Abstract

The neem tree, Azadirachta indica A. Juss., is an important multipurpose tree globally used in agriculture with recalcitrant and chilling-sensitive seeds. Here, we studied the encapsulation in sodium alginate of in vitro-derived nodal segments of neem as a method to preserve in vitro culture material of this species for laboratory exchange and for the medium-term storage. A good gel complexation was achieved using 3% sodium alginate and 70 mM CaCl2·2H2O. An average bead conversion of 75%, 0.5 cm of shoot length and 2 leaves were recorded after 4 weeks of culture, irrespective of the polymerisation duration (5 to 20 min). The growth of nodal segments was completely inhibited when they were kept at 4 °C or at 8 °C for 4 weeks, while those encapsulated and stored at 12 °C for 4 weeks, sprung up only 20% under optimal conditions, 23 °C. However, bud sprouting of encapsulated nodal segments stored at 12 °C for 4 weeks increased to 75% under optimal conditions by incubating the nodal segments with 25 µM acetylsalicylic acid (ASA) for 4 weeks prior to encapsulation. We observed that this ASA pre-treatment stimulated the antioxidative defenses of the explant, especially ascorbate peroxidase, catalase, peroxidase, dehydroascorbate reductase and glutathione reductase enzymes that could have improved the viability of the buds stored at 12 °C. Additionally, ASA seemed to protect the cell membranes, as observed by the lipid peroxidation results. All these data together led us to suggest the use of ASA in short- and medium-term storage of in vitro-derived nodal segments of neem.

Key message

Neem nodal segments, encapsulated in alginate beads and stored at 12 °C recovered their viability when were pre-treated with acetylsalicylic acid, which improved buds’ antioxidant defences.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The neem tree, Azadirachta indica A. Juss., is an important multipurpose tree, the products of which are globally used in agriculture, medicine, cosmetics and animal health care (Kumar et al. 2013). The neem tree is mainly propagated by seeds. However, as many other recalcitrant tropical seeds, neem seeds are chilling-sensitive and rapidly lose viability even if stored at high relative humidity (Kumar and Mishra 2014; Sacandé et al. 2000). This limits progress in the conservation and evaluation of germplasm, ex-situ collection, material exchange and, overall, tree improvement. Tissue culture techniques have been described to overcome these limitations. Micropropagation from juvenile (Joshi and Thengane 1996; Shahin-Uz-Zaman et al. 2009) and adult material (Arora et al. 2010; Quraishi et al. 2004) has been described. In that context, organogenesis (Chaturvedi et al. 2004; Srivastava et al. 2009) and somatic embryogenesis (Gairi and Rashid 2005; Rout 2005) protocols have been reported from flower and seed derived material. Thus, it is important to develop a methodology to preserve in vitro culture material and collections of this species for laboratory exchange at medium and long term. Encapsulation of vegetative propagules has become a potentially cost-effective clonal propagation system and can be used as an alternative to synthetic seeds derived from somatic embryos. Encapsulation of nodal segments or shoot tips is used as a method for germplasm conservation and to exchange material between laboratories (Rihan et al. 2017). This technique offers an easy and cheap method and a space-saving option for short- and medium-term storage due to the use of small capsule size and relative ease of handling these structures above 0 °C, whereby liquid nitrogen and expensive equipment is not necessary. Encapsulation of vegetative propagules and regeneration of complete plantlets from these have been reported for fruit trees, medicinal plants, ornamentals, conifers and woody crops (Gupta et al. 2019; Hung and Trueman 2012; Khan et al. 2018; Kulus and Zalewska 2014, Kulus 2019; Muslihatin et al. 2018; Nair et al. 2019; Rai et al. 2008; Sharma et al. 2015; Varshey and Anis 2014).

