Abstract

The base free oxidation of glycerol with molecular oxygen in water using bimetallic Au–Pt catalysts on three different acidic zeolite supports (H-mordenite, H-β and H-USY) was explored in a batch setup. At temperatures between 140 and 180 °C, lactic acid formation was significant and highest selectivity (60 % lactic acid at 80 % glycerol conversion) was obtained using Au–Pt/USY-600 (180 °C). A selectivity switch to glyceric acid (GLYA) was observed when the reactions were performed at 100 °C. Highest conversion and selectivity towards GLYA were obtained with Au–Pt/H-β as the catalyst (68 % selectivity at 68 % conversion).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The progressive depletion of fossil resources combined with environmental- and economic issues have led to the development of biomass derived fuels and chemicals. A well-known biofuel is biodiesel, obtained by the transesterification of vegetable oils with short chain alcohols in the presence of a catalyst. The main byproduct is glycerol (10 wt% based on plant oil). Growing global biodiesel production levels have led to an oversupply of glycerol and as such, the identification of value added outlets for glycerol has been actively pursued. Well known examples are esterification, etherification, oxidation and reduction reactions leading to many (potentially) attractive bulk- and fine-chemicals [1–3].

Oxidation of glycerol using noble metal catalysts is an active field of research [4–8]. For instance, gold nanoparticles immobilized on various solid supports have shown to be very attractive heterogeneous catalysts for alcohol oxidations. The oxidation of glycerol in aqueous alkaline conditions using Au supported catalyst may lead to glyceric acid (GLYA), tartronic acid (TART), hydroxypyruvic acid (HYPA), mesoxalic acid (MOXA) and lactic acid (LACT) in association with C2 acids such as glycolic acid (GLYC), oxalic acid (OXAL) and formic acid (FORM) [4, 9–11]. Selectivity is a critical issue, though may be tuned by proper selection of the process conditions and the choice of the catalyst components (noble metal(s) and support type).

LACT is currently used as the monomer for the production of poly(lactic-acid), a biodegradable plastic. LACT is also an interesting platform molecule from which a number of bulk chemicals such as acrylic acid, pyruvic acid and propionic acid can be derived [12, 13]. The current commercial production of LACT by fermentation generates large amounts of salts and extensive purification/downstream processing is required. Separation and purification of LACT from fermentation broths contributes up to 50 % of the production costs [14].

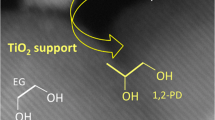

A limited number of publications have appeared on the direct conversion of glycerol to LACT or its Na salt. Examples are the base assisted hydrothermal conversion of glycerol to sodium lactate (90 mol% yield) at elevated temperatures (300 °C, 4 equivalents of NaOH to glycerol) [15] and various metal catalyzed conversions in aqueous media [16–20]. Recently, we have shown the use of an Au–Pt/nanoceria catalyst for the efficient conversion of glycerol to LACT (80 % selectivity at 99 % glycerol conversion) in water at 100 °C in the presence of NaOH (4 equivalents of NaOH to glycerol) [21]. Very recently an Au–Pd/TiO2 catalyst in combination with a homogeneous Lewis acid catalyst (AlCl3) has been reported for the direct conversion of glycerol to LACT in base free conditions. However severe hydrolysis of AlCl3 in water resulted in the deposition of precipitates on the catalyst surface, leading to catalyst deactivation [22].

The main disadvantage of noble metal based catalytic systems for the conversion of glycerol in water to LACT is the necessity of the presence of a strong base, typically in a fourfold excess compared to glycerol, to achieve reasonable reaction rates. The base results in the formation of carboxylic acid-salt and further downstream processing is required to purify the product and neutralize the excess base. Furthermore, the presence of a base also affects the selectivity towards the desired product by inducing base catalyzed side reactions. Therefore, the development of catalysts that are able to convert glycerol to LACT without the addition of a base or other additives is highly desirable, and this, to the best of our knowledge, has so far not been reported to date.

