Abstract

Tribocorrosion behaviour of heat-treated NiP and NiP–SiC composite coatings was investigated in a 0.6 M NaCl solution. The tribocorrosion tests were performed in a linear sliding tribometer with an electrochemical cell interface. It was analyzed the influence of SiC particles dispersion in the NiP matrix on current density developed, on coefficient of friction and on wear volume loss. The results showed that NiP–SiC composite coatings had a lower wear volume loss compared to NiP coatings. However, the incorporation of SiC particles into the metallic matrix affects the current density developed by the system during the tribocorrosion test. It was verified that not only the volume of co-deposited particles (SiC vol.%) but also the number of SiC particles per coating area unit (and consequently the SiC particles size) have made influence on the tribocorrosion behaviour of NiP–SiC composite coatings.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Many coatings have been applied to increase the wear resistance of surfaces. Electrolytic codeposition is a low-cost and low-temperature method suitable for producing metal matrix composite coatings.

Ni–P alloys have attracted the attention of researchers in the last few decades due to its characteristics concerning the effect of phosphorous content on its crystalline structure [1]. A transition from a crystalline to amorphous structure takes place progressively with phosphorous content in electrodeposited Ni–P coatings, resulting in amorphous structures when it exceeds 15 at.% [2]. However, Ni–P alloys, present low hardness and consequently low wear resistance, restraining its use by industry. Crystalline Ni–P structures can be obtained, though, by heat treatment above 350 °C, when crystallization of nickel and precipitation of nickel phosphide, Ni3P, take place [1]. The heat treatment of Ni–P alloys has resulted in hardness of the order of 1000 Hv, the same as obtained for hard chromium [3]. Moreover, studies to improve the properties of NiP coatings have been performed and structures with better wear resistance have been successfully achieved by the incorporation of ceramic particles in the metallic matrix, such as SiC, Al2O3 and Cr2O3 [4–7].

The composite coatings electrodeposition process consists of SiC particles co-deposition in a NiP metallic matrix. The particles are intentionally added to the electrolyte during the electrochemical deposition. Several mechanisms are proposed to explain it [8–13]. Electroplated composite coatings with metallic matrix are used to obtain new layers with different properties under the technological point of view for industrial applications. The incorporated particles in a metallic matrix increase the wear resistance of some coatings and the tribological properties can be higher than those of hard chrome coatings. An equivalent mass loss was observed for NiP–SiC (17 at.% P) and hard chrome layers [14]. With the increasing availability of nanoparticles, the interest for electrolytic and electroless composite coatings containing nanoparticles is growing [15–17]. The major challenges with the codeposition of nanoparticles are the achievement of a high level of codeposition, and the agglomeration of particles suspended in the electrolytes.

Most of the research on NiP composites is focused on mechanical and wear properties [18–21] and corrosion resistance of these coatings [6–13, 22, 23]. The results from the electrochemical and tribological characterization showed a very complex particle/matrix system. Previous investigations on composite NiP and NiP–SiC coatings (mean size of SiC particles values about 600 nm) revealed that heat-treated NiP coating has a lower wear volume loss compared to composite NiP–SiC coatings in bi-directional ball-on-disc sliding tests [19]. On the other hand, some studies [22] concerning the corrosion resistance of Ni–P–SiC revealed that the corrosion resistance has a direct dependence of matrix/particles interface characteristics. The results showed that the densities of current developed by the heat-treated NiP–SiC composite coatings increased with the amount of particles incorporated, probably due to the voids produced by discontinuous interface around the particle. This effect, however, is more important for heat-treated composite coatings than as-plated ones.

