Abstract

Whole crop rice was harvested 120 days after planting and chopped to 2–3-cm length for silage making. The whole crop rice silage (WCRS) was supplemented with different levels of molasses and urea to study nutritive value and in situ rumen degradability. The ensiling study was randomly assigned according to a 6 × 5 factorial arrangement, in which the first factor was molasses (M) supplementation at M0, M1, M2, M3, M4, and M5 %, and the second was urea (U) supplementation at U0, U0.5, U1.0, U1.5, and U2.0 % of the crop dry mater (DM), respectively. After 45 days of ensiling, temperature, pH, chemical composition, and fermentation end products of the silages were measured. Ten U and M treatment combinations of WCRS were subsequently selected to study rumen degradability by nylon bag technique. The results showed that temperature and pH of the silages linearly increased with U supplementation level, while total volatile fatty acid (TVFA), acetic acid (C2) and propionic acid (C3) decreased. In contrast, increasing level of M supplementation decreased WCRS temperature and pH, whereas TVFA, C2, and C3 concentrations increased dramatically. Both M and U supplementation increased concentration of butyric acid (C4). Dry matter, organic matter (OM), and acid detergent fiber (ADF) contents of the silages were not influenced by either M or U supplementation. Increasing U supplementation increased crude protein (CP) content, while M level did not show any effect. Furthermore, neutral detergent fiber (NDF) content in silage was decreased by both M and U supplementation. The results of the in situ study showed that M and U supplementation increased both ruminal DM and OM degradation. The water-soluble fraction (a) was the highest in WCRS U1.5M3 and lowest in U0M0. Increasing M and U supplementation levels increased the potentially degradable fraction (b) of both DM and OM. Total rumen degradable fraction (a + b) was highest in WCRS U1.5M3, whereas OM degradability was highest in U0M3. However, effective degradation of both DM and OM were the highest in WCRS U1.5M3 and the lowest in U0M0. We conclude that supplementation of U and M increases WCRS quality and rumen degradability. Supplementation of U at 1.5 and M at 3–4 % of the crop DM is recommended for lactating dairy cows and fattening beef cattle.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

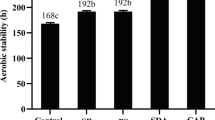

In most parts of the world, forage conservation is a key element for productive and efficient ruminant livestock production. Forage conservation also provides farmers with means of preserving forage when production exceeds that of grazing animals. Silage making increased considerably from the 1960s and is the predominant method of forage preservation in temperate areas of the world (Cheli et al. 2013). Silage is widely used in farms and has a substantial role in animal production systems. High silage quality is a key factor to minimize cost of production and sustained animal health. Increasing use of silage has resulted in continuing efforts to minimize the quality losses (Bartzanas et al. 2013; Dunièrea et al. 2013). The primary goal of making silage is to maximize the preservation of original nutrients in the forage crop for feeding, usually a difficult task, since the fermentation process usually leads to less than optimal preservation of nutrients. The main aim of ensiling is to preserve fodder under anaerobic condition, where anaerobic microbes build up organic acids mainly lactic acid by using fermentable carbohydrates, and aerobic stability describes the length of time that silage remains stable (Mohd-Setapar et al. 2012; Seppälä et al. 2013).

Ensiling process is defined as involving the following steps: harvesting the crop at the optimal stage of maturity, chopping, loading into a silo, compacting and sealing to exclude air, storing, and finally unloading for animal feeding (Dunièrea et al. 2013). Ensiling, a preservation method for moist crops, is based on anaerobic fermentation, whereby epiphytic lactic acid bacteria convert water-soluble carbohydrates in to organic acids, mainly lactic. As a result, the pH decreases, and the forage is preserved (Weinberg et al. 2010). Various different plant materials can be used for ensiling: grass, clover, alfalfa, barley, corn, wheat, sorghum, and various moist “by-products” of the food industry, such as apple pomace, beet pulp, and brewer's mash (Ajila et al. 2012) and have been used to feed dairy and beef animals in both developed and developing countries (Touqir et al. 2007a, b). Rice (Oryza sativa L. Japonica) is the main cash crop in Southeast Asian countries. Attention has been recently paid to rice whole crop as a new feed resource. The utilization of whole crop rice (WCR) as an animal feed has proven economically viable, not only as a way of disposing of rice straw residues but also as a real alternative for feeding livestock in regions, where rice is the main crop (Cao et al. 2009). Silage must be made from plant material with suitable moisture content, about 55–70 %. Paddy rice is the main crop in Thailand, and rice crop have properties which can be used for silage making, since it contains 70.5 and 12.4 % of moisture and CP, respectively.

