Abstract

The dissolution of cellulose under 5 MPa of H2 in the absence of catalyst is temperature and time dependant. The presence of Pt/γ-Al2O3 increases the initial rate of dissolution. The presence of H2/Pt is essential although its exact role has not been well elucidated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

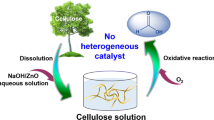

Direct transformation of cellulose into valuable organic chemicals is of great interest [1]. Due to its structure, cellulose is almost insoluble and very resistant to chemical transformations. However, cellulose can be hydrolyzed with liquid acids [2], enzymes [3], or supercritical water [4]. The use of heterogeneous catalysis has recently been reported with catalysts such as sulfonated carbons [5, 6], metal carbides [7] or bi-functional solids [8]. In general results obtained from control reactions would provide insights to the reactivity of the substrate in the reaction media but are not reported. Fukuoka et al. report the direct formation of sorbitol from cellulose in 25% yield, with Pt/γ-Al2O3 (190 °C, H2O, 5 MPa H2, 24 h). While the influence on the sorbitol yield of various supports and metals is well established there is no mention of either the cellulose conversion or the influence of the reaction media. Here we report the conversion of cellulose in the absence of catalyst under conditions used by Fukuoka as well as the promoting effect of H2 in the presence of Pt/γ-Al2O3.

2 Experimental Part

Microcrystalline Avicel® cellulose (Aldrich) was used as received. Pt/γ-Al2O3 (2.5 wt%) was prepared by wet impregnation of γ-Al2O3 by H2PtCl6. Before using, the catalyst was reduced under H2 (350 °C, 3 h). Reactions were performed in a 150 mL autoclave equipped with a vigorous mechanical agitation system. The autoclave was filled with water (100 mL) and cellulose (0.800 g, 5 mmol equiv of C6H10O5 units), (0.340 g of catalyst), flushed three times with He. The autoclave was heated up and the pressure adjusted to 5 MPa with H2. The reaction was stopped by cooling the autoclave using an ice bath. After filtration of the residual solid (0.45 μm Teflon filters), the liquid phase was analysed by HPLC (CarboSep 87C column and RID detector) and Total Organic Carbon analyzer. Solubilisation (dissolution-conversion) was calculated as the ratio between the total molar amount of carbon in the filtrate obtained from TOC analysis and the molar amount of initial carbon: ci (mol) = mcellulose/162*6 (162 = M of C6H10O5). Product yields are expressed as molar yields.

3 Results and Discussion

3.1 Cellulose Dissolution-Conversion in Hydrothermal Conditions in the Absence of Solid Catalyst

We evaluated the influence of temperature on the dissolution-conversion of cellulose in the absence of catalyst. Figure 1a shows that only 2% of cellulose was dissolved or converted upon hydrothermal treatment at 150 °C for 24 h. Significant cellulose dissolution was observed at higher temperatures: 11% of cellulose was dissolved at 175 °C and 35% at 190 °C, after 24 h of reaction under 5 MPa of H2 (Entry 1, Table 1). Similar results were observed for the reaction of cellulose in water at 190 °C in the absence of pressurized H2 (Entry 3, Table 1), showing that the solubilisation ratio seems to be only temperature dependant. The extent of non-catalyzed cellulose dissolution at relatively mild hydrothermal conditions (175–190 °C) was unexpected and not reported in the recent publications. We evaluated the influence of residence time. Figure 1b shows that the cellulose dissolution-conversion increased with time until reaching a plateau at 60% after 100 h of reaction. In the absence of catalyst, the liquid reaction mixture analysis showed a yield of 2% of glucose and 3% of 5-hydroxymethylfurfural (5-HMF, a dehydration product of glucose) (Entry 1, Table 1). This monomer distribution did not change significantly with the residence time, indicating that the observed phenomenon is rather limited to the dissolution-conversion of the cellulose into soluble polymers and that higher residence time does not favour further transformation into monosaccharides and other derivatives.

To determine if the dissolution-conversion phenomenon occurred on a specific part of the cellulose material (amorphous or crystalline), un-dissolved cellulose was used as reactant with the same conditions. Again, 38% of the re-used solid cellulose was dissolved after 24 h, a similar result of fresh cellulose (35%) (Entry 2, Table 1). This may indicate that the recovered cellulose does not correspond to a less reactive part of the material and there is no evidence of differences of dissolution-reaction for the amorphous and crystalline parts of the polymer. It may be possible that the observed 60% solubility after 100 h (480 mg of cellulose dissolved) corresponds to a maximum solubility of the cellulose in our conditions (i.e. saturation of the solution with soluble polymeric species). This would mean that with a lower concentration of cellulose a higher percentage of dissolution could be obtained. Using half of the initial cellulose concentration, 400 mg into 100 mL of water instead of 800 mg, the percentage of solubility reached 60% after 100 h (corresponding to 240 mg of cellulose dissolved) (Entry 4, Table 1). Moreover, using twice amount of cellulose, 1600 mg in 100 mL, 35% of solubility were obtained after 100 h, corresponding to 560 mg of cellulose dissolved (Entry 5, Table 1). This ruled out the possibility of a saturation of the solution since increasing the amount of cellulose in the reactor increased the amount of cellulose dissolved. Our results suggest dissolution-conversion of cellulose is dependent of the severity of the main parameters for the hydrothermal treatment (temperature and residence time) under the relatively mild conditions (temperature range of 175–190 °C).

