Abstract

In this paper, we reported the tribological behaviors of polyelectrolyte multilayers (PEMs) containing copper hydroxide nanoparticles, polymer films were prepared by the sequential adsorption Poly(diallyldimethylammonium chloride) (PDDA) and poly(sodium 4-styrenesulfonate) (PSS) alternately on substrate. The nucleation of copper hydroxide nanoparticles was achieved using a cyclical absorption-hydrolysis process in which copper ions were absorbed into the polymer matrix (which bind to the sulfonate groups) and then hydrolysis in an alkali solution. The structure and the morphology of before and after the in-situ synthesis copper hydroxide nanoparticles in the PEMs matrix have been explored. The coefficient of friction as a function of sliding velocity and normal load also has been studied. The composites exhibited increased wear resistance compared with the pristine polymer films. This may partly be attributed to the enhanced load-carrying capacity of the inorganic nanoparticles in the PEMs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Modern magnetic storage systems and microelectro-mechanical systems (MEMS) require a protective coating which is crucial for providing lower friction, and higher antiwear life for inherently brittle electronic materials [1]. Molecular order films such as LB films, polyelectrolyte multilayers (PEMs) and self-assembled monolayers as one of the most promising technologies have drawn much attention.

PEMs have many advantages such as they are easy to fabricate; assembly is automated and proceeds at ambient conditions from aqueous solutions. The process is not associated with release of byproducts. Unlike other surface engineering techniques, PEMs can be assembled on a wide variety of substrates with little or no pretreatment. Devices with complex architectures can be coated uniformly over large areas. But, as we all know, Electrostatic interactions between the functional groups of the two polyelectrolytes is poor [2], antiwear life of PEMs is shorter when PEMs are sliding against counterpart [3]. If we enhance wear resistance of PEMs, they are thus ideally suited to combat the tribological challenges in MEMS operations.

In the recent years, PEMs as nanoreactors were reported in many fields, there were metal [4–7], semi-conductor [8], hydroxide [9,10] and oxy-hydroxide [11, 12] synthesized in PEMs. Their tribological properties, however, have received little or no attention.

The tribological behaviors of composite LB films consisted of organic molecule and inorganic nano- particles have been systematically investigated. Zhang and his copartner [13–15] reported that the LB films of nanoparticles modified with organic molecules have a higher antiwear life and load-carrying capacity, which is attributed to the enhanced load-carrying capacity of the inorganic nanocores in the LB films. They also suggested that C60 in LB films has “rolling effect”, which is related to the low friction force [16]. In addition, wear of polyetheretherketone (PEEK) is much reduced by having a filler of CuS through the effect of enhancing adhesive transfer of PEEK on to the counter surface [17]. So we can draw a conclusion nanoparticle plays an important role in enhancing the antiwear life of organic film.

In our previous work, we observed that Cu nanoparticles coated with organism as lubricating oil additive possess excellent load-carrying capacity and good antiwear property [18]. In the present work, we in-situ synthesize copper hydroxide nanoparticles in the PEMs matrix. The correlation between the structure, morphology and tribological behaviors of before and after the in-situ synthesis has been explored. The composites possess higher antiwear life compared with the pristine PEMs. And the friction coefficient of the composites has little affected by the normal load. It is thought that nanoparticles in the PEMs are influential on the tribological behaviors of PEMs.

Experimental

Materials

All materials were used without further purification. Poly (diallyldimethylammonium chloride) (M W = 100,000∼200,000; PDDA) and poly (sodium 4-styrenesulfonate) (M W = ca 70,000; PSS) were purchased from Sigma-Aldrich. And other chemicals used were all analytical pure reagents.

Deionized water ((18M Ωcm, Millipore Milli-Q) was used for preparation of all aqueous solutions, and during rinsing procedures.

PEMs assembly

Quartz slides, which were used as substrates for ultraviolet-visible (UV-vis) analysis and silicon slides used for other characterization were thoroughly cleaned by soaking in a piranha solution (H2O2:H2SO4 = 3:7 v/v) for 1 h at 80°C, followed by a rinse and sonication in deionized water. Caution: Extreme care must be taken at this step as piranha solution is extremely corrosive and is known to cause serious damage to skin and tissues. The piranha treatment removes traces of organic and inorganic impurities sticking to the surfaces of substrates and, at the same time, makes the surfaces hydroxylated.

The polyionic solution of PDDA and PSS were both prepared in 20 mM concentration. The former was dissolved in deionized water, while the latter was dissolved in a 0.1 M NaOH solution and then adjusted to a pH of 4.5 by dropwise addition of 0.1 M HCl. All concentrations were calculated based on the monomer molecular weights.

