Abstract

It seems that, looking with a historical perspective, there is a major step change advance in porous materials science about once every decade. Usually, these advances take the form a new type of solid and depend on the expertise of synthetic chemists to develop new materials. So the question is what will be the next great leap forward in this area. Here I will offer several examples of very recent results that suggest challenges that remain in zeolite and porous materials science. They range from control over chirality and location of catalytic sites inside pores, to the preparation of ultrathin films and coatings of zeolite materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since the inception of the field of preparative zeolite science [1] in the middle of the twentieth century, there has been a major, revolutionary step change about every decade. Most of these great advances have been based on the synthesis of new types of material. From the earliest discovery of how to make synthetic zeolites [2], the discovery of AlPOs [3] and mesoporous materials [4] through to the current hot topic of metal organic frameworks [5]. The big question is, of course, what will be the next big discovery? Part of the delight in science is that it is very difficult to predict this. However, what we can do is formulate some challenges in nanoporous materials science that are currently difficult, but that do show some signs of being possible. In this short paper I will look at some of the challenges I see in zeolite science. It is not by any means comprehensive but constitutes a personal view of the areas of synthetic chemistry that may be important in the next few years (others have their own views [6]). The areas range from the synthesis of bulk solid materials with controlled chirality, the control over the where catalytic sites are in zeolites and the preparation of novel morphologies, such as ultra thin layers.

2 A Historical Perspective

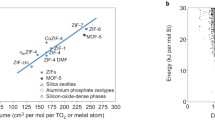

The science of nanoporous materials has, over the last 60 years or so, provided many fascinating advances. Figure 1 shows an interesting (albeit personal) view of the history of the major advances in zeolite science. If we include mesoporous materials and metal organic frameworks (MOFs) there has been a really major advance in this field about every decade. Starting with the first general demonstration of zeolite synthesis, progressing through the development of the great industrial catalysts, aluminophosphates and mesorporous materials to MOFs. Of great interest to anyone with any stake in this field is obvious—it is about time for a new ‘big’ advance, what is it likely to be? Such questions are, by their very nature, extremely difficult to answer. What we can do is to formulate some of the challenges that might lead themselves to interesting, and potentially groundbreaking advances in zeolite science. In this short perspective, I will look at several areas where I believe the challenges in zeolite synthesis lie. It is not meant to be completely exclusive, and is of course coloured by my own personal favourite areas, but it is meant simply as a starting point for discussion.

3 Homochirality

Ever since it was recognised that zeolite-beta [7], one of the great industrial catalysts, has a potentially chiral structure there has been an incentive to produce chiral zeolites [8, 9]. On several occasions zeolite structures have been published with the tag chiral attached to them based on the symmetry of the framework structure. Several of these have been in high profile publications, with structures that have aroused great excitement, like SU-32 [10] and ITQ-37 [11]. ITQ-37 in particular has a chiral framework structure combined with large pore sizes—something that is surely of interest to many researchers in both academia and industry [12]. But the problem goes further than just making a ‘chiral’ zeolite. To be of any use the sample of a zeolite (or any other material for that matter) must be homochiral—it must all be of the same handedness (or at least there must be significant excess of one hand over the other). It is very common for the homochirality of a sample not to have been characterised at all. Figure 2 shows the different possibilities in a bulk sample of a solid that has a chiral structure. The material can be homochiral (all crystals have the same hand), it can be a recemic conglomerate (50% of crystals have one hand, 50% the other) or the sample can exist as a rccemic twin (each crystal comprises 50% of one hand and 50% of the other). Clearly only the first option will be of significant use for any enantioselective processes. So the major question in this area is how do we control the handedness of all the crystals in a bulk sample so that they are all the same in any one sample, and that they are all the same from one synthesis to the next? This now looks like a very great challenge.

