Abstract

This paper describes the adsorption of the unsaturated fatty acids, oleic-, linoleic-, and linolenic acid onto steel coated quartz crystal surfaces from 2,2,4,4,6,8,8-heptamethylnonane as monitored by the quartz crystal microbalance (QCM) technique. It is shown that addition of fatty acid to the oil results in changes in bulk density and viscosity and that these changes must be considered before the sensed mass can be evaluated. The change in viscosity of the solution is larger for oleic acid than for linoleic acid and linolenic acid, which results in a larger correction for oleic acid with respect to bulk effects. After considering the effects due to changes in bulk properties, the influence of the viscoelastic properties of the adsorbed layer on the sensed mass was evaluated. The correction for the viscoelastic properties of the adsorbed layer was found to be very small for the systems studied. The sensed mass, at 1.1 weight percent, ranged from 0.5 mg/m2 for oleic acid to 5 mg/m2 for linolenic acid.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fatty acids are widely used as friction modifiers in fuels and oils. For this reason the adsorption of saturated fatty acids has been studied since the beginning of the 20th century. However, the underlying mechanisms on how the unsaturated fatty acids adsorb onto a steel surface is not yet fully understood. Nowadays, ellipsometry is often employed for measuring adsorption of surfactants and polymers onto surfaces since it is relatively quick and straightforward to use. However, this technique is less suitable for determining fatty acid adsorption from alkanes. The reason is that the ellipsometry response is dependent on changes in refractive index with increasing solute concentration and a clear difference in refractive index of the adsorbed layer and the solution. Since the difference in refractive index between fatty acids and alkanes is very small, it leads to difficulties with quantification and large uncertainty in the results. For this reason the quartz crystal microbalance (QCM) method was chosen for investigating adsorption of fatty acids from alkanes.

The QCM was initially developed for measuring the deposition of gas onto quartz. In the 1980s theories were developed that showed that the technique could also be used in fluids, and since then the QCM has found use in an increasing number of research fields. Nowadays the QCM is used to study, among other things, adsorption of surfactants from aqueous solutions [1,2], adsorption and swelling of polymer layers [3–5], viscoelastic properties of for example polymers [6,7], deposition of vesicles [8,9], and coadsorption of surfactant and polymers [10].

Reviews of the QCM technique have been provided by Benes [11], Mecea [12], and Kanazawa and Melroy [13] among others. In QCM, one normally uses gold electrodes that are sputtered or evaporated onto a single crystal of quartz with a particular cut (AT-cut). An electrical potential across the crystal causes a shear strain. By alternating the electric field, shear waves will be induced and when the quartz thickness is an odd, integer of half the wavelengths of the induced wave, electromechanical resonance will occur. Any increase in the mass will change the resonance frequency. The change in resonance frequency can be directly related to the added mass when it is rigid and firmly attached to the quartz surface. However, when the adsorbed layer is viscous or viscoelastic or not firmly attached to the surface the resonance frequency does not change linearly with the added mass and a more complex evaluation procedure has to be adopted.

Although aqueous solutions have been used most frequently in QCM studies, other solvents can be used as well. For instance, hexane was used for investigating adsorption of cholesterol surfactants [14] and alkanethiols [15], and the adsorption of asphaltenes and resin [16] have been studied in heptane/toluene mixtures. The QCM technique has also been applied in studies using more viscous solutions like oils [17,18].

In the present article results for adsorption of fatty acids from alkane solution as determined by QCM are reported. Three different fatty acids with 18 carbons in the hydrocarbon chain, but with different degrees of unsaturation, have been investigated in order to learn how the structure of the fatty acid affects the adsorption. Quartz crystals coated with steel have been used due to its relevance in tribological applications. The importance of making proper corrections for changes in the bulk properties, viscosity and density as well as for the viscoelastic properties of the adsorbed film has been evaluated for these systems. The common method of accounting for bulk effects is to replace the solution with pure solvent after allowing adsorption to occur. This only work when the adsorption is irreversible with respect to dilution, which is often a reasonable assumption for polymers [19]. However, for low molecular weight adsorbing species rinsing normally results in desorption, see e.g. [20] and the more elaborate experimental protocol described in this article has to be used.

Data evaluation

Investigations by Sauerbrey [21] at the end of the 1950’s on quartz crystal resonators showed that an added mass, Δm, to the quartz crystal induces a change in resonance frequency, Δf. This relation is linear as long as the added mass is rigid, firmly attached to the surface and small compared with that of the crystal. Equation (1) was derived and is now known as the Sauerbrey relation

where ρ q and ν q are the specific density and the shear-wave velocity in quartz, respectively, t q is the thickness of the quartz crystal, f 0 the fundamental resonance frequency and n is the harmonic number (ρ q=2648 kg/m3, ν q=3340 m/s, t q=0.33 mm, f 0=5 MHz, C is 0.177 mg/m2 in our system). Equation (1) has been shown to be accurate up to a mass load of 2% of the mass of the crystal [22].

