Abstract

Magnetite (Fe3O4) is a zerovalent iron corrosion product; it is also formed in natural soil and sediment. Sorption of arsenate (As(V)) and arsenite (As(III)) on magnetite is an important process of arsenic removal from groundwater using zerovalent iron-based permeable reactive barrier (PRB) technology and natural attenuation. We tested eight magnetite samples (one from Phoenix Environmental Ltd, one from Cerac, Inc. and six from Connelly-GPM, Inc.) that contained from 79 to 100% magnetite. The magnetites were reacted in the absence of light with either As(V) or As(III) in 0.01 M NaCl at 23°C at equilibrium pH 2.5–11.5 for 24 h. As(V) sorption showed a continuous drop with increasing pH from 2.5 to 11.5; whereas, As(III) sorption exhibited maxima from pH 7 to 9. Equal amounts of As(V) and As(III) were sorbed at pH 5.6–6.8. Higher amounts of As(III) were sorbed by the magnetites than As(V) at pH values greater than 6.8. The solution speciation test did not show any chemical reduction of As(V) in any magnetite suspension, which is consistent with the X-ray Photoelectron Spectroscopy (XPS) study of a Connelly-GPM magnetite (CC-1048) suspension. Conversely, XPS results show that the As(III) is partially oxidized in the magnetite (CC-1048) suspension. This is also consistent with the batch test results that also show more oxidation occurring at alkaline pH. Complete oxidation of As(III) occurred in a synthetic birnessite (δ-MnO2) suspension after 24 h of reaction. The minute impurities of Mn (possibly as an oxide form) in the magnetite samples may have been responsible for As(III) oxidation. In addition, the structural Fe(III) in magnetite and hydroxyl radicals in solution could also serve as oxidants for As(III) oxidation. The conversion of As(III) to As(V) in the magnetite suspensions would be beneficial in a remediation scheme for As removal, since As(V) is considered less toxic than As(III). Information from the present study can help predict the sorption behavior and fate of arsenic species in engineered PRB systems and natural environments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Arsenic (As) is considered to be the greatest health threat in public groundwater supplies in the USA because of its wide presence and severe toxicity (Knox and Canter 1996). In Southeast Asia, drinking water polluted with naturally occurring arsenic adversely affects the health of millions of people (Nickson et al. 1998; Berg et al. 2007). In Taiwan, blackfoot disease (a peripheral vascular disease) is generally attributed to the high concentrations of As found in deep well waters, with a predominant As species being arsenite (As(III)) (Chen et al. 1994). Sources of arsenic contamination of groundwater include smelters, coal-burning, electric plants, pesticides, natural weathering processes, and runoff from mining operations. Arsenic is subject to several processes in the subsurface. Under various conditions, it is adsorbed, desorbed, oxidized, reduced, methylated, and volatilized (Cullen and Reimer 1989; Smedley and Kinniburgh 2002).

As(III) is more prevalent in groundwater than previously believed, and As(III) is extremely toxic (teratogenic), so it may damage the neurological system at aqueous concentrations as low as 0.1 mg l−1 (Korte and Fernando 1991). The realization of carcinogenic effects of arsenic at lower concentrations than previously thought has prompted the U.S. Environmental Protection Agency to lower the maximum contaminant level for total arsenic in drinking water from 0.05 to 0.01 mg l−1. Previous studies have shown that sorption onto iron oxides and other phases in the subsurface plays an important role in controlling the concentrations of and, therefore, mobility of As in groundwater (Ford 2005).

Various materials have been studied as potential candidates to be used for treating arsenic-laden groundwater and wastewater. Among them, zerovalent iron (ZVI) and iron oxides are the most promising (Su 2007). The particle size of iron oxides has a dramatic influence on the capacity of As removal. Nanosized magnetite particles (12 nm in diameter) show removal of As(V) or As(III) orders of magnitude higher than their microsized counterparts (300 nm; Yavuz et al. 2006). In the study of Yavuz et al. (2006), nanoscale, uniform-sized magnetite particles were suspended in As-containing water. A magnetic field was used to pull the particles out of solution, leaving only the purified water. Since nanoparticles are expensive to make, economical alternative materials may be needed for large-scale applications.

Magnetite is a ZVI corrosion product that will be persistent in a permeable reactive barrier of ZVI in the subsurface (Wilkin et al. 2002; Morrison et al. 2002; Kanel et al. 2005). In addition, magnetite occurs naturally in soil and sediment. Magnetite can be derived via microbial pathways as well (Tadanier et al. 2005). Previous studies show similar As(V) and As(III) sorption capacities between natural iron oxides (hematite, magnetite, and goethite) and their synthetic counterparts, normalized to their surface area, at a wide range of pH values from 2 to 13 (Gimenez et al. 2007); however, the redox transformation of As(III) in the iron oxide systems are not well understood. A systematic study of the interactions between inorganic arsenic species and magnetite is necessary for a more complete understanding of the behavior of arsenic removal and transformation, because ZVI has been tested recently at several field sites for groundwater arsenic removal (Vlassopoulos et al. 2005; Nikolaidis et al. 2005). In a recent field pilot scale study, magnetite particles and amorphous iron oxyhydroxides present in electrocoagulation products were reported to remove As(III) and As(V) with an efficiency of more than 99% from groundwater (Parga et al. 2005). Furthermore, sorption on metal oxides in soils and sediments is potentially an important mechanism for natural attenuation of arsenic in groundwater (Ford 2005).

The objectives of this study were to (1) investigate the sorption behavior of both As(V) and As(III) on model magnetite specimens as iron corrosion products in engineered ZVI-based PRB, and also as constituents of natural soil and sediment; and (2) examine the possible roles and mechanisms of As sorption by magnetite in relation to As sequestration under conditions associated with PRB and natural attenuation.

