Abstract

The films of three kinds of 3-butyl-1-methylimidazolium base ionic liquids with thickness of 2 nm were prepared on hydroxyl-terminated and amino-terminated Si substrates by dip-coating method. As anions, tetrafluoroborate, hexafluorophosphate, and adipate, respectively, were chosen. The tribological performances of these thin films were examined by the determination of the film durability and friction coefficient by means of a UMT-2MT tribometer using a steel ball as counterpart. The morphologies of worn surfaces were investigated by a non-contact interferometric microscope. The findings showed that 3-butyl-1-methyl-imidazolium hexafluorophosphate having the poorest hydrophilicity of the ionic liquids exhibited the best tribological properties on aminated Si surface at 0.4 N and 4 Hz.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Ionic liquids, a kind of novel material, have attracted great attention due to their unique properties, such as negligible volatility at a relatively high temperature, non-flammability and high-thermal stability, etc. [1], and they have been used in many potential applications, especially in recent years, for instance, catalysis, electrochemistry, separation science for extraction of heavy metal ions, as solvents for green chemistry and materials for optoelectronic applications [2–5]. The above-mentioned properties of ionic liquids make them potential excellent lubricants. Therefore, extensive efforts have been made to understand the lubrication effect of ionic liquids. Ye et al. [6] investigated the tribological behavior of two kinds of alkylimidazolium tetrafluoroborate, and found them versatile lubricants for the contacts of steel/steel, steel/aluminum, steel/copper, steel/SiO2, Si3N4/SiO2, steel/Si (100), steel/sialon ceramics. More studies [7–10] have been done to investigate the tribological properties of other alkylimidazolium base ionic liquids and proved them superior to traditional lubricants—such as X-1P, PFPE, and ZDDP—in terms of anti-wear performance and load-carrying capacity. Bermúdez et al. [11–13] discovered that some ionic liquid additives had better lubricating and anti-wear properties than neat ionic liquids in aluminum/steel contact. Recently, some ionic liquids with cations such as phosphonium, pridinium and ammonium and functionalized ionic liquids were synthesized and proved to have better tribological properties than common alkylimidazolium base ionic liquids [14–17].

More recently, ultra-thin ionic liquid films with 30–50 nm were prepared and investigated. Yu et al. [18] prepared two kinds of ionic liquid films carrying vinyl and hydroxyl functional groups on modified Si surfaces and investigated their tribological properties on a dynamic-static friction coefficient measurement apparatus with PFPE as a comparison. They found 1-allyl-3-hexyl-imidazolium hexafluorophosphate films on hydroxyl-terminated and vinyl-terminated surface showed excellent reduction-friction and anti-wear properties and the ionic liquid exhibited better friction-reducing and anti-wear abilities than the Zdol-2000 film. They attributed the excellent tribological properties of these ionic liquid films to their strong adsorptions to the interface and the good transfer film-forming abilities on the counterpart surfaces. Yu et al. [19, 20] synthesized several kinds of novel ionic liquids and tested their tribological properties as thin films. They found that asymmetrical bis-substituted ionic liquids have the best tribological properties among the tested lubricants, i.e., PFPE, corresponding ionic liquids with single cation, and symmetrical bis-substituted ionic liquids, and the anti-wear life of these films increased with the increment of chain length. These ultra-thin ionic liquid films had been proved to be available film lubricants and have extensive applications in magnetic storage systems and micro/nano electromechanical systems (MEMS/NEMS), etc. However, such a thickness was still relatively large and if the thickness of films could be decreased to several nanometers, the efficiency of these applications could increase greatly.

In this article, three kinds of ultra-thin ionic liquid films with thickness of about 2 nm with the same cation but different anions were prepared, and the corresponding tribological properties of them were investigated. The relationships between the tribological properties of these ionic liquid films and their different hydrophilicities were also addressed.