The Sauerbrey relation was developed for adsorption from gas phase, and it was initially thought that liquid media would dampen the mechanical resonance completely. However, in the beginning of the 1980’s Nomura and Okuhara [23] showed that a quartz crystal does resonate in organic liquids and that the liquid induces a frequency change that is dependent on its density and viscosity.

Stockbridge [24] derived a relationship that describes how the frequency change is dependent on the density and viscosity for adsorption onto the crystal from vacuum or gas. Kanazawa and Gordon [25,26] extended this work to liquids and measured the frequency change in water with increasing concentration of glucose. Glucose does not adsorb at the surface, implying that the measured frequency change in this system is due to changes in bulk viscosity and density of the solution. The frequency changes received from the measurements were in good agreement with the values calculated from equation (2).

where μ q is the elastic shear modulus of quartz (2.95×1011 g/cm2), and ρ f and η f are the density and viscosity of the fluid.

Models for predicting the added mass, taking into account the viscoelastic properties of the attached layer, have been derived by Benes [11], Johannsmann et al. [27], Kanazawa [28] and Nwankwo and Durning [29] among others. Johannsmann et al. [27] have derived an expression allowing the true added mass to be calculated also for viscoelastic layers (equation (3)).

where \(\delta {\hat f}\) is the shift in the complex frequency and f 0 is the fundamental resonance frequency of the quartz crystal in air, respectively. Here f is the resonance frequency of the crystal in contact with solution, d is the thickness of the film and \({\hat J}(f)\) is the complex shear compliance.

Equation (3) can be transformed into a more convenient form by using the equivalent mass [27], which is defined by

and with this definition equation (3) reads

This equation can be used to calculate the true mass m 0 under the assumption that \({\hat J}(f)\) is independent of the frequency in the accessible frequency range. By calculating the equivalent mass (from equation (4)) using various harmonics (n), and then plotting the equivalent mass against the square of the resonance frequency f 2, m 0 is obtained as the intercept, provided a straight line is obtained. If the relationship is not linear the elastic compliance is not independent of the frequency. Finally we note that the true added mass is due to both the adsorbing species and solvent that may be incorporated within the layer and thus oscillate with the crystal. We will refer to this quantity as the true sensed mass to distinguish it from the adsorbed amount evaluated with ellipsometry, for example.

In 1995, Rodahl et al. [30] extended the use of the QCM technique when they showed how to measure the dissipation factor simultaneously as the resonance frequency. The measured change in dissipation is due to changes in the coupling between the oscillating sensor and the surroundings. It is affected by any energy dissipating process and thus influenced by the layer viscoelasticity and slip of the adsorbed layer on the surface. The dissipation factor D, is the inverse of the Q factor and defined by

where E dissipated is the energy dissipated during one period of oscillation and E stored is the energy stored in the oscillating system. During measurement, the driving power to the piezoelectric oscillator is switched on and off. The resonance frequency is measured when the oscillator is on and when it is turned off the amplitude of oscillation, A, decays as an exponentially damped sinusoidal function:

where τ is the decay time, ω is the angular frequency at resonance, ϕ is the phase angle and the constant, c, is the dc offset. The dissipation factor is related to the decay time through equation (8).

The dissipation changes with the density and viscosity of the solution according to equation (9) [31]. It is also affected by the properties of the adsorbed layer.

Experimental

Material

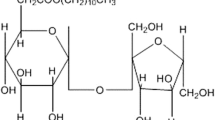

2,2,4,4,6,8,8-heptamethylnonane (98%) was obtained from Sigma-Aldrich. cis-9-octadecenoic acid (oleic acid), cis,cis-9,12-octadecadienoic acid (linoleic acid), and cis,cis,cis-9,12,15-octadecatrienoic acid (linolenic acid), with purities of 99.5, 99, and 99%, respectively, were purchased from Sigma-Aldrich. The chemicals were used as received. The surfaces used were quartz crystals coated with stainless steel, supplied by Q-Sense, Gothenburg, Sweden. The steel that was sputtered onto the quartz crystal is a Swedish standard steel number 2343.

