Abstract

The selective oxidation of vanillin to vanillic acid was achieved using gold nanoparticles supported on alumina and titania. Selectivities up to 99 % at conversions over 90 % were obtained with pressurized oxygen as green oxidant in alkaline aqueous media. Our studies showed that the addition of at least 2 equivalents of strong Brönsted base had a crucial role in suppressing vanillin degradation and achieving high selectivity and conversion. The highest activities involved turn-over frequency values up to 1300 h−1 and were achieved using alumina supported catalysts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The demand for chemicals derived from renewable resources has increased remarkably due to the depletion of fossil fuels and the serious concerns about climate change [1]. Biomass lignin is an aromatic amorphous polymer and the major source of renewable aromatic compounds [2]. However, there are few methods for the valorization of lignin despite the extensive research ongoing in the area, and therefore most of the produced lignin is burned as fuel. Vanillin (4-hydroxy-3-methoxybenzaldehyde) is currently one of the few value-added chemicals commercially produced from lignin [2, 3]. Vanillin along with its derivatives is widely used in food, perfume and pharmaceutical industries [4]. Vanillic acid, produced by selective oxidation of vanillin, has various chemical, biological and medicinal applications in addition to its use in food and fragrance industries [5–7]. The oxidation of lignin into vanillin can produce vanillic acid but is usually accompanied by undesired degradation processes [3, 8]. To prepare vanillic acid, the selective oxidation of vanillin is therefore carried out using stoichiometric oxidants, such as chlorite and hexacyanoferrate(III) [9–11] or, in few cases, catalytic systems, namely hydrotalcites [5].

Selective oxidation is one of the major transformations in organic chemistry. Replacement of stoichiometric poisonous oxidants with catalytic systems employing air or oxygen as terminal oxidant is an important goal in green and sustainable chemistry [12]. In recent years, gold catalysts have gained attention in a variety of transformations, such as CO oxidation, hydrogen peroxide synthesis and especially, selective oxidation reactions [13]. Gold nanoparticles, supported on e.g. metal oxides or carbon, have shown very high activities and selectivities in the aerobic oxidation of various alcohols, benzyl alcohol being one of the most studied [14]. Traditionally, in nonpolar organic solvent, such as toluene, benzyl alcohol is converted to benzaldehyde, whereas further oxidation takes place in alkaline aqueous media to produce benzoic acid [15]. Using gold catalysts, various substituted benzylic alcohols have been quantitatively converted to the corresponding aldehydes [16], including vanillyl alcohol to vanillin [17]. Herein, we report the first selective oxidation of vanillin to vanillic acid using gold nanoparticle catalysts (Scheme 1).

2 Experimental

2.1 Catalyst Synthesis

Two methods for catalyst preparation were applied: direct ion-exchange method (Au/Al2O3-DIE) and deposition precipitation method (Au/Al2O3-DPU and Au/TiO2). We reported the preparation and characterization of Au/Al2O3-DIE previously in Ref. [18]. Gold was supported on alumina and titania using deposition–precipitation method with urea as precipitation agent, adapted from [19]. An aqueous solution of HAuCl4 (99.9 %, Strem Chemicals) of concentration 1 × 10−3 M was prepared corresponding to final Au loading of 2 wt%. Urea was dissolved (0.42 M) at 80 °C and powdered support, Al2O3 (Alfa Aesar, γ-phase, 40 µm, S.A. 200 m2 g−1) or TiO2 (Sigma-Aldrich, >95 % anatase, –325 mesh, <44 µm, S.A. 9 m2 g−1 [20]) was added. The slurry was mixed for 17 h at 80 °C, washed with water until neutral, filtered and dried at 80 °C. The catalyst was calcined in air at 300 °C for 4 h, heating rate 2 °C/min.

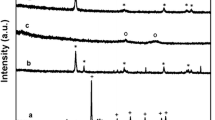

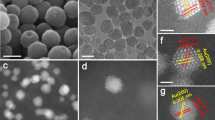

2.2 Catalyst Characterization

Gold particle size distribution and the metal dispersion were determined by transmission electron microscopy (TEM) by counting 100 particles from multiple separate catalyst particles. A FEI Tecnai F20 TEM operated at 200 kV was used for collecting the bright-field images. Scale calibration was done using Electron Microscopy Sciences combined test specimen with both gold islands and graphitic carbon. Gold dispersion was calculated from the particle size distribution as reported by Delidovich et al. [21]. Gold loading was determined by atomic absorption spectrophotometer (AAS), Perkin Elmer 3030, after dissolving the catalyst into aqua regia using microwave heating.

