Abstract

Clinoptilolite is investigated as a possible regenerable sorbent for acid rock drainage based on its adsorption capacity for Zn, adsorption kinetics, effect of pH, and regeneration performance. Adsorption of Zn ions depends on the initial concentration and pH. Adsorption/Desorption of Zn reached 75% of capacity after 1–2 h. Desorption depended on pH, with an optimum range of 2.5 to 4.0. The rank of desorption effectiveness was EDTA > NaCl > NaNO3 > NaOAc > NaHCO3 > Na2CO3 > NaOH > Ca(OH)2. For cyclic absorption/desorption, adsorption remained satisfactory for six to nine regenerations with EDTA and NaCl, respectively. The crystallinity and morphology of clinoptilolite remained intact following 10 regeneration cycles. Clinoptilolite appears to be promising for ARD leachate treatment, with significant potential advantages relative to current treatment systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Acid rock drainage (ARD) is one of the most serious environmental problems faced by the mining industry worldwide. The environmental damage is devastating (D. Banks, Younger, Arneson, Iversen, & S. Banks, 1997; García, Morena, Ballester, Blázquez, & González, 2001) and adversely affecting highways (Li, 2005). ARD encompasses heavy metals and inorganic compounds at concentrations well above allowable limits in water quality guidelines for the protection of aquatic life. The low pH and high metal concentrations threaten fragile aquatic life forms. Dissolved metals like copper, zinc and cadmium can be toxic to flora and fauna.

Several remediation techniques have been developed to reduce effluent acidity and sulfur, and to immobilize heavy metal ions. These include alkalinity addition (Bellaloui, Chtaini, Ballivy, & Narasiah, 1999; Bernier, 2005; Duchesne & Doye, 2005; Kongolo, Benzaazoua, de Donato, Drouet, & Barrès, 2004; Xenidis, Mylona, & Paspaliaris, 2000), bioremediation (García et al., 2001; Lindow & Borden, 2005), passivation (Belzile, Maki, Chen, & Goldsack, 1997) which involves coating the individual particles with an oxidation preventive substance such as acetylacetone, sodium silicate, lignin, and oxalic acid, passive systems and effluent treatment (Burgess & Stuetz, 2002). However, no remediation scheme has been cost-effective for all mine locations. Most remediation techniques generate additional solid waste for disposal.

Zeolites have been intensively studied in recent decades for catalysis, ion exchange, adsorption, molecular sieves, dehydration and rehydration. Applications include petroleum refining, pollution control, energy conservation, agriculture, aquaculture, mining, and metallurgy (Mumpton, 1981). A locally available and inexpensive soil—mineral zeolite-clinoptilolite—has high metal-adsorption capacity and significant buffering capacity (Lai, 2005; Li, 2002, 2005; Li, Chen, & Grace, 2005). It could have potential as a sorbent for ARD, especially if the clinoptilolite could be regenerated on site.

Thirty-nine naturally occurring zeolites have been studied (Bernal & Lopez Real, 1993), with clinoptilolite being one of the most abundant. Its relatively low cost, cation exchange capacity, and selectivity of cations have led to its use in waste water treatment (Baykal, 1998; Komarowski & Yu, 1997; Lahav & Green, 1998; Nguyen & Tanner, 1998; Veigh & Weatherley, 1999), agriculture and aquaculture (Kithome, Paul, Lavkulich, & Bomke, 1999a; Kithome, Paul, Lavkulich, & Bomke, 1999b; Milan et al., 1997); radioactivity treatment (Faghihian, Ghannadi Maraeh, & Kazemian, 1999); and adsorption of heavy metal ions Pb2+, Zn2+, Cd2+, Ni2+, Fe2+ and Mn2+ (Malliou, Loizidou, & Spyrellis, 1994; Ouki & Kavannagh, 1997; Yuan, Seyama, Soma, Theng, & Tanaka, 1999). Clinoptilolite has been found (Lai, 2005; Li, 2002, 2005; Li et al., 2005) to have high adsorption capacity for Cu, Zn and Al from artificial solutions and natural ARD (pH 3.3). It is chemically stable in acidic environments with pH > 2.0. Clinoptilolite has the highest Si/Al molar ratio (4.3–5.3) among its group of zeolites (Beck, 1996) and is less easily destroyed by losing Al at low pH than other zeolites (Boles et al., 1977).

