Abstract

We generalize a model for friction at a sliding interface involving the motion of misfit dislocations to include the effect of thermally activated transitions across barriers. We obtain a comparatively simple form with the absolute zero-temperature Peierls barrier replaced by an effective Peierls barrier which varies exponentially with temperature, in agreement with recent experimental observations of thermally activated friction. Going further, we suggest a plausible method for generalizing the frictional drag at a more constitutive level by replacing the Peierls stress in a more general sense where the microstructure (e.g., dislocation density, grain size etc.) is built in. Last, but not least, we point out that when barriers are included the static coefficient of friction becomes larger than the dynamic coefficient of friction, which is an important connection to reality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A classic problem in tribology is to understand the nanoscale processes that lead to energy dissipation at a sliding surface. While there are many models for what is taking place at a macroscopic level where continuum elasticity and plasticity dominate (e.g., the Bowden–Tabor ploughing model [1]), as well as models for atom-by-atom processes (e.g., the Tomlinson model [2] or molecular dynamics simulations [3, 4]), less is known about processes which involve the collective motion of atoms at the nanoscale. Many decades of research has shown that for bulk crystalline materials the fundamental unit of plasticity is the dislocation. The macroscopic behavior under stress is dominated by the collective behavior of dislocations, how they interact with each other, as well as with barriers to dislocation motion such as point defects, grain boundaries, or second phases.

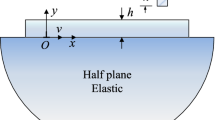

A sliding interface between two crystalline materials is really only a special case of plastic deformation, where the majority of the deformation is taking place at the interface itself. By geometry, misfit dislocations must exist at this interface, and we have previously [5] argued that one can understand many of the collective tribological phenomena by considering these dislocations as moving in a specific crystallographic environment, rather than some general isotropic medium. The density and character of these misfit dislocations are determined by the bicrystallography of the interface using the Coincident Site Lattice model developed by Bollmann [6, 7] and Grimmer et al. [8], and conventional contact mechanics [9–11]. Interfacial sliding can then be completely described by the motion of these dislocations. Dissipative forces, primarily phonon excitation, can then be analyzed using well-established (and proven) models for dislocations in the bulk [12–23, Indenbom VL, Orlov AN, 1967, presented at the proceeding conference dislocation dynamics, Kharkov, unpublished]; see also [24] for a recent paper which includes aspects of thermal activation, albeit in a different fashion. This comparatively simple model, which can be constructed in a closed, analytic form [5], does a reasonably good job of predicting frictional coefficients for a number of materials. Perhaps more importantly, one obtains very good agreement [25] with experimental measurements of frictional anisotropy [26, 27] and the size of wear debris [28], to give a few examples.

However, the model is far from perfect. Most importantly, it is a “Keep it Short and Simple” (KISS) model for a perfect, semi-infinite interface free of any defects. As mentioned above, it is well established that one has to consider additional dislocation barriers to obtain any reasonable model for bulk plasticity.

The intention of this note is to take a small step forward with this model, and to include barriers not just at absolute zero, but also at more realistic temperatures where thermal activation is included. We will show that the relevant form is in fact rather simple with an effective Peierls barrier/stress with a standard Arrhenius behavior replacing the zero temperature Peierls barrier/stress. Because this formulation is analytic, it also has predictive power. Our results on the temperature dependence of friction are in quite good agreement with recent experimental results where the friction was observed to increase exponentially with decreasing temperature in the low temperature range and increase gradually at the high temperature range with activation energy barriers of ~0.3 eV for the MoS2 basal plane [29] or 0.44 eV for PbS (100) [30]. This is approximately what would be expected if the barriers are point defects (see, for instance [31, 32]). Going further, we suggest a plausible method for generalizing the frictional drag at a more constitutive level by replacing the Peierls stress in a more general fashion where the microstructure (e.g., dislocation density, grain size etc.) is built in. Last, but not least, we point out that when barriers are included the static coefficient of friction becomes larger than the dynamic coefficient of friction, which is an important connection to reality.

2 Thermally Activated Dislocation Motion with Barriers

We will now generate a model to include the effect of barriers on the motion of dislocations sliding at an interface, based upon corresponding models for dislocations in bulk materials. The retarding force on a dislocation has two components which are intimately linked. The first is the barrier to motion of the dislocation, due to the local deformation of the atomic sites. The minimum stress to move a dislocation from one stable lattice site, a Peierls valley [33, 34], to the next is defined as the Peierls stress, and the total potential energy to overcome this barrier, the Peierls energy. In addition to this there is a quasi-viscous retardation since a dislocation moving in a crystalline material has a moving elastic strain field, and this interacts with other quasiparticles in the solid (electrons, plasmons, phonons etc.) much the same way that phonons do [5]. If the dislocation is moving slowly enough, the stored potential energy to overcome the barrier is dissipated as internal excitations, effectively as heat, before the dislocation climbs over the next barrier. In this limit, common in conventional plasticity, only the Peierls barrier matters. If the dislocations are moving fast enough (which they may be at a sliding interface), additional contributions from the viscous dissipative terms can become important.