Possibilities for crystallites with a ‘chiral’ structure in a bulk sample. The two top scenarios are both overall non-chiral having equal numbers of left handed (red) and right handed (blue) crystals (or parts of crystals). The goal of the zeolite scientist is to make a homochiral sample where all crystallites are of the same hand

The great advantage of MOFs is that it is perfectly possible to choose your organic linker to be chiral and enantiomerically pure. As long as it does not racemise during the synthesis process the resulting MOF should be homochiral. This approach has been used with great success on several occasions [13]. But what about when there isn’t the chance of using a chiral building block in the structure—what are the options then? Most MOF materials, as well as zeolites, fall into this category. Using chiral templates is one way that this has been approached, but with only limited success. Fortunately, recent advances do point to some techniques we can use, and chiral induction seems to be the most promising. Here a chiral additive (or even a chiral solvent) is used to select out one of the hands of the structure so that the final bulk solid is homochiral. This technique is still only in its infancy, but there are now several examples in the literature. One uses a chiral ionic liquid as a solvent in an ionothermal synthesis [14, 15] of a homochiral coordination polymer [16]. If an achiral solvent is used an achiral product is formed. If one uses the solvent of the opposite hand then the product of the opposite hand is formed. All this points to the chiral solvent passing its chiral information onto the product, but without becoming incorporated into the final structure itself. Similar excellent results have been found using different chiral additives [17, 18]. However, perhaps the most important recent contribution in this areas has come from Bu’s group in the USA, where he has shown that a chiral phosphate additive can be used to prepare a homochiral zinc phosphate with the CZP structure—the first time a homochiral zeolite analogue has been prepared (Fig. 3) [19]. Mechanistic aspects of the different chiral induction approaches have been discussed in a recent review article [20], but this method looks to be an exciting way of preparing homochiral bulk solids, and I certainly look forward to seeing advances in this area in the coming years.

Homochiral samples of zeolite CZP can be prepared using a chiral induction agent (a phosphate functionalised with a chiral organic group). Such chiral induction offers great potential for future preparations of useful homochiral zeolites. Figure taken from Ref. [20]

3.1 Controlling Where the Negative Charges and Catalytic Sites are!

Many of the most important chemical properties of zeolites arise from the location of aliovalent dopant atoms in the framework structure. For example, Al3+ doped for (nominally) Si4+ in a zeolite leads to an overall negative charge on the framework that needs to be balanced by a cation. This is where the ion exchange and many of the catalytic properties (particularly those based on Brønsted acidity) come from. It is probably obvious to most of us that the location of such dopant atoms, and the location of the subsequent negative charge, has to play an important part in controlling the properties of a zeolite. Iglesia and co-workers [21] have demonstrated just that recently with some really elegant work showing that certain sites in the side pockets of mordenite are much more catalytically important than others in the solid. Since we intuitively know that the locations of, for example, the aluminium ions, in a zeolite are so important it stands to reason that we should strive to control where the substituents are located to maximise their potential effect. This is another great challenge. At the moment it is really difficult even to characterise exactly where features such as Brønsted acid sites are, never mind exert any sensible measure of control over their location during the synthesis process. Neutron diffraction and other advanced crystallography techniques, combined with clever spectroscopy have been used to characterise where the substituents are found in certain zeolites [22], but the subset where this has been done is limited. Our best opportunity to accomplish such control is likely to be in really clever use of templating molecules and perhaps mineralisers. Solid state NMR measurements, using techniques such as cross polarisation and dipolar recoupling (REDOR), particularly those carried out by Koller and co-workers [23], have shown us that the positive charges of the template are generally located close in space to the negative charges on the framework. Similarly, negative charges supplied by fluoride ion mineralisers [24] have been shown to impose polar ordering on structure directing agents during synthesis even though the overall framework of the zeolite is ceontrosymmetric (and therefore nonpolar) [25, 26]. All this work shows that there is a close relationship between where the negative charge on the zeolite is and where positive charge on the template is. Can we turn this the other way around and use the location of the positive charge on the template to alter the distributions of where the negative charges, and from there where the active sites are, in zeolites? To return to the case of mordenite, the fraction of Bronsted acid sites located within the most catalytically-important 8-ring pockets varies widely (from 10 to 80%) depending on how the material is made. Directing all (or as many as possible) of the aluminium ions to the correct crystallographic site in the structure could have a significant influence on the material properties. So how could we do this in principle? One way may be by moving the positive charge on the template to a different position in the molecule so that it subtly alters where the aluminium is sited in the subsequent zeolite. There are, of course, complications to this approach. The location of the positive charge on a template molecule may be the consequence of the organic chemistry used to prepare it, and it might be difficult or impossible to move the positive charge easily in all cases. In addition, for the process to work the template cannot be too mobile in the material at the synthesis temperature otherwise the location of the aluminium-based negative charge would probably still control the location of the template charge rather than the other way around. All in all however, I feel that this is a mechanism that is worth exploring.

