Abstract

There is evidence in the literature that the ratio of mass of sorbent (M) to volume of solution (V) affects the results of batch tests with soils and sediments. This restricts the use of such data to conditions with the same M/V ratio they were derived with, unless its influence is corrected. To find a correction, we conducted batch tests with soil and zinc solution using four M/V ratios. For each ratio, the experiments produced a different relationship between the mass of zinc sorbed per unit mass of soil (a s) and the zinc concentration in the solution after shaking and removal of the solid phase (C det), which is usually taken as the equilibrium concentration (C eq). A theoretical analysis revealed that the M/V effect can be accounted for by dividing C det by the M/V ratio, if it is caused by the presence of a “third phase”. The relationship between a s and C det×V/M is the same for all ratios then.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Groundwater is a major source of drinking water in many parts of the world. The protection of groundwater quality is therefore an important environmental concern. Soils play an important role in this, because pollutants generally have to pass through a soil profile to reach the groundwater, and soils can bind pollutants through sorption. The term sorption is often used to refer to all processes, which reduce the pollutant load in seepage water. They include absorption, adsorption, complexation, ion exchange and precipitation (Mayer 1978; Falbe and Regitz 1992; Wienberg 1998). In this paper, we regard only absorption, adsorption and ion exchange as true sorption processes, and complexation and precipitation as side reactions.

Batch tests are frequently used to assess the sorption capacity of soils. The most widely used procedure for such tests is as follows: A known mass of soil (M) and a known volume of solution (V) with a series of different known initial concentrations (C 0) of the substance in question are placed in vessels and shaken for some time. Then the soil (sorbent) is separated from the suspension by centrifugation or filtration, and the concentration of the substance (sorptive) remaining in solution (C det) is determined. (There is also a so-called fixed contaminant concentration method, which we shall briefly comment on in the Results and Discussion section.) C det is usually taken as the equilibrium concentration (C eq), i.e. one sets C eq = C det. Finally, the mass of the substance removed from the solution (i.e. sorbed) by the soil per unit mass of soil (a s) is calculated as:

The result of batch tests, i.e. the sorption behaviour at a given constant temperature of the sorbent–sorptive system under investigation, is typically depicted as a sorption isotherm, which, in the usual form, relates a s to C eq. In mathematical terms, this implies:

While the basic experimental procedure for batch tests outlined above is generally followed, no single standard has yet been established for every aspect of it (Engelmann 1998). The time allowed for shaking as well as the mass of sorbent (M) and the volume of solution (V) employed varies. Different M/V ratios are recommended, too (e.g. OECD 1981; DIN 38414, Teil 4 1984). Furthermore, it may actually not be possible to use the same parameters for every problem or sorbent–sorptive system under investigation (Wienberg 1998).

We recently worked on a project using batch tests to assess the sorption capacity for zinc of soils around the city of Erfurt in Thuringia, Germany. As recommended in a relevant German guideline (DIN 38414, Teil 4 1984), we used an M/V ratio of 1 g of soil to 10 ml of solution at first. With this ratio, the soils sorbed virtually all zinc in solutions of initial concentrations up to several hundred mg l−1. We therefore tried various smaller ratios and thus obtained well-defined isotherms, but, to our surprise, a different one for each M/V ratio.

In reviewing the literature, we found that a large number of researchers (e.g. Aston and Duursma 1973; Rohatgi and Chen 1975; Curl and Keoleian 1984; Kukowski 1989; Wang and Grady 1994; Bobé et al. 1997) had noticed that the M/V ratio affects the result of batch tests, i.e. the relationship between a s and C eq. This was observed with many different soil and sediment substrates, as well as with various types of sorptives, e.g. organic compounds and metal ions (O’Connor and Connolly 1980). In addition, it was found with lignite coal ash (Fehse 2004).

