Abstract

NiO is an important heterogeneous catalyst employed in chemical processes. However, it is a new topic to explore NiO as a counter electrode catalyst for dye-sensitized solar cells (DSSCs). In this paper, NiO with poly(3,4-ethylenedioxythiophene):polystyrenesulfonate (PEDOT:PSS) was demonstrated an efficient DSSC counter electrode with a maximum power conversion efficiency of 7.58 %. Furthermore, electrochemical impedance spectroscopy and cyclic voltammetry measurements revealed that the excellent photovoltaic performance is due to the combination between the high catalytic activity of NiO and the superior electrical conductivity of PEDOT:PSS. The optimum weight ratio of NiO to PEDOT:PSS is 48.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

As a representative of the third-generation solar cell, dye-sensitized solar cells (DSSCs) have generated intense interest due to their easy fabrication, low cost, and high energy conversion efficiency [1–4]. In a DSSC, electrons transfer from an excited dye sensitizer into the semiconductor conduction band, then pass through the transparent conductive electrode to the external circuit, and finally to the counter electrode. The oxidized dye could be regenerated by a redox electrolyte, and the oxidized electrolyte could diffuse to the counter electrode and be reduced by electrons [5, 6]. As one of the most important components, an ideal counter electrode would possess both excellent catalytic activity for the reduction of oxidized electrolyte and high conductivity for electron transfer from the external circuit to the electrolyte [7–11].

Nickel oxide (NiO) is widely employed as a heterogeneous catalyst used in chemical and petrochemical processes, such as syngas production [12–15]. Furthermore, as a p-type semiconductor, NiO-based photocathode was combined with n-type TiO2-based photoanode to form a tandem DSSC, yielding an open-circuit voltage of 0.73 V [16]. Many efforts, such as morphology control of NiO film [17] and modification of NiO preparation [18], were attempted to achieve higher performance for tandem DSSCs, but their power conversion efficiencies are stills very low (<1 %) [17–20]. On the other hand, NiO was also exploited for DSSC counter electrodes. Guai et al. [21] showed that a DSSC with the counter electrode consisting of sulfur-doped NiO exhibited a high power conversion efficiency up to 5.04 %. Bajpai et al. [22] deposited NiO nanoparticles on graphene platelets as electrocatalyst for DSSCs, yielding 3.06 % efficiency. Okumura et al. [23] reached a high efficiency of 5.11 % with the DSSC using NiO hybridized carbon film as a cathode. However, the combination between NiO and a conductive polymer as a DSSC counter electrode has not been explored.

As a counter electrode material for DSSC, the ionic feature of NiO would promise its strong interaction with the ions of iodine-based electrolytes, leading to excellent catalytic activity. However, because the poor electrical conductivity of NiO, its combination with a conductive component (such as conductive polymer) is necessary. For this reason, we combined NiO with a conductive polymer—(poly(3,4-ethylenedioxythiophene):polystyrenesulfonate (PEDOT:PSS) as a composite counter electrode and revealed its properties in this work. The excellent performances of DSSCs with the NiO/PEDOT:PSS counter electrodes were demonstrated.

2 Experiment

2.1 Counter Electrode Preparation and Characterization

NiO powder (Aldrich) was mixed with 2.5 % PEDOT:PSS aqueous solution with stirring for 5 min to prepare a homogeneous paste with a selected weight ratio (16:1, 48:1, 64:1, or 96:1) of NiO to PEDOT:PSS. The paste was deposited on fluorine-doped tin oxide (FTO) coated glass to form a composite film by doctor blading method. The NiO-based counter electrode was obtained by heating the NiO/polymer coated FTO glass at 80 °C for 4 h. For comparison, pure PEDOT:PSS and NiO counter electrodes were also prepared using the approach, in which aqueous pastes of PEDOT:PSS and NiO were coated on FTO glasses with doctor blading method, respectively, followed by heating at 80 °C for 4 h. The X-ray diffraction spectrometer (Scintag XDS2000 Powder Diffractometer) was employed to characterize the crystalline structure of NiO, PEDOT:PSS, and NiO/PEDOT:PSS films.