Slow growth storage protocols generally use low temperatures, and, sometimes, a modified culture medium containing a sugar alcohol or a growth retardant to reduce in vitro growth rates and the frequency of the cyclic subculture of shoots (Bhushan and Gupta 2017; Kulus 2018; Marino et al. 2010). Plant growth retardants (PgRs) are natural or synthetic substances that modify plant growth and development retarding or inhibiting shoot elongation, leaf development, and usually intensifying green leaf pigmentation (Grossmann 1990). Therefore, they have been used for in vitro shoot collection maintenance in vegetable crops mainly (Jarret 1997). Apart from these morphological modifications, physiological alterations such as improved resistance to environmental stress conditions, e.g. cold and chilling, have been reported (Korsukova et al. 2015; Moradi et al. 2017; Zhao et al. 2019) in response to PgRs, which may have practical implications in in vitro cold storage.

The mode of action of PgRs depends on the class of substance (Grossmann 1990). Acetyl-salicylic acid (ASA), a derivative of the natural metabolite salicylic acid (SA), has been described as a growth inhibitor in potato in vitro cultures (López-Delgado and Scott 1997). Moreover, SA seems to be involved in the plant defense response to biotic and abiotic stresses (Ojaghian et al. 2013; Zhang et al. 2013) by regulating antioxidant enzymes biosynthesis (Fujita et al. 2006; Zhang et al. 2011). Successful sunflower encapsulation and cold preservation of shoot tips in alginate beads containing SA have been reported as well as consecutive plant regeneration (Katouzi et al. 2011).

As a first step for the establishment of an in vitro conservation protocol for neem shoots, the effect of several growth retardants on the sprouting and development of nodal segments and on meristem development at the histological level was evaluated (Padilla et al. 2015). Among the retardants tested, the results obtained demonstrated the great effectiveness of ASA, which decreased bud sprouting, bud length and leaf number and, once transferred to ASA-free medium, permitted the recovery of neem bud growth (Padilla et al. 2015). Here, ASA was tested for the improvement of cold conservation of nodal segments encapsulated in alginate beads. To the best of our knowledge, this is the first study on the encapsulation of neem nodal segments from in vitro shoots in alginate beads for germplasm distribution and exchange and focusing on the effect of ASA on antioxidant metabolism of neem nodal segments during cold storage.

Material and methods

Explant source

Neem cultures originated from in vitro seed germination. Depulped mature fruits were kindly provided by Dr. Elaine Solowey, the Arava Institute for Environmental Studies, Kibbutz Ketura, Israel. After removing the endocarp of the fruits, the seeds were surface disinfected by immersion in a 1% calcium hypochlorite solution for 20 min and rinsed four times in sterile distilled water. Subsequently, seeds were cultured onto germination medium consisting of Murashige and Skoog (1962) (MS) basal medium, with the macroelements at half strength, 30 g L−1 sucrose and 0.7% agar (HispanLab, S.A., Madrid, Spain). In vitro shoots were maintained for 3 years by sub-culturing at 4-week intervals onto Neem Multiplication Medium (NMM), which consisted of Driver and Kuniyuki (1984) medium supplemented with 0.005 mg L−1 benzyladenine and 10 mg L−1 sequestrene (Syngenta, Basel, Switzerland). For all experiments, explants consisted of nodal stem segments (4–8 mm-long), containing one axillary bud and no leaves.

Preparation of beads: concentration of alginate and complexation agent

Prior to the preparation of beads, we studied the influence of alginate and of calcium chloride concentrations on the consistency and strength of beads. Thus, sodium alginate (Batch number 106k01131, Sigma-Aldrich, Madrid, Spain), at a concentration of 3%, 3.5% or 4% (w/v), was added to MS1 medium consisting of liquid MS basal medium including vitamins (Duchefa, Netherland) with 30 g L−1 sucrose and 0.2 g L−1 MES, 2-(N-morpholino)ethanesulfonic acid (pH 5.7). Additionally, different calcium chloride solutions (70, 80, 90 and 100 mM) were prepared to study the complexation of the beads. Both the gel matrix and calcium chloride solutions were autoclaved at 104 kPa and 121 °C for 20 min. Twelves treatments were tested in total, with ten beads per treatment, to study their consistency, shape and aspect visually.