Several causes for the M/V effect are given in the literature. Among them:

-

1.

a change in the coagulation of solid particles (Grover and Hance 1970; Anderson et al. 1985),

-

2.

the existence of a “third phase” (Suzuki et al. 1979; Voice et al. 1983; Geschwend and Wu 1985; Voice and Weber 1985; Staples and Geiselmann 1988; Servos and Muir 1989), perceived as a sorbing agent, which originates from the soil or sediment (first phase), but is in solution and therefore not removed from the liquid (second phase) by particle separation techniques,

-

3.

a change in particle interaction (Di Toro 1985; Di Toro et al. 1986; Mackay and Powers 1987),

-

4.

a change in pH (Horzempa and Di Toro 1983),

-

5.

a change in ion concentration pressure (Karickhoff and Brown 1978; Horzempa and Di Toro 1983),

-

6.

the existence of sorption sites with different binding energies (Hamaker and Thompson 1972; Horzempa and Di Toro 1983),

-

7.

differences in the kinetics of sorption (Horzempa and Di Toro 1983),

-

8.

measurement errors due to a deviation from 50% sorption (McDonald and Evangelou 1997).

The existence of a “third phase” seems to be the most frequent cause (Di Toro et al. 1986). However, neither this nor any of the other suggested mechanisms explains the M/V effect in all data sets where it was observed.

As will be explained later, one may regard the M/V effect as an experimental artefact. However, it is one which cannot be avoided all the time. So, if the M/V ratio affects the results of batch tests with soil or sediment material, then data obtained with a certain ratio cannot be applied to conditions with a different one, unless they are adjusted for the M/V effect. Hence, an adjustment method is needed. None was suggested by the aforementioned authors. To find one, we conducted a set of batch tests with soil and zinc solution using different M/V ratios but otherwise equal conditions. The results are presented here.

2 Materials and Methods

Soil material from the A-horizon of a rendzic leptosol near Erfurt was taken as sorbent. Its properties are: Sand=3.9%, silt=45.9%, clay=50.2%, organic carbon=3.95%, specific surface area = 26.2 m2 g−1, pH = 7.4, electrical conductivity = 15.6 mS m−1. Zinc applied as ZnCl2 was chosen as sorptive, because it is easy to handle and sorbed well by the substrate employed here.

The M/V ratio can be altered by changing M or V. In one series of batch tests, we therefore held M constant and varied V; in another, we kept V constant and varied M. Table 1, which presents the results, shows the seven combinations of M and V employed and the four resulting M/V ratios. Except for the 1:100 ratio, each one appears twice but obtained with different values of M and V. This allows checking, if the M/V effect is only due to the ratio or due to the way it is generated, too. For each M and V combination, solutions with eight initial zinc concentrations were used, namely C 0 = 5, 25, 50, 100, 200, 300, 400 and 500 mg l−1. The actual concentrations differed slightly from these nominal values (cf. Table 1).

The various combinations of mass of sorbent and volume of solution were placed in 500-ml plastic bottles (Qualilab 500-ml wide-mouth bottles, Merck, Darmstadt, Germany) and agitated at 20°C for 24 h on a vibrating shaker. In preliminary trials with various shaking times, we had ascertained that 24 h were sufficient to reach equilibrium.

To separate the sorbent from the suspension, after shaking, the OECD guideline (OECD 1981) recommends centrifugation. Filtration is possible, too (Wienberg 1998). We selected filtration, as prescribed in DIN 38414, Teil 4 (1984), after we established that the filter paper (No. 391, Sartorius, Göttingen, Germany) did not react with zinc and that filtration yielded the same result as centrifugation. The filtrates (and the initial solution) were stabilised with 100 μl nitric acid (Suprapur 65%, Merck, Darmstadt, Germany). Zinc concentrations of the initial (C 0) and the filtered solutions (C det) were measured with an ICP-OES (PU 7000, Philips, Eindhoven, The Netherlands) with a precision of 0.5 mg l−1. Lastly, the mass of zinc removed from the solution by the sorbent was calculated with Eq. 1 and setting C eq = C det.

3 Results and Discussion

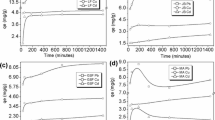

The results of our batch tests are summarised in Table 1. Figure 1 depicts the data from the series with a constant M but different V’s in the form of a standard sorption isotherm, where a s is related to C eq, assuming that, for our data, C eq = C det. Figure 2 presents the data from the series with a constant V but different M’s in the same fashion. Note that, in both figures, no error bars appear because they are smaller than the symbols.