Nevertheless, NiP–SiC composite coatings have been investigated to replace the hard chromium in conditions where a continuous sliding of the metal components is combined with the presence of an aggressive environment and in this case, when a metal or alloy is subjected to sliding wear in a corrosive environment, the total material removal rate differs from that predicted by simply adding the wear rate measured in the absence of corrosion and the corrosion rate observed in absence of wear [24, 25]. Hence, through tribo-electrochemical techniques it is possible to obtain combined effects during a wear test in an electrolyte under controlled conditions [26–31]. In this way, the tribo-electrochemical techniques will contribute to the fundamental understanding of chemical and mechanical effects in a total material degradation process.

The aim of this work is to study the tribocorrosion behaviour of heat-treated NiP–SiC (17 at.% P) composite coatings with different particles incorporated concentrations (number of SiC particles/μm2 and volume (%) of SiC particles). The electrochemical and tribological performances of the composite coatings were characterized by current density developed, coefficient of friction and wear volume loss in a 0.6 M NaCl solution.

2 Experimental

NiP–SiC (17 at.% P) composite coatings with different amount of SiC particles incorporated were prepared on steel substrates (A = 1.76 cm2) by electrodeposition from a plating bath containing NiSO4 50 g L−1, NiCl2 6H2O 60 g L−1, H3PO3 20 g L−1, H3PO4 50 g L−1, Na2SO4 50 g L−1 and different SiC particles concentration (with a mean diameter of 600 nm) in suspension. The electrolyte temperature was 80 °C and pH 2.

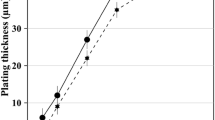

The electrodeposition was carried out at 0.1 A cm−2 current density for 45 min (what resulted in a 50 μm thickness composite coating measured by optical microscopy cross-sections) in a thermostatic cell (140 ml), where both static vertical electrodes were immersed. A stirring system was used keeping the particles in suspension and moving them towards the cathode.

After electrodeposition, the specimens were cleaned by ultrasound for 2 min, heat treated at 420 °C for 1 h in an inert atmosphere and polished before the tribocorrosion tests.

The particles incorporated per unit area were evaluated by image analysis (Imagetools software) of micrographs obtained by Scanning Electron Microscopy. The SiC particles volume (SiC vol.%) was evaluated through chemical analysis of composites and Energy Dispersive Spectroscopy (EDS).

The electrochemical behaviour of obtained composite coatings was investigated by cyclic voltammetry. Measurements were performed using a computer-controlled potentiostat EGG PAR model 273 in a conventional three-electrode cell. Platinum was used as a counter electrode and saturated calomel as a reference electrode. Potentiodynamic polarization was measured with a scan rate of 0.5 mV s−1, from −400 to +500 mV (SCE). The electrolyte was a 0.6 M NaCl solution (corrosive electrolyte) and the exposed area of working electrode was 0.64 cm2.

Vickers microhardness measurements were carried out at a load of 50 g along the metallographic cross-section of the samples.

Surface morphology and surface modifications of composite coatings were characterized by Optical Microscopy and Scanning Electron Microscopy.

During the tests wear samples were kept under potentiostatic control and the current density was monitored (tribocorrosion system). With this system it was possible to control mechanical and electrochemical parameters in the interface cell. The experiments were performed at room temperature (25 °C) in a 0.6 M NaCl solution. The same three-electrode setup employed for the cyclic voltammetry was used to impose an electrochemical potential on the exposed surface of the samples and to measure the current density. The given values of the electrochemical potential are referred to the SCE saturated in KCl electrode.

Tribocorrosion tests were conducted by reciprocating tribometer with a ball-on-plate configuration and properly interfaced to an electrochemical cell (Fig. 1); both were developed at Fraunhofer Institut (IPA). The tests were performed at a normal load of 8 N, an oscillation frequency of 2 Hz, a stroke length of 1 mm and an anodic potential (+400 mVSCE). The number of fretting cycles was 3,500. All the tribocorrosion tests were performed against 5 mm diameter corundum balls. Corundum balls have high wear resistance, good chemical inertness and high electrical insulating properties.

