Abstract

Methods for controlling leakage from water distribution systems vary with respect to cost and personnel requirements. The benefits of leakage reduction should be compared to the cost of alternative management options to determine which is the most cost effective. This study presents a new method for evaluating leakage from water distribution systems via combined cost benefit analysis (CBA) and uncertainty analysis. The case study considers four alternatives for leakage control. The results show that the inclusion of uncertainty analysis represents an improvement over traditional CBA where there is a high degree of uncertainty in the input data. Moreover, a clearer understanding of the available alternatives is obtained in situations where multiple alternatives show similar performances and there is no clear best choice. It was determined that in the case study distribution system, it is significantly more cost-effective to reduce leakage volumes by reactively repair broken pipes than to proactively replace them, despite large leakage losses.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Water loss or leakage from pipes inevitably occurs in water distribution systems (WDSs). When water is scarce, leakage can lead to insufficient pressure and reduced water supply to consumers. Leakage can also increase the risk of pollution intrusion, particularly in systems with frequent and/or sudden pressure losses (Besner et al. 2011).

Real losses are typically reported in the range of 215–315 l (L) per service connection per day, as an average across studies, with values ranging between 30 and 800 (Chastain-Howley et al. 2013; Lambert et al. 1999; SWWA 2013). In Scandinavia, real losses represent around 20–30 % of the total water produced in Sweden and Norway where raw water is abundant (SWWA 2013; Norwegian Water 2013), and around 9 % in Denmark where water is scarcer (Danva 2013).

It takes considerable effort to identify leaks from WDSs. Whereas leakages due to major pipe bursts are often obvious, drinking water can seep into sewer pipes or via permeable gravel into trench ditches and may not be observable from the ground. Additionally, it is often difficult to locate leaks without actively searching for them, which means that leaks in sparsely populated areas may remain undiscovered for long periods of time (Hamilton and Charalambous 2013). Also, there are often long distances between valves and other fittings within water mains, which make it hard to pinpoint leaks using listening equipment (Hamilton and Charalambous 2013).

Methods for locating leaks include direct methods such as acoustic monitoring, inline inspection, gas injection or manual listening stick (Hamilton and Charalambous 2013), and indirect methods such as district flow metering or pressure analysis (Misiunas 2005). Acoustic monitoring (loggers) is performed using vibration sensors or hydrophones, which are attached to the pipe fittings, typically 200 to 500 m apart (Misiunas 2005). In district flow metering, the WDS is divided into district-metered areas (DMAs) generally comprising 500–3000 service connections (Gomes et al. 2012). Flow (and sometimes pressure) sensors are placed on the DMA boundaries and data is collected by the SCADA system and subsequently analysed for identification of leakage trends (Misiunas 2005). Leakage can also be reduced by pressure control and optimisation, as demonstrated by for example Araujo et al. (2006) and Tabesh et al. (2009), with the additional benefits of reducing pipe failure rates and extending asset life. International experience suggests that for every 1 % in pipe pressure reduction, burst rates decrease by 1.4 % (Thornton and Lambert 2007).

The costs and effort of identifying leaks can preferable be balanced against the benefits with a cost benefit analysis (CBA), including lower costs for treatment and delivery of water, avoidance of costly alternative water supplies in case of water scarcity, more stable water quality with lower risk of contamination, and reduced costs caused by sudden delivery interruptions. The latter affect consumer confidence and, when leaks have to be repaired in the middle of the night, generate extra costs. The greater the value of drinking water, and the higher the level of leakage, the more there is to gain from leakage mitigation. In Sweden, saving water is motivated by political rather than economical factors (Malm et al. 2009).

Methods for implementing CBAs for WDSs vary. Lambert and Lalonde (2005) suggest a CBA for direct costs and benefits, including a rate of (future) leakage increase, if no action is taken. When more water has to be produced as a result of leakage, more chemicals are used for treatment and more energy is consumed, which means that not only the direct costs to the utility, but also the external, environmental and social, costs should be included, as suggested by e.g. Ofwat (2008), Ashton and Hope (2001) and Kanakoudis et al. (2011).

Environmental costs include for example changes in ecosystems and carbon emission costs Ofwat (2008). Most of the environmental costs (recreation, biodiversity, fisheries etc.) are due to impacts on the water cycle, which are close to zero when water is abundant.

Social costs include for example disruption in delivery, traffic delays due to repair work and health costs caused by impaired water quality during repairs. A lower frequency of leaks may also reduce the cost of health risks, as each pipe failure repair may involve a risk.

Sánchez et al. (2005) trialled permanent acoustic monitoring systems in three regions of Madrid. Their CBA concluded that the high installation cost of permanent acoustic loggers could be justified in a heavily deteriorated network, i.e. when the number of burst pipes exceeded 2 per km per year, considering only direct costs. In Oslo, Venkatesh (2012) performed a CBA case study where the cost of pipe replacement was much higher than the benefits associated with the reduction in leakage; however, this CBA covered only a short period of time; 10 years, and although extending the time period ought to narrow the gap, this would not be enough to justify pipe replacement for the purpose of leakage reduction alone. None of the case studies mentioned took into account health effects due to pipe failure repairs, nor were environmental effects included as costs.