2 Materials and Methods

2.1 Materials Characterization

Eight magnetite specimens were used in the study to cover a wide range of surface area and purity of the mineral, as shown in Table 1. The Phoenix magnetite sample (average particle size: 5 μm) was obtained from Phoenix Environmental Ltd. (Montgomery, PA); the Cerac magnetite sample was purchased from Cerac, Inc. (99% pure with an average particle size of 5 μm); and the six Connelly-GPM magnetite samples (CC-1042, CC-1043, CC-1044, CC-1046, CC-1047, and CC-1048) were acquired from Connelly-GPM, Inc. (Chicago, IL). A manganese dioxide specimen (birnessite, δ-MnO2) was synthesized following a method of McKenzie (1971) by the addition of 168 ml of concentrated HCl drop-wise to 2,500 ml of boiling water containing 158.0 g of KMnO4 (Baker, 99.0%) in a 3,000-ml glass beaker in a ventilation hood. The resulting suspension was allowed to cool and settle for 24 h, at which time a suspension pH of 5.73 was measured. The suspension was poured equally into six 500-ml centrifuge bottles and centrifuged at 3,600 rpm for 30 min. The solids were washed with deionized water and centrifuged five times so that the electrical conductivity of the supernatant solution after the fifth wash was 17 μs cm−1 and the pH was 6.90. Subsequently, the solids were dried at 70°C in an oven. Both iron and manganese oxide materials in duplicates were subjected to microwave-assisted acid digestion in a 10% HNO3 solution at 175°C in a sealed pressurized vessel (modified after EPA SW-846 Method 3051A, which uses concentrated HNO3), followed by total dissolved element (As, Fe, Mn, Si, P, and S) determination using Inductively Coupled Plasma—Optical Emission Spectrometry (ICP-OES) or ICP-Mass Spectrometry (MS) for concentrations below 100 ng l−1. Total Carbon (TC) content of solids was determined using the LECO CR-412 carbon analyzer (LECO Corp, St. Joseph, MI) via combustion at 1450°C. Solids for Total Organic Carbon (TOC) were first treated with hydrochloric acid (18%) to remove inorganic carbon prior to combustion. Total Inorganic Carbon (TIC) value was taken as the difference between TC and TOC values.

Powder X-ray diffraction data for the oxides were collected with a Philips X-ray diffractometer using CuKα radiation generated at 40 kV and 20 mA. The composition of the sample was determined as semi-quantitative compound percentages (wt.%). Surface area was determined by BET N2 adsorption analysis on a Coulter SA 3100 surface area analyzer (Coulter Co., Hialeach, FL).

2.2 Batch Tests

Reagent grade Na2HAsO4 (Aldrich) and NaAsO2 (Baker) were used as the As(V) and As(III) sources, respectively, for the preparation of stock solutions (1,000 mg As l−1). Working solutions (generally 2 mg As l−1) were freshly prepared every day for each batch test. Preliminary tests showed that both As(V) and As(III) sorption by magnetites reach equilibrium in less than 24 h, which is consistent with previous studies by other researchers who have shown that the adsorption reactions of As(V) and As(III) are relatively fast, with reactions completed within the first eight hours (Manning and Goldberg 1996). A next test was conducted to evaluate the effect of varying the mass to solution ratio of the Phoenix magnetite on the shape of an As(V) sorption envelope (a plot of As(V) sorption percentage versus the pH). The results were then used to derive the optimum mass to solution ratio for subsequent tests of the rest of the materials. Varying amounts of Phoenix magnetite (0.05, 0.1, 0.25, 0.5, and 1.0 g) were reacted separately with 35 ml of a 0.01 M NaCl solution containing 2 mg l−1 As(V) in 50-ml polypropylene copolymer centrifuge tubes. The suspension pH was adjusted with 0.1 M HCl or 0.1 M NaOH. Samples were covered with aluminum foil to prevent light exposure, and placed on a reciprocating shaker at a shaking frequency of 50 excursions per minute at 23 ± 1°C for 24 h. The suspension was centrifuged at 3,600 rpm for 30 min, and 30 ml of supernatant solution were filtered through a 0.1-μm membrane and then analyzed for total dissolved elements of As, Fe, and Mn using ICP-OES or ICP-MS. The quantity of As sorption was calculated as the difference between the initial amount of added As and dissolved As at the end of 24 h reaction. Arsenic speciation in solution was accomplished as described in section 2.3 below. The pH and Eh values were determined for the remaining supernatant solutions with an Orion ion analyzer (Orion Research Inc., Boston, MA) by using a combination pH electrode and a Pt electrode, respectively. The Eh readings were reported relative to the normal hydrogen electrode. For general sorption envelope experiments of other oxides for both As(V) and As(III), 0.1 g of minerals were reacted for 24 h with 35 ml of 2 mg l-1 As(V) or As(III) in 0.01 M NaCl, and the samples were treated the same way as described above.

2.3 Analytical Method for Aqueous Arsenic Speciation

Speciation analysis of dissolved As in aqueous solutions was accomplished by Ion Chromatography (IC)–Hydride Generation (HG)–Atomic Fluorescence Spectrometry (AFS). As(V) and As(III) species were first separated with IC using a Hamilton PRP-X100 reverse phase anion exchange column (250 mm × 4.6 mm, 10 μm particle size), then determined using HG–AFS on a PS Analytical Excalibur Spectrometer (PS Analytical Ltd., Orpington, Kent, UK). Column gradient elution flow rate was at 1.0 ml min−1 using 2.5 mM K2HPO4/KH2PO4 and 20 mM K2HPO4/KH2PO4 solutions.

2.4 X-Ray Photoelectron Spectroscopy (XPS)

One Connelly-GPM magnetite sample (CC-1048) was used to speciate solid phase arsenic using XPS. One gram of magnetite (CC-1048) was reacted for 5 days with 41.0 ml of 500 mg l−1 As(V) or As(III) in 0.01 M NaCl in a 50-ml centrifuge tube (with a measured volume of 41.6 ml). Small amounts of 1.0 M HCl were added to adjust the pH of As(V)-doped magnetite suspension to about pH 2.5 and the pH of As(III)-doped magnetite to about pH 4.0 to ensure near maximum sorption. The samples were centrifuged, and supernatant solutions were analyzed for pH and Eh. The solids were washed twice with 20 ml of acetone and quickly air-dried under nitrogen atmosphere. The resulting samples were transferred into small vials, and then filled with nitrogen gas. These vials then were stored in an anaerobic chamber filled with nitrogen gas.