Several processes have been developed to improve the fermentation and nutritional value of whole crop silage from forage paddy rice. Breeding programs are carried out, and newly developed rice varieties with increased yield and amount of digestible nutrients are being grown and tested. Also, harvesting, preparation, and storage techniques are constantly being improved. However, WCR is usually insufficient in sugars and lactic acid bacteria and may produce silages rich in ethanol rather than lactic acid and volatile fatty acid (VFA) (Cao et al. 2009). During the ensilage process, some bacteria are able to break down cellulose ad hemicelluloses to various simple sugars. Other bacteria break down simple sugars to smaller end products (acetic, lactic, and butyric acids). The most desirable end products are acetic and lactic acid. As the bacteria degrade starches and sugars to acetic and lactic acid, dry mater is lost. As bacteria consume sugars, end products produced, as it is the most efficient fermentation acid and will drop the pH of the silage the fastest. The faster the fermentation is completed, the more nutrients will be retained in the silage. Addition of carbon and nitrogen sources could improve the quality of silage. Therefore, the aim of this study was to investigate the effect of molasses and urea supplementation on whole crop rice silage quality and rumen degradation.

Materials and methods

Whole crop rice silage

Whole crop rice was harvested 120 days and immediately chopped to 2–3-cm length and ensiled to the respective supplementation treatments according to a 6 × 5 factorial arrangements in CRD. Factor A was molasses (M) supplementation at 0, 1, 2, 3, 4, and 5 %, and factor B was urea (U) supplementation at 0, 0.5, 1.0, 1.5, and 2.0 % of the crop DM. Whole crop rice was mixed with M and U and then packed into plastic bags. The silage bags were kept in ambient temperature (about 25–30 °C). All treatment combinations were done in triplicates at 1 kg each. After 45 days of ensiling, temperature and pH of silage were measured, and 200 g of whole crop rice silage were sampled for later chemical analysis. The samples were divided into two parts; first part was for DM analysis and second part was dried at 60 °C for 48 h and ground to pass through a 1-mm sieve in the feed mill using Cyclotec Mill, Tecator, Sweden for analysis of DM, OM and CP (AOAC 1990), and ADF and NDF (Van Soest et al. 1991).

In addition, silage was rinsed with distilled water and collected for volatile fatty acid analysis by using high-pressure liquid chromatography (Instruments by Water and Novapak model 600E; water mode l484 UV detector; column Novapak C18; column size 3.9 × 300 mm; mobile phase10 mM H2PO4 [pH 2.5]) according to Samuel et al. (1997).

In situ trial

Ten treatment combinations were selected to study on rumen degradation by using nylon bag technique. Treatments were U0M0, U0M3, U0M4, U0M5, U1.5M3, U1.5M4, U1.5M5, U2M3, U2M4, and U2M5, where U is urea levels, and M is molasses levels. Samples were collected, oven-dried at 60 °C for 72 h, ground passed through a 1-mm screen and prepared for in Sacco analysis. Ruminal DM degradation of the feed fractions was determined by the nylon bag technique (Orskov and McDonald 1979). Bags, 8 × 14 cm in size with a pore size of 40 μm, were used. Two grams of each sample treatments were placed into the bags and tied tightly with nylon thread. Two rumen fistulated swamp buffaloes, about 4 years old, with 440 ± 10 kg liveweight, were used in this study. All buffaloes were fed with rice straw ad libitum and supplemented with 0.5 % BW concentrate per day. All treatment bags were suspended in the rumen of swamp buffaloes. Incubation times (0, 3, 6, 9, 12, 15, 24, 48, and 72 h) were measured by placing the bags of each treatments into the rumen before the morning feeding and removals of two bags at each time. After removal, the bags were washed immediately in tap water until the water was clear and oven-dried at 60 °C for 72 h. Three bags of each treatment were washed under water without incubation in order to estimate losses at 0 h post feeding. Dry composited samples and the residues in the bag removed at the end of incubation time of treatments were measured for DM and organic matter (OM).