Several types of data needed to carry out a CBA of a WDS are difficult to gather or with high uncertainty. This is particularly true for the environmental and social costs as described by Ashton and Hope (2001). Uncertainty in these and other input data could affect the ranking of alternatives adversely, whereas the explicit inclusion of measurement uncertainties in the CBA would probably lead to a more robust ranking. Uncertainty analysis has previously been used in combination with CBA to evaluate water supply risks, including water treatment failures to consumers (Lindhe et al. 2011) and evaluation of a proactive sensor system for pipeline failures (Morimoto 2010), but has never before been used to evaluate alternatives for mitigating or remediating leaks from a WDS.

The aim of this study has been to present a CBA method for decision support in WDS leakage control management, demonstrated with a case study of the WDS in Gothenburg, Sweden. A specific objective has been to show how uncertainty analysis of leak reduction alternatives can improve the decision support when input parameters are uncertain and when alternatives are close in performance, and also identify which input parameters that have the greatest impact on the total uncertainty.

2 Material and Methods

The steps in the CBA scheme used in this study were developed by Rosén et al. (2008). In this study, their method has been extended to include an uncertainty analysis and a probabilistic evaluation of the alternative options.

2.1 Study Site

In 2012, the WDS in the city of Gothenburg, Sweden, had 1750 km of pipes constructed primarily of grey cast iron, ductile iron and polyethylene (PE).

Gothenburg has adopted a high-priority target reducing the total leakage from 770 L per service connection per day in 2012 to 520 L per service connection per day in 2024 (SWW 2006). The current ILI is 9 and the leakage represents approximately 20 % of the drinking water produced. The ILI of 9 is defined as ‘very bad’ according to the World Bank Institute Banding system (Seago et al. 2005). Gothenburg spent around 0.6 million € per year on leak detection in 2007–2012, corresponding to 7 % of the operation and maintenance costs for distributing drinking water, including pumping costs. Around six employees have leak detection as their main duty in Gothenburg.

Around half of Gothenburg’s water distribution falls within 53 high pressure zones with additional booster stations. The remainder forms one large low elevated zone pressurized from the waterworks. The average pressure in Gothenburg’s WDS is 470 kPa (48 m water column). In the high pressure zones, the leakage can be monitored via night-time measurements in the booster stations. When the pumped flow exceeds a threshold level, between the hours of 2 and 4 am, an alarm is triggered and leak detection personnel can locate the leaks.

Replacement of pipes within the WDS is performed continuously. The pipe sections with the highest failure rates and the greatest number of people affected are prioritised, although not necessarily those with the highest volumes of water losses. In the last 10 years, pipe replacement in Gothenburg has averaged about 8 km per year, or 0.5 % of the total length of the WDS (SWW 2014). It is expected that the replacement rate will have to increase steadily, and to double in 20 years, if the city is to maintain current levels of WDS failure and robustness (Malm et al. 2012). The current pipe failure rate is 0.16 failures per km per year (mean value 2009–2013), which includes both leaks and pipe breaks (SWW 2014). In Gothenburg’s WDS, many pipe breaks are circumferential (grey cast iron) or due to rupture/blow-out (grey cast iron). These types of failures are usually quickly reported and repaired. Unreported leakages from failures that are not as easily detected have to be found by active leakage control. According to the Gothenburg’s databases, active leakage control repairs made up 30 % of all pipe failure repairs in Gothenburg between 2008 and 2012.

Pipe materials strongly influence the amount of water that is lost. Analysis of Gothenburg’s water losses within high-elevated zones has shown that there is a clear correlation between the volume of water lost and the proportion of grey cast iron pipes. In a worldwide study of transmission mains, Laven and Lambert (2012) showed that the rate of unreported leakage from grey cast iron pipes is more than twice as high as from other materials. In Gothenburg, leakage from grey cast iron occurs primarily from joints and corrosion pits. When corrosion pit leakage is discovered, the size of the pit is typically around 25 mm, corresponding to a leakage of 550 l per minute (at a pressure of 470 kPa, see e.g. Besner et al. (2011) for calculation principle). Pits develop over many years and the total leakage from grey cast iron pipes can therefore be significant. There is no correlation between the volume of water lost and the proportion of ductile iron in Gothenburg, probably because most leaks from iron pipes are due to sudden total failure. This is because even if the iron in a pipe is completely corroded, its cement mortal lining prevents leaking until it finally bursts. Pipes made of PVC can develop longitudinal cracks and smaller cracks in joints, and any unreported leakage may be significant if not detected quickly. In Gothenburg, leakage from PE pipes is rare.

2.2 Objective Function and Definition of Leakage Reduction Alternatives

2.2.1 Objective Function

This study has implemented an objective function that maximizes the current value of a stream of benefits, minus the costs for each leakage reduction alternative. Using CBA, costs and benefits are compared for each alternative, i, in an objective function (e.g. Hanley and Barbier 2009) over time t:

where

- Φ i :

-

net present value (NPV)

- B it :

-

the benefit of leakage reduction (expressed as a function)

- C it :

-

the costs of leakage reduction measures (expressed as a function)

- r :

-

discount rate

- T :

-

time horizon in years, t.

This study used a fixed reference discount rate, r = 3 %, corresponding to the internal discount rate in Gothenburg. A scenario analysis was also carried out, where the discount rate varied. The discount rate for public investments, such as infrastructure projects, recommended by Heatco (2006) is 3 %, and the HM Treasury Green Book (2003) recommends a rate of 3.5 %. The Swedish recommendation is also 3.5 % (STA 2014). The time horizon, T, for the NPV calculation was set to 100 years.

