Abstract

In this paper, the effect of nitrogen addition on the aerobic bioremediation of a diesel-contaminated soil was studied. Soil was artificially contaminated with diesel at an initial 2% concentration (on a dry soil basis). Nitrogen was added as NH4Cl in a single load at the start of the experiment at concentration levels of 0, 100, 250, 500, 1,000, and 2,000 mg N/dry kg soil, and uncontaminated and unamended soil O2 consumptions were studied. Diesel degradation was indirectly studied via measurements of O2 consumption and CO2 production, using manometric respirometers. Results showed that the 250 mg N/dry kg concentration resulted in the highest O2 consumption among all runs, whereas O2 consumption was reduced by N additions greater than 500 mg N/dry kg. Zero to 0.6 order degradation kinetics appeared to prevail, as was calculated via the oxygen consumption rates. A theoretical biochemical reaction for diesel degradation was developed, based on measurement of the final diesel concentration in one of the runs. According to the stoichiometry, the optimal N requirements to allow complete diesel degradation should be approximately 0.15 g N/g diesel degraded or 1,400 mg N/dry kg of soil, based on the initial diesel concentration used in this study. This implies that N should be added in incremental loads.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Diesel fuel is a complex mixture of normal, branched, and cyclic alkanes and aromatic compounds. Diesel leaks from underground storage tanks are a well-documented source of pollution of soils and groundwater. Several bioremediation techniques exist in order to treat soils contaminated with petroleum hydrocarbons, which are relatively easily biodegradable compounds, although not biogenic in origin. These techniques can be in situ or on-site, with the former being usually less expensive, since excavation is commonly required in the latter option. Land farming has been a common technique to aerobically bioremediate soils contaminated with diesel or other organic pollutants (Atlas 1991; Bartha 1986; Leahy and Colwell 1990; Marquez-Rocha et al. 2001; Morgan and Watkinson 1989; Shen and Bartha 1994). Soil bioremediation is dependent upon several factors that commonly affect biodegradation processes, such as moisture content, N and P levels, temperature, oxygen content, micronutrients etc. A characteristic of diesel-contaminated soils is its high concentration in carbon compared to the concentration of nutrients, such as N and P. Nitrogen is particularly expected to affect degradation rates and extents, since soils commonly lose nitrogen due to nitrogen leaching and/or due to denitrification processes (Brook et al. 2001). Therefore, N is, usually, the limiting nutrient in soils and several studies have focused on the effect of N on bioremediation of contaminated soils (Atlas 1991; Brook et al. 2001; Dibble and Bartha 1979; Gallego et al. 2001; Walecka-Hutchison and Walworth 2006; Zhou and Crawford 1995). Even in arctic regions, soil bioremediation can be an effective technique to decontaminate hydrocarbon contaminated soils, as long as there is addition of nutrients (Aislabie et al. 2006; Margesin and Schinner 2001). Therefore, the addition of nutrients has become a common practice, which is accounted for even in relevant life cycle inventory studies (Toffoletto et al. 2005).

The interest on the biodegradation of diesel in soils has appeared since the 1970s (Dibble and Bartha 1979; Jobson et al., 1972; Raymond et al. 1976). Dibble and Bartha (1979) were among the first that performed a thoroughly controlled laboratory study of the effect of various parameters (i.e., moisture content, temperature, treatment frequency, oil sludge loading rates, pH, C/N ratio, C/P ratio, C/K ratio, trace element, and organic supplements concentration) onto the degradation of total petroleum hydrocarbons (TPH) in soil. Various other studies have, since, studied the effect of nutrient addition or other factors to the biodegradation of petroleum products in contaminated soils. Tables 1 and 2 include selected relevant work from the 1970s up to date. According to Tables 1 and 2, it appears that the N addition has been expressed either as N content achieved (in mg/dry kg soil) and/or as initial C:N ratio achieved. The C:N ratios have been extensively used to express soil N levels. However, there are large variations regarding the optimum C:N levels in the literature, as shown in Tables 1 and 2. Optimum C/N ratios range from 2.9:1 to up to approximately 80:1. According to Walworth et al. (1997), the variability of the optimal C:N ratios reported by the individual researchers may be attributed to the variable initial contaminant levels. That is, the reported optimal C:N ratios observe a wide range due to the fact that various initial diesel concentrations have been applied in relevant research works. Walecka-Hutchison and Walworth (2006) clearly showed that the optimal N content was constantly the 250 mg N/kg soil level at three different initial diesel concentrations, namely 5,000, 10,000, and 20,000 mg TPH/kg soil. Therefore, the three resulting optimal C:N ratios were 17:1, 34:1, and 68:1. The other N contents that the above authors studied were 0, 500, and 1,000 mg N/kg soil. Aspray et al. (2008) found three different optimum N contents—from 47 to 373 mg N/dry kg soil—depending on the initial TPH concentration and the type of soil.

As a result of the above, Walworth et al. (1997) and Walworth et al. (2007) have particularly focused on the expression of N levels and the relation of the N levels to the resulting soil water potential. Walworth et al. (1997) introduced an alternative way to express N levels, namely on a per kilogram of soil water basis (NH2O). For the same amount of N added, the lower the moisture content of the soil, the higher the N salt concentration in the soil pore water and the lower the resulting soil water potential due to increased osmotic potential. The above expression of N, according to the authors, is more accurate compared to per dry kilogram of soil basis, since the nitrogen salts will eventually dissolve in the soil pore water. Walworth et al. (1997) proposed an upper limit of approximately 2,500 mg N/kg soil H2O, above which inhibition of the microbial activity starts to occur. They clearly showed a relationship between soil water potential and oxygen consumption in petroleum-contaminated soils. As the osmotic stresses increase from the addition of salts, and the soil water potential eventually becomes more negative, the microbial O2 consumption decreases. The same authors also showed that microbial activity is inhibited by osmotic stresses, regardless of whether the soil water potential is decreased through application of a fertilizer salt (e.g. NH4NO3) or of a non-nitrogenous salt (e.g., NaCl). Walworth et al. (2007) showed a clear negative correlation between the added N (in mg/kg soil) and the soil water potential. As the former increased, the latter became more negative and the O2 consumption decreased.