Recent studies have shown that base free glycerol oxidations to GLYA are indeed possible by proper tailoring the oxidation catalyst. These findings may also provide valuable input for the conversion of glycerol to LACT and will as such be reviewed shortly. Most attention so far is given to mono- and bi-metallic noble metal based catalyst on basic supports. For instance, Brett et al. [23] have reported the use of bimetallic Au–Pt and Au–Pd on MgO as promising catalysts for the base free oxidation of glycerol to GLYA up to 85 % selectivity (ambient conditions and 3 bar oxygen, 24 h reaction time). When using Pt on hydrotalcites, a high GLYA selectivity of 78 % at 47 % glycerol conversion (6 h, room temperature) was reported [24]. Recently, bimetallic Pt–Au particles deposited on a hydrotalcite using starch as the stabilizing/reducing agent showed promising activity at ambient and base free conditions for the conversion of glycerol to GLYA (78 % selectivity at 73 % glycerol conversion) [25]. Carbon supports have been also explored. For instance, Liang et al. [26] have shown that Pt on multiwalled carbon nanotubes give 50 % yield of GLYA (70 % GLYA selectivity at 70 % conversion after 6 h at 60 °C), another example is the use of Pt-Cu/C which resulted in GLYA selectivities of 71 % at 86 % glycerol conversion (base free conditions, 60 °C, oxygen atmosphere) [27]. The only report to date on the use of acidic supports is from Villa et al. [28] where it was shown that the use of H-mordenite for monometallic (Au and Pt) and bimetallic (Au–Pt) nanoparticles gives GLYA in 83 % selectivity at 70 % glycerol conversion (Au–Pt/H-mordenite, 100 °C, 3 atm of oxygen). In this paper, we report on the synthesis, characterization and performance of bimetallic (Au–Pt) catalysts on various commercially available acidic zeolite supports such as H-mordenite, H-β and H-USY for the base free, one pot conversion of glycerol to LACT in water using molecular oxygen as the oxidant. The liquid phase product composition after reaction was determined in detail and reaction pathways are proposed to explain the observed product selectivities.

2 Experimental Section

2.1 Materials

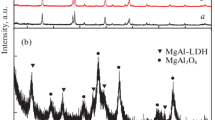

Glycerol (≥99 %), HAuCl4.3H2O (≥99.9 %), K2PtCl4 (98 %), polyvinyl alcohol (PVA) (Mw 13.000–23.000) and NaBH4 (≥98 %) were obtained from Sigma-Aldrich. Zeolite-Y (CBV-720, CBV712 and CBV 600), mordenite (CBV-21A), and zeolite-β (CP814E) were procured from Zeolyst international. Zeolites in their ammonium form were calcined at 550 °C for 6 h to convert to the H-form. Oxygen (99.995 %) was obtained from Linde Gas Benelux B.V., the Netherlands and hydrogen (9.86 vol% in nitrogen) from Praxair, Belgium.

2.2 Catalyst Synthesis

2.2.1 Monometallic (Au and Pt) Catalysts

Monometallic Au and Pt catalysts were synthesized by a procedure reported elsewhere [29]. HAuCl4.3H2O or K2PtCl4 (0.072 mmol) was dissolved in milli-Q water (140 mL) containing polyvinyl alcohol (2 wt% solution, 1.9 mL) as the protecting agent. Metal reduction was performed using NaBH4 (2.13 mL of a 0.1 M solution). The pH of the colloidal suspension was adjusted to 2.5 using diluted H2SO4 (0.2 M). The support was added to the colloidal suspension under vigorous stirring. An adsorption time of 2.5 h was employed for the deposition of the colloid on the support. The intake of support was set to obtain a final metal loading of 0.7 wt%. The catalyst was separated by filtration and washed thoroughly with deionized water. Finally, the catalyst was dried at 100 °C under static air.