Quartz crystal microbalance

The adsorption measurements were carried out employing a quartz crystal microbalance with dissipation measurements (QCM-D) from Q-sense, Gothenburg, Sweden. All measurements with the QCM were made at a temperature of 25 °C. The QCM cell, crystal and the tubing were cleaned with a 2% Hellmanex® II solution (an alkaline cleaning liquid from Hellma GmbH & Co. KG, Müllheim, Germany) for 1 h. The system was then rinsed with water (about 200 ml) and the crystal was removed and rinsed with more water and ethanol. The crystal was finally cleaned with a Harrich plasma cleaner, model PDC-32G, (5 min to pump down vacuum and 5 min on low effect, 6.8 W) to take away any remaining organic impurities. The surfaces composition of the steel after different stages of this cleaning process was determined with X-ray photoelectron spectroscopy, XPS, and it was observed that the oxygen content in the surface region had increased during plasma cleaning, i.e. the plasma produced an oxidized surface. The QCM cell and tubing were dried with nitrogen gas after which the crystal was remounted.

Density measurements

A density and sound velocity analyzer (DSA 5000) from Anton Paar, Austria was used for the density measurements. The temperature was kept at 25 °C. The density was found to be a linear function of the fatty acid content in the concentration range used as described by equation (10).

where C is the concentration of the fatty acid expressed in weight percent. The slope for the different systems, k 1 ( \({{\rm g}/{\left({{\rm ml}*{\rm w}\%}\right)}}\)), is given in table 1.

Viscosity measurements

The viscosity was measured with an Ubbekohde viscometer from SCHOTT-GERÄTE, Hofheim. The kinematic viscosity, ν, (mm2/s) is calculated from equation (11).

where K is the instrument constant, in this case 0.02726 mm2/s2, and t is the measured time of drainage in seconds. By multiplying the kinematic viscosity by the density, the dynamic viscosity is received. The measurements were performed at a temperature of 25 °C.

The viscosity was determined to be a linear function of the fatty acid content at the concentrations used as shown by equation (12).

The slopes for the different systems, k 2 (\({\rm g}/{\left({\rm cm*s*w\%}\right)}\)), are summarized in table 1.

It has been demonstrated, using the surface force apparatus, that the viscosity in thin films are the same as in bulk down to gap sizes of a few nanometers [32]. Thus, the bulk values of the viscosity and density are regarded as being the appropriate ones to use when correcting for bulk effects.

Results and discussion

The adsorption of the unsaturated fatty acids oleic, linoleic, and linolenic acid from a branched alkane, 2,2,4,4,6,8,8-heptamethylnonane, onto steel has been investigated with the QCM. The primary data obtained during a typical QCM measurement is illustrated in figure 1. In this example, three concentrations of oleic acid are injected, 0.005, 0.05 and 0.5 w% after 10, 30 and 50 min, respectively. A second measurement was made for oleic acid with the concentrations 0.01, 0.1 and 1.1 w%. The data obtained by increasing the concentration stepwise has been compared with those obtained by injecting one given concentration per experiment. It was found that both methods gave the same result to within 8%. Thus, the adsorption is a unique function of the bulk concentration, independent of how this bulk concentration is reached.

An illustration of the primary data obtained during a QCM experiment. The filled symbols are the frequency change and the unfilled are the dissipation change. The sudden changes in the graphs occur as a result of injecting increasing concentration of oleic acid in 2,2,4,4,6,8,8-heptamethylnonane (0.005, 0.05 and 0.5 w%). The number of the harmonic in this case is 3.

The frequency changes determined from the QCM measurements were first calculated into sensed mass using the Sauerbrey equation. These results are shown as circles in figures 2–4. To obtain the true sensed mass from the raw data, corrections were performed for changes in bulk properties, viscosity and density, as well as for the viscoelastic properties of the adsorbed film.

The sensed mass of oleic acid adsorbed from 2,2,4,4,6,8,8-heptamethylnonane. The uncorrected results are shown as circles. The squares are results obtained after correction for bulk effect. The triangles are the results obtained after correcting for bulk effects and the viscoelastic properties of the adsorbed layer.

The sensed mass of linoleic acid adsorbed from 2,2,4,4,6,8,8-heptamethylnonane. The uncorrected results are shown as circles. The squares are results obtained after correction for bulk effect. The triangles are the results obtained after correcting for bulk effects and the viscoelastic properties of the adsorbed layer.

The sensed mass of linolenic acid from 2,2,4,4,6,8,8-heptamethylnonane. The uncorrected results are shown as circles. The squares are results obtained after correction for bulk effect. The triangles are the results obtained after correcting for bulk effects and the viscoelastic properties of the adsorbed layer.

