Abstract

This study evaluated the copper ion adsorption capacity of sugarcane bagasse in natura and chemically modified with citric acid and sodium hydroxide. Adsorption analyses in batch system were carried out in function of contact time with the adsorbent and adsorbate concentration. Flame atomic absorption spectrometry was used to determine the copper concentrations. Adsorption experimental data were fitted to Langmuir and Freundlich linear models, and the maximum adsorption capacity was estimated for copper ions in function of modifications. The chemical modifications were confirmed at 1,730 cm−1 peak in infrared spectra, referring to the carboxylate groups. The required time for the adsorption to reach equilibrium was 24 h and the kinetics follows the behavior described by the pseudo-second order equation. Besides, a significant improvement of the copper adsorption has been observed after the bagasse treatment, where the maximum adsorption capacity was 31.53 mg g−1 for copper using modified bagasse with nitric acid according to Langmuir isotherm linear model. The high uptake of copper ions from aqueous medium verified by chemically modified sugarcane bagasse makes this material an attractive alternative for effluent treatment and avoids environmental contamination.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

One of the most serious problems that affect the environment is the contamination caused by organic and inorganic chemical contaminants (Pergher et al. 2005). Due to the constant demographic and industrial growth of many regions, associated to the consumption, production, and exploitation of raw materials like fossils and minerals, the generation of effluents containing heavy metals like copper has been increasing. Most heavy metals, when thrown away without previous treatment, are highly mobile besides being bioaccumulative in the food chain, becoming harmful to fauna, flora, and the human health (Rodrigues et al. 2006; Albertini et al. 2007; Sousa et al. 2007). Copper is considered essential in certain concentrations (0.6 mg/day for woman and 0.7 mg/day for man); however, in excess, it causes intoxication and may cause hepatitis, erythematosus lesions, brain congestion, and bleeding (Schvartsman 1991; Gaetke and Chow 2003).

Heavy metals can express their polluting potential directly on the soil because of their availability to plants through the contamination of superficial waters due to erosions, and sub-superficial waters due to their movement. Therefore, it is essential to know the destination of these elements in the soil to evaluate the environmental impact (Oliveira et al. 2002; Mehrasbi et al. 2009). Thus, governmental organs like the National Council for the Environment (CONAMA-BRASIL), through resolution no. 357 of March 17, 2005, established 1.0 mg L−1 of copper as the maximum concentration level for discharge of aqueous effluent (CONAMA-BRASIL 2005); whereas other international organs like the Environmental Protection Agency (EPA) established 1.3 mg/L as the maximum allowed level of copper in drinking water (EPA 2010).

For effluents contaminated by metals, conventional treatment methods like precipitation, ionic exchange, electrochemical treatment, flocculation, ozonization, and filtration are many times limited by technical and/or economical inviabilities. These techniques generally need a long detention time, making the implementation difficult, mainly when the metals are dissolved in great volumes of water. Another relevant factor in these treatments is the generation of solid residues that are stored and disposed, causing another serious problem (Sousa et al. 2007; Ferreira et al. 2007; Abbas et al. 2008; Karnitz Júnior et al. 2010).

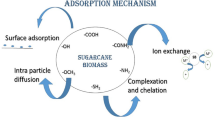

Adsorption is an alternate treatment which is very efficient to remove toxic metals (Sousa et al. 2007). During adsorption, there is the accumulation of a certain element or substance in the interface between two phases, i.e., between the solid surface and the adjacent solution (Cohen-Shoel et al. 2002; Sousa et al. 2007; Karnitz Júnior et al. 2009).