2.2.2 Alternatives

In a CBA, the alternatives can be set up in different ways. The present situation can be used as a reference point and the NPVs of various alternatives can be compared to this reference point. The alternatives can also be set up to meet a specified benefit target, or to yield the maximum benefit at a specified cost (Lindhe et al. 2011). In this study, the alternatives were designed to meet the Gothenburg leakage target of no more than 520 L per service connection per day, corresponding to a leakage reduction of 3,810,600 m3 annually. Here, the target was assumed to be reached linearly over 10 years (2012–2021).

Four alternatives have been assessed in this study (with more detailed description in sections 2.3 and 2.4):

-

Alternative 1. Replace pipes faster than the present rate of 8 km per year. New, correctly installed pipes are then assumed to have a leakage close to zero.

-

Alternative 2. Extend leak detection efforts by increasing the personnel working force using traditional leak detection methods, including manual listening sticks and acoustic correlators.

-

Alternative 3. Extend leak detection efforts by increasing the number of acoustic loggers that detect leak noise and transfer data via text messaging.

-

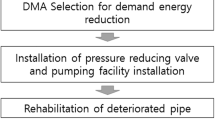

Alternative 4. Extend leak detection efforts using DMA, i.e. divide the city into metering zones to limit the size of the areas that need to be scanned. Active leak detection would be needed to locate leaks within each DMA.

2.3 Identifying Costs and Benefits

2.3.1 Costs

The costs considered in this study were those incurred by the utility, i.e. the costs of leakage control and of efforts to reach the leakage reduction target. The social, environmental and carbon emission costs in the guideline from Ofwat (2008) were evaluated to determine whether they needed to be included, but due to their low monetary value, they were found to be negligible.

Environmental costs for raw water abstraction were assumed to be small in the Gothenburg case study. The raw water flow is less than 1 % of the river flow and does not disturb the natural flow. The use of the river for drinking water may lead to a need for investments in upstream wastewater treatment plants and cleaner maritime traffic. However, according to the EU Water Framework Directive, 2000/60/EC, a good surface water status must be achieved no later than by 2015, which means that restrictions will have to be implemented anyway.

The costs related to carbon emissions were determined based on a life cycle analysis carried out for the Gothenburg system, which showed that the emission of CO2 is 94 g per m3, including treatment, pumping and distribution energy, as well as energy for aluminium sulphate (Wallén 1999). The cost of emission allowance is 0.0058 € per m3 produced water (EU Emission Allowances 2014). The Swedish energy tax is 0.03 € per m3, i.e. the tax is much higher than the emission allowance cost, and the carbon emission cost was therefore assumed to be included in the energy cost. The tax on fossil energy in Sweden is 120 € per ton CO2 (Traffic analysis 2014) and it was assumed that the carbon emission cost for fossil energy was also included in the energy cost.

The social costs were assumed to be small in this case study. Traffic-related problems are small as most leak repairs are performed in local streets, and also noise disturbances (Bäckström and Gustafsson 2005), as well as costs of disruption in water distribution in Sweden (Bylund and Lille AB 1999).

Alternative 1: Increased Replacement Intensity of the WDS

An estimated unit cost for pipe replacement was calculated using data from 45 replacement projects undertaken in Gothenburg in 2011–2012. The result gave the average cost for replacement to be 640 €/m. In all the projects, the pipes were replaced by bursting, a trenchless technology method most commonly used in Gothenburg. The median length of replaced pipe per project was 274 m, and the total costs were calculated using a function of the starting cost, pipe diameter, replacement distance, and the number of service connections and fire hydrants.

The depreciation period for the pipes was set to 50 years, according to routines in Gothenburg. The lifetime of the new pipes was assumed to be 100 years, i.e. 50 years longer than the depreciation period, based on the results from Malm et al. (2012).

Alternative 2: Increased Leakage Detection Using More Personnel Resources

The main expense associated with increased personnel resources is employment costs. Additional equipment costs were assumed to be negligible in comparison to salaries. A full-time position costs on average 68,000 € per year, including overheads. This cost was assumed to be the societal alternative cost for labour where the person recruited to the position comes from a labour-market with no unemployment.

Alternative 3: Increased Leakage Detection Using More Loggers

Deploying additional loggers would increase both equipment and personnel costs. In Sweden, the current market price of loggers that send data by text message is 1130 € per unit. The time required to handle each logger was assumed to be 2 h per year (180 €), including planning, installation, monitoring and analysis. In the calculations the loggers were depreciated over 5 years. The lifetime of the loggers was set to 10 years, thereafter new loggers would have to be purchased. It was assumed that the new loggers would have the same price and similar performance as the original ones.

Alternative 4: Increased Leakage Detection Using More DFMs

To improve leakage detection by using more district flow meters (DFMs) would translate to increased equipment and personnel costs. DFMs may be installed in the ground and run on batteries, and the mean cost of installing one DFM is about 15,800 € including planning, purchasing, installation and management.

In this study, the DFMs were depreciated over 10 years, with an assumed lifetime of 20 years. After 20 years, new DFMs would have to be purchased. The new DFM’s were assumed to have the same price and performance as the original DFMs.

2.3.2 Benefits

Benefits considered in the CBA analysis were reduced water losses, savings as a result of fewer repairs, reduced exposure to health risks during repairs and reduced maintenance costs for a newer and more robust WDS. The avoided costs of increasing the delivery capacity due to large leakages and efforts needed to reclaim community trust and confidence, for example after a water-borne outbreak, were also taken into account.