2 Experimental

2.1 Materials

(3-aminopropyl) trimethoxysilane (APS, produced by Aldrich Chemical Company, purity≥97%) was commercial products and used directly. Since ionic liquids ever used mostly had an inorganic anion with one charge, a novel ionic liquid, 3-butyl-1-methyl-imidazolium adipate (denoted as IL3), which has an organic anion with two charges, was synthesized and was chosen as comparison. The other two ionic liquids, 3-butyl-1-methyl-imidazolium tetrafluoroborate (denoted as IL1) and 3-butyl-1-methyl-imidazolium hexafluorophosphate (denoted as IL2) were synthesized and purified exactly according to the reported methods [1]. Their chemical structures were characterized by means of 1H nuclear magnetic resonance spectroscopy (1H-NMR) with acetone-d6 as solvent. Scheme 1 shows the structures of these ionic liquids. All the other reagents of analytical grade were used as received.

2.2 Pretreatment of Silicon Wafers

Cleaned silicon wafers were immersed in Piranha solution (volume ratio 7:3 of 98% H2SO4 and 30% H2O2) at 90 °C for 40 min to get a hydroxyl-terminated surface [21]. The hydroxylated Si wafer was immersed in 5 mmol·l-1 APS/acetone solution for 24 h to obtain an amino-terminated surface [22]. Above two kinds of surfaces were rinsed three times with distilled water, and then dried in fast nitrogen flow.

Scheme 2 shows the schematic diagrams of two kinds of Si surfaces with different terminals.

2.3 Film Preparation

About 0.1, 0.2, 0.5, 1.0, and 2.0% (wt. %) ionic liquids were dissolved in acetone respectively. The corresponding films were prepared on the two kinds of surfaces mentioned above with dip-coating method. The thicknesses of these films were measured by L116-C ellipsometer (Gaertner, USA) equipped with a He–Ne laser (λ = 632.8 nm) at a fixed incidence angle of 50°. Figure 1 shows the relationship between the concentration of IL1 and the thickness of its film on amino-terminated surface. It could be seen that the film thickness is in proportion to the concentration of the ionic liquid solution. It should be noted that this relationship is also applicable to the other two ionic liquids of IL2 and IL3 if their concentrations were appropriate, for example, lower than 2.0%, though the figures were not shown here. According to this relationship, three kinds of ionic liquid films with a thickness of about 2 nm were easily prepared.

2.4 Ionic Liquids and Films Characterization

The thermal properties of three kinds of ionic liquids were examined on TGA-7 thermogravimetric analyzer (Perkin-Elmer, USA) from 25 °C to 800 °C with a heating rate of 10 °C·min-1 in flowing nitrogen. The static contact angles of distilled water on the films were measured on a CA-A contact angle meter (Kyowa Scientific Company Ltd., Japan). Five repetitive measurements were operated at different regions of the same film surface, and the averaged contact angles were obtained.

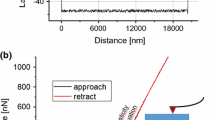

The friction and wear properties of these films were evaluated on a UMT-2MT tribometer in ambient condition (20–25 °C, RH = 30–40%) with a reciprocating-sliding mode. The reciprocating distance is 5 mm, and the reciprocating times per second are defined as frequency. A standard AISI-52100 steel ball of 3 mm in diameter was selected as the counterpart. The root mean square roughness (Rms) of the ball employed was about 50 nm. The chemical components of the film and the wear tracks were analyzed with a PHI-5702 multifunctional X-ray Photoelectron Spectroscopy (XPS), using Al Kα radiation as the exciting source. The binding energies of the target elements were determined at a pass energy of 29.35 eV, with a resolution of about ±0.3 eV, using the binding energy of contaminated carbon (C 1s: 284.8 eV) as the reference. The surface morphologies and wear tracks of the films on silicon wafers prepared as described in Sects. 2.1 and 2.2 were examined with non-contact interferometric microscope (ADE Phase-Shift).

3 Results and Discussion

3.1 Characterization of Ionic Liquids

TGA curves of the three kinds of ionic liquids are shown in Fig. 2. It shows that IL1 and IL2 have high decomposition temperature, assigned to 402.6 °C and 370.1 °C, respectively, but that of IL3 is about 264.4 °C. The reason for the difference in the three ionic liquids was assumed to their various anions since they have the same cation. A lower thermal stability of IL3 was probably due to its organic anion since IL1 and IL2, which have inorganic anions, exhibited higher-thermal stability. In addition, the source of the ∼2% weight loss observed at the beginning of the TGA curve for IL3 is unknown as there was no H2O or adipic acid observed in the 1H-NMR spectroscopy (not shown here).

