and 5.6. There was, therefore, a very narrow pH range over which red mud was an effective adsorbent for As(V) and Se(IV). In this regard, water treatment sludge was a much more effective adsorbent in that it removed 50 % or more of solution As(V) between pH 2.0 and 10.8, Se(IV) between 2.0 and 8.9, Se(VI) between 2.0 and 5.8 and As(III) between 8.4 and 10.9. Furthermore, in the pH range 8.0–11.0, water treatment sludge could be used to effectively remove both As(V) and As(III) from solution.

3.3 Adsorption Isotherms

It is evident that at pH 5.0, adsorption of metal ions generally increased with increasing equilibrium concentration of the metalloid anions in solution and tended to reach a maximum value as the adsorbent became progressively saturated (Fig. 2). Both Freundlich (1906) and Langmuir (1918) equations are commonly used to empirically describe sorption isotherms for metal cations and anions onto adsorbent materials (Apak 2002). The Freundlich equation explains adsorption onto a heterogeneous surface with uniform energy:

where q e and C e are the equilibrium concentrations of metal in the adsorbed (mmol g−1) and liquid phases (mmol L−1), respectively. K f and n are the Freundlich constants which are related to adsorption capacity and intensity, respectively. On the other hand, the Langmuir equation is based on monolayer adsorption on active sites of the adsorbent:

where q e and C e are equilibrium concentrations of metal in the adsorbed (mmol g−1) and liquid phases (mmol L−1), respectively. q max and b are the Langmuir constants which are related to the adsorption capacity and energy of adsorption, respectively.

Isotherm constants and correlation coefficients for the Langmuir and Freundlich equations describing the data are presented in Table 3. Over the equilibrium metal concentrations studied, adsorption of As(V) and Se(IV) by water treatment sludge was much greater than that for Se(VI) and As(III) (Fig. 2). As(III) showed a different pattern of adsorption to that of the other three oxyanions in that adsorption tended to be linear between equilibrium concentrations of 1.0 to 5.3 mM resulting in a high value for 1/n (0.728). That is, a value of 1 indicates linear adsorption and may suggest some type of precipitation reactions are occurring.

For red mud, adsorption of As(V) more pronounced than that for Se(IV) which was, in turn, more pronounced than that for Se(VI) and As(III). As a result the q max value for As(V) was at least an order of magnitude greater than that for the other three oxyanions. Adsorption of Se(VI), and to a lesser extent As(III) tended to be linear resulting in high values for 1/n.

For the strongly adsorbed metals, As (V) and Se(IV), adsorption on both materials fitted better to the Langmuir than Freundlich equation whilst for As(III) and Se(VI) the reverse was the case. Unlike the Langmuir equation, the Freundlich equation does not predict a maximum metal removal. The K f factor is indicative of the extent of adsorption and the slope 1/n is the sorptive intensity. Values of n >1 (as recorded for all oxyanions onto both adsorbents) indicate that bonding energies decrease with increasing surface adsorption densities in accordance with preferential adsorption occupying surface sites in the order from strongest to weakest binding strength (Apak 2002). In addition, n >2 is sometimes interpreted as an indication of an adsorbent with good adsorbent characteristics for the solute being considered (Treybal 1980). Values of n >2 were recorded for As(V) and Se(VI) on water treatment sludge and As(V) onto red mud. However, as already noted, the effectiveness of water treatment sludge as an adsorbent for As(III) would be greatly improved by raising the pH of adsorption into the range 9.0–10.0. Indeed, when adsorption isotherms were constructed at pH 9.0 (data not shown), q max values for As(III) and As(V) were 0.25 and 0.21, respectively, and values of n were >2 for both ions.

3.4 Effect of Contact Time

For all four oxyanions, their adsorption onto water treatment sludge was rapid and 90 %, or greater, of maximum adsorption had occurred after 120 min. This was also true for As(V) and Se(VI) onto red mud but for Se(IV) and more particularly As(III) adsorption continued over the 360-min contact time. This slow kinetics is probably attributable to the diffusion of arsenite species into the adsorbent matrix. In order to evaluate the kinetic mechanisms that controlled the adsorption process, pseudo-first-order and pseudo-second-order models were employed to interpret the experimental data. The pseudo-first-order equation can be represented by:

where k 1 (min−1) is the pseudo-first-order adsorption rate constant, q t is the amount adsorbed at time t (min) and q e denotes the amount adsorbed at equilibrium, both in millimoles per gram. The pseudo-second-order equation can be expressed as:

where k 2 [g (mmol min)−1] is the adsorption rate constant of pseudo-second order.