All benefits were assumed to increase linearly over the 10 years it will take to reach the leakage target.

Benefits associated with either goodwill when leakage reduction targets are reached or increased water supply security were not included due to their expected low monetary values. Swedish water utilities enjoy high confidence among consumers and substantial delivery interruptions are rare (SALAR 2013).

Alternative 1: Increased Replacement Intensity of the WDS

The benefits of Alternative i = 1 are calculated by considering the reduction in water loss volume, the reduced number of leak repairs and increased system robustness:

where

- B WP :

-

cost reduction due to lower drinking water production and distribution including reduced chemical usage and lower energy costs (€/m3)

- B WWT :

-

lower costs for wastewater treatment, due to less leakage from drinking water pipes entering waste water pipes (€/m3)

- V R,t :

-

volume of drinking water saved by limiting leakage, (m3/year)

- B C,t :

-

reduced investment costs due to not reaching the capacity limit. If the water utility already delivers drinking water volumes close to production capacity, it must invest in order to increase production or else risk not being able to meet drinking water demands (€/year)

- N P,1 :

-

number of leak repairs no longer required (No./km/year)

- B P :

-

cost per leak repair (€)

- L t,1 :

-

pre-emptive pipe replacement (km)

- B M,t,1 :

-

reduction in the cost of monitoring and maintaining a newer WDS, including planning and analysis (€/year).

The reduced cost of avoiding production of one extra cubic metre of water (B WP ) is 0.085 €, including chemical costs, costs for pumping raw water and costs at the treatment plant. Pumping costs within the WDS are on average 0.017 € per m3 of produced drinking water. In reality this cost varies within the network, from zero in the lowest parts of the city to a maximum in the elevated zones. Pumping efficiency also varies depending on the condition of the pump and whether or not there is a reservoir in a particular high elevated-zone. Overall, the marginal cost for producing an extra cubic metre of drinking water is approximately 0.10 €.

The amount of drinking water that leaks into sewers linked to a wastewater treatment plant (WWTP) varies spatially depending on the type of sewer system and the soil conditions. In a system with combined wastewater pipes for sewage and stormwater, a greater share of the drinking water is assumed to go to the WWTP than in a system with a separate stormwater pipe. According to a water balance calculation for the entire WDS of Gothenburg, approximately 50 % of the leaked drinking water goes to the WWTP (SWW 2010). The marginal cost (B WWT ) for treating a cubic metre of wastewater at the WWTP is about 0.06 €, i.e. 0.03 € per m3 of leakage.

In 2020, the two waterworks in Gothenburg will be extended so that each is able to independently meet the city’s water demands if necessary. Until then, the more drinking water is lost to leakage, the closer the waterworks are to their maximal production capacities. In the event of a production failure at one of the waterworks, there is a risk of water scarcity. Should this occur, there would be a loss in water pressure and a risk of pollution intrusion, which means that the WDS would have to be thoroughly flushed in its entirety to limit the risk of contamination. Other possible consequences include problems in public services, as well as businesses and shopping malls being forced to close due to water scarcity or non-functioning sprinkler systems. Assuming that scarcity is a 1 in 50 year event and costs 10 million €, the annual cost of the scarcity risk (B C,t ) is almost negligible (0.003 € per m3 per year).

The cost of repairing a leak or pipe break (B P ) was estimated based on data from Gothenburg’s database of leak repairs performed in 2007–2009. The average repair costs for pipes of various diameters are provided in Fig. 1. The average cost (total cost for all repairs divided by the total number of repairs) is 8100 € per repair, including costs for producing and treating the leaked drinking water. The cost of the water loss per repair (1100 €) is based on an estimate by Bäckström and Gustafsson (2005), where the average water loss is 8500 m3 from each pipe failure before the pipe is repaired.

The pipe repair frequency varies between different pipe materials, which affect the benefit of replacement. The benefit can be calculated by multiplying the actual failure rate reduced by the failure rate for a new pipe with the average cost per pipe failure repair. Table 1 lists the benefits associated with repairing pipes of various materials. The assumed break rate for new pipe materials was set to 0.03 per km per year, slightly above the actual failure rate for PE pipes in Gothenburg, which is 0.029 per km per year (SWW 2014).

Pre-emptive pipe replacement could be seen as “too early replacement”, as these pipes would otherwise have been replaced according to the ordinary replacement scheme, i.e. included in the annual 8 km of pipe replacement. This “too early replacement” cannot be used as a benefit in the CBA. Renewing pipes instead of doing spot repairs results in a younger WDS. The benefits of a rejuvenated WDS are fewer pipe repairs and less leakage; benefits that have already been taken into account. However, the increased security (B M,t,1 ) that a newer WDS provides should be included. This is partly a financial security, as some of the future replacement costs have already been paid. In addition, the utility can be certain that the WDS is in a good condition and therefore invest less time in monitoring it.

Alternative 2–4: Increased Leakage Detection

The benefits of Alternatives i = 2, 3 and 4 were calculated by considering the reduction in water loss volume, reduced costs for leak repairs and increased knowledge of the WDS status:

where

- B WP , B WWT , V R,t and B C,t :

-

are defined as for Alternative 1

- N PL,t,i :

-

Number of pre-located leak repairs per year

- B PL :

-

Pipe break and leak repairs are performed within normal working hours if possible. Repairs performed outside normal working hours carry additional overtime costs. Each acute pipe break repair that can be avoided and repaired during working hours (N PLt ) reduces the repair cost by about 12 % of 8100 €, or 970 € per repair, based on additional costs for overtime.