3.2 Hydrophilic Properties of the Films

It is well known that the hydrophilic/hydrophobic property of ionic liquid depends on the attached alkyl chains of cation and counter anion [23, 24]. The contact angles of water on three kinds of ionic liquid films and two kinds of substrates pretreated with different methods are listed in Table 1. It can be clearly seen that the contact angles of water on hydroxyl-terminated and amino-terminated Si were below 5° and 44°, respectively, indicating that the hydrophilicity of amino-terminated Si substrate is poor in comparison with that of hydroxyl-terminated Si substrate. But the contact angles of water on IL1, IL2, and IL3 films were around 21°, 71°, and 27°, respectively, inferring that IL1 and IL3 exhibited better hydrophilicity than IL2. Moreover, the contact angles of water on the three ionic liquid films were almost same either on hydroxylated or on aminated Si surfaces, which may be due to the uniformity of the films coated on Si surface, and it could prove that the dip-coating was successful.

3.3 Tribological Properties

Tribological performance was evaluated for bare substrates of hydroxylated, aminated Si surfaces, and ionic liquid coated surfaces with film thicknesses of about 2 nm. The test parameters are listed in Table 2.

Without the protection of ionic liquid films, the bare substrates of hydroxyl-terminated and amino-terminated Si are easy to be broken (lifetime < 10 s) and the final friction coefficient is steady at 0.7.

Figure 3 presents three representative curves of friction coefficient versus sliding time for IL1, IL2, and IL3 films on amino-terminated surface at a load of 0.1 N and frequency of 2 Hz. The lifetime of films are defined as the sliding time when the friction coefficient increased sharply to 0.6. It can be seen that the lifetime of IL1 was lower than 50 s. The lifetime of IL2 and IL3 were >7,200 s and about 5,000 s, respectively, greatly longer than IL1.

Tables 3–5 present more detailed information about the tribological properties of the three ionic liquid films on both surfaces of aminated and hydroxylated Si.

Table 3 lists the friction coefficient and the lifetime of the IL1 films on two kinds of surfaces at different conditions. It shows that the friction coefficient of the film of IL1 on amino-terminated Si was kept constant, about 0.1, and its corresponding lifetime was about 471 s at a load of 0.1 N and a frequency of 1 Hz. With the increase of load or frequency, the film lifetime of IL1 on amino-terminated Si was shortened sharply and the film was almost broken at the beginning (<20 s). Compared to the film of IL1 on amino-terminated Si, the film of IL1 on hydroxyl-terminated Si was a little more stable. At 0.1 N and 1 Hz, the friction coefficient of IL1 film on hydroxyl-terminated Si was 0.09 and its corresponding lifetime was about 574 s. Also, with the increase of load or frequency, the IL1 film on hydroxyl-terminated Si became weak, and the film lifetime was nearly 0 when the load increased to 0.4 N or the frequency increased to 4 Hz.

Table 4 lists the friction coefficient and lifetime of IL2 films on two kinds of surfaces at various conditions. IL2 films had a long lifetime (>7,200 s) on both hydroxyl-terminated Si and amino-terminated Si even at a severe condition of 0.4 N and 4 Hz. For the film of IL2 on amino-terminated Si, its friction coefficient was about 0.11 at the load of 0.1 N and frequency of 1 Hz, and it slightly decreased with the increase of load or frequency. When the test load increased to 0.4 N and the frequency increased to 4 Hz, the friction coefficient of IL2 film even decreased to 0.07 and the lifetime was still beyond 7,200 s. For IL2 film on hydroxyl-terminated Si, its friction coefficient increased with increasing frequency under lower load (0.1 N) and finally even reached at 0.23. While under higher load (0.2 and 0.4 N) its friction coefficient decreased with the increase of the frequency and finally decreased to 0.07 at a load of 0.4 N and a frequency of 4 Hz with a long lifetime (>7,200 s).