Isotherms for the sorption of zinc ions from an aqueous solution on soil at 20°C. Data from batch tests with the same amount of soil in different volumes of zinc solution, all other conditions being equal (a s = mass of zinc sorbed per unit mass of soil, C det = zinc concentration in the solution after shaking and removal of the solid phase). It is assumed here that C det = C eq = zinc concentration in the solution at equilibrium

Isotherms for the sorption of zinc ions from an aqueous solution on soil at 20°C. Data from batch tests with different amounts of soil in the same volume of zinc solution, all other conditions being equal (a s = mass of zinc sorbed per unit mass of soil, C det = zinc concentration in the solution after shaking and removal of the solid phase). It is assumed here that C det = C eq = zinc concentration in the solution at equilibrium

As can be seen in Table 1, up to some initial concentration, which depends on the M/V ratio, virtually all of the zinc ions were sorbed. As a result, the sorption data fall very close to the ordinate and only begin to depart from it after a certain amount of sorption has taken place (Figs. 1 and 2). None of the most commonly used sorption equations (Henry-, Freundlich- or Langmuir-isotherm), or any other closed-form sorption equation we know, can describe this behaviour. Therefore, no isotherm was fitted to the data, and no statistical analysis of isotherm parameters could be performed. This problem was noticed in several studies before (e.g. Syers et al. 1973; Shuman 1975).

Sorption data can usually be described well by either the Henry-, Freundlich- or Langmuir-equation. Hence, one may question whether sorption data, which cannot be described by one of them, are correct. However, the Henry-isotherm is based on experiments where absorption was the only sorption process at work, the Freundlich-isotherm on experiments where adsorption was the dominant, and the Langmuir-isotherm on experiments where adsorption was the only process. In our experiments, as in most others concerning the sorption of cations on soil or sediment material, ion exchange was the dominant process. Hence, if none of these three isotherms fits the sorption data at hand, it does not mean that the data are wrong. It is more likely that the dominant sorption process was a different one than in the studies of Henry, Freundlich or Langmuir.

Nevertheless, it is clearly visible in both figures that the data for each M/V ratio follow a separate curve. A superposition of the figures reveals that the curves only depend on the ratio and not on the absolute values of M and V used to generate it. The a s values for each M/V ratio differ substantially for any given value of C det (assumed to equal C eq) and vice versa.

The laws of physical chemistry for a reversible physicochemical process state that there is a unique relationship between a s and C eq, as the following derivation shows. We start with the stoichiometry of the exchange of the mass of a substance A sorbed by the solid phase (M(A solid)) and the mass of that substance remaining in the liquid phase (M(A liquid)):

In terms of the activities of the substance one may write:

which states that the activity of the substance sorbed by the solid ({A solid}) is in an equilibrium with the activity of the substance remaining in the liquid phase ({A liquid}). Concentration and activity of a substance in solution are related:

where [A liquid] = concentration of substance A in the liquid phase, γ A = activity coefficient of substance A in the liquid, which is ≈1 for small values of [A liquid], and V liquid = volume of solution (previously and again later simply called V, but for now with the subscript “liquid” added for greater clarity). Ignoring the activity coefficient, Eq. 5 can be formulated as:

Similarly one can write for the solid phase:

where V solid = volume of the solid. The activities {A solid} and {A liquid} in Eq. 4 can now be described with Eqs. 7 and 6, respectively, to obtain:

Multiplying both sides with V solid and dividing by the mass of the solid (M solid, previously and again later simply called M, but for now with the subscript “solid” added for greater clarity) yields:

As defined in the Introduction, at equilibrium M(A solid)/M solid = a s, and M(A liquid)/V liquid = C eq. Also, M solid/V solid = ρ = density of the solid, which does not change and can therefore be incorporated into the overall constant for the equation. Hence, one finally arrives at:

which declares that there is a unique relationship between a s and C eq, which does not depend on the M/V ratio employed. Note that this relationship only holds for a stable system, i.e. one where the properties of the sorbent or the sorptive are not altered by experimental conditions.