XPS spectra were acquired on a Physical Electronics 5500 ESCA system. The X-ray source on this instrument was a monochromated radiation at AlKα 1486.7 eV. The acceptance angle was 0 ± 7°. The diameter of analysis area of the sample was 800 μm, and the depth of samples analyzed ranged from 8 to 10 nm. Samples were prepared within a glove box purged and maintained with dry nitrogen, and then transferred directly from the glove box into the ultrahigh vacuum instrument chamber with the aid of an in-vacuo transfer vessel in order to minimize atmospheric exposure. Chemical state information for As was determined from nonlinear least squares fitting of the As (3d) spectra and represented the best estimates of the species present based upon reference data (bonding energies).

3 Results and Discussion

3.1 Characteristics of Sorbents

Table 1 shows the mineralogy and specific surface area values of the mineral sorbents. For the eight magnetite samples, magnetite contents ranged from 79 to 100%, and specific surface area values ranged from 2.43 to 16.5 m2 g−1. Birnessite had the highest surface area of 39.9 m2 g−1. Some Connelly-GPM magnetites (CC-1042, CC-1043, CC-1044, and CC-1046) contained substantial amounts of impurities of TOC, TIC, hot-HNO3-extractable As, Fe, Mn, Si, P, and S (Table 2).

3.2 Sorption Envelopes

Sorption of As(V) onto Phoenix magnetite as a function of pH (2.5–11.5) and solid to solution ratios (0.05 to 1.0 g in 35 ml) is shown in Fig. 1. Sorption generally decreased with increasing pH, and the edge of sorption envelopes shifted to higher pH values as the sorbent mass to solution ratios increased. Complete (100%) sorption was achieved at 0.50 and 1.0 g per 35 ml ratio at pH less than 5.0, and complete sorption was achieved at 0.25 g per 35 ml ratio at pH less than 4.0.

Figure 2a,b, and c present sorption envelopes for the initially added species of As(V) and As(III) sorbed to the Phoenix magnetite and Connelly-GPM magnetites (CC-1042 and CC-1043) at 1.0 g per 35 ml ratio. A 100% sorption of either As(V) or As(III) equals the amount of As(V) or As(III) sorption at 700 mg kg−1. The effect of pH on As(III) sorption was different from that on As(V) sorption in that As(III) sorption increased with increasing pH to reach a broad sorption maximum before decreasing with further increases in pH. As(III) sorption rose from ca. 20% near pH 2.5 to a maximum of ca. 40% near neutrality, but above pH 9, the completeness of sorption fell to near 20% by pH 11.5 (Fig. 2a). The sorption envelopes for As(V) and As(III) sorption onto CC-1042 are similar to those for sorption onto CC-1043 (Fig. 2b and c). The similarity may be attributed to the almost identical surface area values of the two magnetites (Table 1). A small difference in mineralogy does not seem to influence the sorption envelops substantially; CC-1042 was a relatively pure magnetite as determined with X-ray diffraction, and CC-1043 was 85% magnetite, 10% goethite, and 4% hematite (Table 1). Magnetites of different sources seem to show slightly different sorption envelopes. The specific surface area of Phoenix magnetite was only 15% of that of CC-1042 and CC-1043, yet As(III) sorption maximum value was about 40% for Phoenix magnetite and 60% for both CC-1042 and CC-1043. This implies that the relationship between the specific surface area and the maximum sorption is not strictly linear. It is noteworthy that Phoenix magnetite contained significant amounts of extractable Si, P, and S than CC-1042 and CC-1043 (Table 2). These extractable impurities are likely present in the form of surface-sorbed anions that have already occupied some available sorption sites that may otherwise be available for As(V) and As(III) sorption. Silicate and phosphate are known competitors of As(V) and As(III) for sorption onto zerovalent iron and iron oxide minerals (Su and Puls 2003; Tyrovola et al. 2007).

Sorption envelopes for the initial species of As(V) and As(III) (left panels) for the Phoenix magnetite, Connelly-GPM magnetites (CC-1042 and CC-1043), as well as the species distribution of As(V) and As(III) (right panels) in the magnetite suspensions (1.0 g in 35 mL) after 24 h reaction. A value of 100% sorption equals sorption at 700 mg kg−1

The same type of information for three more Connelly-GPM magnetites (CC-1044, CC-1046, and CC1047) is presented in Fig. 3. The specimen CC-1046 was 88% magnetite and 12% hematite (Table 1). The presence of a small amount of hematite in CC-1046 does not seem to change the sorption envelopes of As(V) and As(III) substantially as compared to CC-1044 which was 99% magnetite (Fig. 3a and b, Table 1).

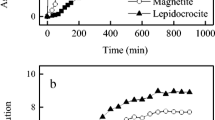

Figure 4a,b, and c show As sorption envelopes for the Connelly-GPM magnetite (CC-1048), Cerac magnetite, and synthetic birnessite. As(III) sorption increased from ca. 70% near pH 2.5 to a maximum of ca. 95% near neutrality for CC-1048 (Fig. 4a), making it the highest for As(III) sorption among all studied Connelly-GPM magnetites. Above pH 9, the completeness of sorption fell to 55% by pH 11.3. The Cerac magnetite exhibited different sorption envelopes relative to those of Connelly-GPM magnetites (Fig. 4b). The pH value at which equal As(V) and As(III) sorption occurred was the highest (pH 6.8) among all studied magnetites (Table 2). Higher amounts of As(V) and As(III) sorption were observed on the Cerac magnetite than on Connelly-GPM magnetites from pH 7 to 11. This again may be due to the fact that Cerac magnetite contained much less Si, P, and S than did the Connelly-GPM magnetites (Table 2).