2.2.2 Bimetallic (Au–Pt) Catalysts by Sequential Deposition

Bimetallic catalysts on zeolites were prepared by a seqential deposition method as reported previously [28]. In a typical procedure, Au on zeolite (1 g) having a gold loading of 0.7 wt%, was suspended in milli-Q water (120 mL) containing K2PtCl4 (0.0064 g) and a PVA solution (220 µL, 2 wt%). Hydrogen gas (9.86 vol% in nitrogen) was bubbled through this slurry at a flow rate of 150 mL/min at atmospheric pressure and room temperature for 6 h. This slurry was stirred overnight (16 h). The catalyst was recovered by filtration, subsequently washed exhaustively with deionised water and finally dried at 100 °C under static air.

2.3 Catalyst Characterization

Transmission electron microscopy (TEM) measurements were performed on a JEOL JEM 1011 instrument operating at 200 kV. Catalyst samples were finely powdered and dispersed in ethanol. A small drop of this dispersion was deposited on a copper grid coated with carbon. Particle size distributions of the catalysts were determined from the TEM pictures by measuring the dimensions of 150–200 particles. Spherical aberration (Cs) corrected STEM was performed using a FEI Titan XFEG 60-300, operated at 200 kV equipped with an EDAX EDS detector, and a CEOS probe corrector allowing a point resolution of 0.8 Å.

ICP-OES analyses to determine the amount of metals in the solid catalysts were performed using a Perkin Elmer optima7000 DV instrument.

2.4 Catalytic Experiments

Catalytic experiments were performed in 75 mL Hastelloy C-276 autoclaves (Parr Series 5000 Multiple Reactor System). The autoclave was charged with a glycerol solution (6 mmol) in deionised water (20 mL). Subsequently, the catalyst was added (glycerol to noble metal ratio of 1,000 mol/mol) and the autoclave was closed, flushed with oxygen and finally pressurized with 3 bar of oxygen. The reactor contents were heated to the desired temperature under stirring with a magnetic stirring bar (700 rpm). After the specified reaction time, the reactor was cooled immediately to room temperature using an ice water bath, depressurised and samples were taken for HPLC analyses.

2.5 Product Analyses by HPLC

Reaction mixtures were analysed on a Waters high pressure liquid chromatography (HPLC) instrument equipped with an Alltech IOA-1000 column maintained at 90 °C using H2SO4 (3 mM) in ultra-pure water as the eluent with a flow rate of 0.4 mL/min. The components were identified using an UV (210 nm) and an RI detector by comparison with authentic samples. Concentrations were determined using calibration curves obtained by injecting standard solutions of known concentrations.

2.6 Definitions

Glycerol conversion is defined as:

where Cg is the concentration of glycerol after a certain reaction time and Cg,0 is the initial glycerol concentration.

Product selectivity for a compound P is C-based and defined as:

where Cp is the concentration of a product after a certain reaction time. Carbon based selectivities were used to compensate for the effects that not all products have a similar carbon number.

The percentage of HPLC detectable compounds (PDC) is C-based and defined as follows:

3 Results and Discussions

3.1 Catalyst Synthesis and Characterization

The bimetallic (Au–Pt) catalysts were prepared by a colloidal deposition method using a two step procedure. In the first step, monometallic Au catalysts were prepared and isolated, followed by a second step involving the introduction of Pt. Commercially available acidic supports were used: H-mordenite (H-MOR) with a Si/Al ratio of 20; Zeolite β with a Si/Al ratio of 25 and three USY zeolites with different Si/Al ratios (USY-720 (Si/Al = 30), USY-712 (Si/Al = 12) and USY-600 (Si/Al = 5.2). All catalysts contained 0.7 wt% of Au and 0.3 wt% of Pt (ICP-EOS).

Relevant catalysts were characterised bright-field transmission electron microscopy (BF-TEM) and Cs-corrected STEM-HAADF. Representative TEM pictures are given in Fig. S-1; the average metal particle size for the zeolite supported catalysts was estimated after the analysis of 200 different nanoparticles (NPs) obtaining a value of 4–4.5 nm.

Metal distribution can be clearly observed in Fig. 1a and Fig. S-2 for Au–Pt/H-β. An even distribution of the NPs over the zeolitic surface was observed. In a closer inspection in Fig. 1b the zeolite pore structure can also be identified together with the bimetallic nanoparticles. A number of particles of this bimetallic catalyst were analysed by energy dispersive X-ray spectroscopy (XEDS) to obtain the composition of individual metal nanoparticles (Fig. 2; Fig. S-3 and S-4) corroborating the bimetallic nature (AuPt) of the NPs.