In Brazil, due to the large agricultural production, there is a generation of several agro industrial byproducts and residues, such as sugarcane bagasse, cashew, green coconut, wood, algae, and compost. However, the disposal of these residues has become an environmental problem. A lot of them are reused, but most of them are still not utilized at all (Ajmal et al. 2000; Annadurai et al. 2002; Kadirvelu et al. 2003; Tarley and Arruda 2004; Rodrigues et al. 2006; Albertini et al. 2007; Khormaei et al. 2007). Thus, due to economical viability and origin of renewable sources, some studies have been done on the use of these agro industrial residues as alternative biosorbents of heavy metals in order to treat aqueous effluent (Tarley and Arruda 2003; Tarley and Arruda 2004; Karnitz Júnior et al. 2010). Biosorption results from the electrostatic interaction and also from the formation of complexes between metallic ions and functional groups present in biomass, when they have chemical affinity to the metal. In addition, these properties can be significantly increased when the biomass undergoes chemical modification. For example, a significant increase of the biomass capacity to retain metallic ions was verified in soybean hull submitted to a treatment with alkaline solution (NaOH), followed by a modification with citric acid at high temperatures (Annadurai et al. 2002; Tarley and Arruda 2003; Tarley and Arruda 2004; Feng et al. 2009; Pérez-Marín et al. 2007; Karnitz Júnior et al. 2009; Karnitz Júnior et al. 2010).

The utilization of sugarcane bagasse as biosorbent is considered economically viable to industries that need to treat effluents containing heavy metals because large amounts of this material are discharged from alcohol distilleries. Although most of them is processed and used to feed furnaces, there is exceeding sugarcane bagasse that corresponds to 8% in auxiliary distilleries and 12% in independent ones. Hence, this residue can be reutilized to improve the quality of the environment as a biosorbent of heavy metals (Karnitz Júnior et al. 2009; Karnitz Júnior et al. 2010).

According to comments, in this study, sugarcane bagasse in natura and chemically modified was evaluated as a new and alternate biosorbent of copper removal from aqueous medium.

2 Experimental

2.1 Reagents

Analytical grade chemical reagents were used throughout the experiment. Copper stock solution of 1,000 mg L−1 was prepared from copper nitrate (Cu(NO3)2 Vetec, 99%), and necessary dilutions were done with deionized water; 0.1 mol L−1 NaOH (F. Maia, 97%), 0.1 mol L−1 HCl (F. Maia, 37%), and 1.2 mol L−1 HNO3 solutions were used for pH adjustment.

2.2 Equipment

A BOMEM (model MB-102) FT-IR infrared spectrometer was used to elucidate the functional groups present in the adsorbents. Bagasse samples were proportionally macerated with KBr crystals (1 mg sample/100 mg KBr) and put in a pastillator, then 4,000 to 400 cm−1 spectral range was analyzed. A flame atomic absorption spectrometer (FAAS; GBC 932plus), equipped with deuterium lamp for background correction and a hollow cathode lamp as radiation source for lead, was used for metal quantification.

2.3 Adsorbent Preparation—Sugarcane Bagasse Modification

Sugarcane bagasse was obtained from Santa Terezinha mill, located in Ivaté—PR, Brazil. Prior to use, the sugarcane bagasse was ground and sieved (Bertel sieve, 100 mesh) in order to obtain a more homogenous particle size. Furthermore, three chemical modifications were performed.

2.3.1 Modification Using NaOH (B-S)

The modification of sugarcane bagasse with NaOH [NaOH (B-S)] was done in the following way: for each gram of the material, 20 mL of a 0.1 mol L−1 NaOH solution was added; then the mixture was agitated for 2 h and the supernatant was discharged. Then, the material was repeatedly washed with deionized water and dried at 55°C for 24 h. This procedure was carried out in order to withdraw any impurity that could interfere in the effluent quality (Rodrigues et al. 2006).

2.3.2 Modification with Citric Acid (B-CA)

The second treatment of sugarcane bagasse was carried out by using citric acid (B-CA). A solution of 1.2 mol L−1 citric acid was added to the bagasse at 8.3 mL solution/gram of bagasse ratio. After that, the mixture was agitated for 30 min and the supernatant discharged. The bagasse was dried at 55°C, and after 24 h the temperature was increased to 120°C and kept for 90 min. Afterwards, the bagasse was repeatedly washed with deionized water and dried at 55°C for 24 h (Rodrigues et al. 2006).