The Peierls stress is determined by the nature and strength of the interatomic chemical bonds, the short range atomic ordering, the shape of the crystalline potential and the core structure of the dislocations [35, 36]. The amplitude of the Peierls stress varies from about 20–3000 MN/m2 for different crystals [37, 38]. In general, diamond-cubic semiconductors and some inorganic compounds have higher Peierls stresses, while close-packed metals and ionic crystals have lower ones. We start by writing the barrier as an energy [39],

where σP is the Peierls stress, b the Burgers vector, and a the translation distance for a single jump of a dislocation. Following Alshits et al. [22], the frictional back force including the velocity v d and the drag terms can be written as [5]:

where B is the total intrinsic drag coefficient due to quasiparticle excitations [5]. In addition to the lattice barrier, there are additional barriers due to obstacles such as precipitates, impurities, and vacancies which are often much larger. Following the concept of obstacle strength, we define a barrier energy including these at 0 K as,

where σ0 is the obstacle strength. We can then substitute from (3) into (2) to give the back force for a specific barrier. The average retardation can be written as an average, i.e.,

where P(E 0) is the probability of encountering an obstacle of a specific strength. If we now include temperature effects, the dislocation can “borrow” an energy ε from the thermal bath to overcome part of the barrier, which leads to a straightforward definition of an effective Peierls barrier as

And an average retardation of

A useful simplification can be made. Both at the low-velocity limit (when the viscous term drops out) and at the high-velocity limit (which is independent of the Peierls barrier) the integration over temperature can be replaced, exactly, by the effective barrier of Eq. 5. From numerical integration tests this can be done in general with minimal error leading to the simplification:

The numerical checks were performed for reasonable range of both Peierls stress and obstacle strengths from about 20 to 300 GN/m2, assuming Gaussian probabilities for P(E 0). For completeness, we note that an effective barrier is not quite the same as a temperature-dependent velocity as originally suggested by Landau [40] (see also [24] and references therein). Note that we are concerned here with the retarding force, rather than the velocity, hence the different form (Fig. 1 ).

To continue the analysis, we first need to define a reasonable model for the barriers. We will assume a Gaussian probability distribution of barrier strengths, as shown in the solid curve in Fig. 2. Here the maximum peak of obstacle numbers is at a medium strength [37, 38] of 2.5 × 108 Nm−2, and the figure also illustrates the effect of elevated temperature. Except at very low temperatures, only relatively strong obstacles are important, and in most cases the “true” Peierls stress of the defect-free material will be far less important than that due to defects in the material. If there are no obstacles at the sliding surface, the shape and position of interfacial dislocations related to the sliding asperity just depend on the mismatching of the crystalline structure between the asperity and sliding surface. In this case, there is no dependence on the specific location at the sliding interface, the sliding speed of the asperity, or the temperature, as illustrated in Fig. 3a, b. To account for the density, we also need to include the mechanism whereby the dislocation overcomes the barrier. For this, we will assume a simple and somewhat conventional model where the additional stress overcomes the barrier, inducing elongation of the line-length and shape of the dislocations, as sketched in Fig. 3c, d. In practice, in addition to the dependence on obstacle position, the line-length and shape of the dislocation is temperature dependent. We will ignore strengthening mechanisms such as those associated with Orowan loops, which can be included as appropriate. In this case, we can write P(E 0) as just the probability of encountering a given obstacle per unit area of the surface.

Schematics of the motion of dislocations. The dashed circle represents an asperity in contact with the sliding surface. The average velocities of dislocations and probe are the same in all cases (different from each other), and in the same direction as shown by the arrow in (a) and (c). a, b represent the asperity motion on a perfect surface without obstacles; c, d illustrate dislocations overcoming barriers during asperity motion

The final results including both velocity and temperature are shown in Fig. 4 for representative values of barrier strength. There are two key results:

-

(a)

At low velocities one has a classic thermally assisted reduction in the frictional retardation.

-

(b)

At high velocities the effect of temperature becomes smaller although there are components of the drag term B which are temperature dependent, primarily the term of the phonon-scattering components which will of course increase substantially with temperature.

These results are all for a finite velocity. One additional effect should be noted for a system at rest: in such a case the interfacial dislocations will be attracted to the barriers if they are locations of lower energy, or will be repelled from them if they are locations of higher energy. Therefore, the distribution of defects encountered by the dislocation at rest is different from that in steady-state motion. This automatically introduces a difference between the static and dynamic frictional coefficients, with the static frictional retardation being higher independent of the character of the barriers. For instance, consider two states:

-

(a)

The static state where the dislocations are in a low-energy configuration. If, for instance, the barriers are attractive then all the dislocations will intersect the barriers.