Encapsulation of nodal segments

Encapsulation was accomplished by adding the nodal segments to the sodium alginate medium and, with the help of a 5 mL pipette (Eppendorf Ibérica SL, Madrid, Spain) coupled with a 5 cm long and 1 cm diameter silicone tube, nodal segments were collected and dropped into the calcium chloride solutions. Each drop had 400 µL alginate medium and one nodal segment. The beads were retrieved with wide-tipped forceps and rinsed for 10 min in doubled-distilled water. Finally, the beads were briefly blotted on sterile filter paper and individually cultured lightly immersing the bead in the medium.

Effect of polymerization duration on beads physical resistance

The resistance of empty beads, without explants, was studied by measuring penetration and compression after different bead polymerisation durations (5, 10, 15 and 20 min). In these experiments, bead composition was MS1 medium with 3% sodium alginate, and polymerization was achieved with a 70 mM calcium chloride solution. Ten beads per treatment were evaluated, and each bead was considered a single repetition. Two texture parameters were determined using a TX-XT2i Texture Analyzer (Stable Microsystems, Godalming, UK) interfaced to a PC.

Force–deformation ratio (compression) was measured using a flat steel plate mounted on the machine. For each sphere, the diameter was measured and then a force that achieved a 3% deformation of the bead diameter was applied. The machine was prepared to travel at 0.3 mm s−1 after contacting, and results were expressed in Newtons (N). Also, Magness-Taylor firmness (penetration) was recorded using a 2-mm diameter probe mounted on the same machine, prepared to travel at 0.3 mm s−1. The machine determined the maximum force of the sphere penetration, and the results were also expressed in N.

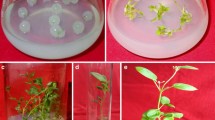

Effect of polymerization duration on bud sprouting

The effect of polymerisation duration on nodal segment sprouting was studied by encapsulating nodal segments and holding them for 5, 10, 15 and 20 min in a 70 mM calcium chloride solution to achieve polymerisation. Thereafter, alginate beads were cultured on NMM and placed at standard room culture conditions, i.e., in the culture room at 23 ± 1 °C with a 16-h photoperiod and 55 µmol m−2 s−1 light intensity provided by cool white fluorescent tubes (Sylvania Gro-lux, Madrid, Spain). In these experiments the alginate bead composition was MS1 medium with 3% sodium alginate. The experiments were repeated twice with a total of 30 beds per treatment. Data on bud sprouting, shoot length and leaf number were recorded after 2 and 4 weeks of culture. A bud was considered sprouted when it broke the bead and grew out of it.

Effect of temperature on bud sprouting

The effect of temperature on sprouting of neem nodal segments was studied. In a first experiment, nodal segments from proliferating shoots were cultured, one per tube, on NMM and placed at standard room culture conditions as above (control) or at 4 °C, 8 °C and 12 °C in a refrigerator in the dark for 2 or 4 weeks, after which were sampled and transferred to the culture room. Parallel experiments to these were carried out with encapsulated nodal segments. The beads, with one nodal segment each, were formed using MS1 with 3% sodium alginate as matrix medium and 5 min of polymerisation time in a 70 mM calcium chloride solution and cultured one per tube. Data of sprouting and shoot development were recorded after 4 weeks at 23 °C. Experiments were repeated twice with 20 beads per treatment.

Effect of ASA on cold storage of encapsulated nodal segments

Neem nodal segments were incubated on NMM with the addition of 0, 25 µM or 100 µM ASA (Sigma-Aldrich Quimica SA, Madrid, Spain), one nodal segment being incubated per tube (Padilla et al. 2015). After 4 weeks, these nodal segments pre-treated or not with ASA were encapsulated. The beads, with one nodal segment each, were formed using MS1 with 3% sodium alginate as the matrix medium and 5 min of polymerisation time in a 70 mM calcium chloride solution. Then, one half of beads of each treatment was cultured, one per tube, on fresh NMM medium and placed at standard culture conditions for 4 weeks (Controls). The other half, were stored introducing them in a sterile plastic container placed in the fridge at 12 °C in the dark for 4 weeks (cold storage), and, after that, they were cultured on fresh NMM medium and placed at standard culture room conditions for another 4 weeks. Next, data of sprouting and shoot development were recorded after 4 weeks in culture conditions. The experiment was repeated twice with 20 beads per treatment.