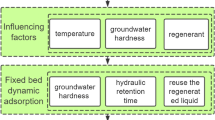

Previous studies have emphasized the removal of heavy metals using zeolite. Little research (Erwe, Mavrov, & Chmiel, 2003) has been conducted to investigate regeneration techniques for the contaminated zeolite by which the adsorbed contaminants can be removed at high concentrations and the sorbent restored to a state where it can be reused. Greater understanding of desorption of heavy metals is needed to assess possible regeneration. The goal of this project was to explore clinoptilolite as a potential ARD sorbent. The objectives were to (1) determine the adsorptivity of clinoptilolite for Zn and the effect of pH; (2) examine adsorption and desorption kinetics of heavy metals; (3) explore possible extraction chemicals for removing heavy metals from loaded clinoptilolite; and (4) assess regeneration of contaminated clinoptilolite in multiple adsorption/desorption cycles. The results provide information for the design of a more sustainable cost-effective system for on-site ARD treatment.

Materials and Methods

The clinoptilolite was provided by Canmark International Resources from Sunday Creek, near Princeton, B.C. Physical and chemical characteristics are shown in Table I. Acid rock drainage from the Britannia Mines near Squamish, British Columbia was used to study adsorption and desorption of clinoptilolite. Acid rock drainage from Highway 97C, (Coquihalla Merritt-to-Peachland connector), B.C. (designated as HW97C ARD) was employed for detailed adsorption, desorption, and regeneration experiments.

The batch equilibrium test technique (US EPA, 1987) was used to investigate Zn2+ and Cu2+ adsorption characteristics. The solution/solid ratio was 10:1 (by weight) as recommended in the standard EPA procedures and shaken for 24 h to achieve chemical equilibrium.

The adsorption kinetics of clinoptilolite were determined via the same procedures as for the batch equilibrium test, with nine different durations from 10 to 1,440 min, for HW97C ARD to which 100 ppm Zn had been added. The desorption kinetic tests followed the same procedure as the adsorption kinetic tests. The samples were spiked with 690 mg Zn/kg clinoptilolite and were submitted for desorption with 20 g/l NaCl extractant solution.

Sodium chloride (NaCl), carbonate (NaCO3), bicarbonate (NaHCO3), hydroxide (NaOH), acetate (NaOAc) and disodium ethylenediaminetetraacetic acid (EDTA) were tested as possible extractants from clinoptilolite samples spiked with Zn2+ and Cu2+ (extractant test program using Britannia Mine ARD is summarized in Table II). Each Zn ion-spiked sample was washed with an extractant solution for 1 h, with shaking, to reach equilibration. The most effective extractant solutions were selected and then optimized for their pH, concentration, buffer and H+ (see Tables III, IV, and V).

EDTA at a concentration of 4 g/l at pH 3 and 30 g/l NaCl at pH 3 were selected as extractant solutions for regeneration of clinoptilolite spiked with 280 mg Zn concentration/kg clinoptilolite, in cyclic sorption/regeneration studies. One-hour contact was chosen for each cycle, based on the adsorption and desorption tests. All tests were performed in duplicate at 25 ± 2 °C. The pH of each equilibrated solution was measured by an Orion model 420-A pH meter. The Zn concentration in the supernatant was determined by a Video 22 Thermo Jarrell Ash aa/ae Spectrophotometer-Model 957.

The concentrations of adsorbed or desorbed metal were obtained from the differences between their initial and final concentrations in the supernatant. The amount of each metal desorbed from the clinoptilolite (in mg/kg soil) was calculated from:

where C was the final solution concentration (mg/l), V the solution volume (l), and M the sorbent mass (kg).

Acid digestion was conducted according to the procedures described by Li (1999) on samples after the 10th desorption period. This allowed the heavy metals still attached to the contaminated clinoptilolite after desorption to be determined to eliminate discrepancies from the desorption residuals. Mass balances on the metals in the supernatant and contaminated clinoptilolite were calculated to check the accuracy of the determinations.

Clinoptilolite was prepared at random orientations for X-ray difftraction (XRD) scanning. The powder was mounted on the square concavity of a glass slide and set up on the XRD stage. The scanning was at a controlled room temperature of 22°C using a Rigaku RINT 2000 X-ray diffractometer with CuKα radiation, at 40 kV and 30 mA based on the 2°θ/θ method with a scan speed of 1°/min. For Scanning Electron Microscopy (SEM), dry thin dispersed clinoptilolite powder was pressed onto a carbon-typed 10-mm Φ aluminium stub. This sample was then carbon-coated with 2-nm thickness using TB500-Carbon Flash Evaporation system EMSCOPE with string × 1 filament type at a 3-A outgas current. The image was observed by SEM (JEOL JSM-5200LV) with an energy dispersive sample on an X-ray spectrometer (Philips-ECX PV 9800STD). For Transmission Electron Microscopy (TEM), clinoptilolite was dispersed in a droplet of distilled waster, and then a copper microgrid was carefully placed on top of the droplet. After 1 min the TEM grid was removed for drying. TEM images of clinoptilolite were taken by a JEOL JEM-2000Ex Electron Microscope at a 200 kV accelerated voltage.