The ruminal disappearance characteristics of DM was fitted to the exponential following the procedure described by Orskov and McDonald (1979):

-

P = a + b (1-e-ct), where, p = disappearance (in percent) of DM and OM from the bags at the time t, a = proportion of immediately soluble faction of DM and OM (in grams per kilogram), b = potentially but not immediately degradable fraction (in grams per kilogram), c = fractional rate of soluble degradation (in percent per hour) of b, and t is the incubation time (in hours). Solubility of DM and OM were determined similarly by washing of 0 h bags.

-

Data were fitted by using the NEWAY program (Chen 1996). The effective degradability of nutrients was calculated using the equation shown below, using a rumen out flow rate (k) of 0.02 per hour which is an average value for animals fed at approximately maintenance level (AFRC 1993): ED = a + {bc/(c + k)}.

Statistical analysis

All data were subjected to analysis of variance using Proc. ANOVA, and responding to level of urea and molasses were tested using orthogonal polynomial (SAS 1998). Dry matter and OM degradation means were statistically compared using Duncan's new multiple range test (Steel and Torrie 1980).

Results and discussion

Nutritive value of WCRS

Effect of M and U supplementation on WCRS characteristics and nutritive values are shown in Table 1. Temperature and pH of WCRS were increased, while total volatile fatty acid, acetic acid, and propionic acid concentration was decreased linearly with increasing level of U. In contrast, supplementation of M decreased silage temperature, while no change of pH was found. Moreover, total volatile fatty acid (TVFA), acetic acid (C2), and propionic acid (C3) concentration were increased by M level supplementation. This was in contrast to the report of Alli et al. (1984) that silages were treated with M at a rate of 2.3 or 4.5 % fresh weight at the time of ensiling, which led to increased rates of lactic acid production, lower pH, and decreased DM loss. Lower pH value in silage could be due to higher lactic acid concentration in those silages. Cao et al. (2009) stated that lactic acid is the strongest of all silage acids, and its presence will drop pH more effectively than other VFA. The present study revealed that the result of pH was still above the ideal silage pH of 4.0 to 4.5. Moreover, proportion of C2/C3 was decreased with the increasing level of U supplementation in the silage, while M supplementation could increase the proportion of C2/C3. The VFAs comprises of C2, C3, butyric acid (C4), and other acids. The production of these acids is a reflection of an inefficient fermentation or of secondary fermentation of lactic acid to butyric acid and degradation of amino acids to ammonia with the production of acetic acid from the carbon skeleton of the amino acid (Santoso et al. 2011). Concentrations of TVFA, C2, and C3 were increased by M supplementation but not by U. This implied that M could improve the quality of silage. However, both U and M supplementation could increase the proportion of C4. The increased C4 in those silages could be due to higher pH (above 4.0 to 4.5) of the silage, which may favor the activity of clostridia. Santoso et al. (2011) stated that reducing pH silage prevented the growth of undesirable microbes, e.g., Listeria, clostridia, Enterobacteriaceae, and molds. However, it was found that interaction effect between M and U level was found on TVFA and proportion of C2/C3.

The greatest improvement in chemical composition was found in supplementation of U at 2 % and M at 4 % of the crop DM, which contained 15.2, 84.6, 63.7, and 47.2 % DM of CP, OM, NDF, and ADF, respectively. Based on this result, it showed that supplementation of M can improve WCRS quality, but not by U addition. Urea supplementation increased the CP content (P < 0.01). Moreover, both U and M supplementation decreased NDF content in the silage linearly. Molasses supplementation decreased DM and ADF content but U did not. However, OM, CP, and NDF were affected by interaction between U and M levels of supplementation. The nutritive values were relatively higher than the value of Ki et al. (2009), especially the CP content. Based on the findings of Khan et al. (2006) and Touqir et al. (2007a, b), who reported that increased concentrations of NDF and ADF but reduced CP in the silage were found when compared to whole rice crop, indicating the loss of CP during ensiling. This was similar to the present study that NDF and ADF content were increased by U supplementation; however, U level could increase the CP content in the present WCRS. On the other hand, M could reduce NDF and ADF content but not CP. This indicated that combination of U and M supplementation could enhance the quality of the WCRS.