2.3.3 Modification with NaOH and Citric Acid (B-CAS)

In the third treatment, the sugarcane bagasse was modified with NaOH followed by a chemical modification with citric acid solution (B-CAS). For each gram of the material, 20 mL of 0.1 mol L−1 NaOH solution was added for this procedure; the mixture was agitated for 2 h and the supernatant discharged. Next, the material was repeatedly washed with deionized water and dried at 55°C for 24 h. Then, 8.3 mL of a 1.2 mol L−1 citric acid solution was added per each gram of bagasse and agitated for 30 min; the supernatant was discharged and the bagasse was dried at 55°C. The temperature was raised to 120°C after 24 h and kept for 90 min; next, the bagasse was repeatedly washed with deionized water (60–80°C) and dried at 55°C for 24 h (Rodrigues et al. 2006).

2.4 Metal Adsorption Experiment

2.4.1 Adsorption in Function of Time

The adsorption of copper ions in the modified bagasse (B-S, B-CA, and B-CAS) and natural bagasse (B-N) was carried out by using 50 mL of 1,000 mg L−1 Cu2+ solutions, which was agitated with 0.5 g of bagasse in an orbital shaker. Ten aliquots of 500 μL were collected from supernatant in a time interval ranging from 15 to 1,440 min, and deionized water was added until the volume reached 50 mL. The concentration of copper ions was determined by FAAS. Necessary correction regarding the amount of copper ions in initial solution was made for each aliquot. The amount of adsorbed metal per gram of bagasse (q eq) in function of time was calculated as the following:

where C 0 and C eq are the initial metal concentration and in equilibrium of the solution (mg L−1), respectively, V is the solution volume (mL), and M the bagasse mass (g).

2.4.2 Adsorption Isotherms

Solutions of Cu2+ ions at different concentrations were prepared, ranging from 100 to 1,000 mg L−1. Afterwards, 50 mL of Cu2+ solutions at pH 5.0 were individually used and agitated with 0.5 g of bagasse in an orbital shaker for 24 h. Next, the mixtures were filtrated and the solutions were analyzed by FAAS. Using the Eq. (1), the amount of adsorbed metal per gram of bagasse was calculated and a plot of q eq in function of C eq was built.

3 Results and Discussions

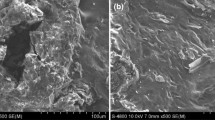

3.1 Adsorbent Characterization

Figure 1 shows the infrared spectra of modified and in natura sugarcane bagasse. After the bagasse modification with citric acid (Fig. 1 (C and D)), the presence of carboxylate groups at 1,730 cm−1 was observed. Such result corroborates the study done by Rodrigues et al. (2006) that verified the occurrence of carboxylic groups in Paraju sawdust after treatment with NaOH and citric acid. Considering that carboxylic groups present in natural adsorbents are usually weak acids and make negative sites in medium moderately acid, the interaction of cations in solution becomes easier. According to Rodrigues et al. (2006), Sousa et al. (2007), and Feng et al. (2009), the adequate pH for these sites to become more reactive is usually around pH 5. Therefore, pH 5 was chosen to be used throughout the experiments and was maintained at 5 with the addition of hydrochloric acid or sodium hydroxide 0.1 mol L−1.

3.2 Influence of Time on Adsorption

Figure 2 depicts the copper adsorption in the B-S, B-C, B-CAS, and B-N materials as a function of shaking time. The highest adsorption was observed for the B-CA material, and thus, preliminarily, it was observed that the chemical modifications improved the adsorbing properties of the bagasse. Regarding the shaking time, it was observed that, for all experiments, the system tends to reach equilibrium around 500 min; however, a slight increase on adsorption was verified around 1,440 min (24 h). Pergher et al. (2005) obtained system equilibrium after a longer period, around 12 h.