Tables 1 and 2 also include the type of contaminant and contaminant levels, as well as the optimum N level found in each study. Contaminant levels also appear to range from as low as 1,780 mg TPH/kg soil to up to 60,000 mg TPH/kg soil, which, as discussed above, justifies the variability in the optimal C:N ratios.

According to Tables 1 and 2, a preferred form of adding N is inorganic nitrogen, mostly as ammonium salts; however, other N sources have been used, such are urea and nitrate salts (Brook et al. 2001). According to Jin and Fallgren (2007), not only NH4Cl enhanced the biodegradation of TPHs more than urea, when added at similar levels, but actually urea inhibited TPH biodegradation. In general, ammonium nitrogen is the form of nitrogen that is most easily utilized by microorganisms, compared to other nitrogen forms, such as nitrates. Nitrogen in ammonium is in a reduced stage, as is in the amino acids, which makes the former energetically more favorable for amino acid formation and other metabolic processes, compared to nitrates (Walworth and Reynolds 1995). According to Shewfelt et al. (2005), ammonium nitrogen enhances degradation rates and results in a shorter lag time before degradation, compared to nitrates.

Tables 1 and 2 show a variability in optimal C:N ratios and N contents. Thus, despite the amount of research, there are questions on issues related to optimal N levels during the aerobic bioremediation of petroleum-contaminated soils. The objective of this research was to investigate the effect of six initial nitrogen contents—and therefore six initial C/N ratios—on the biodegradation of an artificially contaminated soil with diesel. This simulates a scenario of soil contaminated after a recent diesel release. The initial diesel concentration was kept constant for all treatments and the duration of the experiments was more than 200 days for most of the runs, in order to approach the extent of biodegradation. Based on the literature review, the N levels in this study were expressed in all three forms, namely as C/N ratio as well as in units of milligrams of N per kilogram of dry soil and milligrams of N per kilogram of soil H2O. The work also focused on calculating degradation kinetics (order and kinetic constant). The kinetics of degradation of hydrocarbons in soil have been occasionally studied in the literature, with the first order kinetic approach being the most common to model the pertinent degradation processes (Ronĉević et al. 2005). The research work presented here tested several other kinetic models to describe the degradation process. In addition, the kinetic analysis was applied to two different experimental durations to investigate their effect on kinetic parameter estimation. Finally, a stoichiometric biodegradation equation was developed based on the results of the experiment. The degradation process was followed by monitoring the overall oxygen consumption and CO2 production with the use of 1-L bench scale manometric respirometers. The final TPH concentration was measured in one of the treatments, which allowed the estimation of overall TPH loss in that run.

2 Materials and Methods

Approximately 2 kg of soil were collected from the university area and were screened through a 3 mm screen to remove large particles. Undersized material was then air-dried for 7 days. Sieve analysis was performed using a sieve shaker (Retsch, Model AS 200 Basic) and nine sieves of different mesh sizes. The air-dried material was then spiked with automobile diesel purchased from a local gasoline station at an initial content of 2% (20,000 mg/kg dry soil). The artificially contaminated soil was air-dried under a hood for an additional 3-day period to remove the readily volatile compounds contained in the diesel. The diesel content in the soil was quantified as TPHs using a four-step sequential extraction with dichloromethane followed by GC/FID analysis (Karamalidis and Voudrias 2007). The GC column was a capillary HP-5 (30 m × 0.32 mm i.d.), while temperature programming comprised an initial 50°C oven temperature, kept constant for 1 min, ramping to 250°C at a rate of 15°C/min and a final bake out at 280°C for 5 min. Injector and detector temperatures were 300°C and 290°C, respectively. Helium was the carrier gas at a constant flow of 1.2 ml/min. One microliter of sample was injected into the GC in a splitless mode. A four-point calibration was performed by preparing standards of diesel in dichloromethane at concentrations equal to 10 mg/L, 50 mg/L, 100 mg/L, and 200 mg/L. A linear fit was performed that passed through the origin and resulted in a coefficient of determination (R 2) equal to at least 0.95 (significant at p = 0.05) for all runs. The wet weights of the soil samples used during TPH analysis ranged from 1 g, for the initial analysis, to 1.7 g, for the final analysis. TPHs were quantified via integration of the total hump area above the baseline (Karamalidis and Voudrias 2007).

Moisture content was measured by weight difference at 75°C till constant weight and was expressed on a wet weight basis (ww). Organic matter was measured in a muffle furnace through the loss on ignition at 550°C for 2 h and was expressed on a dry weight (dw) basis. Total C and total N contents were measured using an elemental analyzer (CE Instruments, CHNS-O Model EA-1110). The water holding capacity (WHC) of the soil was measured based on weight difference following systematic saturations of dry soil samples (approximately 75 g) and a drainage period of 24 h. The particle density of the soil solids was measured via water displacement of a known mass of dry soil. The pH was measured using a glass electrode and a WTW InoLab® pH meter on a 5:1 ratio of water to air-dried soil. All above measurements were performed in duplicates.