3.2 Catalyst Screening Experiments

The oxidation of glycerol in water (0.3 M) was carried out in a batch reactor set-up. A variety of bimetallic Au–Pt catalysts on a number of zeolite support were screened (USY-600, USY-712, HMOR, H-β). The oxidation reactions were carried out in the absence of a base using oxygen as the oxidant (3 bar). Initially, a reaction temperature of 140 °C was selected, the glycerol to total metal intake was set at 1,000 mol/mol and a reaction time of 2 h was employed. The results are given in Table 1.

The Au–Pt catalysts on the two USY supports were the most active and glycerol conversion of up to 71 % were obtained. The catalyst supported on HMOR was the least active (40 % glycerol conversion), indicative for strong support effects on the activity of the catalysts. The main product for all experiments was LACT, though the selectivity was at maximum 24 %. A multitude of byproducts was formed (HPLC), the main ones being GLYA and GLYC, see Eq. 4 for details.

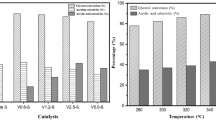

The best selectivity (24 %) was obtained for the bimetallic Au–Pt on the USY supports. Compared to USY catalysts, H-mordenite and H-β catalysts gave lower selectivities of LACT, indicating the significance of extraframe work aluminium species in the USY catalysts for the reaction [30]. The two USY based catalysts were also tested at 180 °C and considerable improvements in catalytic performance were observed. When the temperature is increased from 140 °C to 180 °C, the glycerol conversion increased from 70 to about 80 %, whereas the selectivity to LACT increased to 60 %. Thus, a LACT yield close to 50 % was observed, which is to the best of our knowledge the highest LACT yield reported to date when using glycerol as the source in base free aqueous solutions. Catalyst performance for the bimetallic complexes on a USY-600 and 712 support were about similar, indicating that the Si/Al ratio does not play a major role when considering catalyst activity and selectivity.

The product composition may be rationalised by assuming an initial oxidative dehydrogenation of glycerol to glyceraldehyde (GLA) and/or dihydroxyacetone (DHA). The first compound was indeed detected in the reaction mixtures, though in limited amounts (<3 %, Table 1). This reaction requires an oxidation catalyst in the form of a supported noble metal or a combination of noble metals. GLA may be converted according to two parallel reaction pathways, an oxidation reaction to GLYA and a dehydration/rearrangement to LACT with pyruvaldehyde as the intermediate, see Scheme 1 for details. The latter reaction requires a catalyst with both Lewis and Brønsted acid sites, without the need of a noble metal oxidation catalyst [30–34]. For instance, West et al. [30] have shown that the reaction of GLA or DHA to LACT is well feasible using an acid catalyst like USY, even in the absence of noble metals (125 °C).

Further proof for the dehydration/rearrangement pathway was obtained by performing two separate experiments with GLA as the feed (140 °C, 0.15 M in water, 3 bar oxygen, 2 h), one using the support only (USY-600), the other with Au–Pt on USY-600. Qunatitative GLA conversion was observed in both cases. In case of the support only, the carbon selectivity to LACT was 63 %, whereas it was reduced to 38 % for Au–Pt on USY-600. The intermediate pyruvaldehyde was not observed, indicating that the internal Cannizzaro reaction is fast at these conditions. Thus, these experiments indicate that GLA is an important intermediate in the reaction sequence from glycerol to LACT.

GLYA is known to be prone to subsequent oxidation and C–C splitting reactions, giving among others TART and GLYC. The latter was found in significant amounts (selectivity up to 14 %), an indication that C–C splitting pathway occurs to a significant extent. The thermal, non catalytic reaction occurs only to a minor extent, as was shown by a blank reaction in the absence of a catalyst at 180 °C, giving a glycerol conversion of only 5 % (Table 1, entry 7).