Results and Discussion

Adsorption capacity, adsorption/desorption kinetics

Previous work (Lai, 2005; Li, 2002, 2005) indicated that clinoptilolite has a high metal adsorption capacity at different pHs, when the acidity was augmented by HNO3 with Britannia Mine ARD as the background solution. Zn is of major concern along HW97C. Its adsorption isotherm, Figure 1 (in which C denotes clinoptilolite), further demonstrates that clinoptilolite has the ability to retain Zn ions and that the amount adsorbed is a function of the initial Zn concentration, in agreement with previous findings (Curkovic, Cerian-Stefanovic, & Filipan, 1997; Langella, Pansini, Loizidou, & Grigoropoulou, 2001).

The kinetics of clinoptilolite adsorption are important with respect to whether this material could be suitable as a reactive bed or barrier material. Kinetic tests were carried out with a solution containing both Cu and Zn in natural ARD (pH 3.9) from Britannia Mine. Figure 2 shows the Cu and Zn adsorption as functions of time in a stirred-batch system where the initial Cu and Zn concentrations were 131 and 137 mg/l, respectively. The results indicate that adsorption was almost complete within 120 min, in agreement with a previous study (Lai, 2005) which reported that sorption of heavy metals by natural zeolite was essentially complete after shaking for 1–2 h. In view of these findings, all subsequent adsorption periods were 1 h.

The affinity of clinoptilolite for heavy metals is based on physical adsorption (Curkovic et al., 1997). Adsorption has been found to occur by ion exchange and to be reversible. Figure 3 presents desorption kinetic results for extraction by a 20-g/l NaCl solution at pH 3.0. The samples were spiked with 250 mg Zn/kg C, with Highway 97C ARD as the background matrix. No copper was added, since Cu is not of concern for this ARD.

The results in Figure 3 follow a similar trend as those in Figure 2. Within 24 h, the Zn desorption increased by 34 mg/kg clinoptilolite. Most removal was complete within 80 min, again consistent with the adsorption process. This similarity suggests that the adsorption/desorption processes are nearly reversible, i.e.,

where M2+ designates the heavy metal ion, and subscripts s and c denote the “solution” and “clinoptilolite” phases. The exchanging groups responsible for the desorptive capacity of zeolite are known to be dispersed randomly in aqueous solution throughout the pores and capillaries of the zeolite (Kithome, Paul, Lavkulich, & Bomke, 1998). Given the importance of being able to cycle rapidly between adsorption and desorption, the desorption time was limited to 1 h in subsequent experiments.

pH effect on adsorption

Three initial Zn2+ concentrations—93, 735, 1,290 ppm—were tested to investigate the effect of pH between 1.0 and 5.0 on adsorption. The results in Figure 2 and the adsorption isotherm in Figure 4 confirm that the adsorption is affected by the original Zn concentration, possibly because most sorption is due to physical sorption at low pH, with H+ ions competing with Zn2+ ions for adsorption sites. The efficiency of adsorption of Zn was higher for pH ≥ 3, possibly due to fewer H+ ions being available at high pH, providing less competition with Zn2+ for the limited number of adsorption sites on the clinoptilolite surface.

Efficiency of various extractant solutions

Desorption efficiencies for Cu and Zn from contaminated clinoptilolite using extractant solutions containing NaCl, NaOH, Ca(OH)2, Na2CO3, and Na2HCO3 at alkaline pHs are compared in Figure 5. These samples were contaminated with Britannia mine ARD, with extra Cu and Zn added to bring each of their concentrations to 1,000 ppm (Table II shows the actual concentrations). The Cu and Zn retained in clinoptilolite were 2,350 and 1,600 mg/kg, confirming the finding of Lai (2005) that the selectivity for Cu2+ > that of Zn2+. The results at alkaline pH indicate that all extractants removed less than 25% of the metals. NaCl had the highest removal of Cu and Zn from metal-loaded clinoptilolite (6% removal for Cu and 22% for Zn) of the various extractants, followed by NaHCO3. There was insignificant Zn and Cu removal using the Na2CO3, NaOH and Ca(OH)2 extractant solutions.

Figure 6 compares the effectiveness of removing adsorbed Cu and Zn from clinoptilolite by NaCl, NaCO3 and EDTA extractant solutions at various pHs and concentrations. The tested samples were contaminated with Britannia mine ARD, where the Cu and Zn were artificially increased to a design concentration of 100 ppm each (see Table II). These more realistic concentrations were used in all subsequent tests. Figure 6 shows that EDTA removed 60% of the copper and 29% of the zinc from the contaminated clinoptilolite. There was some influence of the EDTA concentration (2.5 vs. 5.0 g/l) on the removal. Whereas the NaCl solution desorbed more Cu and Zn from the contaminated clinoptilolite at pH 6.1 than at pH 8.1, varying the NaCl concentration (10 vs. 20 g/l) had little effect. At high Na concentration and low pH, there were more Na+ and H+ ions in the solution. This promoted ion exchange for the Zn and Cu from the clinoptilolite. NaNO3 had a slightly lower removal efficiency than NaCl, but it had the same trend with respect to pH and concentration. The results show that the concentration, extractant chemical and pH all affected the removal efficiency from metal-loaded clinoptilolite. EDTA was the most effective extractant among the extractants tested.