Sorption envelopes for the initial species of As(V) and As(III) (left panels) for the Connelly-GPM magnetites (CC-1048), Cerac magnetite, and synthetic birnessite, as well as the species distribution of As(V) and As(III) (right panels) in the aqueous solution of the magnetite suspensions after 24 h reaction

The amounts of As(V) sorption ranged from 0 at pH 11.5 to 700 mg kg−1 at pH 2.5 to 4.0, and the amounts of As(III) sorption ranged from 150 mg kg-1 at both low and high pH values to 650 mg kg−1 at near neutrality for all the magnetites tested in this study. The magnitude of As sorption observed in this study is comparable to As concentrations reported for naturally occurring iron oxide minerals in some cases. For example, the concentration of total As in coated iron oxyhydroxides with residual magnetite and ilmenite in the sandy layer was found to range from 14 to 112 mg kg−1 in a basin area in West Bengal, India (Pal et al. 2002). That study suggests that arsenic is introduced into the aquifer sediments in a soluble state and then gets adsorbed on iron-rich clastic grains and authigenic siderite concretions. Adsorption of the element on the sites and its consequent desorption to the groundwater seem to be controlled by microbial activity in the aquifer sediments. In another study, Berg et al. (2007) examined the magnitude of arsenic pollution in the Mekong and Red River Deltas located in Cambodia and Vietnam, respectively. They found that the sediments of 12–40 m deep cores from the Red River delta contain arsenic levels of 2–33 mg kg−1 (average 7 mg kg−1, dry weight) and show a remarkable correlation with sediment-bound iron. The concentrations of As in the iron oxides should be much higher than these values because the iron oxides are the largest sink for As and they account for only a small portion of the total sediment mass. In all three areas, the groundwater arsenic pollution seems to be of natural origin and caused by reductive dissolution of arsenic-bearing iron phases buried in aquifers.

Arsenic acid, H3AsO4, has three pK a values (pK 1 = 2.20, pK 2 = 6.97, and pK 3 = 11.53) (Wagman et al. 1982). In the pH range of 3 to 6, \({\text{H}}_2 {\text{AsO}}_4^ - \) is the predominant species, and presumably, the major species being sorbed. The iron oxide surfaces exhibit a net positive charge in this pH range and adsorption of anionic As(V) is enhanced by columbic attractions. Hingston et al. (1971) demonstrated that the adsorption behavior of As(V) on hydrous oxides is similar to that of phosphate because arsenate ion and phosphate ion are chemically alike. Woolson et al. (1973) observed that arsenate could be desorbed from soils by leaching with phosphate, which suggests that As(V), like phosphate, is adsorbed in soils by a ligand exchange mechanism. Raven et al. (1998) showed that both As(V) and As(III) have strong affinities for ferrihydrite, and that As(III) is adsorbed in much larger amounts than As(V) at pH greater than 7.5. The present study shows a similar trend for magnetites.

Arsenous acid, H3AsO3, also has three pK a values (pK 1 = 9.22, pK 2 = 12.13, and pK 3 = 13.4), which are larger than those corresponding to H3AsO4 (Wagman et al. 1982). For As(III), the neutral H3AsO3 molecule is the predominant species from pH 0 to 9. The \({\text{H}}_2 {\text{AsO}}_3^ - \) species becomes significant as pH rises above 9. The amount of As(III) adsorption should increase as pH increases to the pK a of the acid. Hingston (1981) argued that the maximum adsorption of an anion occurs near the pK a of the corresponding weak acid, and this is in general agreement with our experimental results.

This study shows that the As(III) sorption maximum for magnetite occurs around pH 7. Similar results have been reported for other iron oxides such as hematite (Singh et al. 1988) and amorphous iron hydroxide (Pierce and Moore 1980). These authors explained the pH effect with the concept of zero point of charge (ZPC) of the adsorbents. Magnetite has a ZPC of 6.6 (Sverjensky 1994). Low pH favors surface protonation of the iron oxide, and As(III) occurs as a neutral H3AsO3 species. When pH increases above 5, surface protonation diminishes and approaches zero at pH 7, facilitating maximum adsorption. When pH is above 9, the negatively charged \({\text{H}}_3 {\text{AsO}}_3^ - \) becomes predominant and the oxide surface becomes negatively charged, the resulting electrostatic repulsion leads to decreased sorption. For the eight magnetite samples, this study shows that more As(V) was sorbed than As(III) at pH less than 5.8, that equal amounts of As(V) and As(III) were sorbed at pH 5.8–6.8 (Table 2), and that more As(III) was sorbed than As(V) at pH greater than 6.8.

3.3 Speciation of As in the Solution

There is strong evidence for substantial oxidation of As(III) to form As(V) in all magnetite suspensions at pH values greater than 6 (Figs. 2, 3, 4, right panels). The most notable is the Connelly-GPM (CC-1048) magnetite sample that shows As(III) oxidation at a wide range of pH (2.5–11.5), with more oxidation at alkaline pH (Fig. 4d). Above pH 7, the percent As(III) in the supernatant liquid fell from 70% at pH 7 and below to 0% by pH 11.5, at which point all of the dissolved arsenic in the supernatant was present as As(V). Interestingly, this sample does not have the highest acid-extractable Mn concentration (Table 2).

Complete oxidation of As(III) was observed in the birnessite suspension at pH 2.5 to 11.5 (Fig. 4f) such that almost identical sorption envelopes for both initially added As(V) and As(III) were obtained (Fig. 4c). The presence of manganese, possibly in the form of manganese dioxides in the iron oxide samples as minor impurities (Table 2), might have contributed to the oxidation of As(III).