The volumetric material losses after the wear tests were determined by white light interferometry.

3 Results and Discussion

3.1 Elaboration of NiP–SiC Composite Coatings

The tribocorrosion behaviour of NiP–SiC (17 at.% P) composite coatings, with different particles incorporated concentrations, was investigated in this work (Table 1).

The SiC particles were embedded as individual particles in the NiP matrix (Figs. 2 and 3). And they were homogeneously distributed in the matrix through all the coating thickness (Fig. 3).

It was verified that, as it is shown in Fig. 4, the amount of SiC incorporated particle (SiC vol.%), evaluated by chemical analysis, increased rapidly, starting from low concentration of particles in suspension reaching a level of high concentration, which shows the saturation of the incorporation phenomenon, agreeing with the results reported in literature [7]. However, the SiC incorporated particle number by coating area unit, evaluated by images analysis (SEM micrographs), continued increasing with the quantity of particles in suspension. This effect was followed by the size reduction of the incorporated particle (Fig. 2 and Table 1) and demonstrated a selective phenomenon of incorporation that was discussed in previous works published [10, 22, 32, 33]. This selective phenomenon of incorporation can be explained based on the probability of mechanical interaction between the cathode and the particles in suspension. It should be considered that the particle is completely incorporated in the metallic matrix after a certain critical thickness of the deposit, when its ejection caused by arriving particles is not possible. The necessary time for the definitive incorporation of one particle is, therefore, a function of the particle size, i.e., the bigger the particle size, the larger the time required to its definite incorporation into the metallic matrix [13]. Grosjean [34] studying the SiC incorporation (average size of 1 μm, and granulometric distribution between 0.3 and 1.5 μm to 80% of the particles) in a NiP matrix obtained by autocatalytic (nickel electroless) reduction, observed a higher amount of incorporated particles with size between 0.3 and 0.9 μm, and the particles with size (over 3.9 μm) were not incorporated. Nevertheless, differently from the results presented in this work, this characteristic does not change as a function of the amount of particles in suspension; the author worked with low concentrations of SiC in suspension (from 5 to 30 g L−1) and used experimental conditions different from those used in the present work. The increase of particles concentration in suspension, increases the probability of ejection of the higher particles during the incorporation process, as a result of the impacts caused by particles in suspension. This effect reduces, therefore, the probability of incorporation of bigger particles comparatively to smaller ones, which are more rapidly incorporated and over which the impact is less effective. Because of that, the incorporation of smaller particles is more favourable [10]. For the codeposition of Ni–SiC with particle sizes between 0.3 and 5 μm, it was found that for a given number density of particles in the plating solution, the number density of codeposited SiC-particles increases with decreasing particle size. Hence, small SiC particles codeposit easier than large particles. Based on a relation between the number density of codeposited particles and the number density of particles in the plating solution, it was shown that the size and number density of SiC particles in the plating solution are important parameters in the codeposition process [32].

3.2 Electrochemical Behaviour of Heat Treated NiP–SiC Composite Coatings

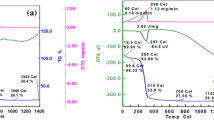

In previous investigations, it was shown [22] that not only the volume of co-deposited particles (SiC vol.%) but also the number of SiC particles per coating area unit (and consequently the SiC particles size) have an influence on the electrochemical behaviour of NiP–SiC composite coatings. The measurements of the open circuit potential showed no correlation between the measured potential and the amount of particles incorporated in the composite coatings. All the samples presented the mean values of open circuit potential by -270 mVSCE. However, the electrochemical measurements without load (Fig. 5) showed that NiP–SiC200 composite coatings developed higher current density than NiP–SiC80 and both had the same quantity of incorporated SiC600, in volumetric fraction (SiC vol.%). On the other hand, for the NiP/SiC200 composite coatings, the particle number by area units is about 50% higher than in the case of NiP/SiC80, due to size reduction of the incorporated particle. This behaviour indicates that the composite coatings containing smaller particles developed higher current density. The size reduction of the incorporated particle increased the metallic matrix/particle interface area; hence, the composite coating has a tendency to diminish its resistance against local corrosion, because of the voids produced by discontinuous interface around the particles. It was reported in the literature that there are voids in the composite coatings, producing discontinuous particle/matrix interfaces. Verelst [35] observed the formation of an interface between the nickel matrix and alumina particles. In the present work the results agree with those obtained by Garcia et al. [13], who observed the remarkable improvement on the susceptibility to localized corrosion of the nickel composite coatings containing sub-micrometric SiC-particles.