Optimization of extraction solutions—EDTA and NaCl

Preliminary experiments conducted to find the most suitable extraction chemicals and optimum conditions using Britannia Mine ARD indicate that the order of desorption effectiveness is: EDTA > NaCl > NaNO3 > NaOAc > NaHCO3 > Na2CO3 > NaOH > Ca(OH)2. These preliminary tests also showed that the concentrations and pHs of the extractants can play major roles. Desorption of Zn and Cu from clinoptilolite was found to depend on pH, with an optimum range of 2.5 to 4.0.

EDTA Extraction Solution

As noted above, EDTA was the most effective extractant for blackflushing metal-loaded clinoptilolite. The reaction of metal with EDTA can be expressed as:

where M2+ designates the heavy metal ion, and H2Y2− represents EDTA. The fully deprotonated form of EDTA binds to the metal ion. The equilibrium constants for metals are very large (1018.8 for Cu2+ and 1016.5 for Zn2+) (http://tardiscsudhedu/fromero/chemistry/complex). Hence the reactions shift to the right. This process is pH-dependent (http://tardiscsudhedu/fromero/chemistry/complex). The optimization for EDTA extraction solution (including concentration, pH, buffering and H+ ion effects) is summarized in Figure 7a–d.

Optimization of EDTA for Zn removal from loaded clinoptilolite: (a) EDTA concentration effects at pH 4, (b) effect of concentration 4 g/l, with pH adjusted by HOAc, (c) effect of concentration of buffer (NaOAc–HOAc) with an EDTA concentration of 4 g/l at pH 3, (d) H+ ion effects at a EDTA concentration of 4 g/l, with pH adjusted by HNO3.

EDTA concentrations of 1, 2, 4, 6, and 8 g/l at pH 4.0 were tested for their influence on the desorption efficiency. Figure 7a shows that 121 mg of Zn/kg clinoptilolite and 131 mg of Zn/kg clinoptilolite were desorbed by EDTA at concentrations of 4 and 8 g/l, respectively. As EDTA tends to complex metal ions in 1:1 metal-to-EDTA complexes, higher extraction solution concentrations do not significantly increase Zn desorption. Hence, the EDTA concentration was chosen as 4 g/l.

The effect of pH on Zn desorption from clinoptilolite with EDTA in the extraction solution was investigated at pH adjusted by HOAc to 2.0, 3.0, 4.0 and 4.7. A maximum desorption of 142 mg of Zn/kg clinoptilolite was obtained for pH 3 (Figure 7b). EDTA contributed to the greater selectivity for heavy metal cations. At high pH, metal ions tend to precipitate, preventing formation of a complex, lowering the rate of desorption and reducing the ability to be exchanged. At much lower pH, the EDTA-Metal complexes tended to dissolve, increasing the concentration of cations, causing the desorption to be reversible. In the desorption process, any increases of hydrogen ions might cause the metal complex to dissociate (http://tardiscsudhedu/fromero/chemistry/complex). Therefore, a buffer was employed to maintain constant pH and prevent the formation of metal hydroxides. Furthermore, the formation of hydrogen ions as a reaction product would cause the solution pH to decrease and the desired reaction to cease or even reverse, unless the solution is buffered. NaOAc–HOAc buffer solutions at different concentrations were examined to find the effects of the buffer on Zn removal from contaminated clinoptilolite in a 4 g/l aqueous EDTA extraction solution at pH 3. Figure 7c indicates that the Zn removal efficiency decreased with increasing buffer solution concentration, in agreement with our preliminary experimental results. The greatest Zn removal was 150 mg/kg of clinoptilolite at a buffer concentration of 0.1 M. A higher concentration did not produce greater removal, contrary to a previous finding (R. S. Li & L. Y. Li, 2000).

The effect of H+ on heavy metal desorption in an EDTA extraction solution was investigated by employing HNO3 at pHs of 2, 3 and 4 with an EDTA concentration of 4 g/l. Figure 7d portrays a decrease of desorption with increasing pH. Compared to Figure 7b in which HOAc was used to adjust pH, the desorption of Zn from clinoptilolite was similar (149 vs. 142 mg/kg clinoptilolite, Figure 7b and d). The performance was also nearly the same as for the buffered EDTA extraction solution at low NaOAc concentration. This finding might be due to: (1) The high concentration of H+ may cause the soil edge to break down, liberating aluminum, which has a much higher replacing power because of its high valence and low ionic radius (Yong, Mohamed, & Warkentin, 1992); Al3+ ions would then replace absorbed copper and zinc ions. (2) Free H+ ions can dissolve metal–organic compounds, complex and hydrous oxides, releasing Cu2+ and Zn2+ ions (R. S. Li & L. Y. Li, 2000). This result is consistent with the preliminary tests. Therefore, HNO3 was chosen to adjust the pH to a desired value of 3, simplifying the procedure.