2.3 Oxidation Procedure

The oxidation experiments were carried out in glass liners loaded into a pressurized steel autoclave. For a typical run, 0.133 mmol of substrate, catalyst (10 mg) and water (2 ml) were measured into the glass liners. The preheated autoclave was pressurized with 5 bar oxygen and the mixtures were stirred at 80 °C with magnetic stirring (1000 rpm). After the reaction, the autoclave was depressurized and 3 ml of water/acetonitrile (1:1) was added to the reaction mixture. The catalyst was separated by centrifugation and the solution was filtered.

2.4 Product Analysis

The products were identified using 1H-NMR. Values of reaction conversion and selectivity were determined by HPLC using Agilent 1200 HPLC system equipped with an Agilent ZORBAX Eclipse Plus C18 (4.6 × 150 mm, 5 µm) column at 30 °C. The samples were diluted to concentration ca. 0.5 mg/ml. Separation was achieved with gradient from 20 % acetonitrile/80 % water (both containing 0.1 % trifluoroacetic acid) to 65 % acetonitrile in 9 min. Detection was carried out with DAD at 260/10 nm. Acetophenone was used as a standard at 0.5 mg/ml concentration. See Supporting Information for detailed product analysis.

Turn-over frequencies (TOF) per surface Au atom were calculated from the conversion according to

where n substrate is the number of moles of the substrate, c is conversion, n Au is number of moles of gold, D Au is dispersion and t is time.

3 Results and Discussion

Three metal oxide supported catalysts were applied in the oxidation of vanillin. Previously, we reported oxidation of benzyl alcohol [15] and carbohydrates [18] using Au/Al2O3 catalyst prepared by direct-ion exchange method (DIE), and the same catalyst was used herein to oxidize vanillin. In addition, gold was deposited on alumina and titania using deposition–precipitation with urea (DPU). The mean particle size, gold dispersion and gold loading of the catalysts are summarized in Table 1. According to TEM analysis, Au/Al2O3-DPU had a narrow particle size distribution with a mean particle size of 2.8 ± 0.6 nm (Fig. 1a), similar to Au/Al2O3-DIE. In contrast, Au/TiO2 had a broader particle size distribution and large particles up to 13 nm were observed (Fig. 1b). Due to the different particle sizes, gold dispersion of the catalysts varied from 18 to 43 %.

We initiated our studies on vanillin oxidation by using Au/Al2O3-DPU in water with 5 bar oxygen pressure at 80 °C. Only 6 % conversion was observed when vanillin was subjected to oxidation without added base. According to our previous results, additional base is required to oxidize aldehydes to acids [15]. Hence, we decided to study the effect of base by adding up to 4 equiv of NaOH in a 30 min reaction (Fig. 2). The most dramatic increase of conversion from 19 to 79 % was achieved by switching from 1 to 2 equiv. of added base. Surprisingly, the selectivity to vanillic acid increased simultaneously from 83 to >99 %, showing that the additional base also prevents undesired side reactions. Furthermore, increasing the amount of base to 4 equiv. resulted in even higher conversions (up to 90 %) without affecting the selectivity. In particular, the reaction reached a high TOF value of 1300 h−1 after 15 min with 3 equiv. of NaOH added. In contrast, a prolonged reaction (5 h) with 1 equiv. of NaOH gave only 45 % conversion.

Similarly to Au/Al2O3-DPU, also the Au/Al2O3-DIE and Au/TiO2 catalysts oxidized vanillin with very high selectivities when at least 2 equiv. of NaOH was used (Table 2). The alumina supported catalysts gave high conversions of around 90 %, whereas Au/TiO2 gave only 35 % conversion in 30 min reaction with 3 equiv. of NaOH. However, comparison of the turn-over frequencies shows that the activities per surface gold atom are in the same range for all of the catalysts (Table 2).