-

(b)

The dynamic state where the dislocations are moving. Again for the case where they are attractive there will be a smaller number of intersections.

To start moving there will be an additional energy cost corresponding to the energy needed to move from the lowest-energy configuration, at rest, to the steady-state structure. We note that without barriers there is no difference between these two. We can estimate the magnitude of the difference by considering the energy drop in the static configuration versus the quasi-steady state which will give a change in the back-force of

where 〈L〉 is the mean distance between obstacles.

One final extension is perhaps slightly speculative, but we believe it is justifiable. It would be useful to extend from the very specific formalism here to the more general case in which a complicated set of mobile dislocations at the interface interact with each other, other static dislocations in the material, as well as barriers. It would also be useful to extend away from purely crystalline materials in a more general sense, and to the realm of constitutive equations. If we ignore for the moment that we are dealing with quite rapid sliding and consider the equivalent bulk plasticity problem, the Peierls stress would be replaced by an effective resolved shear stress. We will argue that one can directly use this as an adequate approximation, i.e., write the retarding force as

where σeff would be the effective critical stress in the interfacial selvedge layer where deformation is taking place. The difference between the static and dynamic friction would have a similar behavior. In principle, one could construct a more complete model for interfacial friction, similar to how constitutive models have been generated from micromechanical models of collective dislocation motion. This is an avenue for future study.

3 Discussion and Conclusions

We have shown here that at least at a relatively simple level, one can obtain an analytical form for the friction which includes the effects of thermally activated crossing of barriers, and that this model can qualitatively be extended to a continuum limit. These results are in quite good agreement with recent experimental results of activation energy barriers of ~0.3 eV for the MoS2 basal plane [29] or 0.44 eV for PbS(100) [30], which is approximately what would be expected if the barriers are point defects. More rigorously, one should work more completely from micromechanical models (e.g., [41]) for the two-dimensional problem of a sliding interface. We suspect that the results, at least to first order, will be very similar to those in three dimensions. This limit would be appropriate for macroscopic problems where one needs to consider an effective frictional drag, averaged over a statistical distribution of bi-crystallographic interfaces, but of course it is not accurate and may be very inaccurate for nanoscale measurements with an atomic-force microscope or similar instrumentation.

One point worth repeating is that only when barriers are introduced does one obtains a difference between the static and dynamic coefficients of friction, and that both will have similar temperature dependence.

References

Bowden, F.P., Moore, A.J.W., Tabor, D.: The ploughing and adhesion of sliding metals. J. Appl. Phys. 14(80), 80–91 (1943)

Tomlinson, G.A.: A molecular theory of friction. Philos. Mag. 7(46), 905–939 (1929)

Harrison, J.A., White, C.T., Colton, R.J., Brenner, D.W.: Molecular-dynamics simulations of atomic-scale friction of diamond surfaces. Phys. Rev. B 46(15), 9700–9708 (1992)

Landman, U., Luedtke, W.D.: Nanomechanics and dynamics of tip–substrate interactions. J. Vac. Sci. Technol. B 9(2), 414–423 (1991)

Merkle, A.P., Marks, L.D.: A predictive analytical friction model from basic theories of interfaces, contacts and dislocations. Tribol. Lett. 26(1), 73–84 (2007)

Bollmann, W.: On the geometry of grain and phase boundaries: I. General Theory. Philos. Mag. 16(140), 363–381 (1967)

Bollmann, W.: On the geometry of grain and phase boundaries, II. Applications of general theory. Philos. Mag. 16(140), 383–399 (1967)

Grimmer, H., Bollmann, W., Warrington, D.H.: Coincidence-site lattices and complete pattern-shift in cubic crystals. Acta Cryst. A 30(MAR), 197–207 (1974)

Barthel, E.: On the description of the adhesive contact of spheres with arbitrary interaction potentials. J. Colloid Interf. Sci. 200(1), 7–18 (1998)

Johnson, K.L.: Contact Mechanics. Cambridge University Press, Cambridge (1985)

Unertl, W.N.: Implications of contact mechanics models for mechanical properties measurements using scanning force microscopy. J. Vac. Sci. Technol. A 17(4), 1779–1786 (1999)

Leibfried, G.: Über den Einfluß thermisch angeregter Schallwellen auf die plastische Deformation. Z. Phys. 127, 344 (1950)

Lubenets, S.V., Startsev, V.I.: Sov. Phys. Solid State 10, 15 (1968)

Alshits, V. I.: Progress in materials science. In: Indenbom, V. L., Lothe, J. Elastic Strain Fields and Dislocation, vol. 31, p. 625. Elsevier Science, Amsterdam (1992)