The friction coefficient and the lifetime of IL3 films on two kinds of surfaces under different conditions are listed in Table 5. For IL3 film on amino-terminated Si, it exhibited lower friction coefficient under lower load of 0.1 N, and had a long lifetime (>7,200 s) at low frequency of 1 Hz. The friction coefficient of the film increased as load or frequency increased and its lifetime was mainly affected by the test frequency rather than load. When frequency reached 4 Hz, the film was almost broken at the beginning (<20 s). For IL3 film on hydroxyl-terminated Si, only at 0.1 N and 1 Hz, it had a low friction coefficient (∼0.06) and long lifetime (∼4,000 s). At other conditions, its lifetime was all lower than 20 s and its friction coefficient was hardly obtained, indicating that IL3 films on hydroxyl-terminated Si was not suitable for severe conditions.

According to the results above, it can be seen that IL2 film on amino-terminated Si exhibited almost the same friction coefficient and the longest lifetime compared with IL1 and IL3. Further more, a good wear resistance and friction-reducing effect were maintained even at a load of 0.4 N and a frequency of 4 Hz. While for the films of other ionic liquids, even though some kinds of film such as IL3 on amino-terminated surface exhibited good tribological properties at mild condition (0.1 N and 1 Hz), they were not able to be maintained when the load or frequency was increased.

3.4 Surface Characterization

Figure 4 gives the XPS survey spectra of IL2 film on amino-terminated Si before (signed as UW) and after (signed as AW) tribo-tests. No obvious chemical shift was observed after sliding tests, indicating that there was no chemical change occurred during the friction process and the good tribological properties of the film were not caused by producing of new chemical component. XPS spectra of IL1 and IL3 films on both surfaces before and after tribo-tests were also investigated (not shown here), the results also showed that no obvious chemical shift were observed.

Figure 5 presents the three-dimensional surface profile images of the worn surface of IL1, IL2, and IL3 films on hydroxyl-terminated Si investigated with a non-contact interferometric microscope. The films were tested with UMT-2MT for about 120 s at a load of 0.1 N and a frequency of 1.0 Hz. From the images, it can be seen that there exist very deep wear tracks (∼60 nm and ∼10 nm) on the surfaces of IL1 film (Fig. 5a) and IL3 film (Fig. 5c), respectively. However, the same phenomenon was not observed on the surface of IL2 film (Fig. 5b). But there existed obvious evidence of ionic liquid flowing back into the wear track of the IL2 films, indicating that IL2 had good mobility on the given surfaces. It is reported that the frictional properties of liquid film is mainly affected by the mobility of the lubricants [25]. When steel ball contacted with the film, it squeezed ionic liquid out and formed wear track, but when it left the contact point, part of ionic liquid flowed back into the wear track, protected the substrate. So it can be concluded that the better tribological properties of IL2 films should be attributed to their better mobility. Also, the worn surfaces of the three films on aminated Si surface were investigated (not shown here) and the same phenomena were observed.

Accordingly, IL1 and IL3 films, which had strong hydrophilicity, showed relatively poor tribological properties, especially IL1, who possess the highest hydrophilicity among the three kinds of ionic liquids. IL2 films, which had the weakest hydrophilicity, showed the best tribological properties under various testing conditions. So it is highly suggested that hydrophobic ionic liquids have better tribological properties than hydrophilic ionic liquids, especially on hydrophobic surface. However, obvious difference in the chemical component of the films between before and after tribo-test did not be observed, so the good tribological properties are not due to chemical change. Observing the worn surfaces, we can find some evidence of ionic liquids flowing back into the wear track of wearable films. Therefore, it is concluded that the good tribological properties of IL2 films are owing to their good mobility on substrates. Further more we recognize that low water content in the range of 1,000–5,000 ppm may impact the ionic liquid mobility. Future work will be done to quantify water levels in the ionic liquids and their films.