- B K,t,i :

-

Reduced cost (€) due to a better knowledge of the WDS status. The benefit of a better knowledge of the system occurred only in Alternative 4. In Alternative 3, more information about the flows in the DWS would be gathered by the DMAs. This data would be useful for calibrating the hydraulic model of the DWS. Using the data in this way would save on consultant costs, but as the city does not currently make use of the data, no costs are saved.

2.4 Quantification of Costs and Benefits

2.4.1 Costs

Alternative 1: Increased Replacement Intensity of the Network

Due to the high proportion (40.4 %) of grey cast iron pipes in Gothenburg and the relatively high leakage rate of grey cast iron (Table 1), replacing grey cast iron pipes was expected to produce the greatest benefit. Based on experience at the water utility, grey cast iron was assumed to account for 80 % of the leakage, equivalent to 10,161,600 m3 per year. As there is a lack of information about which groups (i.e. age groups) of the grey cast iron pipes leak most, the leakage was assumed to be equally distributed. To reach the leakage target, Gothenburg additional 265 km of grey cast iron pipes would need to be replaced, at a cost of 640 € per metre, or 170 million € in total. By increasing the current yearly replacement from 8 to 26.5 km, the city would reach its target level within 10 years. The cost of increased replacement (185 km over 10 years) was included in the calculation.

Alternative 2: Increased Leakage Detection Using More Personnel Resources

To achieve the leakage target, it was assumed that an additional four members of the technical staff and one group leader would need to be employed. The figures were based on expert judgement considering the present situation in Gothenburg. All personnel were assumed to be employed in year one, at a cost of 0.34 million € from year one.

Alternative 3: Increased Leakage Detection Using More Loggers

Loggers would be installed at 200–500 m intervals (mean 350 m) within the oldest sections of the WDS (i.e. the 65 % of the existing WDS that was installed before 1980). A total of 3250 loggers would be needed, but as the city already has 150 loggers installed, the actual requirement would be 3100 additional loggers. These would be installed over a 6-year period, at a rate of approximately 540 per year.

Alternative 4: Increased Leakage Detection Using DMA

The high-elevated zones already have district metered areas, but most are too large for district leak detection. An optimal size for a DMA is assumed by the city to be no more than 5000 residents, corresponding to 2–3000 households, depending on the building structure of the area. To achieve this, the high and low elevated zones would have to be divided into 70 DMAs. In areas where delivery reliability is a high priority, most of the WDS is built up as a grid system, which means that each DMA would require at least two or three DFMs. Assuming an average of 2.5 DFMs per DMA, 175 new DFMs would be needed. The plan would be to install the new DFMs over a 10-year period, at a rate of 17–18 per year.

2.4.2 Benefits

Alternative 1: Increased Replacement Intensity of the WDS

To reach the leakage target, the present leakage volume in Gothenburg must be reduced by 3,810,600 m3 annually and the benefit derived from this reduction, after 10 years of accelerated replacement, would be 0.5 million € annually. The benefit resulting from a lower number of breaks in the grey cast iron pipes would be 0.36 million € annually after 10 years, i.e. when the accelerated replacement is supposed to have been completed. The reduced maintenance benefit was assumed to correspond to a full-time position after 10 years, at 68,000 € per year.

Alternative 2–4: Increased Leakage Detection

As for Alternative 1, when the leakage target is reached the benefit of reduced leakage, after 10 years of better leakage detection, would be 0.5 million € annually.

Only certain types of leaks can be found in advance. Many pipe breaks are sudden, with no previous leakage. Based on documented failure codes for previous leaks or pipe breaks, the failure codes “joint leak” and “corrosion” were assumed to be detectable in advance and conversely, pipe failures coded as “circular” and “long crack” typically occur suddenly and can therefore not be located in advance. The presumed number of repairs of pre-located leaks (N PL,t,i ) was set to 23 % of approximately 250 pipe failures per year (mean 2011–2012). Based on an average cost-saving of 970 € per pipe failure repair this results in a saving of 55,800 € per year as these repairs can be carried out during normal working hours.

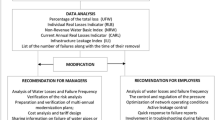

2.5 Uncertainty Calculations

Some data used in CBAs for leakage remediation are based on estimates with a high degree of uncertainty. In this study, the CBA explicitly accounts for uncertainties in the input data. These are represented by normal distributions with mean, standard deviation and 10- and 90-percentiles, as shown in Table 2.

In Alternative 1, estimates of replacement costs were based on historical data, and the uncertainty was assumed to be negligible. Similarly, in Alternative 2, salary costs were reliably known, but the number of additional personnel required was represented by a normal distribution. In Alternative 3, the cost of the loggers was fixed, but the uncertainty associated with the time requirement per logger was represented by a normal distribution. In Alternative 4, the minimum cost of a DFM installation was 11,300 €, but some installations may be significantly more expensive for site-specific reasons. To reflect this uncertainty, a truncated normal distribution was used. The annual labour cost for maintenance, monitoring and analysis was assumed to be approximately 10 h per DFM and year, or about 900 € per year. The uncertainty in the cost is due to the uncertainty in the time required for operation of the DFMs.