Three hundred grams of the artificially contaminated (air-dried) soil, which contained 291 g of dry soil, were placed into each of the twelve 1 L respirometers equipped with Oxi-Top® manometric heads from WTW®. The respirometers (also referred to as vessels) were placed and kept in a dark incubator (WTW® TS 606/2-i), at a constant 22°C temperature, for more than 200 days for most runs. Relatively long experimental times were used, since common field bioremediation times for soil contaminated with petroleum vary between 6 months to 2 years, using biopiles or bioventing (Khan et al. 2004). In addition, the relatively long experimental period allows a better calculation of process kinetics compared to shorter experimental times (Ronĉević et al. 2005). Note that not all runs were prepared with the same batch of artificially contaminated soil. Approximately half of the runs were prepared with a different batch of the same soil that was spiked with the same technique and at the same initial diesel concentration (≈2% dw) at a different time. According to Coles et al. (2009), who performed a similar type of work by measuring TPH losses only, an abiotic control is expected to quantify potential TPH losses mostly due to volatilization and photodegradation. In the current research work, no direct measurements of volatilization of TPHs were performed. However, most of the volatilization must have occurred during the 3 days in which the diesel-contaminated soil was kept in the hood, prior to the beginning of the experiment. Based on the FID chromatograms, the most volatile components detected were n-decane and n-undecane, with boilings points 174°C and 196°C, respectively. These are much higher than the temperatures of 22°C of the experiment. In addition, the experiments were conducted in closed vessels, which were opened for aeration only when the pressure drop was higher than 100 mbar. Therefore, it is expected that volatilization must not have been significant. In addition, photodegradation was not expected to affect the experiment, since all runs were performed in a dark type incubator. Although oxygen consumption due to abiotic processes, such as oxidation of metallic elements in soil, was considered very small, oxygen consumption cannot be considered the same as microbial respiration. As a result, the term “oxygen consumption” is used throughout the text instead of the term “microbial respiration”.

The operation principle of the respirometers is based on quantifying oxygen consumption via pressure drop measurements. The cumulative mass of O2 consumed in each vessel is therefore calculated based on the ideal gas law and the pressure drops that are recorded and logged at regular time intervals separately for each vessel. The headspace in all respirometers used after placement of the soil and after adding the necessary water to reach a close to optimal moisture water content was 688 ± 3 ml. Oxygen consumption was finally expressed in milligrams of O2 per kilogram of dry soil. The 50 ml 1 N KOH trap that was placed in each vessel to trap CO2 was periodically titrated to quantify CO2 production, which was expressed in milligrams of C–CO2 per kilogram of dry soil, on a cumulative basis. The amount of C–CO2 produced was calculated according to Komilis and Ham (2000). The remaining diesel content was measured in only one of the runs (run 100_2), after 138 days, through extraction with dichloromethane and further analysis in the GC/FID, as described above. Respirometers were regularly opened so as to maintain aerobic conditions.

2.1 Experimental Design

The experimental design is included in Table 3. One respirometer contained uncontaminated soil, without diesel or nitrogen addition, to quantify its oxygen consumption; all remaining respirometers contained diesel-contaminated soils. Nitrogen was added as ammonium chloride (NH4Cl) in a single load at the start of the experiments; no N was added in two of the treatments (controls). Ammonium chloride was selected as N source, since, it is energetically favorable for utilization by microorganisms (Walworth and Reynolds 1995), as was discussed in the Section“1”. Ammonium chloride was dissolved into 53 ml of deionized water, which were then added once into each vessel, so as to reach 55% of the water holding capacity of the soil. According to USEPA (1991), a suggested range of soil moisture contents that achieves optimal aerobic bioremediation is from 25% to 85% of the WHC of the soil. The achieved final nitrogen concentrations after N addition were 0 mg N/kg dw (dry soil), 100 mg N/kg dw, 250 mg N/kg dw, 500 mg N/kg dw, 1,000 mg N/kg dw, and 2,000 mg N/kg dw. The corresponding NH2O levels (based on a 20%, on a dry weight basis, initially achieved moisture content) were 0, 500, 1,250, 2,500, 5,000, and 10,000 mg N/kg soil H2O. Approximate corresponding total C/total N ratios varied from 100 to 5, based on the assumption that diesel, the major contributor of carbon, is represented by hexadecane (HXD or C16H34). Note that HXD has been used as a representative compound for diesel in other studies too (Volke-Sepùlveda et al. 2006; Walecka-Hutchison and Walworth 2006). Duplicate runs were performed for all nitrogen levels except for the runs at the 250 and 500 mg N/dry kg dw levels and for the uncontaminated soil run. Runs were terminated when O2 consumption rates approached and remained close to zero for at least 2 days. Therefore, experiment duration varied for each respirometer and run, as shown in Table 3.

3 Results and Discussion

3.1 Soil Properties

Results of the sieve analysis showed that the soil contained 12% by weight of particles with diameters larger than 2 mm (gravel), 86% with diameters between 2 and 0.063 mm (sand), and approximately 2% with diameters smaller than 0.063 mm (silt and clay). The uniformity coefficient (D 60/D 10) of the soil was approximately 6.0. The particle density of the (dry) soil solids was 2.3 g/cm3. The pH of the soil was 6.7. The gravimetric water content (moisture content) and the organic matter content were 1.9% ± 0.022% (ww) and 2.6% ± 0.056% (dw), respectively. The WHC of the soil was 0.36 ml/g dry soil. Total carbon content of the soil was approximately 0.2% (dw), while total (organic and inorganic) N was below the quantification limit (50 mg/dry kg) of the instrument. Based on the TPH analysis of duplicate samples, the initial average diesel concentration of the soil after the 3-day air-drying period, i.e., prior to their introduction into the respirometers, was 0.95% (dw) or 9,500 mg diesel/dry kg of soil based on n = 2 (9,030 mg/kg dw and 9,900 mg/kg dw for each sample, with a coefficient of variation of 7%).