Scott and Morgan (1995) showed rapid oxidation (with a time scale of minutes) of As(III) by birnessite and observed no effect of dissolved oxygen on the rate of oxidation. Their observations suggest that birnessite directly oxidizes As(III) through a surface mechanism. Oscarson et al. (1980, 1981) attributed an initial fast disappearance of As(III) in isolated manganese dioxide suspensions at pH 7 to the rate of As(III) adsorption on the oxide surface, and a second slower rate to the rate of As(III) oxidation by the surface. Scott and Morgan (1995) reinterpreted the data of Oscarson et al. (1983) on As(III) oxidation by birnessite in terms of rapid As(III) oxidation kinetics: As(III) is oxidized immediately and produces Mn(II), and at pH 7, adsorption/retention of Mn(II) is highly favored on the birnessite surface; the slower rate is the result of Mn(II) occupying the newly generated surface sites, thus blocking the adsorption and oxidation of As(III). Scott and Morgan (1995) did not detect any As(V) sorption by birnessite at a solid concentration of 0.21 g l−1, but we found significant sorption in a wide range of pH from 2.9 to 11 (Fig. 4c). This may be due to our much higher birnessite concentration (2.86 g l−1). There is no evidence for reduction of As(V) in any oxide suspension under the experimental conditions. Moore et al. (1990) showed that oxidation of As(III) to As(V) by K-birnessite produced large amounts of K+ to solution and very little Mn2+, and As(V) was released to solution and incorporated into the K-birnessite. In our test, total dissolved Mn in birnessite-As(V) suspension increased from 0.031 mg l−1 at pH 2.91 to reach a maximum of 0.354 mg l−1 at pH 6.59 before decreasing slightly to 0.319 mg l−1 at pH 11.07. Similarly, total dissolved Mn in birnessite-As(III) suspension increased from 0.011 mg l−1 at pH 2.65 to reach a maximum of 0.240 mg l−1 at pH 6.78 before decreasing to 0.109 mg l−1 at pH 11.07. Recent reactor experiments indicate that As(III) is oxidized by MnO2, followed by the adsorption of the As(V) reaction product on the MnO2 solid phase (Manning et al. 2002). The most likely As(V)-MnO2 complex is a bidentate binuclear corner sharing (bridged) complex occurring at MnO2 crystallite edges and interlayer domains. In the As(III)-treated MnO2 systems, reductive dissolution of the MnO2 solid during the oxidation of As(III) causes an increase in the adsorption of As(V) when compared with As(V)-treated MnO2. This suggests that As(III) oxidation causes surface alteration, creating fresh reaction sites for As(V) on MnO2 surfaces (Manning et al. 2002). In the present study, the As(V) sorption envelop is not distinguishable from the As(III) sorption envelop for birnessite (Fig. 4c).

Other alternative oxidants for As(III) are structural Fe(III) ions in the iron oxides (De Vitre et al. 1991; Greenleaf et al. 2003; Su and Puls 2004) and hydroxyl radicals (Voegelin and Hug 2003). It is difficult to pinpoint which oxidant reacted predominantly in the magnetite systems; however, the outcome is beneficial because As(V) is regarded as less toxic than As(III) towards organisms.

3.4 XPS Data

Figure 5 shows the wide XPS scan of As(III)-treated Connelly magnetite (CC-1048) for 5 days at pH 2.4 without light. Figure 6 presents the XPS spectra of As (V) and As(III) species as indicated by the relative intensity of the As(3d) XPS peaks for As(V)-treated and As(III)-treated Connelly-GPM magnetite (CC-1048). Carbon was observed primarily in the form of hydrocarbons (C–C, C–H), with the likely presence of the oxygen functionalities C–O, C=O, and O–C=O. The source of carbon could be residual acetone and grease in the original sample. The form of iron detected on magnetite (CC-1048) was consistent with an oxide form as a mixture of Fe2+ and Fe3+. The As(V) sorbed on magnetite (CC-1048) at pH 2.4 retained its oxidation state after 5 days of reaction (Table 3); whereas, As(III) underwent slight changes at pH 4.1 with 8% of total sorbed As as As(V) and 91% of the total adsorbed As as As(III). The Eh was positive in both initial As(V) and As(III) suspensions (Table 3). The XPS results are in agreement with solution speciation analysis, which shows that 90% of the added As(III) in solution remained as As(III) and 10% of the added As(III) was concerted to As(V) in solution (Fig. 4d).

3.5 Mechanisms of Arsenic Sorption on Magnetite and Birnessite

It is probable that electrostatic interaction and specific adsorption are important mechanisms for As removal by the magnetites and birnessite. Spectroscopic methods such as Extended X-ray Absorption Fine Structure (EXAFS) and infrared spectroscopy studies have provided information on the molecular structures of As(V) complexes on iron oxides (Waychunas et al. 1993; Manceau 1995; Fendorf et al. 1997; Suarez et al. 1998). Waychunas et al. (1993) and Fendorf et al. (1997) suggested that As(V) predominately forms inner-sphere bidentate surface complexes with goethite. For As(III), the main surface species on goethite is a bidentate complex and a minor monodentate species is also found (Stachowicz et al. 2006). Arsenate sorption onto lepidocrocite (γ-FeOOH) occurs via an inner-sphere complex resulting from bidentate corner sharing between AsO4 tetrahedra and adjacent FeO6 octahedra (Randall et al. 2001). An EXAFS study shows As(V) most likely forms a bidentate binuclear corner sharing (bridged) complex at birnessite crystallite edges and interlayer domains (Manning et al. 2002). Spectroscopic information on mechanisms for As(V) and As(III) adsorption on magnetite particles is scarce, and thus further study is needed in this regard.