Dry matter and organic matter digestibility

Table 2 shows WCRS on ruminal DM and OM degradability. It was found that water-soluble fraction (a) was highest in U1.5M3 and lowest in U0M0 (23.8 and 14.6 %, respectively). Potentially degradable fraction (b) differed among treatments (P < 0.05), which were the highest in U1.5M4 and lowest in U0M0 (55.6 and 45.0 %, respectively). Fractional rate of degradation was highest in U0M0 (0.025). Total rumen degradable fraction (a + b) and effective DM degradation similarly responded to treatments and were highest in U1.5M3 and lowest in U0M. Furthermore, although some researchers reported that adding M has no effect on DM digestibility (Granzin and Dryden 2005; Wang and Goetsch 1998, while others studies (Shellito et al. 2006; Sahoo and Walli 2008) have been reported that diets with M had higher ruminal DM digestibility. The OM disappearance (in percent) and estimated parameters of WCRS with different level of M and U are presented in Table 2. At all incubation times, there were significant (P < 0.05) differences in OM disappearance of U0M4 significantly (P < 0.05) higher than those supplemented. Therefore, supplementation of M and U at U0M4 had higher c, b, and ED than in other treatments. Organic matter disappearance could be decreased when M were increasing. However, U supplementation did not affect on OM digestibility.

Based on this study, it could be concluded that supplementation of U and M could efficiently increase whole crop rice silage quality and, thus, could provide good fermentation end product and chemical composition being high in protein and low in NDF contents. Present results suggested that supplementation of U and M to whole crop rice silage enhanced rumen degradation especially by addition U at 1.5 % and M at 3–4 % of the crop DM. Therefore, further study using whole crop rice silage supplemented with U and M in feeding trial emphasizing on lactating dairy cows and fattening beef cattle should be investigated.

Abbreviations

- WCRS:

-

Whole crop rice silage

- DM:

-

Dry matter

- M:

-

Molasses

- U:

-

Urea

- CP:

-

Crude protein

- ADF:

-

Acid detergent fiber

- NDF:

-

Neutral detergent fiber

- OM:

-

Organic matter

- TVFA:

-

Total volatile fatty acid

- C2:

-

Acetic acid

- C3:

-

Propionic acid

- C4:

-

Butyric acid

References

AFRC, 1993. Energy and protein requirements of ruminants. An advisory manual prepared by the AFRC Technical Committee on Responses to Nutrients. Compiled by G. Alderman, in collaboration with B.R. Cottrill. CAB International, Wallingford, UK.

Ajila, C.M., Brar, S.K., Verma, M., Tyagi, D.R., Godbout, S. and Valéro, J.R., 2012. Bio-processing of agro-byproducts to animal feed. Critical Review Biotechnology, 32 (4), 382–400.

Alli, I., Fairbairn, R., Noroozi, E. and Baker, B.E., 1984. The effects of molasses on the fermentation of chopped whole plant leucaena. Journal of the Science of Food and Agriculture, 35(3), 285–289.

AOAC 1990. Official methods of analysis. Association of Official Analysis Chemists, DC, U.S.A.

Bartzanas, T., Bochtis, D.D., Green, O., Sørensen, C.G. and Fidaros D., 2013. Prediction of quality parameters for biomass silage: A CFD approach. Computers and Electronics in Agriculture, 93, 209–216

Cao, Y., Takahashi, T. and Horiguchi, K., 2009. Effects of addition of food by products on the fermentation quality of a total mixed ration with whole crop rice and its digestibility, preference, and rumen fermentation in sheep. Animal Feed Science and Technology, 151, 1–11.

Cheli, F., Campagnoli, A. and Dell’Orto, V., 2013. Fungal populations and mycotoxins in silages: From occurrence to analysis. Animal Feed Science and Technology, doi:10.1016/j.anifeedsci.2013.01.013.

Chen, X.B., 1996. An excel application program for processing feed degradability data. Rowett Research Institute, Bucksburn, Aberdeen, UK.

Dunièrea, L., Sindou, J., Chaucheyras-Durand, F., Chevallier, I., Thévenot-Sergentet, D., 2013. Silage processing and strategies to prevent persistence of undesirable microorganisms. Animal Feed Science and Technology, 182, 1–15.

Granzin, B.C. and Dryden, G.M., 2005. Monensin supplementation of lactating cows fed tropical grasses and cane molasses or grain. Animal Feed Science and Technology, 120(1–2), 1–16.

Khan, M.A., Sarwar, M., Nisa, M., Iqbal, Z., Khan, M.S., Lee, W.S., Lee, H.J. and Kim, H.S., 2006. Chemical composition, in situ digestion kinetics and feeding value of Oat grass (Avena sativa) ensiled with molasses for Nili-Ravi buffaloes. Asian-Australasian Journal of Animal Science, 19, 1127–1133.