When calculating the benefit of reduced leakage, it is difficult to know when the target level is reached, as the size of the leakage reduction is uncertain. The benefit of leak reduction was assumed to be normally distributed for Alternatives 1–4 (Table 2). Alternatives 2 and 4 were assumed to have the highest levels of uncertainty, as the results of active leak detection vary depending on the level of experience of the employees. By using loggers, a more exact position of the leak can be obtained. With respect to the other benefits of Alternative 1, the benefits from leak repairs and increased system security were assumed to be certain. The benefit relating to reduced cost per leak repair with Alternatives 2–4 was also assumed to be certain.

2.6 Calculation of Net Present Value

2.6.1 Result Calculation Including Uncertainties

The NPV was calculated using the costs and benefits modelled as an expected value and a probability distribution. The calculations were performed using Monte-Carlo simulations with 10,000 iterations (Crystal Ball, Oracle Corporation software).

2.6.2 Judgment of Best Alternative(s)

When the NPV is similar for a number of different alternatives and there are major uncertainties in the input parameters, it is difficult to determine which alternative is the most favourable. In this situation, it may be valuable to determine the probability that any given alternative has the most beneficial outcome, i.e. the highest NPV. This is calculated as the fraction of the total number of Monte Carlo runs in which each particular alternative has the highest NPV.

2.6.3 Sensitivity Analysis

A sensitivity analysis was performed by calculating the contribution of uncertainty from each input parameter to the total uncertainty (variance) of the model outputs, in this case the NPVs of each alternative. When used in this way, the sensitivity analysis identifies the parameters that have the greatest impact on the total uncertainty. Efforts should be focused on reducing the uncertainties in these parameters to improve the reliability of the CBA.

2.7 Scenario Analysis

A scenario analysis was carried out, where the fixed discount rate (3 %) was set to 1 and 5 %, respectively.

3 Results

3.1 Base Scenario with Uncertainties and Variability

The median values of the NPVs determined under the base scenario are shown in Table 3. Faster replacement, Alternative 1, was much more expensive than increasing the leak detection effort. Expanding the workforce (Alternative 2) and adding more DMAs (Alternative 4) both yielded a positive NPV, indicating that until the leakage target is reached, the expanded leak detection work will save the water utility money.

The results of simulations with uncertainty estimates on input values are presented in Fig. 2. Although Alternative 2 still appears to be the best option, Alternative 4 is almost as good on average and sometimes more favourable. The results for the probability of each alternative being the most favourable were 0; 64; 2; and 34 % respectively, i.e. Alternative 2 has the highest and Alternative 4 the second highest probability.

The results of the sensitivity analysis are shown in Table 3. The variability in Alternative 1 is related to estimates of leakage reduction which also was the main influence on the variability for Alternative 2. The operating cost was important for Alternative 3, whereas for Alternative 4, the results were most sensitive to leakage reduction and installation costs.

3.2 Scenarios Analysis

When the discount rate was changed, the results changed. A higher discount rate led to a lower NPV. However, how well different options performed in relation to each other will remain the same compared to the reference discount rate, 3 %, see Table 3.

4 Discussion

The aim of this study was to present a CBA method for WDS leakage control, including uncertainty analysis and demonstrated with a case study of the Gothenburg’s WDS. The inclusion of uncertainty analysis improved the results of the CBA and would be useful when active leakage control programs are prepared. When the uncertainties of the CBA results were taken into account it gave a more differentiated overview of the best alternative(s). The most beneficial alternative, using more personnel, was close in performance to using more district flow meters. This finding may encourage the utility to make a more comprehensive change, by combining more DFMs with more personnel.

The sensitivity analysis indicated that the parameters leakage reduction, operating costs and installation costs should be investigated in more detail to support a more reliable analysis and a more certain identification of the best alternative.

The discount rate generally affects the final outcome of a CBA and in this study, higher discount rates were associated with a higher risk of negative NPVs, however the order of the alternatives were not affected. One reason to assume a low discount rate is that a safe and reliable water system is an important long-term issue for society (Hanley and Barbier 2009).

The model used in this study included the externalities considered to be the most significant costs and benefits at the study site. As described in Ofwat (2008), external costs should always be considered and those who might be relevant should be included, even if they are uncertain. Moreover, if a reduced health risk to consumers, as a result of fewer leaks, is to be taken into account, this can be included in Eq. 2 (the benefits of the replacement alternative). However, in Gothenburg, no significant health risks associated with leakage repairs can be proven (Malm et al. 2013).

Leakage reduction can also be achieved using pressure optimization. In Gothenburg the current unavoidable annual real losses are 82 L per connection per day. If the pressure was reduced by 1–2 m in the low elevated zone, and by even more in some high pressure zones e.g. at night, the UARL could be reduced by approximately 4 %, to 79 L per connection per day. If the total loss was reduced to the same extent as the UARL, the leakage could be reduced by 32 L per connection per day, representing 12 % of the total water saving needed to reach the leakage target.

The case study of Gothenburg municipal WDS showed that reactively performing local repairs of water pipe leaks was significantly more economical to reduce leakage volumes than proactively replacing old pipes, despite a high overall leakage rate and abundant water resources. This finding supports the conclusion of Venkatesh (2012); that even in a system with high leakage rates, repairing broken pipes is more effective than a high replacement rate. The results in Gothenburg were also in line with Sánchez et al. (2005) and van der Kleij and Stephenson (2002), who found that having more personnel using traditional methods for leakage detection was more beneficial than installing permanent acoustic loggers.