3.2 O2 Consumption and CO2 Production

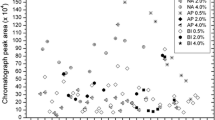

Table 3 includes the respirometric results and Fig. 1 illustrates the cumulative gross oxygen consumptions for all runs. The gross oxygen consumption includes all O2 consumed from the respiration of the soil; however, abiotic O2 consumption was not measured and cannot be omitted as a mechanism of O2 consumption. Due to the sandy nature of the soil, it is believed that abiotic O2 consumption must not have been significant (in relative terms).

According to Table 3, gross O2 consumption varied from approximately 3,400 mg O2/kg dw, for run 0_2 that contained no nitrogen, to 11,700 mg O2/dry kg dw for the run at the 250 mg N/kg dw level (C:N ratio 40:1). Oxygen consumption from uncontaminated soil was 1,280 mg O2/kg dw after 243 days. It is noted that due to the absence of an abiotic control, it is not possible to attribute oxygen consumption to respiration with certainty. Walecka-Hutchison and Walworth (2006) recorded oxygen consumptions that varied from approximately 2,000 mg/dry kg of soil to up to 17,000 mg/dry kg of soil, depending on the initial diesel content in the soil.

Table 3 also includes the net O2 consumption at the end of each experimental run. The net O2 consumption is defined as the gross O2 consumption minus the corresponding O2 consumed from the run with soil only, and is attributed to degradation of diesel. Net O2 consumption values ranged from 2,120 mg/dry kg, for the 0_2 run to 10,350 mg/dry kg, for the 250 run. The net O2 consumption rates calculated by dividing the net O2 consumption by the overall experimental duration of each run (in hours), varied from 0.36 mg/dry kg-h, for the 0_2 run, to 1.6 mg/dry kg-h, for the 250 run with a C:N ratio of 40:1. The average O2 consumption rate from the run with soil only was 0.22 mg/dry kg-h. Note that mixing, which may have affected microbial activity, was not performed in all runs, but only for run 100_2 on the 138th day during a sampling event. Therefore, for consistency purposes, the cumulative net O2 consumptions, were calculated on the 80th, 137th, and 205th day from the initiation of all treatments. The 205th day was selected, because runs 1000_2, 2000_1 and 2000_2 lasted 205 days; all other runs, except from the 100_1 run, lasted more than 205 days. Figure 2 shows the net O2 consumptions at the aforementioned times. The net O2 consumption at the 250 mg N/dry kg concentration was greatest at all time periods.

The optimal N content that enhanced diesel degradation was at the 250 mg N/kg dw, which resulted in the highest net (cumulative) O2 consumption of approximately 9,450 mg O2/dry kg dw at 205 days. The corresponding optimum C/N ratio was 40:1. The above N level (as mg N/kg soil) was also found to be optimum in Walworth et al. (1997) and Walecka-Hutchison and Walworth (2006), regardless of initial diesel concentrations. In addition, Walworth et al. (2007) found that optimal N levels were the 125 and 250 mg N/dry kg. According to Walworth et al. (1997), it is more accurate to express N levels on a per kilogram of soil pore water basis. The corresponding optimum N level in these units was 1,250 mg N/kg soil H2O, compared to a suggested optimum level of 2,000 to 2,500 mg N/kg soil H2O (Walworth et al. 1997). The 250 run had, also, the highest net average O2 consumption rate among all runs (1.6 mg O2/dry kg-h). The 100_2 (C:N ratio 100:1) and 500 runs had the next highest net O2 consumptions, approximately 7,300 mg O2/dry kg and 7,100 mg O2/dry kg at 205 days, respectively. The net average O2 consumption rates for these treatments were 1.4 mg O2/dry kg-h. As the nitrogen concentration increased, however, oxygen consumption was reduced. N levels above 500 mg N/dry kg soil (or 2,500 mg N/kg soil H2O) apparently inhibited microbial activity, as has been also shown by Walworth et al. (1997). Inhibition was evident from the relatively low oxygen consumptions recorded for the 1,000 and 2,000 mg N/dry kg soil levels (or 5,000 and 10,000 mg N/kg soil H2O, respectively). As earlier discussed, the oxygen consumption reduction at the high N levels is likely attributed to the increase of the osmotic stresses, following the nitrogenous salt addition, and the reduction of the soil water potential of the soil. According to Walworth et al. (1997), a soil water potential reduction of 0.50 MPa, which can be a result of any inorganic salt addition, can reduce microbial petroleum degradation by 50%. The negative effect of the reduced soil water potential on the oxygen consumption of petroleum-contaminated soils has been also discussed in Walecka-Hutchison and Walworth (2006). The precision in cumulative gross O2 consumption of the experiments (expressed as the coefficient of variation) was less than 26% at the four nitrogen levels.

Gross cumulative CO2 measurements were made at various intermediate times during each run. As shown in Table 3, the average net CO2 production rates (gross CO2 production rates in contaminated soil minus that in uncontaminated soil) ranged from 0.13 mg C–CO2/dry kg-h, for the 0_2 run, to 1.0 mg C–CO2/dry kg-h, for the 250 run. The net CO2 production rate in uncontaminated soil was 0.049 mg C–CO2/dry kg-h, which was the lowest among all runs. The intermediate net CO2 production measurements also aided in the calculation of the ratio of net CO2 mol produced to net O2 mol consumed (see Table 3), a ratio commonly known as the respiratory quotient (RQ). The RQ can provide an indication of the state of the degradation intensity; usually, higher RQ values characterize a high microbial activity compared to lower RQ values (Gea et al. 2004). The RQ values for contaminated soil ranged from 0.74 to 1.1 in this study. The lowest RQ (0.74) was recorded for the 0_1 run and the highest RQ (1.1) for the 0_2, 1000_2, and 2000_2 runs. The RQ of the uncontaminated and unamended soil was 0.55. It is not easy to draw any clear conclusions regarding a potential relation between the magnitude of the RQ value and the gross or net O2 consumption of the treatments. Aspray et al. (2008) measured RQs that ranged from 0.5 to approximately 3.0. However, the RQs measured for the sandy soils of that study ranged from 0.5 to approximately 1.3 (Aspray et al. 2008).