Based on the obtained correlation coefficients, the pseudo-second-order equation gave a better fit to the experimental kinetic data than the pseudo-first-order model and calculated pseudo-second-order q e values were in good agreement with the experimental values (Table 4). This suggests that chemisorption rather than diffusion/ion exchange was the rate-limiting step to adsorption (Ho and McKay 1999). Chemisorption involves exchange between metal anions and surface ligands and the formation of covalent bonds with the surface (McBride 2000). Arsenate, arsenite and selenite have been shown to form strong inner sphere complexes (bidentate and sometimes monodentate), while selenate forms only outer sphere complexes with Al and Fe oxide surfaces (Sparks 2003). In addition, there will be some adsorption onto surfaces of organic matter which was coagulated with the hydroxyl-Al in water treatment sludge. Adsorption to organic matter occurs through formation of coordination complexes and chelates with surface functional groups (e.g. carboxylic, phenol, enolic, alcoholic OH and C = O) (Stevenson 1994).

3.5 Desorption/Regeneration

The ease and extent of desorption of metals from adsorbent surfaces is important since once the material becomes saturated with contaminant metals, and is no longer effective, it needs to be regenerated and reused or disposed of in a landfill. For water treatment sludge, when desorption was carried out in the 0.01 M NaNO3 electrolyte, very small quantities of metal anions were desorbed (Fig. 4). After three successive desorption cycles, cumulative As(V), As(III), Se(VI) and Se(IV) removed amounted to less than 1, 20, 19 and 4 %, respectively, of that initially adsorbed. Such hysteresis demonstrates that the metals are very strongly held to sludge surfaces and suggests they will not be readily leached from the material in a landfill, at least in the short-term. The most common reagent used for effective desorption of oxyanions from adsorbent surfaces is NaOH (Zhang et al. 2008; Sahu et al. 2010). In agreement with this, As(V), Se(VI) and Se(VI) were effectively desorbed from water treatment sludge by NaOH at 0.1 and 0.5 M concentrations (Fig. 4). The vast majority of metal was removed in the first desorption cycle. By contrast, HNO3 was not an effective desorbing agent for these three oxyanions. Such results reflect the fact that an alkaline environment is least favourable for adsorption of metal anions and favours desorption. Removal of adsorbed As(III) from water treatment sludge was only partially successful using either HNO3 or NaOH. The greatest desorption was achieved using 0.5 M NaOH (i.e. 57 % removal after three cycles).

For red mud, NaNO3 solution was surprisingly effective at removing adsorbed Se(VI) (Fig. 5). As already noted, selenate typically forms weakly bonded outer sphere complexes with adsorption surfaces (Sparks 2003) and it is apparently much more weakly bonded to red mud surfaces than those on water treatment sludge. For all four oxyanions, NaOH was a more effective desorbent than HNO3. The use of NaOH (at 0.1 and 0.5 N concentrations) was very effective at removing As(V) and Se(VI) (i.e. 78–85 and 90–92 % removal in the first desorption cycle, respectively) but less effective for As(III) and Se(IV) (i.e. only 26–49 and 43–58 % removal in first desorption cycle, respectively).