So, if a set of experiments with the same sorbent–sorptive system, where the only intended difference is the M/V ratio, yields a different isotherm for each ratio, the experimental conditions must have changed the system or invalidated the assumption that C eq = C det. It is well known that various factors (e.g. pH, ionic strength, stability of the sorbent) influence the outcome of sorption experiments. Hence, if the experimental conditions affect one or several of these factors, the isotherm will be affected, too.

In our data, the pH (for a given C 0) decreases with the M/V ratio (Table 1). Due to this systematic change, one may suspect the pH to be responsible for the M/V effect. However, the surface charge density of the soil material we used is dominated by 2:1 clay minerals with a large negative permanent structural charge, which far exceeds the pH-dependent charge of the minerals and the organic matter in the substrate. Consequently, its total charge varies little with pH so that there is no significant effect of pH on the sorption characteristics of this soil. In addition, if there was a substantial pH-dependent charge, it would become more negative with an increasing pH (Bohn et al. 1979; Jury et al. 1991). This would result in more cation sorption per unit mass of sorbent, not less, as in our data (Figs. 1 and 2). Hence, pH cannot be the cause of the M/V effect here.

The pH also affects the speciation of the sorptive. In the case of zinc, Zn(OH)2 is the most common species at pH > 7.7; below that, it is Zn++ (Lindsay 1972). At pH < 7.2, Zn++ is over ten times more abundant than all other species. In most of our data, the pH was ≤ 7.7 (Table 1). In Figs. 1 and 2, the M/V effect is most clearly displayed by the data points, which depart clearly from the ordinate. For these points, the pH was ≤ 7.2 (Table 1), which means that Zn++ was always, by far, the dominant species. Hence, our results were not significantly affected by speciation either.

We used initial zinc concentrations of 5 to 500 mg l−1 in our experiments. In step with them, the ionic strength of the solutions changed from 2.3×10−4 to 2.3×10−2 mol l−1. It was not notably influenced by pH or the mass of sorbent. Since the same initial concentrations and therefore the same ionic strengths were used for all our M/V ratios, this parameter cannot be responsible for the M/V effect we encountered.

The M/V effect in our data was most likely caused by a dissolution of organic substances in the soil material, which then formed complexes with some of the Zn++ ions in the solution. According to the definition in the Introduction, this means that it was caused by a “third phase” and involves the following phenomena: The mass of the sorptive attached to the sorbent by absorption, adsorption or ion exchange and the mass fixed by precipitation is removed from the solution, while the mass inactivated by complexation remains in the solution. Consequently, when the sorbent–solution suspension is filtered or centrifuged to remove the solid phase (soil and precipitates) from the suspension, the complexes involving the sorptive will remain in the solution. The analytical methods most widely used today to determine the concentration of the sorptive in the solution (i.e. AAS or ICP-OES for metal ions) measure its total concentration. Hence, such measurements include the mass of sorptive tied up in complexes. As a result, the measured concentration (C det) is higher than the equilibrium concentration (C eq) for true sorption as defined in the Introduction. One may write:

where α A is the fraction of a substance A not bonded to other components in the liquid phase.

To explore α A further, let us consider for the moment that the complexation of A involves only one ligand L in the liquid phase:

(In the following, we only look at A, L and AL in the liquid phase, so a subscript “liquid” can be omitted). In this case α A is given by the ratio:

The formation constant β AL for the complexes is:

Employing this expression rearranged for [AL] in Eq. 13 and cancelling terms yields:

This shows that α A depends on the free concentration of the ligand L in the liquid phase ([L]). The ligand originates from the soil. When soil is added to the solution, the ligand is dissolved into the liquid phase and ultimately yields the compound AL. The total ligand concentration [L tot] is the sum of all forms of the ligand L in the liquid phase, i.e. [L tot] = [L] + [AL] and depends on the mass of soil added to the system (M solid). Let χ L be the fraction of the soil mass, which dissolves to become the ligand. One can then write:

In analogy to Eq. 13, one may define the fraction of ligand L not tied up in a complex (α L) as:

Using this relationship rearranged for [L] + [AL] in Eq. 16 and shuffling terms yields:

Substituting Eq. 18 into Eq. 15 leads to:

If the sorbent is stable, then χ L = 0 and α A = 1. This means that C eq = C det, as Eq. 11 shows. If part of the sorbent dissolves to yield the necessary reactants for complexation, then χ L > 0 and α A < 1, which means that C eq < C det. Hence, if a “third phase” develops with the consequences just described, then setting C eq = C det is wrong. Furthermore, if, for a given sorbent, χ L is constant and > 0, then the mass of ligand L in a solution increases with the mass of sorbent (M solid) added to the solution, i.e. an M/V effect occurs.

The fraction of a ligand L not tied up in a complex (α L) and the fraction of the sorbent, which dissolves and yields the ligand (χ L), are both likely to be <<1. However, depending on the ligand involved, the value of the complex-formation constant β AL can be expected to be in the order of 1010 l mol−1 and is frequently much higher. Hence, in most cases:

so that the 1 in the denominator in Eq. 19 can be dropped. Combining Eq. 19 with this simplification and Eq. 11 yields:

Finally, using this relationship in Eq. 2 and moving the term 1/(β AL×α L×χ L) into the overall constant for the equation produces:

With more than one ligand, the above equations become more cumbersome but lead to the same final result.

So, if a “third phase” led to the M/V effect in our data in the manner just explained, then following Eq. 22 and multiplying our C det values by V liquid/M solid should lead to a unique relationship between a s and C det×V liquid/M solid, because according to Eq. 21 the latter then represents the true equilibrium concentration C eq, and because according to Eq. 10 and its derivation there is a unique relationship between a s and C eq. In Fig. 3, the data for all four M/V ratios from both series of batch tests are displayed, after they were transformed in this way. All data now follow the same curve, which demonstrates that the proposed correction for the M/V effect works.

Sorption isotherms from Figs. 1 and 2 after correcting C det for the M/V effect (a s = mass of zinc sorbed per unit mass of soil, C det = zinc concentration in the solution after shaking and removal of the solid phase; V volume of solution, M mass of soil). Here, C det×V/M ∼ C eq = zinc concentration in the solution at equilibrium

Note that the expression C det×V liquid/M solid (or C det×V/M without the subscripts as in Fig. 3), which has units of mass of sorptive in solution/mass of solid sorbent, is only proportional but not equal to C eq, whose units are mass of sorptive in solution/volume of solution, because the term 1/(β AL×α L×χ L) with units of mass of dissolved sorbent/volume of solution was not figured in (cf. Eq. 21). This term cannot be evaluated, because in batch tests with soil or sediment material it is unknown what dissolves, how much of it and what reactions it enters with the sorptive. Hence, β AL, α L and χ L are unknown. α L and χ L are dimensionless, while β AL has units of volume of solution/mass of dissolved sorbent (cf. Eq. 14).

We subsequently tested this M/V correction on sorption data for five different soil–sorptive systems from other experiments by our group, unrelated to the ones reported here. For each system, at least two different M/V ratios but otherwise identical conditions were used. Without adjustment, the data for each ratio described a different curve in a given experiment, most likely due to the occurrence of a “third phase”. After adjustment, the data for all ratios in an experiment fell onto the same isotherm. This corroborates our procedure.

To further verify it, we applied our correction method to data from Di Toro et al. (1986), who addressed the M/V effect in their paper. The data describe the sorption of nickel ions on montmorillonite at different M/V ratios. As shown in Fig. 4, the authors obtained a different isotherm for each ratio. After applying our correction, all isotherms again fall onto the same line (Fig. 5).