Polymer films were assembled on substrate using the layer-by-layer technique that consists of alternate deposition of PDDA and PSS layers. This procedure was described in detail elsewhere [8,10]. But deposition always ended with the first half of a layer pair in order to terminate the film with a PDDA layer.

The in-situ synthesis of copper hydroxide nanoparticles within the PEMs matrix

Nucleation of copper hydroxide nanoparticles within the polyelectrolyte multilayers occurred by cycling the polymer-coated substrates in Cu2+ and NaOH solutions. The polymer-coated substrates were exposed to the 5 mM or 20 mM Cu2+ solution for 1 min, removing excess Cu2+ by rinsing with purified water for about 20 s. And subsequently treated the slides with 10 mM or 0.1 M NaOH for 2 min (5 mM Cu2+ and 10 mM NaOH were used for UV-vis and transmission electron microscopy). Thus, each reaction cycle consisted of Cu2+ absorption followed by hydrolysis with sodium hydroxide. After each cycle the film was dried with nitrogen stream.

Characterization

UV-vis spectroscopy was used to monitor the multilayer assembly process and the influence of the in-situ synthesis copper hydroxide within PEMs. Whose type is Heλios α, produced by Unicam of UK.

Identification of the nanoparticles existence was determined via X-ray photoelectron spectroscopy (XPS) analysis. XPS was conducted with an axis ultra multi-technique electron spectrometer, produced by Kratos (UK). The AlKα radiation was used as the excitation source with pass energy of 40 mV. The binding energy of C1s (284.8 eV) was used as the reference.

The morphology of the films was studied using a SPA400 AFM (atomic force microscopy, made by Seiko Instruments Inc.) which was operated in tapping mode under ambient conditions (24 ± 2°C) using commercial silicon microcantilever probes. The values for the probe tip radius and probe spring constant are less than 10 nm and 17.5 N/m, respectively.

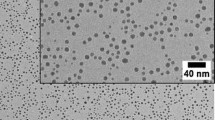

Samples for transmission electron microscopy (TEM) studies were prepared on Formvar-coated grids (300 mesh) with 4.5 layer pairs with 6 cycles of 5 mM Cu2+ and 10 mM NaOH solutions. Images of the films were taken on a JEM-100CX TEM made by Japan.

Tribological test

Tribological behaviors of PEMs containing copper hydroxide were studied using a LKDM-2000 tribology measurement apparatus, which generated reciprocating sliding motion in a ball-on-block configuration.

In all tests, the film surfaces were subject to single reciprocating motion over a 5 mm path length at a series of normal load and sliding speed. The GCr15 steel ball (3 mm in diameter) was selected as the counterpart. The steel ball was cleaned with acetone in a supersonic bath before each test. For tribological characterization at ambient conditions, no effort was made to control the humidity in the test area. Antiwear life was determined by the number of cycles when friction coefficient increase to about 0.70 (which was the value for Si sliding against the GCr15 steel ball).

Results and discussion

Structural characterization

The layer-by-layer deposition technique has emerged as a unique method of forming organized multilayers on substrates. We employed UV-vis spectroscopy for monitoring the layer pair deposition process. Figure 1 shows the UV-vis absorption spectrum of a pristine film of PDDA and PSS deposited on quartz slides in the 200–500 nm regions. The absorption band at 225 nm is due to the aromatic rings in PSS. The absorption of the film at 225 nm increases linearly with the number of layer pairs deposited (see inset of figure 1). The linear increase shows a uniform deposition of PSS with each layer.

A comparison of absorption spectra of before and after the in-situ synthesis of copper hydroxide within PEMs was showed in figure 2. There was significant increment in absorbance after 12 absorption-hydrolysis cycles. It indicates that copper hydroxide nanoparticles are formed in the PEMs with additional absorption-hydrolysis reaction cycles, though identification of the compound is difficult solely with UV-vis data.

To provide further evidence for the formation of Cu(OH)2, the sample was characterized by X-ray photo-electron spectroscopy (XPS). Figure 3 shows the XPS spectra of Cu 2p, the spectra are split by the 2p spin-orbit interactions into the 2p3/2 and 2p1/2 regions. In turn, each one of these two regions presents a main peak and a satellite caused by charge-transfer processes. These charge-transfer satellites are a common occurrence in the corelevel spectra of transition metal compounds. The spectrum of Cu(OH)2 shows the 2p3/2 main peak at 933 eV and the 2p1/2 main peak at 953 eV.