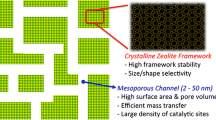

4 New Morphologies for Zeolites

In the last few years it has become clear that new morphologies for zeolites are important. Hierarchical zeolitic solids also containing, for example, mesoporosity, have been of great interest in the literature. I think this will continue as we move forward [27]. Similarly recent work has shown that zeolite materials prepared to highlight their two dimensional properties—thin films and ultra thin (single unit cell) layers)of zeolites have clearly great potential, both in the academic world where we want to control how these materials are formed and in the industrial world where novel properties may have great impact.

Corma and co-workers probably generated the first examples of a ‘two dimensional’ zeolite material when the used ultrasound irradiation to delaminate a zeolite precursor into individual sheets, and then showed it had interesting catalytic properties [28]. Ryoo and co-workers took this concept one stage further by using a surfactant-type template so that only the charged head group acts to direct the zeolite structure, while the long alkyl chain of the surfactant prevents growth perpendicular to the layers [29] (Fig. 4). This is an outstanding result and the TEM images provided in Ryoo’s paper showing single unit cell thick layers of a zeolite structure are particularly striking. Such control over the morphology of zeolites, taking it to the limit of what a zeolite really is, offers some remarkable possibilities for utilising the inherent nanopatterning of such thin zeolite layers. The next challenge in this area is to show that these materials are more generally available, and that their properties can be exploited, something that Ryoo is already beginning to do [30]. Such work will be of great interest over the next few years.

The proposed structure of a single unit cell thick MFI zeolite layer, with the charged head group of the surfactant (red) templating the growth of ultrathin layers of the zeolite, which are prevented from growing in the third direction by the long alkyl chain. Figure by kind permission from Ref. [29]

In a similar vein, at least in terms of moving zeolites from bulk 3D materials towards 2D applicability, is the large amount of work currently being completed on zeolite-based coatings. Yushan Yan has been particularly prevalent in this area, and some of his work shows great promise for applicability in industry in particular. Some of the most striking things he has done in recent times include the use of ionic liquids as the solvent in the ionothermal preparation of thin films of AlPOs and SAPOs [31]. Such work opens up new possibilities for the development of industrial applications in areas where it is difficult or impractical to complete zeolite synthesis in sealed pressure containers. The low vapour pressure of the ionic liquids means that Yan’s zeolite coatings can be made in open containers, simplifying the practical aspects of using these materials in this type of application [32]. The challenge in terms of ionic liquids is to improve their use in the synthesis of silica based zeolites. Despite the first ionothermal synthesis of AlPOs being reported 6 years ago [33] the first use of a truly ionothermal synthesis to prepare an all silica zeolite has only just been reported [34]. This is mostly because the commonly available ionic liquids are not suitable for the dissolution of the silica starting materials. However, now that this problem has been overcome at least once, there should be more scope to continue the development of ambient pressure synthesis of zeolites of all kinds and develop further potential applications in thin films.