The above results suggest that for both water treatment sludge and red mud, NaOH at the 0.5 M concentration is the most effective desorbent and that As(V) and Se(IV) were the two most strongly adsorbed metal species. In addition to the high pH being unfavourable for anion adsorption, the very high pH will favour dissolution of iron oxide and Al hydroxide surfaces thus releasing adsorbed anion from the surfaces. As a result, for As(V) and Se(IV), the two materials were subjected to eight successive cycles of adsorption/regeneration using 0.5 NaOH as the desorbing agent. As shown in Fig. 6, water treatment sludge maintained 90 % or greater relative sorption for both As(V) and Se(IV) in the first five cycles and thereafter its adsorption capacity decreased slowly. The slow decline in adsorption can be explained in that a small amount of undesorbable metal occupied some of the adsorption sites after each desorption cycle, resulting in the number of vacant surface adsorption sites being decreased sequentially with increasing number of cycles. A similar pattern was observed for Se(IV) on red mud. By contrast, there was a very pronounced decline in adsorption of As(V) after three regeneration cycles and the adsorption capacity was negligible after six cycles. Relative adsorption of Se(IV) also decreased at a steeper rate between three and six adsorption/desorption cycles. The reason for this is unclear and analysis of the desorbing solutions from the first three cycles demonstrated it was not due to lack of desorption of arsenate (and thus saturation of adsorption sites). However, treatment of saltwater-neutralized red mud with NaOH will restore it to its original state with a pH above 11.0 and the very high pH at the adsorption surfaces will greatly inhibit anion adsorption.

3.6 Conclusions

Water treatment sludge is a more effective adsorbent for the oxyanions of Se and As than saltwater neutralized red mud. Red mud has a very small pH window (i.e. 4.0–6.0) in which it is effective for As(V) and Se(IV) whilst it is ineffective as an adsorbent for both Se(IV) and Se(VI). By contrast, water treatment sludge is effective for both As(III) and As(V) at pH values between 9.0–11.0 and for As(III), Se(IV) and Se(VI) between pH 2.0 and 5.5. Since it has previously also been shown to be an effective adsorbent for Pb(II), Cd(II), Cu(II), Zn(II), Cr(III) and Cr(VI), it is a suitable material for development of a low-cost adsorbent for removal of heavy metal cations and anions from wastewater streams.

References

Adriano, D. C. (2002). Trace elements in terrestrial environments. Biogeochemistry, bioavailability and risks of metals. New York: Springer.

Apak, R. (2002). Adsorption of heavy metal ions on soil surfaces and similar substances. In A. T. Hubbard (Ed.), Encyclopedia of surface and colloid science (pp. 385–417). New York: Marcel Dekker.

Babel, S., & Kurniawan, T. (2003). A. Low-cost adsorbents for heavy metals uptake from contaminated water: a review. Journal of Hazardous Materials, B97, 219–243.

Chan, Y. T., Kuan, W. H., Chen, T. Y., & Wang, M. K. (2009). Adsorption mechanism of selenate and selenite on the binary oxide systems. Water Research, 43, 4412–4420.

Duc, M., Lefevre, G., & Fedoroff, M. (2006). Sorption of selenite ions on hematite. Journal of Colloid and Interface Science, 298, 556–563.

Freundlich, H. (1906). Uber die adsorption in losungen. Zeitschrift fur Physikaliske Chemie, 57, 387–470.

Gupta, V. K., & Ali, I. (2002). Adsorbents for water treatment: low-cost alternatives to carbon. In A. T. Hubbard (Ed.), Encyclopedia of surface and colloid science (Vol. 1, pp. 136–166). New York: Marcel Dekker.

Genc, H., Tjell, J. C., McConchie, D., & Schuiling, O. (2003). Adsorption of arsenate from water using neutralized red mud. Journal of Colloid and Interface Science, 264, 327–334.

Genc-Fuhrman, H., Tjell, J. C., & McConchie, D. (2004). Adsorption of arsenic from water using activated neutralized red mud. Environmental Science and Technology, 38, 2428–2434.

Goldberg, S. (2002). Competitive adsorption of arsenate and arsenite on oxides and clay minerals. Soil Science Society of America Journal, 66, 413–421.

Hanahan, C., McConchie, D., Pohl, J., Creelman, R., Clark, M., & Stocksiek, C. (2004). Chemistry of seawater neutralization of bauxite refinery residues (red mud). Environmental Engineering Science, 21, 125–138.

Hingston, F. J., Posner, A. M., & Quirk, J. P. (1972). Anion adsorption by goethite and gibbsite. I. Role of the proton in determining adsorption envelopes. Journal of Soil Science, 23, 177–192.