From data presented in Fig. 2, it was possible to characterize the kinetics for each adsorbent, using pseudo-first and pseudo-second order kinetic models. The pseudo-first order kinetics follows the Lagergren model expressed by Eq. 2 (Doğan et al. 2004; Noeline et al. 2005; Özcan et al. 2005; Pérez-Marín et al. 2007; Feng et al. 2009).

where q t is the amount of adsorbed metallic ions (mg g−1) in t time (min) and K 1 is the pseudo-first order constant (min−1). Through the linear and angular coefficient of the log (q eq – q t) plot in function of time, q eq and K 1 can be calculated, respectively. When comparing the experimentally obtained values of q eq to the one calculated by Eq. 2, it is observed that they are not close (Table 1). Besides, the values of r 2 are far from 1, suggesting that the adsorption does not fit the first order reaction.

Therefore, the pseudo-second order model (Eq. 3) was applied for the kinetics of metal adsorption (Doğan et al. 2004; Noeline et al. 2005; Özcan et al. 2005; Pérez-Marín et al. 2007; Feng et al. 2009).

where K 2 is the pseudo-second order constant (g mg−1 min−1) obtained by the angular coefficient of linear plot (t/q t vs t; Fig. 3) and q eq can be calculated using the linear coefficient. Experimental and calculated values of q eq, K 2, are r 2 are shown in Table 1.

Taking into account the values of correlation coefficient for pseudo-first order and pseudo-second order kinetic models, it can be verified that the second one fits those experimental data very well. Besides, the values of q eq for this model are superior to the ones obtained for the pseudo-first order model, and closer to the experimentally obtained values of q eq, but they are not equal to the experimental data of q eq. Thus, the value of r (linear correlation) around 1 for the pseudo-second order confirms that the adsorption kinetics is controlled by this order and that there is a strong interaction between adsorbent and adsorbate.

3.3 Adsorption Isotherms

The adsorption isotherms (Fig. 4) were built by setting the equilibrium time between adsorbate and adsorbent at 24 h. An improvement on adsorption at 10-fold for B-CA was verified regarding the in natura bagasse. Similar results have been observed in copper adsorption in Paraju sawdust modified with sodium hydroxide and citric acid (Rodrigues et al. 2006 ) and other studies by Marshall et al. (1999) and Han et al. (2010). The high adsorption efficiency provided by chemical modification can also be assessed by comparison with other natural materials. The results obtained by Guerra et al. (2008), in which pillar smectites were used in the copper adsorption process, provided lower values of q eq than those observed by using B-CAS material.

In order to verify the adsorptive behavior of copper ions in materials, Langmuir and Freundlich models, Eqs. 2 and 3, respectively, were applied.

where b is a constant that indicates the adsorption intensity; q m is the capacity measurement that indicates the maximum adsorption intensity:

In which K f can indicate the ion adsorption in the biomass and n indicates, quantitatively, the biomass energetic site reactivity (Sodré et al. 2001).

Langmuir model states that the forces that act on the adsorption are similar to chemical reactions; it is also observed that there is no interaction among adsorbed species, only between them and the adsorbent. The adsorption on the solid surface of the adsorbent occurs in one single layer (monolayers). Freundlich model, on the other hand, was one of the first proposed equations to relate the amount of adsorbed ions to the material concentration in the solution and corresponds to the exponential distribution of adsorption values (Özacar and Şengil 2003; Doğan et al. 2004; Dahiya et al. 2008; Gonçalves et al. 2008).

According to Table 2, Langmuir model presents a better adjustment than Freundlich model. Thus, the maximum adsorption capacity of biosorbent towards copper ions was determined from Langmuir linear model.

In fact, Langmuir adsorption model has been broadly used to estimate the adsorption capacity of several elements and chemical species, and its main advantage on other isotherms is that it allows quantifying the adsorption capacity of chemical species (n) and evaluating the constant related to liking energy (b) (Sodré et al. 2001).

Considering the results obtained from Langmuir linear model, it is easily noted that those chemically modified materials adsorb higher amounts of copper ions, specially the sugarcane bagasse modified with citric acid, B-CA. Comparing q eq value for B-CA with other biosorbents (Table 3), a clear advantage in terms of maximum adsorption capacity is attained by using the chemically modified material.