3.6 Implications to Arsenic Remediation Using Iron-Based PRB and Natural Attenuation

Arsenic transformation is affected by the redox condition. As(V) is the predominant form in oxidized waters; whereas, As(III) is predominant in reduced waters. Because of the relatively slow redox transformations, both As(V) and As(III) are often found in either redox environment (Driehaus et al. 1995). The creation and maintenance of an oxidized environment may be desirable in a remediation scheme for aqueous As. For example, Shen (1973) reported enhanced removal of As by ferric chloride coagulation with oxidation of As(III) to As(V) by chlorine or KMnO4 at pH 7.4. Driehaus et al. (1995) used manganese dioxide in flow-through-tests in sand filters to treat As(III) in drinking water. Because in ZVI systems As(III) is known to be partially oxidized to As(V) (Su 2007), an engineered ZVI-based PRB system may be advantageous in this regard. The pH effect on As sorption should be considered when a ZVI-based PRB is to be installed. Because magnetite is a major iron corrosion product of ZVI in the subsurface, As(III) removal would be more favorable relative to As(V) due to an increase in solution pH to the alkaline values (pH 7.5–10) as a result of iron corrosion (Su 2007).

A key step in successful site remediation for arsenic is to assess the natural attenuation capacity of the subsurface for this contaminant (Lin and Puls 2003). Sorption to solid phases is the principal mechanism immobilizing As in soils and removing it from groundwater (Wang and Mulligan 2006). Lin and Puls (2003) studied chemical reactions between arsenic and several iron hydroxides (goethite, lepidocrocite, and green rust). By comparing the arsenic attenuation capacity of iron hydroxides, clay minerals, and feldspars, these authors established an order: iron hydroxides > clays > feldspars. Their results show that arsenic is more strongly bound by iron hydroxides than clays, and that the iron minerals studied can extensively oxidize As(III) to As(V). Under reducing conditions, the concentration of As(III) significantly decreases due to the presence of green rust and parasymplesite (Lin and Puls 2003). These studies provide evidence that some minerals could act as mineral indicators for site characterization. Integration of mineral indicators with geochemical parameters should aid in determining the potential of natural attenuation of the subsurface to remove arsenic from contaminated groundwater.

The often-stated generalization that As(III) is more mobile in the environment than As(V) is too simplistic, especially when iron oxides are available as sorbents (Dixit and Hering 2003). Under typical pH conditions of natural environments (pH 6–9), As(III) sorbs to a similar or greater extent than As(V) on magnetite as shown in this study, or on ferrihydrite and goethite as shown in a previous study (Dixit and Hering 2003). This study does not consider the effects of microbes on the transformation of As species; however, As redox cycling appears to be strongly affected by microorganisms. Rapid biological oxidation of As(III) to As(V) has been reported to occur in soil (Quastel and Scholefield 1953), in acid mine waters (Wakao et al. 1988), and in streamwaters of the Eastern Sierra Nevada of the USA (Wilkie and Hering 1998). Any field implementation of a remediation scheme using iron oxides or elemental iron should not ignore the biological side of As transformation; however, microbial reduction of As(V) would not necessarily enhance its mobility in the subsurface. The reductive dissolution of the iron oxide solid phases and not just As(V) reduction is required to mobilize arsenic in As- and Fe-enriched sediments (Kneebone et al. 2002). A recent laboratory study also implies that during reductive dissolution of iron oxides in natural sediments there will be no simple correlation between the release of arsenate and ferrous iron (Pedersen et al. 2006).

4 Conclusions

It is important to understand the sorption behavior of arsenic and its mechanisms of immobilization and transformation so that suitable remediation approaches (engineered systems and natural attenuation) can be undertaken to treat arsenic-contaminated groundwater. We tested eight commercially available magnetites on their chemical behavior towards As(V) and As(III) in aqueous solution. Sorption of As(V) by magnetites was more favorable than that of As(III) below pH 5.6–6.8; whereas, above pH 7, As(III) exhibited a higher affinity for the minerals. The oxidation of As(III) in the magnetite suspensions was generally increased with increasing pH from 2 to 12. To achieve maximum removal of both As(V) and As(III) that are present at equal concentrations, an adjustment of solution pH to near neutrality may be a practical approach. In an engineered ZVI-based PRB system where magnetite is a major iron corrosion product, As(III) removal would be more favorable relative to As(V) due to an increase in solution pH to the alkaline values (pH 7.5–10) resulting from the elemental iron corrosion.

References

Berg, M., Stengel, C., Trang, P. T. K., Viet, P. H., Sampson, M. L., Leng, M., et al. (2007). Magnitude of arsenic pollution in the Mekong and Red River Deltas—Cambodia and Vietnam. Science of the Total Environment, 372, 413–425.

Chen, S. L., Dzeng, S. R., Yang, M. H., Chiu, K. H., Shieh, G. M., & Wai, C. M. (1994). Arsenic species in ground waters of the Blackfoot Disease area, Taiwan. Environmental Science and Technology, 28, 877–881.

Cullen, W. R., & Reimer, K. J. (1989). Arsenic speciation in the environment. Chemical Reviews, 89, 713–764.

De Vitre, R., Belzile, N., & Tessier, A. (1991). Speciation and adsorption of arsenic on diagenetic iron oxyhydroxides. Limnology and Oceanography, 36, 1480–1485.

Dixit, S., & Hering, J. G. (2003). Comparison of arsenic(V) and arsenic(III) sorption onto iron oxide minerals: Implications for arsenic mobility. Environmental Science and Technology, 37, 4182–4189.

Driehaus, W., Seith, R., & Jekel, M. (1995). Oxidation of arsenic(III) with manganese oxides in water treatment. Water Research, 29, 297–305.

Fendorf, S., Eick, M. J., Grossl, P., & Sparks, D. L. (1997). Arsenate and chromate retention mechanisms on goethite. 1. Surface structure. Environmental Science and Technology, 31, 315–320.

Ford, R. G. (2005). The impact of ground-water/surface-water interactions on contaminant transport with application to an arsenic contaminated site. Environmental Research Brief. National Risk Management Research Laboratory, Cincinnati, OH 45268. EPA/600/S-05/002.

Gimenez, J., Martinez, M., de Pablo, J., Rovira, R., & Duro, L. (2007). Arsenic sorption onto natural hematite, magnetite, and goethite. Journal of Hazardous Materials, 141, 575–580.