3.3 Tribo-Electrochemical Behaviour of Heat Treated NiP–SiC Composite Coatings

The tribocorrosion tests were performed at an anodic potential (+400 mVSCE) and this potential was chosen in the active region for all the studied samples (Fig. 5) and the typical current-time response recorded (Fig. 6), showed the current density evolution during the tribo-electrochemical measurements. A significant rise in the anodic current through to the NiP and NiP–SiC composite coatings is noticed continuously up to the end of the fretting-corrosion tests. This behaviour indicates that the surface is subjected to corrosion by dissolution.

It can be observed (Fig. 6) that samples of NiP and NiPSiC10 had a different performance under tribocorrosion comparatively to those NiPSiC80 and NiPSiC200 showing the influence of volume (%) of SiC particles incorporated. Nevertheless the volume (%) of SiC particles incorporated, and the number of SiC particles incorporated per unit area promoted the increase of current densities developed by NiPSiC80 and NiPSiC200 composite coatings, during tribocorrosion tests (Fig. 6).

It was shown (Fig. 6) that the composite coating NiPSiC200 developed higher current density than NiPSiC80 but both had the same quantity of incorporated SiC in volumetric fraction (Table 1 and Fig. 4). On the other hand, for the NiPSiC200 composite coatings, the particle number per unit area is about 50% higher than in the case of NiPSiC80 and the size reduction of the SiC particles incorporated was noticed (Fig. 2b, c). The results obtained by tribocorrosion tests are probably associated to the reduction in size of the particles incorporated, and consequently increasing of metallic matrix/particle interfacial area. This indicates that composite coating tends to have an unfavourable resistance against localized corrosion at the discontinuous interface around the particles, and it is more effective when smaller particles are co-deposited. In this case, compared to others systems, the high current density values developed by NiPSiC200 composite coatings can occur due to the predominance of reactions at the matrix/particle interface, because it was introduced a mechanical stress from wear process in this area. The gap in the interface increased with the mechanical work and contributed to local corrosion.

Some authors [13, 22, 35] noticed the notable improvement on the susceptibility to localized corrosion of the composite coatings.

The evolution of the friction coefficient (μ) with the sliding time is shown in Figs. 7, 8, and 9. The friction coefficient values of the coatings were very similar: 0.2 for NiP coatings and between 0.2 and 0.3 for NiP–SiC composite coatings. With increasing content of SiC particles in the NiP–SiC composite coatings, a slight increase in the friction coefficient is detected possibly due to the abrasion effect of the hard SiC particles during sliding test.

The tribocorrosion behaviour of sliding contacts under electrochemical control depends on many factors. Landolt [26] describes four types of parameters for these systems: (a) the mechanical solicitations which are related to equipment design and operation, (b) the electrochemical conditions prevailing at the rubbing metal surfaces, (c) the solution properties in the contact and (d) the materials and surface properties of the sample and the antagonist. These parameters usually do not act independently, but their effects on the tribocorrosion behaviour are mutually dependent. The role of third body particles (wear debris) is particularly very complex, because depending on their physical properties, they can act as an abrasive which accelerates wear or as a solid lubricant diminishing friction and wear.