3.4 Thermodynamic Parameters

The thermodynamic parameters for the adsorption of ΔH (enthalpy), ΔS (entropy), and ΔG (Gibbs energy) were calculated using the Eqs. 6 and 7 (Sari et al. 2007; Gonçalves et al. 2008):

where K d corresponds to the ratio between q eq and C eq, R is the gas constant and has the value of 8.314 JK−1 mol−1, T is the experiment temperature expressed in Kelvin (K). Enthalpy and the other parameters (Table 4) were obtained from the graphic construction of lnKd versus 1/T, from Van’t Hoff equation.

After the bagasse modification, it was possible to verify a negative increase in the values of ΔG, when compared to the bagasse without modification. Such result shows that the modifications made in the bagasse lead to a more energetically favorable adsorption, especially for B-CA material, corroborating the higher adsorption capacity. Besides, after the modification, there was an inversion in the system enthalpy and entropy. Enthalpy after the modification became endothermic and there was an increase in the system disorder. Therefore, the process spontaneity after the modification was governed by the disorder increase. In addition, based on values found in enthalpy, it can be reported that the interaction between adsorbate and adsorbent is oriented by a physical adsorption.

3.5 Copper Desorption

The assay to evaluate the copper desorption from materials was carried out by loading the bagasse with known amount of copper (1,000 mg L−1), followed by washing with 150 mL milli-Q water and drying for 24 h in an oven at 50°C. After this period, the bagasse was soaked in a 0.1 mol L−1 HCl solution for copper recovery. The obtained values are expressed in Table 5.

Considering the percentage found for desorption, it is verified that B-CA material is also significant in the desorption process, as well as in adsorption, where the desorbed concentration is higher than the others. Desorbed percentage can be considered satisfactory for a possible reutilization of these materials for new adsorption phases. The precision of repeatability based on relative standard deviation (RSD) was evaluated for the modified bagasse with citric acid, whereas the RSD was found to be 2% for four cycles involving adsorption and desorption.

4 Conclusion

In this study, chemical modification of sugarcane bagasse was carried out aiming to introduce carboxylate groups to improve the adsorption of copper. The modifications were confirmed by infrared data, where the band close to 1,730 cm−1 indicated the presence of the carboxylic group. Significant increase on adsorption capacity was verified in all modified materials, with predominance of sugarcane bagasse modified with citric acid. The adsorption process fitted the Langmuir linear model very well and the copper adsorption in aqueous solution followed the pseudo-second order kinetics. In addition, the chemical modification of the sugarcane bagasse made the system more energetically favorable, as demonstrated by the values of Gibbs free energy; the process was considered endothermic with disorder increase. Finally, it was also verified that, after the modifications, there was an improvement in the copper desorption, indicating that this material can be reutilized.

References

Abbas, M., Nadeem, R., Zafar, M. N., & Arshad, M. (2008). Biosorption of chromium (III) and chromium (VI) by untreated and pretreated Cassia fistula biomass from aqueous solutions. Water, Air, and Soil Pollution, 191, 139–148.

Ajmal, M., Rao, R. A. K., Ahmad, R., & Ahmad, J. (2000). Adsorption studies on Citrus reticulate (fruit peel of orange): Removal and recovery of Ni (II) from electroplating wastewater. Journal of Hazardous Materials, B79, 117–131.

Albertini, S., Carmo, L. F., & Prado-Filho, L. G. (2007). Use of sawdust and pulp from cane as adsorbents of cadmium. Ciência Tecnologia Alimentos, 27(1), 113–118.

Annadurai, A., Juang, R. S., & Lee, D. J. (2002). Adsorption of heavy metals from water using banana and orange peels. Water Science and Technology, 47, 185–190.

Chen, J. P., & Wu, S. (2004). Simultaneous adsorption of copper ions and humic acid onto an activated carbon. Journal of Colloid and Interface Science, 280, 334–342.