The percentage of HPLC detectable compounds (PDC, see Eq. 3) was in the range of 55–92 %. The lower values imply the formation of significant amounts of non-HPLC detectable species. These may either be gas phase components or oligomeric-polymeric products. The latter may either be soluble or insoluble, though the reaction mixtures after reaction appeared transparent. Diglycerol was not present in the reaction mixture (HPLC), an indication that not the reactant glycerol but the products are prone to subsequent reactions. A possible explanation is the decomposition of the organic acids LACT and GLYA at reaction conditions. Carboxylic acids are known to decompose to gaseous products over metal containing or metal free solid acid catalysts such as rare earth modified NaY [38, 39], Pt/Nb2O5 [40] and silica supported heteropolyacids [13] in aqueous conditions. To gain insights in product stability, a LACT solution in water (0.2 M) in the presence of the Au–Pt/USY712 catalyst and oxygen was allowed to react at 140 °C and 180 °C for 2 h. Product stability was indeed limited and considerable conversion of LACT was observed (69–93 %) to mainly pyruvic acid, acetic acid, OXAL and ethanol (Eq. 5; Table 2).

The mechanism for this reaction likely involves the oxidation of LACT to pyruvic acid (PYRA) and the subsequent oxidative decarboxylation to acetic acid (ACET) and carbon dioxide. The latter reaction has been reported in the presence of a catalyst and an oxidant [41, 42]. Ethanol was also detected by HPLC measurements (6 %) when the reaction was performed at 180 °C. Speculatively, it could be formed by a decarboxylation reaction of LACT to either ethanol and carbon dioxide or to acetaldehyde, hydrogen and carbon dioxide followed by the reduction of acetaldehyde to ethanol by molecular hydrogen (from e.g. the decomposition of FORM). The percentage of HPLC detectable compounds (PDC), was about 81 % at 140 °C, indicative for the formation of non-HPLC detectable compounds (e.g. oligomers, polymers and gaseous products). Thus, it may be concluded that LACT is not stable under the prevailing reaction conditions. Similar observations were made for GLYA (Table 2), giving a conversion of 70 % with GLYC as the main product. However, in contrast to LACT, the PDC values for GLYA are low (26 %), indicative for the formation of high amounts gas phase and/or higher molecular weight, non-HPLC detectable compounds.

To lower the rate of LACT decomposition, it seemed worthwhile to investigate the conversion of glycerol at lower temperature (100 °C instead of 140 °C) for the Au–Pt/USY catalysts. The results are given in Table 3. The bimetallic catalysts on the USY support were still active at 100 °C, though the glycerol conversion dropped to levels between 43 % (USY-712) and 50 % (USY-600), compared to >70 % at 140 °C. Surprisingly, a dramatic selectivity switch from LACT to GLYA was observed, the latter being the major component in the reaction mixture with a selectivity of up to 65 % for USY-720. Thus, the temperature has a major effect on selectivity and these findings indicate that the rate of the oxidation pathways from GLY to GLYA is higher than the rate of the dehydration-rearrangement of GLY to LACT when performing the reaction at 100 °C, see Scheme 1 for details.

As such, the temperature is a powerfull tool to steer selectivity and when aiming for LACT, higher temperatures are preferred, whereas GLYA is preferentially formed at lower temperatures. This finding also explains the lower values for the percentage of HPLC detectable compounds (PDC, Eq. 3) when performing the reaction at 140 °C (55–64 %) instead of 180 °C (81–92 %, Table 1). Based on the findings above, GLYA formation is expected to be significant at 140 °C, though is likely reduced considerably due to excessive decomposition of GLYA to non-HPLC detectable compounds (Table 2), and as such leading to lower PDC values.