The appearance of all wear tracks on NiP coating and NiP–SiC composite coatings were very similar and dependent on the amount of SiC particles in the composite coating (Fig. 10). The morphology of the wear tracks area is smooth, indicating probably a fine SiC particles pull out. Some scratches and cracks parallel to the direction of motion are also visible, it can be related with the wear debris, tensile stress in the coating, interface particle/matrix and scar tracks boundary as a cracking preferential point. A local corrosion process can occur into the wear tracks, at the interface matrix/particle, due to a local tensile stress induced by mechanical work.

Both affect the current density developed during the tribo-electrochemical measurements.

Micrographs of NiP (Fig. 10a) and NiPSiC10 (Fig. 10b) composite coatings after tribocorrosion tests showed cracks on borders and in the tracks of wear. Sample NiPSiC80 (Fig. 10c) presented cracks on tracks of wear borders and the sample of NiPSiC200 (Fig. 10d) did not show any cracks.

The microhardness (HV) of composites coatings was measured and the gain in microhardness (in relation to NiP metal matrix without particles incorporated) versus content of SiC particles incorporated was plotted (Fig. 11). It was verified that the microhardness (HV) increases as a function of amount of SiC particles incorporated (number of particles/area unit). These results agree with some results showed in literature that became clear the inhibitor effect of disperses SiC particles incorporated in the metal matrix on the grain growth promoting the hardness increasing [35].

It was also noticed a decrease in wear rate (Table 1 and Fig. 10) to NiPSiC80 and NiPSiC200 composite coatings which exhibited smaller size of tracks (better resistance to the wear) compared to NiP and NiPSiC10. This result seems to be mainly due to the presence of high percentage in volume (vol.%) of SiC particles incorporated in the metal matrix of these metallic matrices (optimum level), and that, over this limit, under tribocorrosion conditions, the corrosion resistance of composite material is reduced.

Many factors can affect the tribocorrosion resistance of NiP–SiC. The presence of debris (from matrix and SiC particle) on the surface, cracks (exposition of substrate), reduction of SiC particles in the composite and residual stress through loading can simultaneously act.

The current density value can be related to the electrochemical/mechanical process inside the wear track and also to the electrochemical process on exposed area (outside the wear track). The current density and friction coefficient indicate a change on the surface, but they are not going necessary in the same direction. The increase of friction coefficient values indicates a surface deterioration (material loss, debris formation and cracks), at the same time, the current density increase is related to an electrochemical/chemical corrosion process on the surface.

The electrochemical process can generate products and when they are as a lubricant, it reduces or stabilizes the friction coefficient. On the other hand, lubricant products can not be generated through electrochemical process. And together with surface roughness change and debris, there is a friction coefficient increase. It depends on applied potential, electrolyte and wear conditions.

4 Conclusions

Similar tribocorrosion behaviour was observed for NiP–SiC composite coatings with low particles incorporated concentration (NiPSiC10 and NiP coating). However, the tribocorrosion tests revealed that, for the composite coatings with a higher particles incorporation in the metallic matrix (NiPSiC80 and NiPSC200), the increase of volume percentage (vol.%) of SiC particles incorporated compromised the electrochemical properties but improved the wear resistance of these coatings compared to NiP and NiPSiC10.

The results showed that the resistance of NiP–SiC composite coatings can be reduced due to reactions at the matrix/particle interface, when factors related to the mechanical and electrochemical behaviour were combined. The current density developed by NiP–SiC composite coatings increased with the amount (number of SiC particles by area unit) of SiC particles incorporated. In the case of NiPSiC80 and NiPSiC200 a significant wear material loss was not observed but the increase of current density was evidenced, indicating an intensive corrosion process.