Cohen-Shoel, N., Ilzycer, D., Gilath, I., & Tel-Or, E. (2002). The involvement of pectin in Sr2+ biosorption by Azolla. Water, Air, and Soil Pollution, 135, 195–205.

Dahiya, S., Tripathi R. M., & Hegde A. G. (2008). Biosorption of heavy metals and radionuclide from aqueous solutions by pre-treated arca shell biomass. Journal of Hazardous Materials, 150, 376–386.

Doğan, M., Alkan, M., Türkyılmaz, A., & Özdemir, Y. (2004). Kinetics and mechanism of removal of methylene blue by adsorption onto perlite. Journal of Hazardous Materials, B109, 141–148.

Environmental Protection Agency (EPA). http://www.epa.gov/safewater/contaminants/index.html. Accessed 20 Mach 2010.

Feng, N., Guo, X., & Liang, S. (2009). Adsorption study of copper (II) by chemically modified orange peel. Journal of Hazardous Materials, 164, 1286–1292.

Ferreira, J. M., Silva, F. L. H., Alsina, O. L. S., Oliveira, L. S. C., Cavalcanti, E. B., & Gomes, W. C. (2007). Equilibrium and kinetic study of Pb2+ biosorption by Saccharomyces cerevisiae. Quimica Nova, 30, 1188–1193.

Gaetke, L. M., & Chow, C. K. (2003). Copper toxicity, oxidative stress, and antioxidant nutrients. Toxicology, 189, 147–163.

Gonçalves, M., Oliveira, L. C. A., & Guerreiro, M. C. (2008). Magnetic niobia as adsorbent of organic contaminants in aqueous medium: Effect of temperature and pH. Quimica Nova, 31, 518–522.

Guerra, D. L., Airoldi, C., Lemos, V. P., Angélica, R. S., & Viana, R. R. (2008). Application of Zr/Ti-PILC in the adsorption process of Cu(II), Co(II) and Ni(II) using adsorption physico-chemical models and thermodinamics of the process. Quimica Nova, 31, 353–359.

Han, R., Zhang, L., Song, C., Zhang, M., Zhu, H., & Zhang, L. (2010). Characterization of modified wheat straw, kinetic and equilibrium study about copper ion and methylene blue adsorption in batch mode. Carbohydrate Polymers, 79, 1140–1149.

Kadirvelu, K., Kavipriya, M., Karthika, C., Radhika, M., Vennilamani, N., & Pattabhi, S. (2003). Utilization of various agricultural wastes for activated carbon preparation and application for the removal of dyes and metal ions from aqueous solution. Bioresource Technology, 87, 129–132.

Karnitz Júnior, O., Gurgel, L. V. A., De Freitas, R. P., & Gil, L. F. (2009). Adsorption of Cu(II), Cd(II), and Pb(II) from aqueous single metal solutions by mercerized cellulose and mercerized sugarcane bagasse chemically modified with EDTA dianhydride (EDTAD). Carbohydrate Polymers, 77, 643–650.

Karnitz Júnior, O., Gurgel, L. V. A., & Gil, L. F. (2010). Removal of Ca(II) and Mg(II) from aqueous single metal solutions by mercerized cellulose and mercerized sugarcane bagasse grafted with EDTA dianhydride (EDTAD). Carbohydrate Polymers, 79, 184–191.

Khormaei, M., Nasernejad, B., Edrisi, M., & Eslamzadeh, T. (2007). Copper biosorption from aqueous solutions by sour orange residue. Journal of Hazardous Materials, 149, 269–274.

Marshall, W. E., Wartelle, L. H., Boler, D. E., Johns, M. M., & Toles, C. A. (1999). Enhanced metal adsorption by soybean hulls modified with nitric acid. Bioresource Technology, 69, 263–268.

Mehrasbi, M. R., Farahmandkia, Z., Taghibeigloo, B., & Taromi, A. (2009). Adsorption of lead and cadmium from aqueous solution by using almond shells. Water, Air, and Soil Pollution, 199, 343–351.