Isotherms for the sorption of nickel ions from an aqueous solution on montmorillonite. Data from batch tests of Di Toro et al. (1986) with the same amount of montmorillonite in different volumes of nickel solution, all other conditions being equal (a s = mass of nickel sorbed per unit mass of montmorillonite, C det = nickel concentration in the solution after shaking and removal of the solid phase; V volume of solution, M mass of montmorillonite). It is assumed here that C det = C eq = nickel concentration in the solution at equilibrium

Sorption isotherms from Fig. 4 after correcting C det for the M/V effect (a s = mass of nickel sorbed per unit mass of montmorillonite, C det = nickel concentration in the solution after shaking and removal of the solid phase; V volume of solution, M mass of montmorillonite). Here C det×V/M ∼ C eq = nickel concentration in the solution at equilibrium

We would have liked to test our M/V adjustment on data from the other papers quoted in the Introduction, where the M/V effect was observed. However, in all of them, apart from Di Toro et al. (1986), some information required to apply our correction was missing. Nevertheless, sufficient evidence was presented here to demonstrate that our method works, if the M/V effect was brought about by a “third phase”.

One may argue that, in the presence of a “third phase,” the M/V effect merely results from measuring the wrong concentration, namely the total concentration of an element in all forms (compounds) in which it is present in the equilibrium solution instead of that of the element in the form it was added to the initial solution as sorptive, and then taking the measured as the equilibrium concentration. However, for many elements there are no feasible analytical methods to distinguish different forms in the same solution or only methods, which alter the distribution of the various forms in the analysis process. Hence, in many cases, one cannot avoid an analytically induced M/V effect caused by the presence of a “third phase”.

One may also argue that the factor(s) leading to the M/V effect should be kept constant by introducing appropriate measures into the experimental procedure. While this may be relatively easy for some factors (e.g. pH), it is difficult (e.g. ionic strength) or impossible (e.g. stability of the sorbent) for others, at least, without altering the system. Hence, this approach to avoid an M/V effect does not work in all circumstances either. Furthermore, keeping a factor constant, which would naturally change, distorts the results.

Consequently, a method to correct the M/V effect is required.

In a review of an earlier version of this paper, the question was raised if the M/V effect can be avoided by using the so-called fixed contaminant concentration method for batch tests, where one keeps the initial concentration (C 0) as well as the volume of solution (V) constant and varies the mass of sorbent (M). This means that, in this method, each data point is obtained with a different M/V ratio. So, if there is an M/V effect, the relationship between a s and C eq is not unique. One would notice this by repeating the experiments with a different C 0, but the same solution volume and sorbent masses.

We simulated the fixed contaminant concentration approach with our data. The result is shown in Fig. 6, which is Fig. 2 with a few additional marks. The points surrounded by a square are for our highest C 0 of 496 mg l−1, a solution volume of 200 ml, and a sorbent mass of 1, 2, 4 and 8 g, i.e. the data in the last line of Table 1. Taken on their own, these data present a reasonable-looking sorption isotherm. The points surrounded by a circle are for our C 0 of 305 mg l−1 and the same solution volume and sorbent masses (third last line in Table 1). They present a reasonable-looking sorption isotherm, too, but a different one. This demonstrates that, if there is an M/V effect in the system, it will occur with the fixed contaminant concentration method, too. One does not get a unique relationship between a s and C eq either.

Figure 2 with the data points for C 0 = 496 mg l−1 (boxed) and C 0 = 305 mg l−1 (circled) marked to simulate isotherms, which would have been obtained with the fixed contaminant concentration approach. For further details see text

4 Conclusions

We presented a way to account for the M/V effect brought about by a “third phase”, which seems to be its most frequent cause. If it is due to some other factor, which also changes the results of batch tests systematically, it should again be possible to adjust for it by somehow incorporating the M/V ratio into the results. Additional testing is required to illuminate this.

The data in the literature (see Introduction) as well as ours leave no doubt that an M/V effect can occur in batch tests with soils and sediments and lignite coal ash. An M/V effect can only be observed, if the experiments are carried out with more than one M/V ratio. Hence, if the sorption isotherm for a sorbent–sorptive system was obtained with only ratio, which is the usual procedure, one cannot tell whether the system is affected by the M/V ratio. As a consequence, one should not apply such data to situations, where the ratio is different from the one they were derived with. To check if a system is influenced by the M/V ratio, batch tests should always be done with more than one ratio.