References

Bonino, J.P., Bruet-Hotellaz, S., Bories, C., Pouderoux, P., Rousset, A.: Thermal stability of electrodeposited Ni-P alloys. J. Appl. Electrochem. 27, 1193–1197 (1997)

Färber, E., Cadel, A., Menand, G., Schmitz, R.: Kirchheim phosphorus segregation in nanocrystalline Ni-3.6 at.% P alloy investigated with the tomographic atom probe (TAP). Acta Mater. 48, 789–796 (2000)

Vaillant S., Datas L., Bonino J.-P.: Co-dépôt électrolytique de particules de SiC dans une matrice Ni-P—Synthèse et propriétés mécaniques. Matériaux & Techniques. 11–12, 47–54 (2001)

Apachitei, I., Tichelaar, F.D., Duszczzyk, J., Katgerman, L.: The effect of heat treatement on the structure and abrasive wear resistance of autocatalytic Ni-P and Ni-P-SiC coatings. Surf. Coat. Tech. 149, 263–278 (2002)

Schenzel, H.G., Kreye, H.: Improved corrosion resistance of electroless nickel-phosphorus coatings. Plating Surf. Finish. 77, 50–54 (1990)

Malfatti, C.F., Ferreira, J.Z., Santos, C.B., Souza, B.V., Fallavena, E.P., Vaillant, S., Bonino, J.P.: NiP/SiC composite coatings: the effects of particles on the electrochemical behaviour. Corros. Sci. 47, 567–580 (2005)

Shawki, S., Hamid, Z.A.: Deposition of high wear resistance of Ni-composite coatings. Anti-Corr. Meth. Mater. 44, 178–185 (1997)

Graydon, J.W., Kirk, D.W.: Suspension electrodeposition of phosphorus and copper. J. Electrochem. Soc. 137(7), 2061–2066 (1990)

Hovestad, A., Jansem, L.J.J.: Electrochemical codeposition of inert particles in a metallic matrix. J. Applied Electrochem. 25(6), 519–527 (1995)

Celis, J.P., Roos, J.R., Buelens, C.A.: Mathematical model for the electrolytic codeposition of particles with a metallic matrix. J. Electrochem. Soc. 134(6), 1402–1408 (1987)

Guglielmi, N.: Kinetics of the deposition of inert particles from electrolytic baths. J. Electrochem. Soc. 119, 1009–1012 (1972)

Fransaer, J., Celis, J.P., Roos, J.R.: Analysis of the electrolytic codeposition of non-brownian particles with metals. J. Electrochem. Soc. 139(2), 413–425 (1992)

Garcia, I., Conde, A., Langelaan, G., Fransaer, J., Celis, J.P.: Improved corrosion resistance through microstructural modifications induced by codepositing SiC-particles with electrolytic nickel. Corros. Sci. 45(6), 1173–1189 (2003)

Vaillant, S.: Revêtements composites NiP/SiC électrodeposés: elaboration et caractérization des proprietés mécaniques. PhD thesis, Universite Paul Sabatier, Toulouse, France (2002), p. 170

Kuo, S.L., Chen, Y.C., Ger, M.D., Hwu, W.H.: Nano-particles dispersion effect on Ni/Al2O3 composite coatings. Mater. Chem. Phys. 86, 5–10 (2004)

Shi, Y.L., Yang, Z., Li, M.K., Xu, H., Li, H.L.: Electroplated synthesis of Ni-P-UFD, Ni-P-CNTs, and Ni-P-UFD-CNTs composite coatings as hydrogen evolution electrodes. Mater. Chem. Phys. 87, 154–161 (2004)

Bigdeli, F., Allahkaram, S.R.: Corrosion behavior of Ni-P-SiC nano-composite coating. Int. J. Mod. Phys. B 22, 3031–3036 (2008)

Aslanyan, I.R., Bonino, J.P., Celis, J.P.: Effect of reinforcing submicron SiC particles on the wear of electrolytic NiP coatings. Part 2: bi-directional sliding. Surf. Coat. Technol. 201(3–4), 581–589 (2006)