Cyclic desorption/adsorption of Zn with EDTA

Results of a cyclic desorption/adsorption test with an EDTA concentration of 4 g/L at pH 3.0 appear in Figure 8, with desorption and adsorption times both 1 h. There were 11 adsorption and ten desorption periods. After the first regeneration, desorption and adsorption increased significantly, with a removal of 202 mg Zn/kg clinoptilolite and an adsorbed mass ratio of 569 mg Zn/kg clinoptilolite in the second cycle. After the second cycle, the desorption and adsorption decreased slowly, but perceptibly, with each successive cycle. By the seventh cycle, the adsorption was only 158 mg Zn/kg clinoptilolite, indicating that the sorptive capacity was nearing exhaustion. Figure 8 indicates that desorption of Zn exceeded adsorption after three cycles. It also shows negative adsorption after seven cycles, probably due to a change in surface charge or structure of the clinoptilolite.

NaCl Extraction Solutions

Test results for NaCl extraction solutions are summarized in Figure 9 for pH 3 with different concentrations of NaCl. Figure 9a shows that the Zn desorption changed little after the NaCl concentration exceeded 20 g/l, so 30 g/l was chosen as the NaCl concentration. The influence of pH on the desorption in NaCl extraction solution was investigated with initial pHs of 2, 3, 4, 5 and 5.7, varied by adjusting the concentration of HCl. The highest desorption mass ratio of 105 mg Zn desorbed/kg clinoptilolite corresponds to a pH of 2. Figure 9b shows that the desorption improved at low pH. The mechanism of desorption is ion exchange. Heavy metal ions are more soluble at lower pH, thus promoting ion exchange and increasing desorption. At pH <2.5, clinoptilolite tends to leach ions from its structure (Lai, 2005; Li, 2005). It is impractical to apply such low pHs in in-situ environmental treatment.

The effects of H+ ion on the desorption process were investigated at various pHs using HCl to adjust the acidity to the designated pHs. Figure 9c indicates that desorption decreases with increasing pH. Desorption of 83 mg of Zn/kg C was observed at pH 2, somewhat less than the 105 mg of Zn/kg in Figure 9c at the same pH with NaCl. In the desorption process, the main exchange ion is Na+. Hence, sodium ions assist the desorption.

Cyclic desorption/adsorption of Zn with NaCl

Results of a cyclic desorption/adsorption test with a NaCl concentration of 30 g/l at pH 3.0 are shown in Figure 10. There were eleven adsorption and ten desorption periods, the same as for the EDTA cyclic desorption/adsorption trials. After the first regeneration, desorption and adsorption increased significantly, with 278 mg Zn removed per kg clinoptilolite and an adsorbed mass ratio of 405 mg Zn/kg clinoptilolite in the second cycle. Beyond the second cycle, the desorption remained relatively constant within the range 250 to 300 mg Zn/kg clinoptilolite. Adsorption decreased slowly, but perceptibly, with each successive cycle. By the eleventh cycle, adsorption was only 140 mg Zn/kg clinoptilolite, indicating that the sorptive capacity of the clinoptilolite was nearing exhaustion. Figure 10 indicates that desorption exceeded adsorption after seven cycles, but it did not show a negative adsorption like EDTA. The fact that the desorption exceeded the adsorption after the seventh cycle probably reflects a change in clinoptilolite surface charge or structure. The effective lifetime of the sorbent appears to be ∼10 cycles for the conditions investigated. Further study is needed to examine the lifetime of the zeolite over broader ranges of conditions.

Table VI summarizes the NaCl and EDTA extraction results in terms of regeneration cycles, cost and environmental impact. Figures 8 and 10 show that the NaCl performed better than the EDTA solution after the second cycle. NaCl surpassed EDTA in the regeneration of zeolite and is less costly. Clinoptilolite pretreatment using 1 M NaCl solution is recommended. For natural clinoptilolite, the adsorption sites are various ions such as Mn, K and Mg. The NaCl treatment homogenizes the adsorption site, as seen in the regeneration test where the second adsorption of Zn ions improved greatly after initial desorption by NaCl.

Mass Balance in Cyclic Adsorption/Desorption Systems

A mass balance after each desorption cycle gives

where m d is the heavy metal desorbed, m r the heavy metal retained on the soil, and m a the heavy metal adsorbed (all in mg/kg clinoptilolite). The amounts adsorbed and desorbed were determined in batch adsorption/desorption tests; m r was measured by total digestion.