Morphological characterization

As we know, atomic force microscopy (AFM) is an increasingly popular technique to assess film roughness and morphology. Figure 4 shows the 3-dimension AFM images of the 4.5 bilayers pristine PEMs, 8.5 bilayers pristine PEMs, 4.5 layer pairs with 12 absorption-hydrolysis cycles, and 8.5 layer pairs with 12 absorption-hydrolysis cycles, respectively. They were all taken over an area of 5.0 μm × 5.0 μm.

The root-mean-square (RMS) roughness values were obtained from those AFM morphologies of PEMs, some interesting points can be found. The roughness of the films is enhancing as the number of layer increases. After the films passed twelve absorption-hydrolysis cyclical processes, the roughness of the films has decreased. Namely, the roughness of 4.5 bilayers pristine PEMs is 2.778 nm, and 3.939 nm for 8.5 bilayers pristine PEMs. While 4.5 bilayer pairs with twelve absorption-hydrolysis cycles and 8.5 bilayer pairs with twelve absorption-hydrolysis cycles have surface roughness RMS of 2.431 nm and 3.539 nm, respectively. These results show that the formation of Cu(OH)2 occurs in the PEMs and that the phenomenon is not a surface effect. If the surface of the PEMs was responsible for the nucleation phenomenon, the amount of copper hydroxide would remain the surface which could be observed here.

Figure 5b shows transmission electron micrograph (TEM) of Cu(OH)2 nanoparticles which were deposited six absorption-hydrolysis cycles in the 4.5 bilayers polyelectrolyte multilayers. By contrast, we also give a TEM micrograph of 4.5 layer pairs PDDA/PSS film (figure 5a)

From figure 5b, it can be seen that the particles present narrow size distribution with the average particle diameter is less than 50 nm. Most particles appear to be nearly spherical shape. In a single absorption-hydrolysis cycle (not shown), only a few nanoparticles are seen. With more cycles, additional nanoparticles are nucleated in the films, while existing particles grow in size.

Tribological behaviors of the films

Figure 6 shows the friction coefficient of 4.5 layer pairs and 8.5 layer pairs as a function of sliding velocity at a normal load of 0.5 N, respectively. In this work, we performed the test at sliding velocities in the range of 20 mm/min and 160 mm/min. As shown in figure 6a and b, the dependence of friction coefficient on sliding velocity is different for different number of layers. For 4.5 layer pairs, the friction coefficient is increasing and then approaches plateau at higher sliding velocities. But the friction coefficient of the PEMs containing Cu(OH)2 nanoparticles is higher than that of pristine PEMs. As for 8.5 layer pairs, the friction coefficient of the pristine PEMs is decreasing as sliding velocity increases and then approaches a constant value at higher sliding velocities. But the friction coefficient of the PEMs containing Cu(OH)2 nanoparticles is increasing, then reproaches a constant value, and then sharply rises at higher sliding velocity. The four films have no obvious change in surface roughness. But the PEMs matrix filled with copper hydroxide nanoparticles would decrease the mobility of the polymer chain segments which can undergo significant and reversible shear deformation [19,20], and the higher shear strength during relative motion must be overcome which results in the higher friction coefficient as compared to pristine films [21]. At the higher sliding velocity of 140 mm/min, we thought, a large number of nanoparticles were brushed off which made the friction coefficient sharply rise.

Figure 7 shows the friction coefficient as a function of normal load at sliding velocity of 100 mm/min. It can be seen that the friction coefficient of pristine PEMs is increasing as the normal load is reinforced. But the friction coefficient of the PEMs containing Cu(OH)2 nanoparticles does not have obvious change with the increasing normal load.

Figure 8 shows the variations in the friction coefficient with the sliding cycles for PEMs against GCr15 steel ball at sliding velocity of 100 mm/min under normal loads of 0.5 N and 1.5 N. Antiwear life was determined by the number of cycles when friction coefficient increases quickly. At normal load of 0.5 N, the antiwear life of 8.5 bilayers PEMs containing Cu(OH)2 nanoparticles is exceeding 1,500 cycles, and the 8.5 bilayers pristine PEMs records an antiwear life 1,100 cycles at the same load. At the higher normal load of 1.5 N, the 8.5 bilayers pristine PEMs registers the antiwear life only 250 cycles, while 8.5 bilayers PEMs containing Cu(OH)2 nanoparticles shows a sharp increment in the friction coefficient after sliding for about 700 cycles. It is indicates that the PEMs containing Cu(OH)2 nanoparticles are suitable to higher load application. Moreover, regardless of the load applied and the number of bilayers, PEMs containing copper hydroxide nanoparticles always has longer antiwear life than the same layer of pristine PEMs under a same load. So we can say the nanoparticles in the PEMs enhanced load-carrying capacity of PEMs [14,15]. But the mechanism of load-carrying of nanoparticles needs further investigations.