Ki, K.S., Khan, M.A., Lee, W.S., Lee, H.J., Kim, S.B., Yang, S.H., Baek, K.S., Kim, J.G. and Kim, H.S., 2009. Effect of replacing corn silage with whole crop rice silage in total mixed ration on intake, milk yield and its composition in Holsteins. Asian-Australasian Journal of Animal Science, 22(4), 516–519.

Mohd-Setapar, S.H., Abd-Talib, N. and Aziz R., 2012. Review on crucial parameters of silage quality. APCBEE Procedia, 3, 99–103.

Orskov, E.R. and McDonald, I., 1979. The estimation of protein degradability in the rumen for incubation measurements weighted according to rate of passage. Journal of Agricultural Science (G.B.), 92, 499–503.

Sahoo, B. and Walli, T.K., 2008. Effects of formaldehyde treated mustard cake and molasses supplementation on nutrient utilization, microbial protein supply and feed efficiency in growing kids. Animal Feed Science and Technology, 142(3–4), 220–230.

Samuel, M., Sagathewan, S., Thomas, J. and Mathen, G., 1997. An HPLC method for estimation of volatile fatty acids of ruminal fluid. Indian Journal of Animal Science, 67, 805.

Santoso, B., Hariadi, B.T., Manik, H. and Abubakar, H., 2011. Silage quality of king grass (Pennisetum purpureophoides) treated with epiphytic lactic acid bacteria and tannin of acacia. Media Peternakan, 30(2), 140–145.

SAS, 1998. User's Guide: Statistic, Version 6, 12th Edition. SAS Inst. Inc, Cary, NC.

Seppälä, A., Heikkiläa, T., Mäkia, M., Miettinenb, H. and Rinne, M., 2013. Controlling aerobic stability of grass silage-based total mixed rations. Animal Feed Science and Technology, 179, 54–60.

Shellito, S.M., Ward, M.A., Lardy, G.P., Bauer, M.L. and Caton, J.S., 2006. Effects of concentrated separator by-product (desugared molasses) on intake, ruminal fermentation, digestion, and microbial efficiency in beef steers fed grass hay. Journal of Animal Science, 84(6), 1535–1543.

Steel, R.G.D. and Torrie, J.H., 1980. Principles and procedure of statistics. New York: McGraw Hill Book Co.

Touqir, N.A., Khan, M.A., Sarwar, M., Nisa, M., Ali, C.S., Lee, W.S., Lee, H.J. and Kim, H.S., 2007a. Feeding value of Jambo grass silage and mott grass silage for lactating Nili buffaloes. Asian-Australasian Journal of Animal Science, 20, 523–528.

Touqir, N.A., Khan, M.A., Sarwar, M., Nisa, M., Lee, W.S., Lee, H.J. and Kim, H.S., 2007b. Influence of varying dry matter and molasses levels on berseem and lucerne silage characteristics and their in situ digestion Kinetics in Nili buffalo bulls. Asian-Australasian Journal of Animal Science, 20, 887–893.

Van Soest, P.J., Robertson, J.B. and Lewis, B.A., 1991. Methods for dietary fiber neutral detergent fiber and non-starch polysaccharides in relation to animal nutrition. Journal of Dairy Science, 74, 3583–3597.

Wang, Z.S. and Goetsch, A.L., 1998. Intake and digestion by Holstein steers consuming diets based on litter harvested after different numbers of broiler growing periods or with molasses addition before deep-stacking. Journal of Animal Science, 76(3), 880–887.

Weinberg, Z.G., Khanal, P., Yildiz, C., Chen, Y. and Arieli, A., 2010. Effects of stage of maturity at harvest, wilting and LAB inoculant on aerobic stability of wheat silages. Animal Feed Science and Technology, 158, 29–35.

Acknowledgment

The authors are grateful for the financial support, research collaboration, and facilitations of the Tropical Feed Resources Research and Development Center (TROFREC), Department of Animal Science, Faculty of Agriculture, Khon Kaen University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wanapat, M., Kang, S., Khejornsart, P. et al. Improvement of whole crop rice silage nutritive value and rumen degradability by molasses and urea supplementation. Trop Anim Health Prod 45, 1777–1781 (2013). https://doi.org/10.1007/s11250-013-0433-0

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11250-013-0433-0