2.2 Photoelectrode Preparation

Fluorine-doped tin oxide (FTO) coated glasses were cleaned and treated by 0.4 mM TiCl4 (70 °C) for 30 min. TiO2 paste (ethanol as solvent) was deposited on the FTO glass by doctor blading method to form a TiO2 nanocrystalline film. The obtained TiO2 photoelectrode was heated at 325, 375, 450, and 500 °C for 5, 5, 15, and 15 min, respectively, followed by TiCl4 treatment again and then heat treatment at 500 °C for another 30 min. The treated TiO2 photoelectrode was immersed in a cis-bis(isothiocyanato) bis(2,2′-bipyridyl-4,4′-dicarboxylato)-ruthenium(II)-bis-tetrabutylammonium (N719, 0.3 mM in ethanol) dye solution for 24 h to achieve dye sensitization.

2.3 Fabrication and Characterization of DSSCs

The sandwich DSSCs were assembled using the N719-sensitized TiO2 photoelectrode and NiO/PEDOT:PSS composite counter electrode with liquid electrolyte (I−/I3 − redox couple) between them. The electrolyte consists of 0.025 M LiI, 0.04 M I2, 0.28 M tert-butyl pyridine (TBP), 0.6 M 1-butyl-3-methylimidazolium iodide (BMII), and 0.05 M guanidinium thiocyanate in acetonitrile/valeronitrile solvent with 85/15 volume ratio. The photovoltaic performance of the obtained NiO-based DSSCs was evaluated by Kithley 2400 under illumination of AM 1.5 simulate sunlight (1sun, 100 mW cm−2) using a Newport solar simulator. Electrochemical impedance spectroscopy (EIS) data were collected at a potential equal to the open-circuit voltage of a DSSC and 10 mV amplitude over the frequency range of 0.1–100 kHz by CHI 600D electrochemical workstation in dark condition. Cyclic voltammetry (CV) measurements were carried out using an electrochemical workstation (EG&G Princeton Applied Research) with a three-electrode system (NiO/PEDOT:PSS composite as a working electrode, Pt wire as a counter electrode, and Ag/AgCl as a reference electrode) containing acetonitrile solution of 10 mM LiI, 1 mM I2, and 0.1 M LiClO4.

3 Results and Discussion

The photovoltanic performances of NiO-based DSSCs with counter electrodes of NiO, PEDOT:PSS, and NiO/PEDOT:PSS composite were evaluated with photocurrent density–voltage (J–V) measurements. The obtained J–V curves are illustrated in Fig. 1 and photovoltaic parameters listed in Table 1. As expected, the DSSC with NiO counter electrode showed a negligible power conversion efficiency (0.28 %) due to its lack of electrical conductivity. When NiO was replaced by PEDOT:PSS for the counter electrode, the DSSC reached a power conversion efficiency of 4.6 %. Furthermore, for the DSSC with NiO/PEDOT:PSS (weight ratio of 48/1) composite counter electrode, its short-circuit current density (Jsc), open-circuit voltage (Voc), fill factor (FF), and power conversion efficiency (η) were 22 mA cm−2, 0.748 V, 0.46, and 7.58 %, respectively. This indicates that the introduction of NiO into the PEDOT counter electrode remarkably increased the power conversion efficiency from 4.6 to 7.58 %. It is well-known that the performance of a DSSC counter electrode is dependent on its electrical conductivity and catalytic activity [1]. Because NiO is unable to increase the conductivity of PEDOT:PSS, the enhancement in energy conversion efficiency of NiO/PEDOT:PSS would be due to the excellent catalytic activity of NiO.

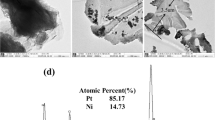

The NiO/PEDOT:PSS composite was further characterized by X-ray diffraction measurements. No diffraction peak was observed for the bare PEDOT:PSS film due to its poor crystalline structure (Fig. 2). In contrast, the rock salt crystal structure of the pure NiO film showed strong characteristic diffraction peaks at 2θ = 37.32°, 43.36°, 62.94°, 75.48° and 79.5°, corresponding to (111), (200), (220), (311), and (222) diffraction planes, respectively. Furthermore, the NiO/PEDOT:PSS composite exhibits the same diffraction patterns as NiO. The crystal particle sizes of NiO with and without PEDOT:PSS, which were calculated from the XRD peak widths at half-height, are about 48 and 52 nm, respectively. This indicates that no change in the crystal structure but a slight increase in particle sizes of NiO was caused by its combination with PEDOT:PSS.