The coefficient of friction as a function of the number of sliding cycles at the normal load of (a) 0.5 N, (b) 1.5 N. (▴) 8.5 layer pairs containing copper hydroxide nanoparticles, (●) 8.5 bilayers pristine PEMs, (▼) 4.5 layer pairs containing copper hydroxide nanoparticles, (■) 4.5 bilayers pristine PMEs. (Sliding velocity: 100 mm/min).

Conclusions

In this work, we have focused on the effect of Cu(OH)2 nanoparticles deposited within the PEMs on the tribological behaviors of polyelectrolyte multilayers. We found that the friction coefficient of pristine PEMs is smaller and greatly affected by normal load. While the composite films which are composed of PDDA and PSS reinforced by nanoparticles enhance the antiwear life of the same layer of pristine PEMs, and the friction coefficient of the composites has little affected by the normal load, though the friction coefficient is higher than that of pristine PEMs. It is attributed to the enhanced load-carrying capacity of the inorganic nanoparticles in the PEMs.

References

Julthongpiput D., Ahn H.S., Kim D.I., Tsukruk V.V. (2002) Tribol. Lett. 13:35

Cao T., Wei F.,Yang Y., Huang L., Zhao X., Cao W. (2002) Langmuir 18:5186

Pavoor P.V., Gearing B.P., Bellare A., Cohen. R.E. (2004) Wear 256:1196

Joly S., Kane R., Radzilowski L., Wang T., Wu A., Cohen R.E., Thomas E.L., Rubner M.F. (2000) Langmuir 16:1354

Dai J., Bruening M.L. (2002) Nano Lett. 2:97

Wang T.C., Rubner M.F., Cohen R.E. (2003) Chem. Mater. 15:299

Shen Y., Liu J., Wu A., Jiang J., Bi L., Liu B., Li Z., Dong S. (2003) Langmuir 19:5397

Dutta A.K., Ho T., Zhang L., Stroeve P. (2000) Chem. Mater. 12:1042

Fojas A.M., Murphy, stroeve P. (2002) Ind. Eng. Chem. Res. 41:2662

Zhang L., Dutta A.K, Jarero G., Stroeve P. (2000) Langmuir 16:7095

Dante S., Hou Z., Risbud S., Strove P. (1999) Langmuir 15:2176

Dutta A.K., Jarero G., Zhang L., Stroeve P. (2000) Chem. Mater. 12:176

Yu L., Zhang P., Du Z. (2000) Surf. Coat. Technol. 130:110

Zhang P., Xue Q., Du Z., Zhang Z. (2000) Wear 242:147

Zhang P., Xue Q., Du Z., Zhang Z. (2003) Wear 254:959

Zhang P., Lu J., Xue Q., Liu W. (2001) Langmuir 17:2143

Koji Kato (2000) Wear 241:151

Zhou J., Zhang Z., Wang X., Liu W., Xue Q. (2000) Tribology 20:123 (in Chinese)

Arrighi V., McEwen I.J., Qian H.H., Serrano Prietob M.B (2003) Polymer 44:6259

Tsukruk V.V. (2001) Tribol. Lett. 10:127

Tsukruk V.V. (2001) Adv. Mater. 13:95

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China (Grant No, 20571024). Members of the characterization group are gratefully acknowledged for helpful assistance with the characterization of PEMs. The authors also thank Prof. Wang for insightful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Dr. Pingyu Zhang, Professor of Laboratory for Special Functional Materials, Henan University. He received his Ph. D. in physical chemistry from Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences. He worked on tribological study in State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences 1983 to 2003. After that he was engaged as a special visiting professor of Henan University. His main research interest is in study on tribology of ultrathin films of ordered assembling systems, tribology of coatings and Micro-nanotribology. And he has authored and co-authored over 40 journal articles in Langmuir, Thin Solid Films, and Wear etc.

Rights and permissions

About this article

Cite this article

Yang, G., Wu, Z. & Zhang, P. Study on the tribological behaviors of polyelectrolyte multilayers containing copper hydroxide nanoparticles. Tribol Lett 25, 55–60 (2007). https://doi.org/10.1007/s11249-006-9148-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-006-9148-y