The mass balance after 10 cycles using EDTA for clinoptilolite regeneration should give \({\left( {{\sum {m_{a} - } }{\sum {m_{d} } }} \right)} = m_{r}\), i.e., the amount retained should equal the summation of the amounts absorbed over these cycles minus the summation of amounts desorbed over the same cycles. The ∑m d value is 1,275 mg/kg clinoptilolite, whereas m r from acid digestion of the samples after desorption in the tenth cycle is 414 mg/kg clinoptilolite, and ∑m a is 1,672 mg/kg clinoptilolite. The difference is only 17 mg/kg clinoptilolite for the EDTA system at pH 3.0. The overall discrepancy (∼1%) is small enough that the results are consistent with respect to the overall mass balance. The discrepancy is larger (6.5%), but still acceptable, for the aqueous NaCl solution extraction (Table VII).

Morphology changes

Clinoptilolite samples were examined before and after cyclic adsorption/desorption tests by XRD, SEM and TEM. The samples were: (1) nontreated clinoptilolite, (2) first cycle contaminated clinoptilolite, (3) after 10.5 cycles, regeneration using EDTA, and (4) after 10.5 cycles, regeneration using NaCl.

XRD patterns for nontreated clinoptilolite, initial contamination, and after 10.5 cycles, regeneration using both EDTA and NaCl, appear in Figure 11. These indicate that the framework of clinoptilolite was not altered by cyclic adsorption/desorption. However, the peak intensity of clinoptilolite after treatment seems to have decreased slightly, possibly due to leaching of Al3+. The cyclic adsorption/desorption results (Figures 8 and 10) indicate that the adsorption capacity was reduced drastically by the 7th cycle of EDTA regeneration and by the 11th cycle for NaCl regeneration. However, the XRD results show that the decreased capacity was not due to any change of integrity of the clinoptilolite. Instead it may have been due to changes in surface properties. Further research is needed to explain the decrease in sorption/regeneration ability.

For SEM results, see Figures 13 to 16 (Refer to Appendix). TEM images of fresh clinoptilolite, after the 1st adsorption, and after cyclic regeneration by EDTA and NaCl solutions appear in Figure 12. Fresh clinoptilolite has a flaky appearance with sharp edges with fine materials attached, likely amorphous (Figure 12a). Aggregation of particles can be observed for the 1st contamination clinoptilolite samples (Figure 12b); no clear shape of the particles can be identified due to the high density and thickness of the aggregates. Mixed morphology is observed with EDTA-treated samples (Figure 12c). Aggregates are seen, some retaining their original appearance. There are also smaller particles. Regenerated particles have smoother edges than untreated ones. Figure 9d shows that there are no thinner particles of the kind observed after clinoptilolite was treated with NaCl. Generally, clinoptilolite particles have a high electrical density, i.e., they are thicker than originally, larger in size and mostly rounded.

In our tests, net absorption of Zn became negative after seven cycles for EDTA regeneration, whereas it remained positive, but was drastically reduced, after 10 cycles for NaCl regeneration. This may indicate that zinc is being displaced by more tightly held species. The sorption/regeneration treatment appears to change the surface properties of the clinoptilolite as demonstrated by the SEM and TEM images. EDX (X-ray Electron Dispersion) with SEM and electron diffraction pattern with TEM may help in the future to determine the Al/Si ratio for different treatment conditions to determine the extent to which the clinoptilolite has been altered. Further tests are needed to determine whether the clinoptilolite can be completely regenerated at this stage. XRD and TEM could be useful to examine the crystallinity and morphology after treatment.

Conclusions and Recommendations

-

Clinoptilolite was able to remove metal cations from Britannia Mine and Highway 97C ARD. Batch equilibrium adsorption tests showed that the ability to adsorb metal ions was related to the metal concentrations and the pH of the extracting solution.

-

Desorption of Zn and Cu from clinoptilolite was found to depend on pH, with an optimum pH range of 2.5 to 4.0.

-

The rank of desorption effectiveness was EDTA > NaCl > NaNO3 > NaOAc > NaHCO3 > Na2CO3 > NaOH > Ca(OH)2.

-

In cyclic absorption/desorption tests, the adsorption by clinoptilolite fell slowly, but remained viable for six regenerations with EDTA present, whereas adsorption by clinoptilolite fell slowly, but remained viable for 10 regenerations using NaCl.

-

Clinoptilolite samples at different stages of cyclic sorption/regeneration observed by XRD have similar XRD patterns, implying that the framework of clinoptilolite is not altered by cyclic adsorption/desorption.

-

Clinoptilolite samples at different stage of cyclic sorption/regeneration observed by SEM and TEM indicate that after treatment the clinoptilolite forms dense aggregates. As well, sharp corners and amorphous-like materials disappeared.