3.2 Cellulose Dissolution-Conversion in Hydrothermal Conditions in the Presence of 2.5 wt% Pt/γ-Al2O3

We also studied the dissolution of cellulose in the presence of heterogeneous Pt/γ-Al2O3 (Fig. 1b). The “initial rate” (0–24 h) of cellulose dissolution is increased by a factor 1.7 in the presence of Pt/γ-Al2O3. Most likely, distinct mechanisms are involved as suggested by the different nature of the produced species. Indeed, a yield of 15% of sorbitol was obtained after 24 h, in agreement with the results reported by Fukuoka et al. (Entry 7, Table 1) [8].

In the absence of H2 the percentage of cellulose dissolution was drastically lowered from 60 to 38% (Entry 9, Table 1). The roles of H2 and Pt in this process are not straightforward. The higher overall activity and the higher yield to sorbitol obtained over Pt/γ-Al2O3 compared to the yield in glucose (2–3%) obtained in the absence of a solid catalyst or even over Pt free γ-Al2O3 (Entry 6, Table 1) may indicate that the metallic function is not restricted to the successive hydrogenation of the monosaccharide to the corresponding sorbitol but also has a role on the dissolution reaction. In the presence of H2, the metallic function may directly affect the initial step of activation of the cellulose by increasing the pool of H+ formed by heterolytic H2 dissociation as proposed by Fukuoka et al. [8]. The metallic centres in the presence of H2 may intervene in the carbocationic chain mechanism initiated by the glycosidic bond cleavage with H3O+. The cyclic carbenium ions, once formed, might react with H2O or they may be involved in a hydride transfer step promoted by H2/Pt which results in H+ release to the media (Scheme 1). The above proposition is based on literature data only [9–11]. Indeed, earlier work reports the possibility of such a heterolytic H2 activation with supported and non-supported Pd catalysts. It was shown that the polarisation Pdδ+-Hδ− or Pdδ−-Hδ+ depends on the polarity of the substrate [9–11]. In our case, a carbocationic substrate would favour Ptδ+-Hδ− species promoting the hydride transfer step. The yield of sorbitol did not increase and even slightly decreased at longer residence times (Entry 8, Table 1). This may be due to sorbitol degradation. Our work suggests that successive transformations of soluble polysaccharides into monosaccharides and derivatives remain of limited importance.

4 Conclusion

We showed that dissolution-conversion of cellulose occurred at 190 °C under 5 MPa of H2 to an extent of 35% of the introduced carbon amount after 24 h even in the absence of catalyst. This temperature is needed to have a significant dissolution and provides a yield of 2% glucose. The presence of Pt/γ-Al2O3 significantly increased the initial rate of dissolution-conversion as well as the selectivity of monomer sugars, especially sorbitol. Pt associated with H2 is proposed to intervene not only in the hydrogenation of glucose into sorbitol but also as an elementary step through H+ generation via H2 heterolytic dissociation and/or hydride transfer.

References

Gallezot P (2007) Green Chem 295

Kamm B, Gruber PR, Kamm M (eds) (2006) Biorefineries-industrial processes and products, volume 1: status quo and future directions. Wiley-VCH, Weinheim

Zhang Y-HP, Lynd R (2004) Biotechnol Bioeng 88:797

Sasaki M, Kabyemela B, Malaluan R, Hirose S, Takeda N, Adschiri T, Arai K (1998) J Supercritic Fluids 13:261

Onda A, Ochi T, Yanagisawa Y (2008) Green Chem 10:1033

Suganuma S, Nakajima K, Kitano M, Yamaguchi D, Kato H, Hayashi S, Hara M (2008) J Am Chem Soc 130:12787

Ji N, Zhang T, Zheng M, Wang A, Wang H, Wang X, Chen JG (2008) Angew Chem Int Ed 47:8510

Fukuoka A, Dhepe PL (2006) Angew Chem Int Ed 45:5161

Faucher N, Cintrat J-C, Rousseau B (2008) Appl Catal A 346:86

Yu J, Spencer JB (1997) J Org Chem 62:8618

Yu J, Spencer JB (1997) J Am Chem Soc 119:5257

Acknowledgements

This work has been supported by IFP-Lyon, the CNRS and the University of Lyon 1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jollet, V., Chambon, F., Rataboul, F. et al. Non-Catalyzed and Pt/γ-Al2O3 Catalyzed Hydrothermal Cellulose Dissolution-Conversion: Influence of the Reaction Parameters. Top Catal 53, 1254–1257 (2010). https://doi.org/10.1007/s11244-010-9577-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-010-9577-6