3.3 Degradation Kinetics

A general kinetic model that can describe the biodegradation process is the following:

with:

- D :

-

the diesel concentration (mg/kg dry soil),

- O2 :

-

the O2 headspace concentration (mg/kg of dry soil),

- n, m:

-

orders of the reaction, and

- k D :

-

the diesel degradation constant (with variable units, according to the values of n, m).

However, since the diesel concentration (D) is relatively large—and therefore not limiting—the oxygen concentration eventually becomes rate-limiting. Therefore, only the kinetics of oxygen consumption were studied.

The difference between the gross final oxygen consumption (FOC) at the end of each experiment and the gross actual oxygen consumption (AOCt) measured at different experimental times is defined as the (gross) remaining oxygen consumption (ROCt), as shown in Eq. 2. All variables have units in milligrams of O2 consumed per kilogram of dry soil.

The differential equation to describe the kinetics of the degradation process is shown below:

with:

- ROC:

-

the remaining oxygen consumption (mg O2/dry kg soil), as defined above. For example, at time t = 0 the ROC equals the final oxygen consumption, as this was determined for each run at the end of the corresponding experimental period. As time t increases, ROC reduces and eventually becomes zero at the end of the experimental period.

- k :

-

the ROC rate constant (with variable units according to n).

According to Brook et al. (2001), the rates of diesel degradation and the rates of oxygen consumption rate are not necessarily similar. The above authors calculated TPH loss constants based on first order kinetics, which were 8 to 60 times higher than the corresponding oxygen consumption rate constants. In addition, the same authors showed that the CO2 production first order rate constants were also much lower than the TPH loss rate constants. The differences in the rates were explained by the incomplete mineralization of TPHs that may result in humified stable by-products that may not be easily extracted during the extraction procedure. That is, the extraction may not measure all metabolic TPH by-products formed. Although this may be true, one has to account for the extraction procedure used. For example, Brook et al. (2001) measured TPHs using a single extraction with dichloromethane; on the other hand, a four-step sequential extraction with dichloromethane was used here. In addition, the incorporation of part of the diesel into biomass, which is normal during organics biodegradation, may lead to non-readily extractable TPHs. Therefore, TPH losses measured through extraction may be much larger than the amounts of TPH actually mineralized during the experimental period. Eventually, all, or most of the intermediate metabolic by-products may be mineralized. Still, the amount of oxygen consumed during the period of the experiment is expected to be smaller than the theoretical oxygen amount computed through stoichiometry.

The gross oxygen consumption data were fitted to the model described in Eq. 3 for each treatment separately. Variable n values were tried that ranged from 0.0 to 2.0 using a 0.1 step. The best fit was the one that resulted in the highest coefficient of determination (R 2) after linearization of the kinetic equations. The linearized zero order, first order, and second order equations are described in detail in Chapra (1997). The linearized equation for all cases with n ≥ 0 and n ≠ 1 is (Chapra 1997):

Therefore, the kinetic constant k is calculated by the optimal value of n and the slope of the line described by Eq. 4. The n values, as well as the kinetic constants (k) for all fits, are included in Table 4.

The results of the modeling show that the orders (n) of all kinetic equations range from 0, for the 0_1 and 0_2 runs, to up to 0.6, for the 100 and 250 runs. Several researchers in the past have modeled petroleum degradation using first order kinetics (Brook et al. 2001; Naziruddin et al. 1995; Paudyn et al. 2008; Ronĉević et al. 2005; Shewfelt et al. 2005). Zhou and Crawford (1995) used Michaelis–Menten type kinetics to describe the degradation of diesel and the effect of various factors onto biodegradation. Ronĉević et al. (2005) used a first order kinetic model as well as another empirical kinetic model to simulate the degradation of TPHs in the soil. According to the authors, both models described adequately the experimental data. They suggested, however, that other, more complex, models could be tried.

All replicate runs have the same or similar orders (n ± 0.1) in the kinetic equations, except in the case of the 2000_1 and 2000_2 runs, in which the n values are 0.5 and 0.2, respectively. This is a rather large difference for replicate runs, which may be attributed to the presence of a temporary steep rise in the oxygen consumption profile of the 2000_1 run; this rise was not observed in the 2000_2 run.

The relatively long duration of the experiments and the use of many experimental data points (more than 2,000 per run) led to a very accurate calculation of the appropriate kinetics. Short-term degradation experiments may not be sufficient to discern the appropriate kinetics (Ronĉević et al. 2005). In this case, the different than 1 reaction order was computed, according to the procedure described in this chapter. Despite the long experimental duration, a plateau was not reached in some of the experiments.

A kinetic analysis is dependent not only on the duration of the experiment but also on the number of data points. Therefore, we analyzed the data of the first 50 days (450 data points) of the experiment and compared the results with those of the whole experiments (more than 200 days and more than 2,000 data points). The comparison indicates that the reaction orders in the 50-day analysis are, in general, lower than the respective orders of the long-term experiments and most of them approach zero (Table 4). The only exception is the uncontaminated soil (n = 0.7) and run 0_2 (n = 0.1). Direct comparison of the kinetic constants (k) for the two kinds of analysis is possible, provided that the reaction orders are the same. The R 2 values are very high in both cases. As indicated in Table 4, although both analyses resulted in good fits, there was a difference in the reaction orders. It therefore appears that short-term experiments will not provide the same kinetic information as the long-term experiments, despite the good data fits in both cases. Kinetic analysis of the first 50 days of the same experiments resulted in lower reaction orders, compared to the respective from the whole experiments. This is important for field applications, when short-term (<2 months) experiments are used to predict the performance of bioremediation in the field. Other investigators reported that relatively long experimental periods allow a better calculation of process kinetics compared to shorter experimental times (Ronĉević et al. 2005).