National Council on the Environment (CONAMA). Resol. n°357 de 17/03/2005 http://www.mma.gov.br/port/conama/legiano1.cfm?codlegitipo=3&ano=2005/ (accessed 10 July 2009)

Noeline, B. F., Manohar, D. M., & Anirudhan, T. S. (2005). Kinetic and equilibrium modeling of lead (II) sorption from water and wastewater by polymerized banana stem in a batch reactor. Separation and Purification Technology, 45, 131–140.

Oliveira, F. C., Mattiazzo, M. E., & Abreu JR, C. H. (2002). Movement of heavy metals in an Oxisol fertilized with municipal solid waste compost. Pesquisa Agropecuária Brasileira, 37, 1787–1793.

Özacar, M., & Şengil, İ. A. (2003). Adsorption of reactive dyes on calcined alunite from aqueous solutions. Journal of Hazardous Materials, B98, 211–224.

Özcan, A., Özcan, A. S., Tunali, S., Akar, T., & Kiran, I. (2005). Determination of the equilibrium kinetic and thermodynamic parameters of adsorption of copper (II) ions onto seeds of capsicum annuum. Journal of Hazardous Materials, B124, 200–208.

Ozsoy, H. D., & Kumbur, H. (2006). Adsorption of Cu (II) ions on cotton boll. Journal of Hazardous Materials, B136, 911–916.

Pérez-Marín, A. B., Zapata, V. M., Ortuño, J. F., Aguilar, M., Sáez, J., & Lloréns, M. (2007). Removal of cadmium from aqueous solutions by adsorption onto orangewaste. Journal of Hazardous Materials, B139, 122–131.

Pergher, S. B. C., Caovilla, M., Detoni, C., & Machado, N. R. C. F. (2005). Remoção de Cu+2 de soluções aquosas em zeólita NaX. Efeito da granulometria. Quimica Nova, 28, 397–401.

Rodrigues, R. F., Trevezoli, R. L., Santos, L. R. G., Leão, V. A., & Botaro, V. R. (2006). Heavy metals sorption on treated wood sawdust. Engenharia Sanitária Ambiental, 11(1), 21–26.

Sari, A., Tuzen, M., Citak, D., & Soylak, M. (2007). Equilibrium, kinetic and thermodynamic studies of adsorption of Pb(II) from aqueous solution onto Turkish kaolinite clay. Journal of Hazardous Materials, 149, 283–291.

Schvartsman, S. (1991). Intoxicações agudas (4th ed., pp. 214–215). São Paulo: Sarvier.

Sodré, F. F., Lenzi, E., & Costa, A. C. (2001). Applicability of adsorption models to the study of copper behaviour in clayey soils. Quimica Nova, 24, 324–330.

Sousa, F. W., Moreira, S. A., Oliveira, A. G., Cavalcante, R. M., Nascimento, R. F., & Rosa, M. F. (2007). The use of green coconut shells as absorbents in the toxic metals. Quimica Nova, 30(5), 1153–1157.

Tarley, C. R. T., & Arruda, M. A. Z. (2003). Adsorbents natural and potential applications of natural sponge (Luffa cylindrica) the removal of lead in wastewater laboratory. Revista Analítica, 4, 26–31.

Tarley, C. R. T., & Arruda, M. A. Z. (2004). Biosorption of heavy metals using rice milling by-products. Characterisation and application for removal of metals from aqueous effluents. Chemosphere, 54, 987–995.

Acknowledgments

This study was supported by UNIVERSIDADE PARANENSE, UNIPAR. The authors would like to thank CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico), FAPEMIG (Fundação de Amparo à Pesquisa do Estado de Minas Gerais) and CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior) for the financial support and fellowships.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dos Santos, V.C.G., De Souza, J.V.T.M., Tarley, C.R.T. et al. Copper Ions Adsorption from Aqueous Medium Using the Biosorbent Sugarcane Bagasse In Natura and Chemically Modified. Water Air Soil Pollut 216, 351–359 (2011). https://doi.org/10.1007/s11270-010-0537-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11270-010-0537-3