Finally, we would like to note that, in many years of working with technically produced sorbents such as zeolite or adsorber polymers, we never observed an M/V effect with these substrates or came across a reference to it in the literature. They are chemically very pure materials and have a stabile structure. Hence, unlike with soil or sediment material, there is no partial dissolution during batch tests, which means χ L = 0 and α A = 1 (Eq. 19) so that C eq = C det (Eq. 11). In addition, adsorption and ion exchange are the only sorption processes, which occur. The absence of an M/V effect with such sorbents is illustrated in Fig. 7. It shows the results of batch tests with NaA-zeolite as sorbent and zinc as sorptive with various M/V ratios, which were conducted in the same manner as the batch tests with soil described above. The data for the different ratios follow the same isotherm without adjustment.

Isotherms for the sorption of zinc ions from an aqueous solution on NaA-zeolite at 20°C. Data from batch tests with the same amount of zeolite in different volumes of zinc solution, all other conditions being equal (a s = mass of zinc sorbed per unit mass of zeolite, C det = zinc concentration in the solution after shaking and removal of the solid phase). Here C det = C eq = zinc concentration in the solution at equilibrium

References

Anderson, M. A., Tejedor-Tejedor, M. I., & Stanforth, R. R. (1985). Influence of aggregation on the uptake kinetics of phosphate by goethite. Environmental Science and Technology, 19(7), 632–637.

Aston, S. R., & Duursma, E. K. (1973). Concentration effects on 137Cs, 65Zn, 6°Co and 106Ru sorption by marine sediments, with geochemical implications. Netherlands Journal of Sea Research, 6(1–2), 225–240.

Bobé, A., Coste, C. M., & Cooper, J.-F. (1997). Factors influencing the adsorption of finopril on soils. Journal of Agricultural and Food Chemistry, 45(12), 4861–4865.

Bohn, H. L., McNeal, B. L., & O’Connor, G. A. (1979). Soil chemistry. New York: Wiley.

Curl, R. L., & Keoleian, G. A. (1984). Implicit-adsorbate model for apparent anomalies with organic adsorption on natural adsorbents. Environmental Science and Technology, 18(12), 916–922.

DIN 38414, Teil 4. (1984). Deutsche Einheitsverfahren zur Wasser-, Abwasser- und Schlammuntersuchung. Schlamm und Sedimente (Gruppe S). Bestimmung der Eluierbarkeit mit Wasser (S 4). Berlin: Beuth.

Di Toro, D. M. (1985). A particle interaction model of reversible organic chemical sorption. Chemosphere, 14(10), 1503–1538.

Di Toro, D. M., Mahony, J. D., Kirchgraber, P. R., O’Byrne, A. L., Pasquale, L. R., & Piccirilli, D. C. (1986). Effects of nonreversibility, particle concentration, and ionic strength on heavy metal sorption. Environmental Science and Technology, 20(1), 55–61.

Engelmann, F. (1998). Verfahren und Methoden zur Ermittlung von Migrationsparametern. In H. J. Voigt & T. Wippermann (Eds.), Handbuch zur Erkundung des Untergrundes von Deponien und Altlasten, Band 6, Geochemie (pp. 303–316). Berlin: Springer.

Falbe, J., & Regitz, M. (1992). Römpp-Chemie-Lexikon, Band 5. Stuttgart: Thieme.

Fehse, K.-U. (2004). Zur Sorption von Zink-Ionen an natürlichen und technischen Sorbentien unter Berücksichtigung des Feststoff:Lösung-Verhältnisses. Ph.D. thesis. Halle (Saale): Martin-Luther-Universität Halle-Wittenberg.

Geschwend, P. M., & Wu, S. (1985). On the constancy of sediment–water partition coefficients of hydrophobic organic pollutants. Environmental Science and Technology, 19(1), 90–96.

Grover, R., & Hance, R. J. (1970). Effect of the ratio of soil to water on adsorption of linuron and atrazine. Soil Science, 109(2), 136–138.

Hamaker, J. W., & Thompson, J. M. (1972). Adsorption. In C. A. Goring & J. W. Hamaker (Eds.), Organic chemicals in the soil environment (Vol. 1, pp. 49–143). New York: Marcel Dekker.

Horzempa, L. M., & Di Toro, D. M. (1983). PCB partitioning in sediment-water systems: The effect of sediment concentration. Journal of Environmental Quality, 12(3), 373–380.