4.1 MOF Synthesis—More Complex Reactivity

Metal organic frameworks (MOFs) are clearly some of the most interesting and researched materials that have been prepared over the last decade or so. Their high porosity makes a good fit with zeolitic materials. There is the feeling that one of the reasons MOFs are so popular is that they are relatively easy to prepare (at least in concept), and that this is why there has been such an explosion in MOF structures over the last few years. But what are the future challenges of MOF synthesis? Is there any reason to simply go for even more porous solids? I believe the biggest challenge in MOF synthesis concerns the synthesis and control over flexible MOF structures. This is an almost unique aspect of MOF materials. Flexible frameworks can be subdivided into two categories: materials that are flexible without any bond breaking and materials that undergo responsive bond breaking and reforming reactions. Examples of the former type of transformation include the fascinating ‘breathing’ MOFs [35] and others where structural changes occur on application of an external stimulus [36].

Transformations where there is a change in network connectivity are rarer, with fewer examples in the literature [37]. This is particularly true of changes of network connectivity in three dimensional solids, which are more rigid than their low dimensional (1D and 2D) counterparts [38]. However, such materials have great importance as they offer the opportunity to develop new materials with vastly different properties to those currently available [39]. Designing and controlling materials to show such transformations, and harnessing any interesting properties that occur, is a significant challenge. Recent progress includes taking more account of the various strengths of bonds in a ligand, using strong bonds to hold the structure together while allowing reactions to happen at the weaker bonds in a structure [40, 41]. Such a strategy led to the development of material that only adsorbed one particular gas (nitric oxide) and none of the other common gases tested, illustrating the promise that this strategy holds (Fig. 5). Even more recently strategies for a whole new type of MOF has been developed, combining the structural stability of the framework with other units that are flexible, so that repeated dynamics on this part of the material does not affect the structural integrity of the system as a whole. The authors of this concept call it ‘robust dynamics’ [42]. While much of the attraction surrounding MOFs is based on how simple they are, the increase in complexity of these materials described above necessarily expands the types of structures that are accessible. I see increasing the complexity of ‘reactive’ MOFs as the next major step in MOF preparative chemistry.

Taking advantage of the ‘reactivity’ of a metal organic framework (top) can lead to a material than shows extreme selectivity to one particular gas, nitric oxide (bottom). Figure taken from Ref. [40]

5 Conclusions

So what is the next big step in zeolite and nanoporous materials chemistry. This perspective doesn’t, of course, really help us get closer to answering this question. By its very nature such step changes are surprises. But at least in terms of synthesis there does seem to be opportunities to increase the subtle control over the complex features of the materials, whether homochirality, superthin zeolites films or robustly dynamic MOFs. I personally think it is a very exciting time to be a porous materials scientist, and I do believe that the next big advance is just around the corner.

References

Wright PA (2009) Microporous framework solids. Royal Society of Chemistry, London

Barrer RM, Denny PJ (1961) J Chem Soc 971

Wilson ST, Lok BM, Messina CA, Cannan TR, Flanigen EM (1982) J Am Chem Soc 104:1146

Kresge CT, Leonowicz ME, Roth WJ, Vartuli JC, Beck JS (1992) Nature 359:710

Ferey G (2008) Chem. Soc. Rev. 37:191

Coronas J (2010) Chem. Eng. J. 156:236

Newsam JM, Treacy MMJ, Koetsier WT, Degruyter CB (1988) Proc R Soc Lond A Math Phys Eng Sci 420:375

Akporiaye DE (1994) Chem Commun 1711

Yu JH, Xu RR (2008) J. Mater. Chem. 18:4021

Tang LQ, Shi L, Bonneau C, Sun JL, Yue HJ, Ojuva A, Lee BL, Lee BL, Kritikos M, Bell RG, Bacsik Z, Mink J, Zou XD (2008) Nature Mater 7:381

Sun JL, Bonneau C, Cantin A, Corma A, Diaz-Cabanas MJ, Moliner M, Zhang DL, Li MR, Zou XD (2009) Nature 458:1154