To calculate the effect of changes in density and viscosity the following procedure was used. Equation 2 provides the calculated value of Δf when moving the crystal from vacuum to liquid. To obtain the frequency shift due to the presence of fatty acids in the bulk phase, the calculated value for pure hexadecane is subtracted from the calculated value for the fatty acid solutions. The calculated frequency shift is then subtracted from the measured frequency shift and a frequency shift corrected for the changes in bulk properties is received. This corrected value is then used to calculate the sensed mass using equation (1). The sensed mass thus obtained is shown in figures 2–4 as squares. We note that the more common method of taking into account bulk effects, by rinsing with solvent, does not work in the present case due to partial desorption, and we found that this method produced irreproducible results, presumably due to ill-defined flow conditions during the rinsing process.

To calculate the true sensed mass, taking into account any effect of the viscoelastic properties of the adsorbed layer, the equivalent mass was calculated using equation (4) for the different harmonics. The frequency shifts obtained after correcting for bulk effects as described above were used as δf in equation (4). The true sensed mass obtained is shown as triangles in figures 2–4.

The corrections made for the bulk effects are of great importance for all three systems. It has the most pronounced effect for oleic acid since the viscosity is highest for this fatty acid and thus the change in viscosity between the solvent and fatty acid is most significant in this case. It is also observed that for these systems the change in viscosity is more important for the measured frequency change than the change in density.

The QCM used in this investigation can measure only three harmonics (n=3,5,7) which leads to an uncertainty when considering the effects of the viscoelastic properties of the layer by applying a straight line fit to the equivalent mass versus square of the frequency plot. The scatter of the results thus leads to an error in this correction in the order of 15%. However, as the corrections for viscoelastic effects in the adsorbed layer are very small in the present case this error is negligible.

A comparison between the corrected and uncorrected results shows that above a concentration of 0.1 w% of fatty acid it is vital to make corrections for changes in bulk viscosity and density for these systems. On the other hand, the effects of the viscoelasticity of the adsorbed layer have very slight impact on the sensed mass over the whole concentration range investigated. After the correction has been made, it is clear that oleic acid reaches a plateau in sensed mass of 0.5 mg/m2 at a concentration of 0.1 w%. This corresponds to a surface area per molecule of 100 Å2. According to molecular models (Framework Molecular Models, Prentice-Hall) a parallel arrangement of oleic acid at the surface requires a surface area of 130 Å2 per molecule [33]. Thus, our results indicate only a slight extension of oleic acid away from the surface. Neither the adsorption of linoleic acid nor linolenic acid does reach a plateau in the concentration range investigated. At the highest concentration investigated the adsorbed amount of linoleic acid reaches approximately 1.2 mg/m2. This corresponds to a surface area of 40 Å2, implying that linoleic acid is significantly extended perpendicular to the surface, but not in a close packed layer. Finally, there is a very high true sensed mass for linolenic acid, approximately 5 mg/m2 at 1.1 w%. At the two highest concentrations the linolenic acid did not reach equilibrium within the time of the measurements (70 min). The reproducibility of the results obtained for linolenic acid is significantly less than those obtained with the other fatty acids, and this will be addressed in our future work.

The dissipation factor is measured simultaneously with the resonance frequency in the QCM used in this investigation. In figure 5, the measured change in dissipation factor is shown as unfilled symbols. As for the frequency shift, the measured dissipation change has to be corrected for changes in bulk viscosity and density. Equation (9) was used to calculate the effect of the changing bulk viscosity and density on the dissipation. This value was subtracted from the measured value and a corrected value of the dissipation is received. This corrected value corresponds to the dissipation change caused by the adsorbed layer and is shown as filled symbols in figure 5.

The experimental and viscosity and density corrected dissipation shift. The unfilled symbols are experimental results and filled symbols are viscosity and density corrected results. Figure (a) is for oleic acid, (b) for is linoleic acid and (c) is for linolenic acid in 2,2,4,4,6,8,8-heptamethylnonane.

Clearly, the increase in viscosity and density of the solution causes the uncorrected dissipation factor to increase. However, after the bulk effects have been considered, the change in dissipation is very low, and close to the resolution of the instrument. We note that if the adsorbed layer is not rigid or firmly attached to the surface then the dissipation will increase. This is clearly not observed, and we conclude that the adsorbed layer can be regarded as firmly attached and rigid, consistent with the negligibly small effect that the correction for the viscoelasticity of the layer had on the sensed mass. Further, we note that the corrected changes in dissipation result in small negative values. The effect is too small to allow us to draw any firm conclusions, but one may propose that the adsorption results in a decreased surface roughness that lowers the energy dissipation somewhat.