Antioxidative metabolism in nodal segments

The effect of ASA on the oxidative stress of nodal segments was studied just after the 4-week pretreatment with ASA (0, 25 or 100 µM, T1) and after the pretreatment, the encapsulation of the nodal segments and cold storage of them at 12 °C for 4 additional weeks (T2). All subsequent manipulations (sample extraction, centrifugation and filtration) suffered by the nodal segments were performed at 0–4 °C, to avoid enzyme inactivation. In all cases, 0.5 g of nodal segments (non-treated, as control, and treated with 25 or 100 µM ASA for 4 weeks), were homogenized with 1 mL of extraction medium (ratio sample/extraction medium, 1/2, w/v) containing 50 mM Tris–acetate buffer (pH 6.0), 0.1 mM EDTA, 2 mM cysteine, and 0.2% (v/v) Triton X-100. Four samples were analyzed for each parameter. For the ascorbate peroxidase (APX, EC 1.11.1.11) activity, 20 mM sodium ascorbate was added to the extraction buffer. The extracts were centrifuged at 10,000×g for 15 min. The supernatant fraction was filtered on Sephadex G-25 NAP columns equilibrated with the same buffer used for homogenization. For the APX activity, 2 mM sodium ascorbate was added to the equilibration buffer. The activities of catalase (CAT, EC 1.11.1.6), superoxide dismutase (SOD, EC 1.15.1.1), peroxidase (POX, EC 1.11.1.7), APX, glutathione reductase (GR, EC 1.8.1.7), dehydroascorbate reductase (DHAR, EC 1.8.5.1) and monodehydroascorbate reductase (MDHAR, EC 1.6.5.4) were measured as described in Barba-Espín et al. (2011). Glutathione-S-transferase (GST, EC 2.5.1.18) activity was analyzed according to Habing and Jakoby (1981). The extent of lipid peroxidation was estimated by determining the concentration of thiobarbituric acid-reactive substances (TBARS) as described in Clemente-Moreno et al. (2010).

Statistical analysis

Data were analysed with the SPSS/PC version 15.0 and SAS version 9.0 programs. Normally distributed variables were analysed by analysis of variance (ANOVA). When significant differences were found the values were compared according to the Student–Newman–Keuls test (p < 0.05). When data were percentages, a Maximum Likelihood Analysis was performed using the SAS program (Littell et al. 2002). All figures were created with SigmaPlot 8.0 program.

Results and discussion

Effect of polymerisation time on bead physical resistance and bud sprouting and development

In a first experiment, we tested 3, 3.5 and 4% sodium alginate and 70, 80, 90 and 100 mM CaCl2·2H2O solution, at a complexation time of 20 min. For these ranges, and in all cases, the beads had a good consistency, so we decided to use 3% of sodium alginate and 70 mM for all subsequent experiments described in this article. It has been found that low concentrations of sodium alginate (1–2%) are unsuitable for encapsulation due to a reduction in its gelling ability after exposure to autoclaving, while at higher concentrations sodium alginate (4–6%) considerably delays sprouting of nodal segments (Ahmad and Anis 2010). At the same time, high concentrations of calcium chloride (100–200 mM) have also been shown to inhibit the conversion of encapsulated shoot tips (Singh et al. 2006).