Greenleaf, J. E., Cumbal, L., Staina, I., & Gupta, A. K. (2003). Abiotic As(III) oxidation by hydrated Fe(III) oxide (HFO) microparticles in a plug flow columnar configuration. Transactions of Institution of Chemical Engineers Part B, 81, 87–98.

Hingston, F. J. (1981). A review of anion adsorption. In M. A. Anderson & A. J. Rubin (Eds.), Adsorption of inorganics at solid–liquid interfaces (pp. 51–90). Ann Arbor Sci. Publ., AM Arbor, MI.

Hingston, F. J., Posner, A. M., & Quirk, J. P. (1971). Competitive adsorption of negatively charged ligands on oxide surfaces. Discussions of the Faraday Society, 52, 334–342.

Kanel, S. R., Manning, B. A., Charlet, L., & Choi, H. (2005). Removal of arsenic(III) from groundwater by nanoscale zero-valent iron. Environmental Science and Technology, 39, 1291–1298.

Kneebone, P. E., O’Day, P. A., Jones, N., & Hering, J. G. (2002). Deposition and fate of arsenic in iron- and arsenic-enriched reservoir sediments. Environmental Science and Technology, 36, 381–386.

Knox, R. C., & Canter, W. (1996). Prioritization of ground water contaminants and sources. Water, Air, and Soil Pollution, 88, 205–226.

Korte, N. E., & Fernando, Q. (1991). A review of arsenic(III) in groundwater. Critical Reviews in Environmental Control, 21, 1–39.

Lin, Z., & Puls, R. W. (2003). Potential indicators for the assessment of arsenic natural attenuation in the subsurface. Advances in Environmental Research, 7, 825–834.

Manceau, A. (1995). The mechanism of anion adsorption in iron oxides: Evidence for the bonding of arsenate tetrahedra on free Fe(O,OH)6 edges. Geochimica et Cosmochimica Acta, 59, 3647–3653.

Manning, B. A., Fendorf, S. E., Benjamin, B., & Suarez, D. L. (2002). Arsenic(III) oxidation and arsenic(V) adsorption reactions on synthetic birnessite. Environmental Science and Technology, 36, 976–981.

Manning, B. A., & Goldberg, S. (1996). Modeling arsenate competitive adsorption on kaolinite, Montmorillonite and illite. Clays and Clay Minerals, 44, 609–623.

McKenzie, R. M. (1971). The synthesis of birnessite, crytomelane, and some other oxides and hydroxides of manganese. Mineralogical Magazine, 38, 493–502.

Moore, J. N., Walker, J. R., & Hayes, T. H. (1990). Reaction scheme for the oxidation of As(III) to As(V) by birnessite. Clays and Clay Minerals, 38, 549–555.

Morrison, S. J., Metzler, D. R., & Dwyer, B. P. (2002). Removal of As, Mn, Mo, Se, U, V and Zn from groundwater by zero-valent iron in a passive treatment cell: Reaction progress modeling. Journal of Contaminant Hydrology, 56, 99–116.

Nickson, R., McArthur, J., Burgess, W., Ahmed, K. M., Ravenscroft, P., & Rahman, M. (1998). Arsenic poisoning of Bangladesh groundwater. Nature, 395, 338.

Nikolaidis, N. P., Cheng, Z., & van Geen, A. (2005). Removal of arsenic from Bangladesh groundwater with zero-valent iron. American Chemical Society Symposium Series, 915, 361–371.

Oscarson, D. W., Huang, P. M., Defosse, C., & Herbillon, A. (1981). The oxidative power of Mn(VI) and Fe(III) oxides with respect to As(III) in terrestrial and aquatic environments. Nature, 291, 50–51.

Oscarson, D. W., Huang, P. M., & Liaw, W. K. (1980). The oxidation of arsenite by aquatic sediments. Journal of Environmental Quality, 9, 700–703.

Oscarson, D. W., Huang, P. M., Liaw, W. K., & Hammer, U. T. (1983). Kinetics of oxidation of arsenite by various manganese dioxides. Soil Science Society of America Journal, 47, 644–648.

Pal, T., Mukherjee, P. K., & Sengupta, S. (2002). Nature of arsenic pollutants in groundwater of Bengal basin—A case study from Baruipur area, West Bengal, India. Current Science, 82, 554–561.

Parga, J. R., Cocke, D. L., Valenzuela, J. L., Gomes, J. A., Kesmez, M., Irwin, G., et al. (2005). Arsenic removal via electrocoagulation from heavy metal contaminated groundwater in la Comarca Lagunera Mexico. Journal of Hazardous Materials, 124, 247–254.

Pedersen, H. D., Postma, D., & Jakobsen, R. (2006). Release of arsenic associated with the reduction and transformation of iron oxides. Geochimica et Cosmochimica Acta, 70, 4116–4129.

Pierce, M. L., & Moore, C. B. (1980). Adsorption of arsenite on amorphous iron hydroxide from dilute aqueous solution. Environmental Science and Technology, 14, 214–216.

Quastel, J. H., & Scholefield, P. G. (1953). Arsenite oxidation in soil. Soil Science, 75, 279–285.

Randall, S. R., Sherman, D. M., & Ragnarsdottir, K. V. (2001). Sorption of As(V) on green rust (Fe(II)4Fe(III)2(OH)12SO4·3H2O) and lepidocrocite (γ-FeOOH): Surface complexes from EXAFS spectroscopy. Geochimica et Cosmochimica Acta, 65, 1015–1023.

Raven, K. P., Jain, A., & Loeppert, R. H. (1998). Arsenite and arsenate adsorption on ferrihydrite: Kinetics, equilibrium, and adsorption envelopes. Environmental Science and Technology, 32, 344–349.

Scott, M. J., & Morgan, J. J. (1995). Reactions at oxide surfaces. 1. Oxidation of As (III) by synthetic birnessite. Environmental Science and Technology, 29, 1898–1905.