Jury, W. A., Gardner, W. R., & Gardner, W. H. (1991). Soil physics (5th ed.). New York: Wiley.

Karickhoff, S. W., & Brown, D. S. (1978). Paraquat sorption as a function of particle size in natural sediments. Journal of Environmental Quality, 7(2), 246–252.

Kukowski, H. (1989). Untersuchungen zur Ad- und Desorption ausgewählter Chemikalien in Böden. Ph.D. thesis. Kiel: Christian-Albrechts-Universität.

Lindsay, W. L. (1972). Inorganic phase equilibria of micronutrients in soils. In J. J. Mortvedt, P. M. Giordano & W. L. Lindsay (Eds.), Micronutrients in agriculture (pp. 41–57). Madison: Soil Science Society of America.

Mackay, D., & Powers, B. (1987). Sorption of hydrophobic chemicals from water: A hypothesis for the mechanism of the particle concentration effect. Chemosphere, 16(4), 745–757.

Mayer, R. (1978). Adsorptionsisothermen als Regelgrößen beim Transport von Schwermetallen in Böden. Zeitschrift für Pflanzenernährung und Bodenkunde, 141(1), 11–28.

McDonald, L. M., & Evangelou, V. P. (1997). Optimal solid-to-solution ratios for organic chemical sorption experiments. Soil Science Society of America Journal, 61(6), 1655–1659.

O’Connor, D. J., & Connolly, J. P. (1980). The effect of concentration of adsorbing solids on the partition coefficient. Water Research, 14(10), 1517–1523.

OECD (1981). Adsorption/Desorption. OECD guideline for testing chemicals, 106.

Rohatgi, N., & Chen, K. Y. (1975). Transport of trace metals by suspended particulates on mixing with seawater. Journal of the Water Pollution Control Federation, 47, 2298–2320.

Servos, M. R., & Muir, D. C. G. (1989). Effect of suspended sediment concentration on the sediment to water partition coefficient for 1, 3, 6, 8-Tetrachlorodibenzo-p-dioxin. Environmental Science and Technology, 23(10), 1302–1306.

Shuman, L. M. (1975). The effect of soil properties on zinc adsorption by soils. Soil Science Society of America Proceedings, 39(3), 454–458.

Staples, C. A., & Geiselmann, S. J. (1988). Influence of sorbent concentration on sorption of kepone to solids. Environmental Toxicology and Chemistry, 7, 139–142.

Suzuki, M., Yamada, T., Miyazaki, T., & Kawazoe, K. (1979). Sorption and accumulation of cadmium in the sediment of the Tama River. Water Research, 13(1), 57–63.

Syers, J. K., Browman, M. G., Smillie, G. W., & Corey, R. B. (1973). Phosphate sorption by soils evaluated by the Langmuir adsorption isotherm. Soil Science Society of America Proceedings, 37(3), 358–363.

Voice, T. C., Rice, C. P., & Weber, W. J. (1983). Effect of solids concentration on the sorptive partitioning of hydrophobic pollutants in aquatic systems. Environmental Science and Technology, 17(9), 513–518.

Voice, T. C., & Weber, W. J. (1985). Sorbent concentration effect in liquid/solid partitioning. Environmental Science and Technology, 19(9), 789–796.

Wang, X., & Grady, C. P. L. (1994). Comparison of biosorption isotherms for di-n-butyl phthalate by live and dead bacteria. Water Research, 28(5), 1247–1251.

Wienberg, R. (1998). Adsorption und Desorption. In W. Hiltmann & B. Stribrny (Eds.), Handbuch zur Erkundung des Untergrundes von Deponien und Altlasten, Band 5, Tonmineralogie und Bodenphysik (pp. 209–222). Berlin: Springer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fehse, KU., Borg, H., Sorkau, E. et al. Correcting the Effect of the Sorbent to Solution Ratio on Sorption Isotherms from Batch Tests with Soils and Sediments. Water Air Soil Pollut 210, 211–220 (2010). https://doi.org/10.1007/s11270-009-0243-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11270-009-0243-1