-

Clinoptilolite appears to be a promising agent for ARD leachate treatment.

-

Clinoptilolite pretreatment using a 1 M NaCl solution is recommended. For natural clinoptilolite, the adsorption sites are various ions such as Mn, K and Mg. The NaCl treatment homogenizes the adsorption sites, as seen in the regeneration test where the 2nd adsorption of Zn ions improved greatly after the initial desorption by NaCl.

-

In the present tests, the net absorption of Zn became negative after seven cycles for EDTA regeneration, whereas the net absorption of Zn remained positive, but was drastically reduced after 10 cycles for a NaCl solution. Further tests are needed to determine whether it is possible to completely regenerate the clinoptilolite at this stage.

References

Banks, D., Younger, P., Arneson, R., Iversen, E., & Banks, S. (1997). Mine–water chemistry: The good, the bad and the ugly. Environmental Geology, 32(3), 157–174.

Baykal, B. B. (1998). Clinoptilolite and multipurpose filters for upgrading effluent ammonia quality under peak loads. Water Science and Technology, 37(9), 235–242.

Beck, W. J. (1996). Acid rock drainage and zeolite potential. Vancouver: Canmark.

Bellaloui, A., Chtaini, A., Ballivy, G., & Narasiah, S. (1999). Laboratory investigation of the control of acid mine drainage using alkaline paper mill waste. Water, Air and Soil Pollution, 111, 57–63.

Belzile, N., Maki, S., Chen, Y., & Goldsack, D. (1997). Inhibition of pyrite oxidation by surface treatment. The Science of the Total Environment, 196, 177–186.

Bernal, M. P., & Lopez Real, J. M. (1993). Natural zeolites and sepiolite as ammonium and ammonia adsorbent materials. Bioresource Technology, 43(1), 27–33.

Bernier, L. (2005). The potential use of serpentinite in the passive treatment of acid mine drainage: Batch experiments. Environmental Geology, 47, 670–684.

Boles, J. R., Flanigen, E. M., Gude, A. J., Hay, R. L., Mumpton, F. A., & Suram, R. C. (1977). Mineralogy and geology of natural zeolite-short course notes (Vol. 4). Washington, DC: Mineralogical Society of America.

Burgess, J., & Stuetz, R. (2002). Activated sludge for the treatment of sulphur-rich wastewaters. Minerals Engineering, 15, 839–846.

Curkovic, L., Cerian-Stefanovic, S., & Filipan, T. (1997). Metal ion exchange by natural and modified zeolites.0 Water Research, 31(6), 1379–1382.

Duchesne, J., & Doye, I. (2005). Effectiveness of covers and liners made of red mud bauxite and/or cement kiln dust for limiting acid mine drainage. Journal of Environmental Engineering, 131(8), 1230–1235.

Erwe, T., Mavrov, V., & Chmiel, H. (2003). Characterization of a synthetic zeolite—P as a heavy metal bonding agent. Chemical Papers, 57(1), 45–49.

Faghihian, H., Ghannadi Maraeh, M., & Kazemian, H. (1999). The use of clinoptilolite and its sodium form for removal of radioactive cesium, and strotium from nuclear wastewater and Pb2+, Ni2+, Cd2+, Ba2+ from municipal wastewater. Applied Radiation and Isotopes, 50, 655–660.

García, C., Morena, D., Ballester, A., Blázquez, M., & González, F. (2001). Bioremediation of an industrial acid mine water by metal-tolerant sulphate-reducing bacteria. Minerals Engineering, 14(9), 997–1008.

Kithome, M., Paul, J. W., Lavkulich, L. M., & Bomke, A. A. (1998). Kinetics of ammonium adsorption and desorption by the natural zeolite clinoptilolite. Soil Science Society of America Journal, 62, 622–629.

Kithome, M., Paul, J. W., Lavkulich, L. M., & Bomke, A. A. (1999a). Thermodynamics of ammonium exchange by clinoptilolite. Communications in Soil Science and Plant Analysis, 30, 895–907.

Kithome, M., Paul, J. W., Lavkulich, L. M., & Bomke, A. A. (1999b). Effect of pH on ammonium adsorption by natural zeolite clinoptilolite. Communications in Soil Science and Plant Analysis, 30, 1417–1430.

Komarowski, S., & Yu, Q. (1997). Ammonium ion removal from wastewater using Australian natural zeolite: Batch equilibrium and kinetic studies. Environmental Technology, 18, 1085–1097.

Kongolo, M., Benzaazoua, M., de Donato, P., Drouet, B., & Barrès, O. (2004). The comparison between amine thioacetate and amyl xanthate collector performances for pyrite flotation and its application to tailings desulphurization. Minerals Engineering, 17, 505–515.