For comparison, the reaction was also performed at 100 °C using the bimetallic catalysts on the H-MOR and three USY supports. Again, the main product was GLYA instead of LACT (Table 3). Best performance at 100 °C was obtained using the bimetallic Zeolite β support, given 68 % selectivity to GLYA at 68 % glycerol conversion after 3 h. Main byproducts are GLA, DHA and GLYC, see Table 3 for details. Performance of the bimetallic H-MOR catalyst was worse than for the USY supports (25 % conversion and 49 % selectivity to GLYA). These results are different from those reported by Villa et al. [28], who reported a 80 % GLYA selectivity at 70 % glycerol conversion with a Au–Pt catalyst on a mordenite support. However, the type of mordenite (for instance the Si/Al ratio) is not given in the paper, making comparison difficult. In addition, experimental conditions for both studies are not equal (e.g. glycerol to metal ratio).

For comparison, monometallic Au and Pt catalysts on the zeolitic supports were also tested for the oxidation of glycerol at 100 °C in base free conditions (Table 4). The monometallic catalysts were by far less active than the bimetallic ones and glycerol conversions were below 20 %. In addition, the Pt catalysts were more active than the Au ones, and the highest activity was observed for Pt/USY-600. In this case, GLYA and LACT acid were observed, indicating that both the oxidative pathways as well as the dehydration/rearrangement pathway occur at these conditions. Thus, it can be concluded that bimetallic catalysts show superior performance.

4 Conclusions

We have shown that glycerol can be converted to either GLYA or LACT in a one pot procedure using base free conditions over various zeolite supported bimetallic Au–Pt catalysts. At 100 °C, the main product was GLYA for all catalysts. Best glycerol conversion and GLYA selectivity was shown by a Au–Pt/H-β catalyst (68 % selectivity at 60 % conversion). Monometallic Au and Pt based catalysts were far less active than the bimetallic ones. At elevated temperature (140–180 °C), the selectivity switched to LACT and highest LACT selectivity was obtained over Au–Pt/USY-600 at 180 °C (60 % selectivity at 80 % conversion). At these conditions, LACT stability is limited leading to a reduction in product yields. To reduce LACT decomposition rates, it is likely preferable to perform the reactions in an alcohol instead of water. In this case, lactic esters are formed which are expected to have reduced decomposition rates. These studies are in progress and will be reported in due course.

References

Pagliaro M, Ciriminna R, Kimura H, Rossi M, Della Pina C (2007) Angew Chem Int Ed 46:4434–4440

Behr A, Eilting J, Irawadi K, Leschinski J, Lindner F (2008) Green Chem 10:13–30

Zhou C-H, Beltramini JN, Fan Y-X, Lu GQ (2008) Chem Soc Rev 37:527–549

Katryniok B, Kimura H, Skrzynska E, Girardon J-S, Fongarland P, Capron M, Ducoulombier R, Mimura N, Paul S, Dumeignil F (2011) Green Chem 13:1960–1979

Demirel-Gülen S, Lucas M, Claus P (2005) Catal Today 102–103:166–172

Purushothaman RKP, van Haveren J, van Es DS, Melian-Cabrera I, Heeres HJ (2012) Green Chem 14:2031–2037

Pagliaro M, Rossi M (2008) The future of glycerol: new uses of a versatile raw material. RSC publishing, Camridge

Hashmi ASK, Hutchings GJ (2006) Angew Chem Int Ed 45:7896–7936

Carrettin S, McMorn P, Johnston P, Griffin K, Hutchings GJ (2002) Chem Commun 696–697

Ketchie WC, Murayama M, Davis RJ (2007) Top Catal 44:307–317

Demirel S, Lehnert K, Lucas M, Claus P (2007) Appl Catal B 70:637–643

Fan Y, Zhou C, Zhu X (2009) Catal Rev 51:293–324

Katryniok B, Paul S, Dumeignil F (2010) Green Chem 12:1910–1913

Corma A, Iborra S, Velty A (2007) Chem Rev 107:2411–2502

Kishida H, Jin F, Zhou Z, Moriya T, Enomoto H (2005) Chem Lett 34:1560–1561

Shen Y, Zhang S, Li H, Ren Y, Liu H (2010) Chem Eur J 16:7368–7371

ten Dam J, Kapteijn F, Djanashvili K, Hanefeld U (2011) Catal Commun 13:1–5

Auneau F, Noël S, Aubert G, Besson M, Djakovitch L, Pinel C (2011) Catal Commun 16:144–149