Figure 3 illustrates the fit of the model to the experimental data of the 500 mg/kg treatment. The fit of the model to the data of this run was typical for all other runs.

Mixing events that took place near the completion of runs 100_1, 100_2, 250, and 500 resulted in small increases of the biodegradation rates that lasted from 8 to 10 days. The increased degradation rates are attributed to the aeration and mixing, as has been shown by pertinent unpublished work in our laboratory

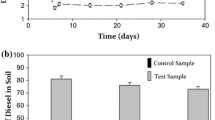

3.4 Theoretical Diesel Degradation Reactions

To estimate the TPH loss, two soil samples were randomly taken from respirometer 100_2 after 138 days. The wet weights of the samples were 1.6 g and 1.7 g; a separate sample (approximately 20 g) was collected to estimate the moisture content, which was measured at 14% (ww) or approximately 16% (dw). It is noted that the initial moisture content at the start of the experiments was fixed at the 55% of the WHC (i.e. 0.36 ml/dry g). The above value corresponds to a gravimetric water content of approximately 17% (ww) or 20% (dw). Therefore, it appears that the losses of H2O during the experiment were small; although no other moisture contents were measured during this experiment, the small water losses in the respirometers over long periods of time has been verified by similar studies in our laboratory (unpublished data). Based on the analysis of TPHs of the duplicate soil samples in run 100_2, the remaining concentration of diesel in the soil after 138 days was 1,660 mg/kg dw and 3,480 mg/kg dw for the two replicates, respectively. The average value was 2,600 mg/kg dw ± 50%. Therefore, an average of 6,900 mg of diesel (TPH)/dry kg of soil were degraded during a period of 138 days, which corresponds to a 73% loss of the initial diesel content. The corresponding cumulative (net) amount of oxygen that was consumed up to day 138 in run 100_2 was approximately 6,300 mg O2/dry kg soil. An estimate of the amount of TPH mineralized was based on the amount of TPH lost, as this was measured via the extraction procedures. Therefore, assuming that measured TPH losses equal the amount of TPH mineralized, stoichiometric reactions can be developed. Based on the above, a theoretical diesel degradation approach can be used based on the assumption that diesel is represented by HXD. Note that HXD has been often used as a model compound for diesel (Geerdink et al. 1996; Shewfelt et al. 2005; Walecka-Hutchison and Walworth 2006).

A simplistic diesel aerobic degradation equation is the following:

The above equation does not include biomass generation and, therefore, does not involve nitrogen. The ratio of CO2 mol to O2 mol, based on Eq. 5, is 0.65, which is much lower than the RQ of 1.0 measured for run 100_2 (see Table 3). According to Eq. 5, 1 mol of hexadecane would require 24.5 mol of O2; that is, theoretical oxygen requirements would approximately be 3,500 mg O2 per g of diesel (hexadecane) consumed. Therefore, if all diesel contained in the artificially diesel-contaminated soil prior to the initiation of the runs (≈9,500 mg/kg dw) was totally degradable, then (maximum) oxygen requirements would approximately reach 33,000 mg O2/dry kg of soil in the system described here. The above value is far higher than the net O2 consumptions recorded for all runs in this study, which were all less than approximately 10,350 mg O2/dry kg of soil (Table 3); this indicates that either not all diesel was degraded, or that the stoichiometric Eq. 5 is over-simplified, and thus not representative. For example, Eq. 5 has not accounted for biomass generation; therefore, N requirements are not shown and some O2 consumption is not accounted for. Additionally, other biotic reactions, such as nitrification or oxidation of mineral soil constituents may have consumed O2.

It is more reasonable to develop a generic theoretical biochemical reaction, which will include biomass (C5H7NO2) generation and the potential nitrification of nitrogen. This generic reaction is represented by Eq. 6.

Using the average amount of diesel reduced (or degraded) in run 100_2 (6,900 mg TPH/kg dw) and the corresponding net O2 consumption up to day 138 (6,300 mg O2/kg dw) for the same run, then 1 mol of diesel (hexadecane) would approximately require 6.4 mol of O2 when degraded. Based on that, oxygen requirements for complete diesel degradation in the contaminated soil used here should be approximately 8,600 mg O2/dry kg soil; the latter value is close to the maximum net O2 consumption recorded for run 100_2 (8,120 mg O2/dry kg soil) after 236 days and close to the corresponding values recorded for the other runs too. The maximum net oxygen consumption recorded in this study is approximately 10,350 mg O2/dry kg of soil for the 250 run after 271 days. In addition, the net CO2/net O2 ratio for run 100_2 was 1.0. Therefore, by keeping a = 1, b = 6.4, e/b ≤ 1.0, and by keeping all the coefficients positive, the optimal stoichiometric coefficients calculated are c = 2.4, d = 2.4, e = 4.0, f = 0, g = 0, and h = 27. This calculation was performed by setting equal to zero the difference between the total mass of the elements in the left-hand side of Eq. 6 and the mass of the same elements in the right-hand side of Eq. 6. In addition, the mass of each element in the left-hand side should equal its mass on the right-hand side. Solver®, by Microsoft’s Excel®, was used in the above calculations. Finally, the best reduced theoretical equation that was developed to satisfy all above constraints was as follows:

According to Eq. 7, the RQ (i.e. fraction e/b) is 0.63, which is much lower than the RQ of 1.0 measured for run 100_2. This may be attributed to the fact that Eq. 7 may still not be representative of the specific biodegradation process. According to Eq. 7, all ammonia-nitrogen consumed is incorporated into biomass; the formation of NO −3 is considered very small and is not included in the products of the reaction. Based on Eq. 7, 1 mol of diesel (hexadecane) requires 2.4 mol of N–NH +4 , while an excess of hydrogen cations is present in the right-hand side of the equation to balance hydrogen. Apparently, the pH of the system is expected to reduce, if not adequately buffered.