Later, we decided to study the resistance of empty beads, without explants, at different polimerization durations (5, 10, 15 or 20 min), recording compression and penetration, to have an idea of the physical resistance that must be overcome by the buds. We found that the polymerisation duration had a significant effect on the texture of beads, thus, as time increased both the compression and penetration were higher (Fig. 1). These results seem logical because the outer layer of the bead could be harder, and probably wider, as the time of exposure of the beads to the CaCl2·2H2O solution is larger. In addition, water content and water availability could be lower as polymerisation time increases. However, in a study about water status and thermal analysis of alginate beads, Block (2003) found that the mean dry weight of the beads declines after more than 10 min polymerisation and, at the same time, the mean water content showed the reverse trend with more water contained in beads that had experienced polymerisation duration longer than 10 min. This author explained that, as the alginate matrix was loaded with 0.75 M sucrose prior to polymerisation, osmotic effects could account for the observed changes in dry bead weight and water content. This would indicate that many physical parameters seem to interact during encapsulation, which deserve to be taken into account, and suggested that the response of the bead containing the encapsulated plant material could be different from that of the bead itself. In our work, we found that the sprouting into shoots of encapsulated neem nodal segments was high and without significant differences irrespective of the polymerisation duration, with an average of bead sprouting of 75% (Fig. 2). This could mean that although the resistance of beads differed for the different polymerisation durations tested, it was not enough to inhibit bud sprouting or that the presence of explant in the bead modified the bead physical parameters, as suggested by Block (2003). Moreover, the development of shoots was good, without significant differences in shoot length and leaf number between explants encapsulated at different polymerisation durations, with an average of 0.5 cm of shoot length and 2 leaves after 4 weeks of culture (Fig. 2). These results led us to choose 5 min as a standard polymerization duration. Nevertheless, it should be mentioned that in experiments performed after this work was completed, we had to change the alginate concentration and the polymerization time due to a different viscosity of the sodium alginate batch purchased.

Effect of polymerisation time on bud sprouting, shoot length and leaves number of neem encapsulated nodal segments. Columns represent shoot length and shoot leaves number mean values ± SE. Bud sprouting percentages are represented by linear plot. Data after 4 weeks of culture. Statistical analysis (ANOVA for shoot length and leaves number and maximum likelihood ANOVA for percentage of bud sprouting) did not find significant differences between treatment means and, therefore, only standard errors of means are shown

Effect of temperature and encapsulation on bud sprouting

Sprouting of both non-encapsulated and encapsulated neem nodal segments was affected by storage temperature (Table 1). Thus, non-encapsulated nodal segments died after 2 weeks at 4 °C or after 4 weeks of exposure at 8 °C, with white and non-responding nodal segments, while when were exposed at 12 °C for up to 4 weeks, the bud sprouting was significantly similar to the controls (Table 1), although during the 4 weeks of growth recovery at room culture conditions (23 °C) we observed that shoots exhibited light green coloured leaves and slower growth but without significant differences (data not shown).