Auneau F, Arani L, Besson M, Djakovitch L, Michel C, Delbecq F, Sautet P, Pinel C (2012) Top Catal 55:474–479

Roy D, Subramaniam B, Chaudhari RV (2011) ACS Catal 1:548–551

Purushothaman RKP, van Haveren J, van Es DS, Melián-Cabrera I, Meeldijk JD, Heeres HJ (2014) Appl Catal B 147:92–100

Xu J, Zhang H, Zhao Y, Yu B, Chen S, Li Y, Hao L, Liu Z (2013) Green Chem 15:1520–1525

Brett GL, He Q, Hammond C, Miedziak PJ, Dimitratos N, Sankar M, Herzing AA, Conte M, Lopez-Sanchez JA, Kiely CJ, Knight DW, Taylor SH, Hutchings GJ (2011) Angew Chem Int Ed 50:10136–10139

Tsuji A, Rao KTV, Nishimura S, Takagaki A, Ebitani K (2011) ChemSusChem 4:542–548

Tongsakul D, Nishimura S, Ebitani K, ACS Catal (2013) 3:2199–2207

Liang D, Gao J, Sun H, Chen P, Hou Z, Zheng X (2011) Appl Catal B 106:423–432

Liang D, Gao J, Wang J, Chen P, Wei Y, Hou Z (2011) Catal Commun 12:1059–1062

Villa A, Veith GM, Prati L (2010) Angew Chem. Int Ed 49:4499–4502

Ketchie WC, Fang Y-L, Wong MS, Murayama M, Davis RJ (2007) J Catal 250:94–101

West RM, Holm MS, Saravanamurugan S, Xiong J, Beversdorf Z, Taarning E, Christensen CH (2010) J Catal 269:122–130

Pescarmona P, Janssen K, Stroobants C, Molle B, Paul J, Jacobs P, Sels B (2010) Top Catal 53:77–85

Pescarmona PP, Janssen KPF, Delaet C, Stroobants C, Houthoofd K, Philippaerts A, De Jonghe C, Paul JS, Jacobs PA, Sels BF (2010) Green Chem 12:1083–1089

Li L, Stroobants C, Lin K, Jacobs PA, Sels BF, Pescarmona PP (2011) Green Chem 13:1175

Taarning E, Saravanamurugan S, Spangsberg Holm M, Xiong J, West RM, Christensen CH (2009) ChemSusChem 2:625–627

Porta F, Prati L (2004) J Catal 224:397–403

Ketchie W, Murayama M, Davis R (2007) Top Catal 44:307–317

Carrettin S, McMorn P, Johnston P, Griffin K, Kiely CJ, Attard GA, Hutchings GJ (2004) Top Catal 27:131–136

Wang H, Yu D, Sun P, Yan J, Wang Y, Huang H (2008) Catal Commun 9:1799–1803

Sun P, Yu D, Fu K, Gu M, Wang Y, Huang H, Ying H (2009) Catal Commun 10:1345–1349

Serrano-Ruiz JC, Dumesic JA (2009) ChemSusChem 2:581–586

Manikyamba P (2003) React Kinet Catal Lett 78:169–173

Watanabe M, Inomata H, Smith RL Jr, Arai K (2001) Appl Catal A 219:149–156

Acknowledgments

The authors would like to thank NWO-ASPECT (The Netherlands) for financial support (ASPECT-project 053.62.020). Gert ten Brink and J. van der Velde (Faculty of Mathetatics and Natural science, University of Groningen) are acknowledged for the TEM and ICP-OES mesurements respectively. PQ-zeolyst is acknowledged for kindly supplying the commercial zeolites.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Purushothaman, R.K.P., van Haveren, J., Mayoral, A. et al. Exploratory Catalyst Screening Studies on the Base Free Conversion of Glycerol to Lactic Acid and Glyceric Acid in Water Using Bimetallic Au–Pt Nanoparticles on Acidic Zeolites. Top Catal 57, 1445–1453 (2014). https://doi.org/10.1007/s11244-014-0316-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-014-0316-2