The effect of NiO content on photovoltaic parameters of DSSCs was evaluated. As shown in Fig. 3a, Voc and FF of DSSCs with the NiO/PEDOT:PSS composite counter electrode exhibited a negligible fluctuation with NiO content. In contrast, Jsc and η are strongly dependent on NiO content in the composite counter electrode. As the content of NiO increased, Jsc increased up to the maximum value of 22 mA cm−2 at 48:1 weight ratio of NiO/PEDOT:PSS and then decreased. The power conversion efficiency (η) exhibited the similar NiO-dependence as Jsc, namely, η increased up to the maximum value (7.58 %) and then decreased with increasing NiO content. This indicates that the enhancement of η for DSSCs with a NiO/PEDOT:PSS counter electrode is mainly due to the increase of Jsc. Furthermore, the highest power conversion efficiency (7.58 %) of NiO-PESOT:PSS is even comparable with that (8.7 %) of a DSSC with an expensive Pt CE.

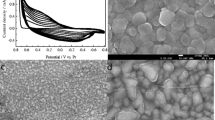

Cyclic voltammograms (CVs) were measured to characterize the electro-catalytic activity of NiO/PEDOT:PSS counter electrodes for I−/I3 − redox couple. For a typical CV curve, two pairs of oxidation and reduction peaks should be observed for the triiodide/iodide and triiodide/iodide redox pairs, respectively [24–26].

Furthermore, the peak current density and peak-to-peak separation (EPP) are two important parameters to evaluate catalytic activities of different electrodes [24]. The higher peak current density and lower EPP, the better catalytic activity that counter electrode has. As shown in Fig. 4a, a PEDOT:PSS CE exhibited typical reduction and oxidation characteristics for I−/I3 − redox couple, whereas no effective redox of I−/I3 − was observed on a bare NiO CE. However, NiO/PEDOT:PSS composite electrode exhibited a remarkable change in both of position and intensity of redox reaction peaks, namely, higher peak current density value and lower peak-to-peak separation positions were observed. This confirms the excellent electro-catalytic activity of NiO/PEDOT:PSS composite counter electrode. In addition, the CV curves of NiO/PEDOT:PSS, NiO, and PEDOT:PSS CEs, which were obtained using an electrolyte without the I−/I3 − redox couple, show no remarkable peak (Fig. 4b). This further supports that the reduction and oxidation peaks (in Fig. 4a) are due to I−/I3 − redox couple.

Electrochemical impedance spectra (EIS) were also exploited to evaluate NiO/PEDOT:PSS composite CEs. Two semicircles were observed in the frequency range of 0.1-100 k Hz for all samples (Fig. 5). The intercept of the first semicircle (left one) represents the ohmic serial resistance (Rs) related to the intrinsic resistance of assembled cells [27, 28] The semicircle in lower Z′ (corresponding to high-frequency) is associated with the charge transfer resistance (Rct) at the CE/electrolyte interface and the semicircle in the higher Z′ (low-frequency range) arises from the Nernst diffusion impedance (ZN) of the triiodid/iodide couple [29–32]. As shown in Table 1, one can see the variation of Rs was negligible (14–17 Ω) for all CEs, whereas Rct and ZN values vary significantly with increasing NiO content in NiO/PEDOT:PSS composite CEs. All composite CEs possess higher Rct and ZN values than those of a pure PEDOT:PSS film. The performance of a counter electrode is determined by both electrical conductivity and catalytic activity [1]. At the beginning, the increase of catalytic activity with increasing NiO content constitutes a determining-factor, leading to the enhancement of current density and thus efficiency. In contrast, when the NiO/PEDOT ratio is larger than 48, ZN significantly increases so that the decrease of conductivity with increasing NiO content becomes a main factor, resulting in the reduction of current density and efficiency (Table 1). Therefore, the excellent photovoltaic performance of the composite counter electrode at NiO/PEDOT:PSS weight ratio of 48 is due to the optimum combination between the high catalytic activity of NiO and the superior electrical conductivity of PEDOT:PSS.

4 Conclusion

NiO is an excellent catalyst for DSSC counter electrode. The DSSC with a NiO/PEDOT:PSS counter electrode reached a maximum power conversion efficiency of 7.58 %. Furthermore, the effect of NiO content on the energy conversion efficiency was demonstrated. As NiO content increased, the energy conversion efficiency increased to the maximum value and then decreased. Such a variation of conversion efficiency with NiO content is dependent on the current density (Jsc), which is determined by combination between the catalytic activity of NiO and the conductivity of PEDOT:PSS.