Lahav, O., & Green, M. (1998). Ammonium removal using ion exchange and biological regeneration. Water Research, 32(7), 2019–2028.

Lai, W. R. (2005). The use of clinoptilolite as permeable reactive barrier substrate for acid rock drainage. PhD thesis, Department of Civil Engineering, The University of British Columbia, Vancouver, British Columbia, Canada.

Langella, A., Pansini, C. D., Loizidou, M. D., & Grigoropoulou, H. P. (2001). Effects of pore clogging on kinetics of lead uptake by clinoptilolite. Journal of Colloid and Interface Science, 215, 54–57.

Li, F. (1999). Heavy metal sorption and hydraulic conductivity studies using three types of bentonite admixes. MASc thesis, Department of Civil Engineering, The University of British Columbia, Vancouver, British Columbia, Canada.

Li, L. Y. (2002). Geoenvironmental study—treatment of acid mine drainage using zeolite clinoptilolite. Emirates Journal for Engineering Research, 7(1), 39–43.

Li, L. Y. (2005). Laboratory study of ARD remediation using clinoptilolite and removal of metals from loaded clinoptilolite by backflushing. PROJECT no. 5572307 (200 p.). Research Report to the Ministry of Transportation and Highways, Engineering Branch, Victoria, British Columbia, Canada.

Li, L. Y., Chen, M., & Grace, J. R. (2005). Sustainable remediation of acid rock drainage along highways (10 p.). Proceedings of the 33rd CSCE Annual Conference, Toronto, EV-183.

Li, R. S., & Li, L. Y. (2000). Enhancement of electrokinetic extraction from lead-spiked soils. Journal of Environmental Engineering, 126(9), 849–857.

Lindow, N., & Borden, R. (2005). Anaerobic bioremediation of acid mine drainage using emulsified soybean oil. Mine Water and the Environment, 4, 199–208.

Malliou, E., Loizidou, M., & Spyrellis, N. (1994). Uptake of lead and cadmium by clinoptilolite. Science of the Total Environment, 149, 139–144.

Milan, Z., Sanchez, E., Weiland, P., de Las Pozas, C., Borja, R., Mayari, R., et al. (1997). Ammonia removal from anaerobic treated piggery manure by ion exchange in columns packed with homoionic zeolite. Chemical Engineering Journal, 66, 65–71.

Mumpton, F. A. (1981). Utilization of zeolites in agriculture soils. Paper no. 10. Background papers for innovative biological technologies for lesser-developed countries (pp. 425–481). Washington, DC: US Government Printing Office.

Nguyen, M. L., & Tanner, C. C. (1998). Ammonium removal from wastewaters using natural New Zealand zeolites. New Zealand Journal of Agricultural Research, 41, 427–446.

Ouki, S. K., & Kavannagh, M. (1997). Performance of natural zeolite for the treatment of mixed metal-contaminated effluents. Waste Management & Research, 15, 383–394.

US EPA (1987). Batch-type procedures of in-situ remediation technologies: Permeable reactive barriers. Washington, DC: US Environmental Protection Agency.

Veigh, R. J., & Weatherley, L. R. (1999). The effect of other cations in wastewaters on the ion exchange removal of ammonium ion. Developments in Chemical Engineering and Mineral Processing, 7, 69–84.

Xenidis, A., Mylona, E., & Paspaliaris, I. (2000). Potential use of lignite fly ash for control of acid generation from sulphuric wastes. Waste Management, 22, 631–641.

Yong, R. N., Mohamed, A. M. O., & Warkentin, B. P. (1992). Principles of contaminant transport in soils. Amsterdam: Elsevier.

Yuan, G., Seyama, H., Soma, M., Theng, B. K. G., & Tanaka, A. (1999). Adsorption of Some Heavy Metals by Natural Zeolites: XPS and Batch Studies. Journal of Environmental Science and Health. Part A, Environmental Science and Engineering, 34, 625–648.

Acknowledgments

Thanks to the B.C. Ministry of Transport and Highways for financial support, R. G. Buchanan for technical input, Susan Harper and Paul Parkinson for experimental assistance and Jenny Ng for secretarial help.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Supporting Information

SEM Results:

Under SEM (Figures 13, 14, 15 and 16), the non-treated (fresh) clinoptilolite looks flaky and granular (Figure 13). After the initial adsorption and EDTA cyclic regeneration, the sorbent appears to be more flaky than the fresh clinoptilolite (Figures 14 and 15). However, the clinoptilolite is more crystallized after the NaCl cyclic regeneration (Figure 16).

Rights and permissions

About this article

Cite this article

Li, L.Y., Chen, M., Grace, J.R. et al. Remediation of Acid Rock Drainage by Regenerable Natural Clinoptilolite. Water Air Soil Pollut 180, 11–27 (2007). https://doi.org/10.1007/s11270-006-9246-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11270-006-9246-3