Aslanyan, I.R., Bonino, J.P., Celis, J.P.: Effect of reinforcing submicron SiC particles on the wear of electrolytic NiP coatings: Part 1. Uni-directional sliding. Surf. Coat. Technol. 200(9), 2909–2916 (2006)

Miranda, A., Ramalho, J.C.: Friction and wear of electroless NiP and NiP + PTFE coatings. Wear 259(7–12), 828–834 (2005)

Hou, K.H., Hwu, W.H., Ke, S.T., Ger, M.D.: Ni-P-SiC composite produced by pulse and direct current plating. Mater. Chem. Phys. 100, 54–59 (2006)

Zhao, Q., Liu, Y., Abel, E.W.: Effect of Cu content in electroless Ni-Cu-P-PTFE composite coatings on their anti-corrosion properties. Mater. Chem. Phys. 87(2–3), 332–335 (2004)

Kaisheva, M., Fransaer, J.: Influence of the surface properties of SiC particles on their codeposition with nickel. J. Electrochem. Soc. 151(1), C89–C96 (2004)

Takadoum, J.: The influence of potential on the tribocorrosion of nickel and iron in sulfuric acid solution. Corros. Sci. 38, 643–654 (1996)

Jemmely, P., Mischler, S., Landolt, D.: Electrochemical modeling of passivation phenomena in tribocorrosion. Wear 237(1), 63–76 (2000)

Landolt, D., Mischler, S., Stemp, M.: Electrochemical methods in tribocorrosion: a critical appraisal. Electrochim. Acta 46(24–25), 3913–3929 (2001)

Assi, F., Böhni, H.: Study of wear-corrosion synergy with a new microelectrochemical technique. Wear 233–235, 505–514 (1999)

Mischler, S., Ponthiaux, P.: A round robin on combined electrochemical and friction tests on alumina/stainless steel contacts in sulphuric acid. Wear 248(1–2), 211–225 (2001)

Fedrizzi, L., Rossi, S., Bellei, F., Deflorian, F.: Wear-corrosion mechanism of hard chromium coatings. Wear 253, 1173–1181 (2002)

Ponthiaux, P., Wenger, F., Drees, D., Celis, J.P.: Electrochemical techniques for studying tribocorrosion processes. Wear 256(5), 459–468 (2004)

Jemmely, P., Mischler, S., Landolt, D.: Electrochemical modeling of passivation phenomena in tribocorrosion. Wear 237, 63–76 (2000)

Garcia, I., Fransaer, J., Celis, J.P.: Electrodeposition and sliding wear resistance of nickel composite coatings containing micron and submicron SiC particles. Surf. Coat. Technol. 148(2–3), 171–178 (2001)

Malfatti, C.F., Veit, H.M., Menezes, T.L., Ferreira, J.Z., Rodriguês, J.S., Bonino, J.P.: The surfactant addition effect in the elaboration of electrodepositated NiP-SiC composite coatings. Surf. Coat. Technol. 201, 6318–6324 (2007)

Grosjean, A.: Étude Fondamentale et Appliquée des Dépôts de Nickel Chimique avec Incorporation de Particules Minerales. PhD thesis, I’u. F.R. Des Sciences et Tecniques de Universitéde Franche-Comté, France (1998), p. 215

Verelst, M., Bonino, J.P., Brieu, M., Rousset, A.: Thermomechanical properties of Ni-Al2O3 metal matrix composites produced by electroforming. Mater. Sci. Eng. A 191, 165–169 (1995)

Acknowledgements

The authors acknowledge the financial support from CNPq, CAPES, FAPERGS, DAAD, and Brasilien Zentrum (BW).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Malfatti, C.F., Veit, H.M., Santos, C.B. et al. Heat Treated NiP–SiC Composite Coatings: Elaboration and Tribocorrosion Behaviour in NaCl Solution. Tribol Lett 36, 165–173 (2009). https://doi.org/10.1007/s11249-009-9471-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-009-9471-1