References

Grätzel M (2003) J Photochem Photobiol C 4:145

Law M, Greene LE, Johnson JC, Saykally R, Yang PD (2005) Nat Mater 4:455

Hagfeldt A, Boschloo G, Sun L, Kloo L, Pettersson H (2010) Chem Rev 110:6595

Yella A, Lee HW, Tsao HN, Yi C, Chandiran AK, Nazeeruddin K, Diau EWG, Yeh CY, Zakeeruddin SM, Grätzel M (2011) Science 334:629

Bach U, Lupo D, Comte P, Moser JE, Weissörtel F, Salbeck J, Spreitzer H, Grätzel M (1998) Nature 395:583

Mende LS, Bach U, Humphry-Baker R, Horiuchi T, Miura H, Ito S, Uchida S, Grätzel M (2005) Adv Mater 17:813

Wang H, Hu YH (2012) Energy Environ Sci 5:8182

Wang H, Wei W, Hu YH (2013) J Mater Chem A 1:6622

Li GR, Wang F, Jiang QW, Gao XP, Shen PW (2010) Angew Chem Inter Ed 49:3653

Han J, Kim H, Kim DY, Jo SM, Jang SY (2010) ACS Nano 4:3503

Chen L, Tanb W, Zhang J, Zhou X, Zhang X, Lin Y (2010) Electrochim Acta 55:3721

Hu YH, Ruckenstein E (2004) Adv Catal 48:297

Hu YH, Ruckenstein E (1998) J Phys Chem A 102:10568

Hu YH, Ruckenstein E (2002) Catal Rev 44:423

Hu YH, Ruckenstein E (1998) J Phys Chem B 102:230

He JJ, Lindström H, Hagfeldt A, Lindquist SE (1999) J Phys Chem B 103:8940

Li L, Gibson AE, Qin P, Boschloo G, Gorlov M, Hagfeldt A, Sun L (2010) Adv Mater 22:1759

Nattestad A, Ferguson M, Kerr R, Cheng YB, Bach U (2008) Nanotechnology 19:295304

Gibson AE, Smeigh LA, Pleux LL, Fortage J, Boschloo G, Blart E, Pellegrin Y, Odobel F, Hagfeldt A, Hammarström L (2009) Angew Chem Int Ed 48:4402

Bandara J, Weerasinghe H (2005) Solar Energy Mater Solar Cells 85:385

Guai GH, Leiw MY, Ng CM, Li CM (2012) Adv Energy Mater 2:334

Bajpai R, Roy S, Koratkar N, Misra DS (2013) Carbon 56:56

Okumura T, Sugiyo T, Inoue T, Ikegami M, Miyasaka T (2013) J Electrochem Soc 160:H155

Gong F, Wang H, Xu X, Zhou G, Wang ZS (2012) J Am Chem Soc 134:10953

Yeh MH, Lin LY, Lee CP, Wei HY, Chen CY, Wu CG, Vittal R, Ho KC (2011) J Mater Chem 21:19021

Li GR, Wang F, Song J, Xiong FY, Gao XP (2012) Electrochim Acta 65:216

Sakurai S, Jiang HQ, Takahashi M, Kobayashi K (2009) Electrochim Acta 54:5463

Han LY, Koide N, Chiba Y, Islam A, Komiya R, Fuke N, Fukui A, Yamanaka R (2005) Appl Phys Lett 86:213501

Joshi P, Zhang LF, Chen QL, Galipeau D, Fong H, Qiao Q (2010) ACS Appl Mater Interfaces 2:3572

Koh JK, Kim J, Kim B, Kim JH, Kim E (2011) Adv Mater 23:1641

Xia JB, Chen L, Yanagida SJ (2011) Mater Chem 21:4644

Hauch A, Georg A (2001) Electrochim Acta 46:3457

Acknowledgments

This work was supported by the U.S. National Science Foundation (NSF-CBET-0931587) and the ACS Petroleum Research Fund (PRF-51799-ND10). Hu also thanks Charles and Carroll McArthur for their great support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Wei, W. & Hu, Y.H. NiO as an Efficient Counter Electrode Catalyst for Dye-Sensitized Solar Cells. Top Catal 57, 607–611 (2014). https://doi.org/10.1007/s11244-013-0218-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-013-0218-8