4 Conclusions

Three kinds of nano-scale ionic liquid films with thickness ranging from approximate 2–50 nm were successfully prepared with dip-coating method. The tribological properties of the three films with thickness of 2 nm were evaluated at the load range of 0.1–0.4 N and the frequency range of 1–4 Hz in ambient air. The following observations are noted:

-

(a)

3-butyl-1-methyl-imidazolium hexafluorophosphate (IL2) with a thickness of about 2 nm possessed the best triblogical performance and long lifetime even at a severe condition of 0.4 N and 4 Hz.

-

(b)

3-butyl-1-methyl-imidazolium adipate (IL3) possess better triblogical performance and long lifetime at mild condition of 1 Hz and 0.1–0.4 N on amino-terminated Si than on hydroxyl-terminated Si.

-

(c)

When ionic liquids have the same cation, their hydrophilic/hydrophobic properties are decided by their anions. For the ionic liquids mentioned in this article, tetrafluoroborate and adipate show hydrophilicity, while hexafluorophosphate shows relatively hydrophobic property.

-

(d)

When the hydrophobic ionic liquid IL2 was used as film, it performed better tribological properties than the hydrophilic ionic liquids 3-butyl-1-methyl-imidazolium tetrafluoroborate (IL1) and IL3. The main reason is presumed that the hydrophobic ionic liquid flows more smoothly on substrate than the hydrophilic ones.

-

(e)

The tribological properties of coated Si surfaces are mainly influenced by ionic liquids than by surface treatment.

References

Hagiwara, R., Ito, Y.: Room temperature ionic liquids of alkylimidazolium cations and fluoroanions. J. Fluor. Chem. 105, 221–227 (2000)

Welton, T.: Room-temperature ionic liquids. Solvents for synthesis and catalysis. Chem. Rev. 99, 2071–2084 (1999)

Wasserscheid, P., Keim, W.: Ionic liquids—new solutions for transition metal catalysis. Angew. Chem. Int. Ed. Engl. 39, 3772–3789 (2000)

Earle, M.J., Seddon, K.R.: Ionic liquids. Green solvents for the future. Pure Appl. Chem. 72, 1391–1398 (2000)

Nakashima T., Kawai T.: Quantum dots–ionic liquid hybrids: efficient extraction of cationic CdTe nanocrystals into an ionic liquid. Chem. Commun. 12, 1643–1645 (2005)

Ye C.F., Liu W.M., Chen Y.X., Yu L.G.: Room-temperature ionic liquids: a novel versatile lubricant. Chem. Commun. 21, 2244–2245 (2001)

Liu, W.M., Ye, C.F., Gong, Q.Y., Wang, H.Z., Wang, P.: Tribological performance of room-temperature ionic liquids as lubricant. Tribol. Lett. 13, 81–85 (2002)

Wang, H.Z., Lu, Q.M., Ye, C.F., Liu, W.M., Cui, Z.J.: Friction and wear behaviors of ionic liquid of alkylimidazolium hexafluorophosphates as lubricants for steel/steel contact. Wear 256, 44–48 (2004)

Lu, Q.M., Wang, H.Z., Ye, C.F., Liu, W.M., Xue, Q.J.: Room temperature ionic liquid 1-ethyl-3-hexylimidazolium-bis(trifluoromethylsulfonyl)-imide as lubricant for steel–steel contact. Tribol. Int. 37, 547–552 (2004)

Xia, Y.Q., Wang, S.J., Zhou, F., Wang, H.Z., Lin, Y.M., Xu, T.: Tribological properties of plasma nitrided stainless steel against SAE52100 steel under ionic liquid lubrication condition. Tribol. Int. 39, 635–640 (2006)

Iglesias, P., Bermúdez, M.D., Carrión, F.J., Martínez-Nicolás, G.: Friction and wear of aluminium–steel contacts lubricated with ordered fluids-neutral and ionic liquid crystals as oil additives. Wear 256, 386–392 (2004)

Jiménez, A.E., Bermúdez, M.D., Iglesias, P., Carrión, F.J., Martínez-Nicolás, G.: 1-N-alkyl -3-methylimidazolium ionic liquids as neat lubricants and lubricant additives in steel–aluminium contacts. Wear 260, 766–782 (2006)