The lower the leakage, the more difficult it is to detect by active leakage control. The level of the target for the Gothenburg utility is not questioned in this article, however, this study indicates that if more efforts were put into leakage control, this would result in a positive NPV and be a way to optimize the target level.

The results of this study will be very useful as a tool to support decisions relating to the DWS in Gothenburg. It has been shown that the utility could save money by investing in more technical equipment and/or employing more personnel. In times of high unemployment, more jobs represent an economic benefit not only for the utility but also to society.

5 Conclusions

Cost benefit analysis (CBA) is a useful tool for comparing measures when leakage control programs for WDS’s are designed. A CBA can compare all costs and benefits of different measures over the longer term.

Uncertainty analysis improves the results of a CBA when input parameters are not sufficiently known. Moreover, a statistical analysis of the best alternatives using the CBA method provides an important opportunity to identify the best alternative when multiple alternatives are close in performance and also to identify which input parameters that have the greatest impact on the total uncertainty.

In the case study for Gothenburg, reactively repairing rather than proactively replacing pipes was found to be significantly more cost-effective, despite a high leakage rate.

Abbreviations

- CARL:

-

Current annual real losses; leakage on transmission and/or distribution mains, at utility storage tanks and on service connections up to point of costumer metering

- CBA:

-

Cost benefit analysis

- DFM:

-

District flow meters for flow measurement on the distribution network

- DMA:

-

District-metered areas, a sectioned zone of a WDS where the flow can be univocally measured

- ILI:

-

Infrastructure leakage index, representing the ratio of CARL and UARL (Lambert et al. 1999)

- NPV:

-

Net present value is defined as the sum of the present values of cash flows over a period of time

- SCADA:

-

Supervisory control and data acquisition, a communication system

- WDS:

-

Water distribution system

- UARL:

-

Unavoidable annual real losses is the lowest technically achievable real losses and depend on service connection density, system pressure and the average length of the service connection pipes between the water mains and the consumer’s water meters.

References

Araujo LS, Ramos H, Coelho ST (2006) Pressure control for leakage minimisation in water distribution systems management. Water Resour Manag 20(1):133–149

Ashton CH, Hope VS (2001) Environmental valuation and the economic level of leakage. Urban Water 3(4):261–270

Bäckström A, och Gustafsson M (2005) Maintenance planning for water distribution systems (In Swedish). Master thesis 2005:114, Dept. of Civil and Environmental Engineering, Chalmers University of Technology, Gothenburg, Sweden. Available at http://publications.lib.chalmers.se/records/fulltext/21671.pdf

Besner M-C, Prévost M, Regli S (2011) Assessing the public health risk of microbial intrusion events in distribution systems: conceptual model, available data, and challenges. Water Res 45(3):961–979

Bylund E, Lille J (1999) Consumers perception of the Gothenburg Water utility business (In Swedish). Bylund & Lille AB, Stockholm

Chastain-Howley A, Kunkel G, Jernigan W, Sayers D (2013) Water loss: the North American dataset. Am Water Works Assoc 105(6):57–60

Danva (2013) Water performance indicators, 2012 (In Danish). Available at http://www.e-pages.dk/danva/120/

EU Emission Allowances (2014) Global Environmental Exchange. https://www.eex.com/en/market-data/emission-allowances/spot-market/european-emission-allowances#!/2014/07/23. Accessed 23 Jul 2014

Gomes R, Marques AS, Sousa J (2012) Decision support system to divide a large network into suitable District Metered Areas. Water Sci Technol 65(9):1667–1675

Hamilton S, Charalambous B (2013) Leak detection technology and implementation. IWA Publishing, London

Hanley N, Barbier EB (2009) Pricing nature: cost-benefit analysis and environmental policy. Edward Elgar Publishing, Cheltenham

Heatco (2006) Proposal for Harmonised Guidelines. HEATCO Deliverable 5, 2nd revision, February 2006. Available at http://heatco.ier.uni-stuttgart.de. Accessed 30 Dec 2013

HM Treasury (2003) Green Book, Appraisal and Evaluation in Central Government, HM Treasury, UK. Accessed at https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/220541/green_book_complete.pdf. 30.12.13

Kanakoudis V, Gonelas K, Tolikas D (2011) Basic principles for urban water value assessment and price setting towards its full cost recovery – pinpointing the role of the water losses. J WSRT-AQUA 9(60.1):27–39

Lambert AO, Lalonde A (2005) Using practical predictions of economic intervention frequency to calculate short-run economic leakage level, with or without pressure management. IWA Leakage 2005, Halifax, Canada, September 12–14, 2005

Lambert AO, Brown TG, Takizawa M, Weimer D (1999) A review of performance indicators for real losses from water supply systems. J WRST- AQUA 48(6):227–237

Laven K, Lambert AO (2012) What do we know about real losses on transmission mains. IWA Specialised Conference Water Loss, Manila, Philippines, Feb/March 2012

Lindhe A, Rosén L, Norberg T, Bergstedt O, Pettersson TJR (2011) Cost-effectiveness analysis of risk-reduction measures to reach water safety targets. Water Res 45(1):241–253

Malm A, Pettersson TJR, Bergstedt O (2009) Rehabilitation planning of water distribution and sewer networks in 18 Swedish municipalities (In Swedish). Paper presented at the 11th Nordic Sewer Conference, Odense, 10–12 Nov. 2009