To further study the effect of base, we carried out vanillin oxidation using sodium carbonate or sodium bicarbonate. NaCO3 provided similar selectivities, though much lower conversions than NaOH in 2 h (Table 3, entries 1–4). NaHCO3 gave only 70 % selectivities regardless of the amount used (entries 5–6). Control experiments in the absence of catalyst showed no conversion or degradation of vanillin after 2 h (without base or with 2 equiv. NaOH). However, when 1 equiv. of NaOH was applied without any catalyst, 20 % of vanillin was converted into a mixture of products after 4 h, even though no vanillic acid was detected. As shown in previous studies on degradation of vanillin under oxygen pressure, in mildly alkaline conditions (pH <12), vanillin undergoes autocatalytic oxidation through radical mechanisms [8]. To suppress these radical reactions, high concentrations of alkali are employed in production of vanillin by oxidative cleavage of lignin [3, 22]. While detailed mechanism of vanillin degradation is unclear, the radical reactions result in complex product mixtures typically containing quinonic compounds with a characteristic red-brown color. Accordingly, we observed in our system a similar colored reaction solution indicating decreased selectivity. However, in highly alkaline conditions, degradation is avoided and oxidation to vanillic acid can take place.

The additional base has multiple roles in gold-catalyzed oxidation reactions [23]. The oxidation of aldehyde proceeds through a geminal diol formed by attack of hydroxide ion on the carbonyl carbon. Subsequent dehydrogenation of the diol produces the carboxylic acid. The hydroxide ion is also required to deprotonate the product to prevent adsorption of the free acid and consequent deactivation of the catalyst. In general, 1 equiv. of NaOH would be enough to achieve this [15]. In case of vanillin however, the acidic phenolic hydroxyl group can also be deprotonated. Previously, Tsukuda’s group studied the effect of ring substituents on the oxidation of benzylic alcohols using polymer-stabilized gold nanoparticles in alkaline aqueous media [24, 25]. P-methoxybenzyl alcohol was readily oxidized into the corresponding acid, whereas p-hydroxybenzyl alcohol gave only the corresponding aldehyde even with 3 equiv. K2CO3. The authors reasoned that deprotonation of the phenolic hydroxyl and delocalization of the negative charge hinders further oxidation of the aldehyde to the acid [24]. Correspondingly, similar mechanism in vanillin oxidation explains the increasing conversions with increasing hydroxide ion concentration.

4 Conclusions

Vanillin was efficiently oxidized into vanillic acid with metal oxide supported gold nanoparticles. Up to 90 % vanillic acid was produced in alkaline aqueous solution in 30 min under oxygen pressure. Au/Al2O3 catalysts, prepared by direct-ion exchange and deposition–precipitation methods gave the highest activities, turn-over frequencies being over 1300 h−1. The amount and nature of the added base had a significant effect on both the selectivity and activity of the catalysts. The selectivity decreased due to degradation of vanillin when 1 equiv. of base or less was used. However, with at least two equivalents of a strong base, such as NaOH, >99 % selectivity and high conversion to vanillic acid were achieved for the first time with heterogeneous gold catalysts.

References

Chatterjee C, Pong F, Sen A (2015) Chemical conversion pathways for carbohydrates. Green Chem 17:40–71

Zakzeski J, Bruijnincx PCA, Jongerius AL, Weckhuysen BM (2010) The catalytic valorization of lignin for the production of renewable chemicals. Chem Rev 110:3552–3599

Fache M, Boutevin B, Caillol S (2016) Vanillin production from lignin and Its use as a renewable chemical. ACS Sustain Chem Eng 4:35–46

Hocking MB (1997) Vanillin: synthetic flavoring from spent sulfite liquor. J Chem Educ 74:1055

Sachdev D, Dubey A, Mishra BG, Kannan S (2008) Environmentally benign liquid phase oxidation of vanillin over copper containing ternary hydrotalcites. Catal Commun 9:391–394

Fache M, Darroman E, Besse V, Auvergne R, Caillol S, Boutevin B (2014) Vanillin, a promising biobased building-block for monomer synthesis. Green Chem 16:1987–1998

Gitzinger M, Kemmer C, Fluri DA, Daoud El-Baba M, Weber W, Fussenegger M (2011) The food additive vanillic acid controls transgene expression in mammalian cells and mice. Nucl Acids Res 40(5):e37. doi:10.1093/nar/gkr1251

Fargues C, Mathias Á, Silva J, Rodrigues A (1996) Kinetics of vanillin oxidation. Chem Eng Technol 19:127–136