Jiménez, A.E., Bermúdez, M.D., Carrión, F.J., Martínez-Nicolás, G.: Room temperature ionic liquids as lubricant additives in steel–aluminium contacts: Influence of sliding velocity, normal load and temperature. Wear 261, 347–359 (2006)

Liu, X.Q., Zhou, F., Liang, Y.M., Liu, W.M.: Tribological performance of phosphonium based ionic liquids for an aluminum-on-steel system and opinions on lubrication mechanism. Wear 261, 1174–1179 (2006)

Kamimura, H., Kubo, T., Minami, I., Mori, S.: Effect and mechanism of additives for ionic liquids as new lubricants. Tribol. Int. 40, 620–625 (2007)

Mu, Z.G., Zhou, F., Zhang, S.X., Liang, Y.M., Liu, W.M.: Effect of the functional groups in ionic liquid molecules on the friction and wear behavior of aluminum alloy in lubricated aluminum-on-steel contact. Tribol. Int. 38, 725–731 (2005)

Jin, C.M., Ye, C.F., Phillips, B.S., Zabinski, J.S., Liu, X.Q., Liu, W.M., Shreeve, J.M.: Polyethylene glycol functionalized dicationic ionic liquids with alkyl or polyfluoroalkyl substituents as high temperature lubricants. J. Mater. Chem. 16, 1529–1535 (2006)

Jin, C.M., Ye, C.F., Phillips, B.S., Zabinski, J.S., Liu, X.Q., Liu, W.M., Shreeve, J.M.: Polyethylene glycol functionalized dicationic ionic liquids with alkyl or polyfluoroalkyl substituents as high temperature lubricants. J. Mater. Chem. 16, 1529–1535 (2006)

Yu, G.Q., Zhou, F., Liu, W.M., Liang, Y.M., Yan, S.Q.: Preparation of functional ionic liquids and tribological investigation of their ultra-thin films. Wear 260, 1076–1080 (2006)

Yu, G.Q., Yan, S.Q., Zhou, F., Liu, X.Q., Liu, W.M., Liang, Y.M.: Synthesis of dicationic symmetrical and asymmetrical ionic liquids and their tribological properties as ultrathin films. Tribol. Lett. 25, 197–205 (2007)

Schreiber, F.: Structure and growth of self-assembling monolayers. Prog. Surf. Sci. 65, 151–257 (2000)

Chen, K., Caldwell, W.B., Mirkin, C.A.: Fullerene self-assembly onto (MeO)3Si(CH2)3NH2-modified oxide surfaces. J. Am. Chem. Soc. 115, 1193–1194 (1993)

Chen, K., Caldwell, W.B., Mirkin, C.A.: Fullerene self-assembly onto (MeO)3Si(CH2)3NH2-modified oxide surfaces. J. Am. Chem. Soc. 115, 1193–1194 (1993)

Chen, K., Caldwell, W.B., Mirkin, C.A.: Fullerene self-assembly onto (MeO)3Si(CH2)3NH2-modified oxide surfaces. J. Am. Chem. Soc. 115, 1193–1194 (1993)

Tsuboi, H., Kishii, N., Kamei, T., Kurihara, K., Kobayashi, K., Iwamoto, Y.: The influence of lubricant recovery on the coefficient of friction of lubricated metal-particulate flexible disks. Tribol. Int. 36, 417–422 (2003)

Acknowledgments

The authors thank the National Natural Science Foundation of China (NSFC 50675217), National 973 Program (2007CB607601), “100 Talents” Program of Chinese Academy of Sciences and Innovative Group Foundation (50421502) for the financial support of this work. The authors also thank Mr. Bo Wang for the XPS investigation and Ms. Xiaoning Wei for the NMR tested.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, M., Yan, J., Mo, Y. et al. Effect of the Anion on the Tribological Properties of Ionic Liquid Nano-Films on Surface-Modified Silicon Wafers. Tribol Lett 29, 177–183 (2008). https://doi.org/10.1007/s11249-007-9294-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-007-9294-x