Conclusions

The QCM technique is suitable for studying fatty acid adsorption from alkane solutions. It does not suffer from the insensitivity of ellipsometry, for example, when studying adsorption of compounds with similar refractive index as the solvent. However, to obtain reliable data it is essential to correct for changes in bulk properties, i.e. the viscosity and density. On the other hand, the results obtained in the present case are not affected by the viscoelastic properties of the adsorbed layer. However, it is advisable to make these corrections when evaluating the true sensed mass. The true sensed mass of the adsorbed layer increases with the degree of unsaturation of the fatty acid. Oleic acid adsorbs essentially flat on steel surfaces, linoleic acid in a more extended but not close-packed layer. The tribo properties of an adsorbed film depends on the properties of the adsorbed layer as well as the tribological system (i.e. rolling/sliding speed, heat generation and contact pressure). The correlation between the properties of the adsorbed layer of the unsaturated fatty acids and the friction and wear protection of tribo surfaces will be the attention of our future work.

References

Boschkova K., Feiler A., Kronberg B., Stålgren J.J.R., (2002) Langmuir 18 (21): 7930

Knag M., Sjöblom J., Gulbrandsen E., (2005) J. Disper. Sci. Technol. 26(2): 207

Plunkett M.A., Claesson P.M., Rutland M.W., (2002) Langmuir 18(4): 1274

Munro J.C., Frank C.W., (2004) Macromolecules 37: 925

Liu G., Zhang G., (2005) J. Phys. Chem. B 109(2):743

Vogt B.D., et al (2005) Polymer 46(5): 1635

Brown M.J., et al (2000) J. Mater. Chem. 10: 115

Reimhult E., Hoeoek F., Kasemo B., (2003) Langmuir 19 (5): 1681

Graneli A., Edvardsson M., Hoeoek F., (2004) ChemPhysChem. 5(5):729

Merta J., Tammelin T., Stenius P., (2004) Colloids Surf. A 250: 103

Benes E., (1984) J. Appl. Phys. 56(3): 608

Mecea V.M., (1994) Sensor Actuat. A 40: 1

Kanazawa K.K., Melroy O.R., (1993) IBM J. Res. Develop. 37(2): 157

Auge A., Hauptmann P., Eichelbaum F., Rösler S., (1994) Sensor Actuat. B 18–19: 518

Kim H.J., et al (1998) Thin Solid Films 327–329: 191

Ekholm P., et al (2002) J. Colloid Interface Sci. 247: 342

Ash D.C., et al (2003) Meas. Sci. Technol. 14: 1955

Dickert F.L., Forth P., Liebrtzeit P.A., Voigt G., (2000) J. Anal. Chem. 366: 802

Cohen Stuart M.A., Fleer G.J., (1996) Ann. Rev. Mater. Sci. 26: 463

Tiberg F.J., (1996) Chem. Soc., Faraday Trans. 92: 531

Sauerbrey G., (1959) Z. Phys. 155: 206

Pulker H.K., (1966) Z. Angew. Phys. 20: 537

Nomura T., Okuhara T., (1982) Anal. Chim. Acta 142: 281

C.D. Stockbridge, in: Vacuum Microbalance technique, Vol. 5 (Plenum Press, 1966) 147

Kanazawa K.K., Gordon J.G., (1985) Anal. Chim. Acta 175: 99

Kanazawa K.K., Gordon J.G., (1985) Anal. Chem. 57: 1770

Johannsmann D., Mathauer K., Wegner G., Knoll W., (1992) Phys. Rev. B 46(12): 7808

Kanazawa K.K., (1997) Faraday Discuss. 107: 77

Nwankwo E., Durning C.J., (1998) Rev. Sci. Inst. 69(6): 2375

Rodahl M., Höök F., Krozer A., Brzezinski P., Kasemo B., (1995) Rev. Sci. Inst. 66: 3924

Rodahl M., Kasemo B., (1996) Sensor Actuat. B 37: 111

Chan D.Y.C., Horn R.G., (1985) J. Chem. Phys. 83: 5311

Wheeler D.H., Potente D., Wittcoff H., (1971) J. Am. Oil. Chem. Soc. 48: 125

Acknowledgment

This project was supported by the VINNOVA Competence Centre “Surfactants Based on Natural Products, SNAP”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lundgren, S., Persson, K., Kronberg, B. et al. Adsorption of fatty acids from alkane solution studied with quartz crystal microbalance. Tribol Lett 22, 15–20 (2006). https://doi.org/10.1007/s11249-005-9000-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-005-9000-9