Lindgren BO, Nilsson T (1973) Preparation of carboxylic acids from aldehydes (including hydroxylated benzaldehydes) by oxidation with chlorite. Acta Chem Scand 27:888–890

Jose T, Nandibewoor S, Tuwar S (2006) Kinetics and mechanism of the oxidation of vanillin by hexacyanoferrate(III) in aqueous alkaline medium. J Solut Chem 35:51–62

Hiremath DC, Kiran TS, Nandibewoor ST (2007) Oxidation of vanillin by diperiodatocuprate(III) in aqueous alkaline medium: a kinetic and mechanistic study by stopped flow technique. Int J Chem Kinet 39:236–244

Davis SE, Ide MS, Davis RJ (2013) Selective oxidation of alcohols and aldehydes over supported metal nanoparticles. Green Chem 15:17–45

Freakley S, He Q, Kiely C, Hutchings G (2015) Gold catalysis: a reflection on where we are now. Catal Lett 145:71–79

Della Pina C, Falletta E, Rossi M (2012) Update on selective oxidation using gold. Chem Soc Rev 41:350–369

Rautiainen S, Simakova O, Guo H, Leino A-R, Kordás K, Murzin D, Leskelä M, Repo T (2014) Solvent controlled catalysis: synthesis of aldehyde, acid or ester by selective oxidation of benzyl alcohol with gold nanoparticles on alumina. Appl Catal A 485:202–206

Liu H, Liu Y, Li Y, Tang Z, Jiang H (2010) Metal–organic framework supported gold nanoparticles as a highly active heterogeneous catalyst for aerobic oxidation of alcohols. J Phys Chem C 114:13362–13369

Enache DI, Edwards JK, Landon P, Solsona-Espriu B, Carley AF, Herzing AA, Watanabe M, Kiely CJ, Knight DW, Hutchings GJ (2006) Solvent-free oxidation of primary alcohols to aldehydes using Au–Pd/TiO2 catalysts. Science 311:362–365

Rautiainen S, Lehtinen P, Chen J, Vehkamäki M, Niemelä K, Leskelä M, Repo T (2015) Selective oxidation of uronic acids into aldaric acids over gold catalyst. RSC Adv 5:19502–19507

Zanella R, Giorgio S, Henry CR, Louis C (2002) Alternative methods for the preparation of gold nanoparticles supported on TiO2. J Phys Chem B 106:7634–7642

Xu A, Chai Y, Nohmi T, Hei TK (2009) Genotoxic responses to titanium dioxide nanoparticles and fullerene in gpt delta transgenic MEF cells. Part Fibre Toxicol 6:1–13

Delidovich IV, Moroz BL, Taran OP, Gromov NV, Pyrjaev PA, Prosvirin IP, Bukhtiyarov VI, Parmon VN (2013) Aerobic selective oxidation of glucose to gluconate catalyzed by Au/Al2O3 and Au/C: impact of the mass-transfer processes on the overall kinetics. Chem Eng J 223:921–931

Fargues C, Mathias Á, Rodrigues A (1996) Kinetics of vanillin production from kraft lignin oxidation. Ind Eng Chem Res 35:28–36

Zope BN, Hibbitts DD, Neurock M, Davis RJ (2010) Reactivity of the gold/water interface during selective oxidation catalysis. Science 330:74–78

Tsunoyama H, Sakurai H, Negishi Y, Tsukuda T (2005) Size-specific catalytic activity of polymer-stabilized gold nanoclusters for aerobic alcohol oxidation in water. J Am Chem Soc 127:9374–9375

Tsunoyama H, Tsukuda T, Sakurai H (2007) Synthetic application of PVP-stabilized Au nanocluster catalyst to aerobic oxidation of alcohols in aqueous solution under ambient conditions. Chem Lett 36:212–213

Acknowledgments

This work was funded by University of Helsinki Doctoral Programme in Chemistry and Molecular Sciences (CHEMS). The authors would like to thank Electron Microscopy Unit of the Institute of Biotechnology in University of Helsinki for providing laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rautiainen, S., Chen, J., Vehkamäki, M. et al. Oxidation of Vanillin with Supported Gold Nanoparticles. Top Catal 59, 1138–1142 (2016). https://doi.org/10.1007/s11244-016-0633-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-016-0633-8