Malm A, Ljunggren O, Bergstedt O, Pettersson TJR, Morrison GM (2012) Replacement predictions for drinking water networks through historical data. Water Res 46(7):2149–2158

Malm A, Axelsson G, Barregard L, Ljungqvist J, Forsberg B, Bergstedt O, Pettersson TJR (2013) The association of drinking water treatment and distribution network disturbances with Health Call Centre contacts for gastrointestinal illness symptoms. Water Res 47(13):4474–4484

Misiunas D (2005) Failure monitoring and asset condition assessment in water supply systems. PhD thesis, Dept. of Ind. Electrical Engineering and Automation (IEA), Lund University, Lund. Available at: http://iea.lth.se/publications/Theses/LTH-IEA-1048.pdf

Morimoto R (2010) Estimating the benefits of effectively and proactively maintaining infrastructure with the innovative Smart Infrastructure sensor system. Socio Econ Plan Sci 44:247–257

Norwegian Water (2013). Condition Assessment of municipal water and wastewater services (In Norwegian). Norsk Vann, Hamar, Norway Available at http://www.bedrekommune.no/bedrekommune.no/filestore/bedrekommuneno/BedreVA_resultatrapport_2012_data_web2.pdf. Accessed 15 Sept 2013

Ofwat (2008) Providing best practice guidance on the inclusion of externalities in the ELL calculation. Appendix 2 (Part 1). V07. Available online at https://www.ofwat.gov.uk/pricereview/pap_pos_pr09supdempolapp2-1.pdf

Rosén L, Back P-E, Soutukorva Å, Söderqvist T, Brodd P, Grahn L (2008) Cost-benefit analysis as a tool for prioritizing remediation (In Swedish). Sweden Environmental Protection Agency, Report 5836, ISBN 9789162058364

SALAR (2013) Critique of Technology 2013 – review of customer surveys in technical municipal administration (In Swedish). Swedish Association of Local Authorities and Regions. Available at http://webbutik.skl.se/bilder/artiklar/pdf/7164-996-6.pdf?issuusl=ignore

Sánchez EH, Ibáñez JC, Cubillo F (2005) Testing applicability and cost effectiveness of permanent acoustic leakage monitoring for loss management in Madrid distribution network, IWA Leakage 2005, Halifax, Canada, September 12–14, 2005

Seago C, McKenzie R, Liemberger R (2005) International benchmarking of leakage from water reticulation systems. IWA Leakage 2005 Conference, Halifax, Canada, September 12–14, 2005

STA (2014) Socio-economic principles and calculation values for the transport sector, ASEK 5 (In Swedish). Swedish Transport Administration (Trafikverket), Borlänge. http://www.trafikverket.se/Foretag/Planera-och-utreda/Planerings--och-analysmetoder/Samhallsekonomisk-analys-och-trafikanalys/Gallande-forutsattningar-och-indata/. Accessed 30 Aug 2014

SWW (2006) Action plans for water: long-term goals for the water supply in Gothenburg (In Swedish). Dept. of Sustainable Waste and Water, City of Gothenburg

SWW (2010) Action plans for sewer: Long-term goals (In Swedish). Dept. of Sustainable Waste and Water, City of Gothenburg

SWW (2014) Annual report 2013. Dept. of Sustainable Waste and Water, City of Gothenburg

SWWA (2013) Statistic Database (in Swedish). The Swedish Water & Wastewater Association. www.svensktvatten.se/Vattentjanster/Management/VASS/. Accessed 06 Aug 2013

Tabesh M, Asadiyani Yekta AH, Burrows R (2009) An integrated model to evaluate losses in water distribution systems. Water Resour Manag 23:477–492. doi:10.1007/s11269-008-9284-2

Thornton J, Lambert A (2007) Pressure management extends infrastructure life and reduces unnecessary energy costs. IWA International Specialised Conference ‘Water Loss 2007’, Bucharest, September 2007

Traffic analysis (2014) The society cost for the transport sector (In Swedish). Report 2014:4, Stockholm, Sweden. Available at http://www.trafa.se/PageDocuments/PM_2014_3_Transportsektorns_samhaellsekonomiska_kostnader_-_bilagor_2014.pdf

van der Kleij FC, Stephenson MJ (2002) Acoustic logging, the Bristol water experience, Leakage Management - A Practical Approach, Lemesos, Cyprus, November 20–22, 2002

Venkatesh G (2012) Cost-benefit analysis - leakage reduction by rehabilitating old water pipelines: case study of Oslo (Norway). Urban Water J 9(4):277–286

Wallén E (1999) Life cycle assessment of drinking water - a case study of water works in Göteborg (In Swedish). Report 1999:3. Dept. of Technical Environmental Planning, Chalmers University of Technology, Göteborg, Sweden. Available at http://boffe.com/rapporter/Dricksvattnet/Diverse/tep_1999_3.pdf

Acknowledgments

This study was carried out within the DRICKS drinking water research centre within the Dept. of Civil and Environmental Engineering at the Chalmers University of Technology in Gothenburg, Sweden.

Conflict of Interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Malm, A., Moberg, F., Rosén, L. et al. Cost-Benefit Analysis and Uncertainty Analysis of Water Loss Reduction Measures: Case Study of the Gothenburg Drinking Water Distribution System. Water Resour Manage 29, 5451–5468 (2015). https://doi.org/10.1007/s11269-015-1128-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11269-015-1128-2