Ho, Y. S., & McKay, G. (1999). Pseudo-second order model for sorption processes. Process Biochemistry, 34, 451–465.

Langmuir, I. (1918). The adsorption of gases on plane surface of glass, mica and platinum. Journal of the American Chemical Society, 40, 1361–1368.

Masue, Y., Loeppert, R. H., & Kramer, T. A. (2007). Arsenate and arsenite adsorption and desorption behaviour on coprecipitated aluminium:iron hydroxides. Environmental Science and Technology, 41, 837–842.

McBride, M. B. (2000). Chemisorption and precipitation reactions. In M. E. Sumner (Ed.), Handbook of soil science (pp. B 265–B 302). Boca Raton: CRC Press.

Paramguru, R. K., Rath, P. C., & Misra, V. N. (2005). Trends in red mud utilization—a review. Mineral Processing and Extractive Metallurgy Review, 26, 1–29.

Raven, K. P., Jain, A., & Loeppert, R. H. (1998). Arsenite, arsenate adsorption on ferrihydrite: kinetics, equilibrium, and adsorption envelopes. Environmental Science and Technology, 32, 344–349.

Rayment, G. E., & Higginson, F. R. (1992). Australian handbook of soil and water chemical methods. Melbourne: Inkata Press.

Sahu, R. S., Patel, R., & Ray, B. C. (2010). Utilization of activated CO2-neutralized red mud for removal of arsenate from aqueous solutions. Journal of Hazardous Materials, 179, 1007–1013.

Smith, E., Naidu, R., & Alston, A. M. (1998). Arsenic in the soil environment: a review. Advances in Agronomy, 64, 149–195.

Sparks, D. L. (2003). Environmental soil chemistry (2nd ed.). Amsterdam: Academic Press.

Stevenson, F. J. (1994). Humus chemistry, genesis, composition, reactions. New York: Wiley.

Treybal, R. E. (1980). Mass transfer operations (3rd ed.). New York: McGraw-Hill.

USEPA (1992) The toxicity characteristic leaching procedure. US Code of Federal Regulations, 40th edition, Part 261, Appendix II, Washington DC, USEPA.

Wang, J. M., Ban, H., Teng, X. J., Wang, H., & Ladwig, K. (2006). Impacts of pH and ammonia on the leaching of Cu(II) and Cd(II) from coal fly ash. Chemosphere, 64, 1892–1898.

Zhang, S., Liu, C., Luan, Z., Peng, X., Ren, H., & Wang, J. (2008). Arsenate removal from aqueous solutions using modified red mud. Journal of Hazardous Materials, 152, 486–492.

Zhou, Y.-F., & Haynes, R. J. (2010a). Sorption of heavy metals by inorganic and organic components of solid wastes: significance to use of wastes as low cost adsorbents and immobilizing agents. Critical Reviews in Environmental Science and Technology, 40, 909–977.

Zhou, Y.-F., & Haynes, R. J. (2010b). Removal of Pb(II), Cr(III) and Cr(VI) from aqueous solutions using alum-derived water treatment sludge. Water, Air and Soil Pollution, 215, 631–643.

Zhou, Y.-F., & Haynes, R. J. (2011). A comparison of inorganic solid wastes as adsorbents of heavy metal cations in aqueous solution and their capacity for desorption and regeneration. Water, Air and Soil Pollution, 218, 457–470.

Acknowledgements

We thank Robert Townsley of Seqwater (Mt Crosby) for supplying the water treatment sludge, the late Dr. David McConchie of Virotec International for supplying the Bauxsol red mud. We are indebted to Mark Raven of CSIRO Land and Water for mineralogical analysis of the materials, Dr. Xin-Lin Hong of Wuhan University College of Chemistry and Molecular Sciences for surface area determinations and David Appleton of the University of Queensland for metal determinations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, YF., Haynes, R.J. A Comparison of Water Treatment Sludge and Red Mud as Adsorbents of As and Se in Aqueous Solution and Their Capacity for Desorption and Regeneration. Water Air Soil Pollut 223, 5563–5573 (2012). https://doi.org/10.1007/s11270-012-1296-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11270-012-1296-0