Alshits, V.I.: Sov. Phys. Solid State Ussr 11(8), 1947 (1970)

Alers, G.A., Buck, O., Tittmann, B.R.: Measurements of plastic flow in superconductors and the electron-dislocation interaction. Phys. Rev. Lett. 23(6), 290–293 (1969)

Kojima, H., Suzuki, T.: Electron drag and flow stress in niobium and lead at 4.2°K. Phys. Rev. Lett. 21(13), 896–898 (1968)

Hikata, A., Elbaum, C.: Ultrasonic attenuation in normal and superconducting lead; electronic damping of dislocations. Phys. Rev. Lett. 18(18), 750–752 (1967)

Tittmann, B.R., Bommel, H.E.: Amplitude-dependent ultrasonic attenuation in superconductors. Phys. Rev. 151(1), 178–189 (1966)

Mason, W.P.: Effect of electron-damped dislocations on the determination of the superconducting energy gaps of metals. Phys. Rev. 143(1), 229–235 (1966)

Huffman, G.P., Louat, N.: Interaction between electrons and moving dislocations in superconductors. Phys. Rev. Lett. 24(19), 1055–1059 (1970)

Alshits, V.I., Shtolberg, A., Indenbom, V.L.: Stationary kink motion in the secondary Peierls relief. Phys. Stat. Sol. B 50(1), 59–69 (1972)

Alshits, V.I., Sandler, Y.M.: Flutter mechanism of dislocation drag. Phys. Stat. Sol. 64, K45–K49 (1974)

Hiratani, M., Nadgorny, E.M.: Combined model of dislocation motion with thermally activated and drag-dependent stages. Acta Mater. 49(20), 4337–4346 (2001)

Merkle, A.P., Marks, L.D.: Comment on “friction between incommensurate crystals”. Philos. Mag. Lett. 87(8), 527–532 (2007)

Dienwiebel, M., Pradeep, N., Verhoeven, G.S., Zandbergen, H.W., Frenken, J.W.M.: Model experiments of superlubricity of graphite. Surf. Sci. 576(1–3), 197–211 (2005)

Dienwiebel, M., Verhoeven, G.S., Pradeep, N., Frenken, J.W.M., Heimberg, J.A., Zandbergen, H.W.: Superlubricity of graphite. Phys. Rev. Lett. 92(12), 1261011–1261014 (2004)

Merkle, A., Marks, L.D.: Friction in full view. Appl. Phys. Lett. 90, 641011–641013 (2007)

Zhao, X., Phillpot, S.R., Sawyer, W.G., Sinnott, S.B., Perry, S.S.: Transition from thermal to athermal friction under cryogenic conditions. Phys. Rev. Lett. 102, 1861021–1861024 (2009)

Zhao, X., Perry, S. S.: Appl. Phys. Lett. (2009) (submitted)

Weertman, J., Weertman, J.R.: Elementary Dislocation Theory, 2nd edn. Oxford University Press, Oxford (1992)

Hirth, J.P., Lothe, J.: Theory of Dislocations, 2nd edn. Krieger Publishing Company, Malabar (1982)

Bulatov, V.V., Kaxiras, E.: Semidiscrete variational Peierls framework for dislocation core properties. Phys. Rev. Lett. 78(22), 4221–4224 (1997)

Hirth, J.P., Lothe, J.: Theory of Dislocations, 2nd edn. Krieger Publishing Company, Malabar, FL (1992)

Duesbery, M.: The influence of core structure on dislocation mobility. Philos. Mag. 19, 501 (1969)

Guyot, P., Dorn, J.: Can. J. Phys. 45, 983 (1967)

Nadgorny, E.: Prog. Mater. Sci. 31, 1 (1989)

Teichler, H.: Berechnung des Peierls-potentials im diamantgitter mit Hilfe der pseudopotential methode. Phys. Status Solidi b 23, 341 (1967)

Wang, G., Strachan, A., Ҫğin, T., Goddard III, W.A.: Calculating the Peierls energy and Peierls stress from atomistic simulations of screw dislocation dynamics: application to bcc tantalum, Modelling Simul. Mater. Sci. Eng. 12, S371 (2004)

Landau, A.I.: The effect of dislocation inertia on the thermally activated low-temperature plasticity of materials. I. Theory. Phys. Status Solidi a 61(2), 555–563 (1980)

Mura, T.: Micromechanics of Defects in Solid. Springer, New York (1987)

Acknowledgment

The authors would like to thank the U.S. Air Force Office of Scientific Research for funding this study on Grant number FA9550-08-1-0016.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liao, Y., Marks, L.D. Modeling of Thermal-Assisted Dislocation Friction. Tribol Lett 37, 283–288 (2010). https://doi.org/10.1007/s11249-009-9520-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-009-9520-9