Harris KDM, Thomas JM (2009) Chemcatchem 1:223

Seo JS, Whang D, Lee H, Jun SI, Oh J, Jeon YJ, Kim K (2000) Nature 404:982

Parnham ER, Morris RE (2007) Acc Chem Res 40:1005

Morris RE (2009) Chem Commun 2990

Lin ZJ, Slawin AMZ, Morris RE (2007) J Am Chem Soc 129:4880

Zhang J, Chen SM, Nieto RA, Wu T, Feng PY, Bu XH (2010) Angew. Chem. Intl. Ed. 49:1267

Zhang J, Bu XH (2009) Chem Commun 206

Zhang H, Chen SM, Chen SM, Bu XH (2009) Angew. Chem. Intl. Ed. 48:6049

Morris RE, Bu XH (2010) Nature Chem. 2:353

Gounder R, Iglesia E (2010) Angew Chem Int Ed 49:808

Smith L, Cheetham AK, Morris RE, Marchese L, Thomas JM, Wright PA, Chen J (1996) Science 271:799

Fild C, Eckert H, Koller H (2000) J Am Chem Soc 122:12590

Zones SI, Darton RJ, Morris R, Hwang SJ (2005) J. Phys. Chem. B 109:652

Villaescusa LA, Wheatley PS, Bull I, Lightfoot P, Morris RE (2001) J Am Chem Soc 123:8797

Wragg DS, Slawin AMZ, Morris RE (2001) J. Mater. Chem. 11:1850

Park KH, Park HJ, Kim J, Ryoo R, Jeon JK, Park J, Park YK (2010) J Nanosci Nanotechnol 10:355

Corma A, Fornes V, Pergher SB, Maesen TLM, Buglass JG (1998) Nature 396:353

Choi M, Na K, Kim J, Sakamoto Y, Terasaki O, Ryoo R (2009) Nature 461:246

Na K, Choi M, Park W, Sakamoto Y, Terasaki O, Ryoo RJ (2010) Am Chem Soc 132:4169

Cai R, Sun MW, Chen ZW, Munoz R, O’Neill C, Beving DE, Yan YS (2008) Angew. Chem. Intl. Ed. 47:525

Morris RE (2008) Angew. Chem. Intl. Ed. 47:442

Cooper ER, Andrews CD, Wheatley PS, Webb PB, Wormald P, Morris RE (2004) Nature 430:1012

Wheatley PS, Allan PK, Teat SJ, Ashbrook SE, Morris RE (2010) Chem Sci. doi:10.1039/C0SC00178C

Serre C, Mellot-Draznieks C, Surble S, Audebrand N, Filinchuk Y, Ferey G (2007) Science 315:1828

Zhang JP, Lin YY, Zhang WX, Chen XM (2005) J Am Chem Soc 127:14162

Ghosh SK, Zhang JP, Kitagawa S (2007) Angew. Chem. Intl. Ed. 46:7965

Horike S, Shimomura S, Kitagawa S (2009) Nature Chem. 1:695

Cussen EJ, Claridge JB, Claridge JB, Rosseinsky MJ, Kepert CJ (2002) J Am Chem Soc 124:9574

Xiao B, Byrne PJ, Wheatley PS, Wragg DS, Zhao XB, Fletcher AJ, Thomas KM, Thomas KM, Peters L, Evans JSO, Warren JE, Zhou WZ, Morris RE (2009) Nature Chem. 1:289

Allan PK, Xiao B, Teat SJ, Knight JW, Morris RE (2010) J Am Chem Soc 132:3605

Deng H, Olson MA, Stoddart JF, Yaghi OM (2010) Nature Chem. 2:439

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Morris, R.E. Some Difficult Challenges for the Synthesis of Nanoporous Materials. Top Catal 53, 1291–1296 (2010). https://doi.org/10.1007/s11244-010-9586-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-010-9586-5