It is interesting to note that if the coefficients of Eq. 6 are not forced to be positive numbers, then the optimal stoichiometric equation that would satisfy all constraints would have H2O present in the left-hand side of the equation and hydrogen cations, still, in the right-hand side of the equation. Nitrates would, still, not be formed. In this case, 1 mol of diesel (hexadecane) would require 1.9 mol of N–NH +4 . In addition, fraction e/b (RQ) would equal 1.0, which fully agrees with the experimental findings.

Based on Eq. 7, if all diesel contained in the soil (9,500 mg TPH/kg dw) was degraded, then (maximum) N requirements would have been approximately 0.15 g N/g TPH degraded. Based on this, at the initial levels of diesel used in the system described here, optimal N concentration would be approximately 1,400 mg N–NH +4 /kg dw. This theoretical value is far greater than the optimal value found in this study, namely 250 mg N/kg dw. However, even if the amount of 1,400 mg N/kg dw was the optimal nitrogen concentration to allow complete diesel degradation, its addition to the system in a single load from the start of the treatment process would probably lead to inhibition of the biodegradation. This was clearly shown in this study, since additions of N beyond the concentration of 500 mg N/kg dw led to reduced oxygen consumptions. Still, it is noted that caution is required when using Eq. 7, due to its being based on a single measurement of the final concentration of TPHs.

According to the above discussion, a future research goal might be the verification of Eq. 7, using incremental loads of N during the remediation process as well as additional measurements of final TPH concentrations.

4 Conclusions

From the results of the study, it appears that:

-

The optimum N content that led to the highest net O2 consumption was 250 mg N/kg dw, followed by the 100 mg N/kg dw and 500 mg N/kg dw contents. The corresponding optimum C:N ratios were 40:1 followed by 100:1 and 20:1, respectively. As the concentration of added nitrogen increased beyond 500 mg N/dry kg (or a reduction of the C:N ratio below 20:1), diesel biodegradation was reduced.

-

The optimum NH2O content was approximately 1,250 mg N/kg soil H2O. N values greater than approximately 2,500 mg N/kg soil H2O inhibited the degradation process.

-

The oxygen consumption rates followed zero to 0.6 order kinetics based on an experimental duration of more than 200 days. Kinetic analysis of the first 50 days of the same experiments resulted in lower reaction orders, compared to the respective from the whole experiments. This is important for field applications, when short-term (<2 months) experiments are used to predict the performance of bioremediation in the field.

-

According to a theoretical diesel biodegradation equation developed in this study, the theoretical optimal N concentration to allow complete degradation of all diesel contained in the soil used here was 0.15 g N/g TPH degraded or approximately 1,400 mg N/dry kg of soil. However, the addition of N in a single load at such levels at the initiation of the experiment led to inhibition of the biodegradation processes. It is, therefore, implied that N should be added in incremental loads.

References

Aislabie, J., Saul, D. J., & Foght, J. M. (2006). Bioremediation of hydrocarbon-contaminated Polar soils. Extremophiles, 10, 171–179.

Aspray, T., Gluszek, A., & Carvalho, D. (2008). Effect of nitrogen amendment on respiration and respiratory quotient (RQ) in three hydrocarbon contaminated soils of different type. Chemosphere, 72, 947–951.

Atlas, R. M. (1991). Microbial hydrocarbon degradation—bioremediation of oil spills. Journal of Chemical Technology and Biotechnology, 52, 149–156.

Bartha, R. (1986). Biotechnology of petroleum pollutant biodegradation. Microbial Ecology, 12, 155–172.

Brook, T. R., Stiver, W. H., & Zytner, R. G. (2001). Biodegradation of diesel fuel in soil under various nitrogen addition regimes. Soil & Sediment Contamination, 10, 539–553.

Chapra, S. C. (1997). Surface water-quality modeling (pp. 29–31). New York: McGraw-Hill.

Coles, C. A., Patel, T. R., Akinnola, A. P., & Helleur, R. J. (2009). Influence of bulking agents, fertilizers and bacteria on the removal of diesel from Newfoundland soil. Soil & Sediment Contamination, 18, 383–396.

Dibble, J. T., & Bartha, R. (1979). Effect of environmental parameters on the biodegradation of oil sludge. Applied and Environmental Microbiology, 37, 729–739.

Gallego, J. L. R., Loredo, J., Llamas, J. F., Vazquez, F., & Sanchez, J. (2001). Bioremediation of diesel-contaminated soils: Evaluation of potential in situ techniques by study of bacterial degradation. Biodegradation, 12, 325–335.

Gea, M. T., Barrena, R., Artola, A., & Sánchez, A. (2004). Monitoring the biological activity of the composting process: Oxygen uptake rate (OUR), respirometric index (RI) and respiratory quotient (RQ). Biotechnology and Bioengineering, 88, 520–527.

Geerdink, M. J., van Loosdrecht, M. C. M., & Luyden, K Ch A M. (1996). Biodegradability of diesel oil. Biodegradation, 7, 73–81.