Shen, Y. S. (1973). Study of arsenic removal from drinking water. Journal of American Water Works Association, 65, 543–548.

Singh, D. B., Prasad, G., Rupainwar, D. C., & Singh, V. N. (1988). As(III) removal from aqueous solution by adsorption. Water, Air, and Soil Pollution, 42, 373–386.

Smedley, P. L., & Kinniburgh, D. G. (2002). A review of the source, behavior and distribution of arsenic in natural waters. Applied Geochemistry, 17, 517–568.

Stachowicz, M., Hiemstra, T., & van Riemsdijk, W. H. (2006). Surface speciation of As(III) and As(V) in relation to charge distribution. Journal of Colloid and Interface Science, 302, 62–75.

Su, C. (2007). Utilization of zero-valent iron for arsenic removal from groundwater and wastewater. In I. M. C. Lo, R. Surampalli, & K. C. K. Lai (Eds.), American society of civil engineers. zero-valent iron reactive materials for hazardous waste and inorganics removal (pp. 111–150). Reston, Virginia: ASCE Chapter 8.

Su, C., & Puls, R. W. (2003). In situ remediation of arsenic in simulated groundwater using zerovalent iron: Laboratory column tests on combined effects of phosphate and silicate. Environmental Science and Technology, 37, 2582–2587.

Su, C., & Puls, R. W. (2004). Significance of iron(II, III) hydroxycarbonate green rust in arsenic remediation using zerovalent iron in laboratory column tests. Environmental Science and Technology, 38, 5224–5231.

Suarez, D. L., Goldberg, S., & Su, C. (1998). Evaluation of oxyanion adsorption mechanisms on oxides using FTIR spectroscopy and electrophoretic mobility. American Chemical Society Symposium Series, 715, 136–178.

Sverjensky, D. A. (1994). Zero-point-of-charge prediction from crystal chemistry and salvation theory. Geochimica et Cosmochimica Acta, 58, 3123–3129.

Tadanier, C. J., Schreiber, M. E., & Roller, J. W. (2005). Arsenic mobilization through microbially mediated deflocculation of ferrihydrite. Environmental Science and Technology, 39, 3061–3068.

Tyrovola, K., Peroulaki, E., & Nikolaidis, N. P. (2007). Modeling of arsenic immobilization by zero valent iron. European Journal of Soil Biology, 43, 356–367.

Vlassopoulos, D., Rivera, N., O’Day, P. A., Rafferty, M. T., & Andrews, C. B. (2005). Arsenic removal by zero-valent iron: A field study of rates, mechanisms, and long-term performance. American Chemical Society Symposium Series, 915, 344–360.

Voegelin, A., & Hug, S. (2003). Catalyzed oxidation of arsenic (III) by hydrogen peroxide on the surface of ferrihydrite: An situ ATR-FTIR study. Environmental Science and Technology, 37, 972–978.

Wagman, D. D., Evans, H. H., Parker, V. B., Schumm, R. H., Harlow, I., Bailey, S. M., et al. (1982). Journal of Physical and Chemical Reference Data, Supplement II, 2, 392.

Wakao, N., Koyatsu, H., Komai, Y., Shimokawara, H., Sakurai, Y., & Shiota, H. (1988). Microbial oxidation of arsenite and occurrence of arsenite-oxidizing bacteria in acid mine water from a sulfur–pyrite mine. Geomicrobiology Journal, 6, 11–24.

Wang, S., & Mulligan, C. N. (2006). Natural attenuation processes for remediation of arsenic contaminated soils and groundwater. Journal of Hazardous Materials, B138, 459–470.

Waychunas, G. A., Rea, B. A., Fuller, C. C., & Davis, J. A. (1993). Surface chemistry of ferrihydrite: Part 1. EXAFS studies of the geometry of coprecipitated and adsorbed arsenate. Geochimica et Cosmochimica Acta, 57, 2251–2269.

Wilkie, J. A., & Hering, J. G. (1998). Rapid oxidation of geothermal arsenic(III) in streamwaters of the Eastern Sierra Nevada. Environmental Science and Technology, 32, 657–662.

Wilkin, R. T., Puls, R. W., & Sewell, G. W. (2002). Long-term Performance of Permeable Reactive Barriers Using Zero-valent Iron: An Evaluation at Two Sites, Environmental Research Brief, U.S. EPA, National Risk Management Research Laboratory, Ada, OK, EPA/600/S-02/001, March 2002.

Woolson, E. A., Axley, J. H., & Kearney, P. C. (1973). The chemistry and phytotoxicity of arsenic in soils II: Effects of time and phosphorus. Soil Science Society of America Proceedings, 37, 254–259.

Yavuz, C. T., Mayo, J. T., Yu, W. W., Prakash, A., Falkner, J. C., Yean, S., et al. (2006). Low-field magnetic separation of monodisperse Fe3O4 nanocrystals. Science, 314, 964–967.

Acknowledgments

Although the research described in this article has been funded wholly by the USEPA, it has not been subjected to the Agency’s peer and administrative review and therefore may not necessarily reflect the views of the Agency and no official endorsement may be inferred. We thank Mr. Jeff Cheetham of Phoenix Environmental Ltd. for supplying the milled magnetite sample and Mr. Stephen M. Klein of Connelly-GPM, Inc. for the six magnetite samples. We appreciate the analytical assistance of Mr. Steve Markham and Dr. Ning Xu of Shaw Environmental Inc., and the constructive comments and suggestions of the anonymous reviewers. The XPS analyses were performed by Drs. Edward L. Principe and Angela Y. Craig of Charles Evans & Associates.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Su, C., Puls, R.W. Arsenate and Arsenite Sorption on Magnetite: Relations to Groundwater Arsenic Treatment Using Zerovalent Iron and Natural Attenuation. Water Air Soil Pollut 193, 65–78 (2008). https://doi.org/10.1007/s11270-008-9668-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11270-008-9668-1