Jin, S., & Fallgren, P. H. (2007). Site-specific limitations of using urea as a nitrogen source in biodegradation of petroleum wastes in soil. Soil & Sediment Contamination, 16, 497–505.

Jobson, A., Cook, F. D., & Westlake, D. W. S. (1972). Microbial utilization of crude oil. Applied Microbiology, 23, 1082–1089.

Karamalidis, A. K., & Voudrias, E. A. (2007). Cement-based stabilization/solidification of oil Refinery sludge: Leaching behavior of alkanes and PAHs. Journal of Hazardous Materials, 148, 122–135.

Khan, F. I., Husain, T., & Hejazi, R. (2004). An overview and analysis of site-remediation technologies. Journal of Environmental Management, 71, 95–122.

Komilis, D. P., & Ham, R. K. (2000). A laboratory method to investigate gaseous emissions and solids decomposition during composting of municipal solid wastes. Compost Science and Utilization, 8, 254–265.

Leahy, J. G., & Colwell, R. R. (1990). Microbial degradation of hydrocarbons in the environment. Microbiological Reviews, 54(3), 305–315.

Margesin, R., & Schinner, F. (2001). Bioremediation (natural attenuation and biostimulation) of diesel-oil-contaminated soil in an Alpine glacier skiing area. Applied and Environmental Microbiology, 67(7), 3127–3133.

Marquez-Rocha, F. J., Hernandez-Rodriguez, V., & Lamela, M. T. (2001). Biodegradation of diesel oil in soil. Water, Air, and Soil Pollution, 128, 313–320.

Morgan, P., & Watkinson, R. J. (1989). Hydrocarbon degradation in soils and methods for soil biotreatment. Critical Reviews in Biotechnology, 8, 305–333.

Naziruddin, M., Grady, C. P. L., Jr., & Tabak, H. H. (1995). Determination of biodegradation kinetics of VOCS through the use of respirometry. Water Environment Research, 67, 151–158.

Oliveira, F. J. S., & de França, F. P. (2005). Increase in removal of polycyclic aromatic hydrocarbons during bioremediation of crude oil-contaminated sandy soil. Applied Biochemistry and Biotechnology, 122, 593–603.

Paudyn, K., Rutter, A., Rowe, R. K., & Poland, J. S. (2008). Remediation of hydrocarbon contaminated soils in the Canadian Arctic by landfarming. Cold Regions Science and Technology, 53, 102–114.

Rasiah, V., Voromey, R. P., & Kachanoski, R. G. (1991). Effect of N amendment on C mineralization of an oily waste. Water, Air, and Soil Pollution, 59, 249–259.

Raymond, R. L., Hudson, J. O., & Jamison, V. W. (1976). Oil degradation in soil. Applied and Environmental Microbiology, 31, 522–535.

Ronĉević, S., Dalmacija, B., Ivančev-Tumbas, I., Tričković, J., Petrović, O., Klašnja, M., et al. (2005). Kinetics of degradation of hydrocarbons in the contaminated soil layer. Archives of Environmental Contamination and Toxicology, 49, 27–36.

Shen, J., & Bartha, R. (1994). On-site bioremediation of soil contaminated by No. 2 fuel oil. International Biodeterioration and Biodegradation, 33, 61–72.

Shewfelt, K., Lee, H., & Zytner, R. G. (2005). Optimization of nitrogen for bioventing of gasoline contaminated soil. Journal of Environmental Engineering and Science, 4, 29–42.

Toffoletto, L., Deschenes, L., & Samson, R. (2005). LCA of ex-situ bioremediation of diesel-contaminated Soil. International Journal of LCA, 10, 406–416.

United States Environmental Protection Agency. (1991). Site Characterization for Subsurface remediation. EPA/625/R-91/026, Office of Research and Development, US EPA Washington, DC.

Volke-Sepùlveda, T., Gutierrez-Rojas, M., & Favela-Torres, E. (2006). Biodegradation of high concentrations of hexadecane by Aspergillus Niger in solid-state system: Kinetic analysis. Bioresource Technology, 97, 1583–1591.

Walecka-Hutchison, C. M., & Walworth, J. L. (2006). Assessment of C:N ratios and water potential for nitrogen optimization in diesel bioremediation. Bioremediation Journal, 10, 25–35.

Walworth, J. L., & Reynolds, C. M. (1995). Bioremediation of a petroleum-contaminated cryic soil: Effects of phosphorus, nitrogen and temperature. Journal of Soil Contamination, 4, 299–310.

Walworth, J. L., Braddock, J. F., & Woolard, C. R. (2001). Nutrient and temperature interactions in bioremediation of cryic soils. Cold Regions Science and Technology, 32(2–3), 85–91.

Walworth, J., Pond, A., Snape, I., Rayner, J., Ferguson, S., & Harvey, P. (2007). Nitrogen requirements for maximizing petroleum bioremediation in a sub-antarctic soil. Cold Regions Science and Technology, 48, 84–91.

Walworth, J. L., Woolard, C. R., Braddock, J. F., & Reynolds, C. M. (1997). Enhancement and inhibition of soil petroleum biodegradation through the use of fertilizer nitrogen: An approach to determining optimum levels. Journal of Soil Contamination, 6(5), 465–480.

Zhou, E., & Crawford, R. L. (1995). Effects of oxygen, nitrogen and temperature on gasoline biodegradation in soil. Biodegradation, 6, 127–140.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Komilis, D.P., Vrohidou, AE.K. & Voudrias, E.A. Kinetics of Aerobic Bioremediation of a Diesel-Contaminated Sandy Soil: Effect of Nitrogen Addition. Water Air Soil Pollut 208, 193–208 (2010). https://doi.org/10.1007/s11270-009-0159-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11270-009-0159-9