On the other hand, the impact of temperature on neem encapsulated nodal segment sprouting and growth was even more significant. Thus, encapsulated nodal segments stored for 2 or 4 weeks at 12 °C showed a significant drop in bud sprouting, 55% or 20% respectively, after 4 weeks in the culture room at 23 °C (Table 1). Chilling injury has been widely described in tropical and subtropical plants exposed to temperature below 12 °C (Lukatkin et al. 2012). Similarly, in cassava, an important tropical tuber crop, Danso and Ford-Lloyd (2003) found that nodal segments and shoot tips stored at 4 °C remained green throughout the storage period, but upon transfer to culture medium did not sprout but rather turned white and died. This whitening of the explants has not been described, for example, in pineapple (Gangopadhyay et al. 2005) or in pomegranate (Naik and Chand 2006). A negative effect of temperature (4 °C) on plantlet recovery from non-encapsulated nodal segments has been reported by Chand and Singh (2004) in Dalbergia sisso Roxb., with a drop from 98 to 13% of sprouting rate after 30 days, and in shoot tips of Phyllanthus amarus (Singh et al. 2006), with a drop of 65% also after 30 days. In pomegranate, a tropical fruit tree, beyond 30 days of storage of encapsulated nodal segment at 4 °C there was a significant decline in sprouting percentage, with nodal segments completely losing their viability after 60 days (Naik and Chand 2006). A significant effect of storage temperature and incubation duration was also observed on encapsulated pineapple micro-shoots (Gangopadhyay et al. 2005). The decline in bud response after cold storage of the encapsulated nodal segments has been attributed to inhibited respiration of tissues by the alginate matrix or loss of moisture due to partial desiccation (Danso and Ford-Lloyd 2003). In addition, the conversion of encapsulated nodal segments seems to be influenced by culture medium and bud developmental stage, with better response for breaking buds compared to dormant buds (Naik and Chand 2006). However, in encapsulated and non-encapsulated nodal segments of neem, an important effect of low temperature per se could be responsible for the low sprouting of buds. Temperature is one of major environmental factors that quantitatively and qualitatively affects plants, with direct and indirect effects. Growth, morphogenetic response, bud break and colour change are some of these temperature-sensitive processes. The sensitivity of the plant’s organs differs according to their growth stage. Tropical and subtropical species exhibit a poor tolerance to low temperature and fail to grow or are damaged by exposure to temperatures in the range of 0–15 °C (Karpinski et al. 2002). In this respect, the neem tree can tolerate temperatures up to 50 °C but is very sensitive to low temperatures and frost (Allan et al. 1999). Chilling injury is a complex phenomenon and appears in different forms, such as loss of vigour, chlorosis and numerous cellular and metabolic dysfunctions. Plants under chilling stress show impaired photosynthesis, altered respiration, cessation of protoplasmic streaming and changes in membrane integrity (Lyons 1973). One of the direct effects of temperature on plants is a higher production of reactive oxygen intermediates during low-temperature exposure, which induce oxidative stress (You and Chan 2015) that could be responsible for the low conversion rate of neem bud segments at low temperature.

Effect of ASA on cold storage of encapsulated nodal segments

ASA affected sprouting of cold-stored encapsulated nodal segments Thus, when control encapsulated nodal segments were cultured only at culture room conditions (23 °C), bud sprouting was 80%, irrespectively of ASA treatment (Table 2). We observed that shoot length was slightly higher when buds were pre-treated with ASA, although without significance (data not shown). However, ASA pre-treated nodal segments stored at 12 °C for 4 weeks, maintained higher viability (75%) compared with those that were not treated with ASA and stored under the same conditions (19%). It was observed that during the 4 weeks of growth recovery at room culture conditions (23 °C), those shoots from ASA pre-treated nodal segments that maintained their viability after the cold storage exhibited light green coloured leaves and significant slower growth, with 0.4 cm shoot length versus 0.7 cm in controls. López-Delgado et al. (1998) added ASA into the culture medium, during in vitro cold storage of potato plants, for up to 12 months, with good results, and Katouzi et al. (2011) encapsulated sunflower shoot tips in alginate beads with 50 µM SA for up to 90 days, after which cold preservation and plant recovery was observed in 59% of explants. In both cases, the survival rate of explants increased with the addition of ASA or SA to the medium, without negative effect on the explants. In our study, neem shoots from encapsulated nodal segments pretreated with ASA grew at 23 °C with similar length and leaf number as the controls. In a previous study, we found that when nodal segments were incubated in a medium with high ASA concentrations (100 or 400 mM) reduced bud sprouting, shoot length and shoot leaf number were observed. Later, when these nodal segments were transferred to a medium without ASA the growth was not recovered compared to the controls, while nodal segments exposed to 25 mM ASA for the same duration and transferred to ASA-free medium recovered their growth (Padilla et al. 2015). Therefore, an ASA pretreatment before encapsulation of the nodal segments was preferred to the inclusion of ASA in the bead matrix. Additionally, since ASA improves the antioxidant metabolism of plants against cold stress when the treatment is applied before the cold stress (Mutlu et al. 2013; Soliman et al. 2018), application of the ASA treatment was done before exposing the nodal segments to the cold storage.

Effect of ASA on the antioxidative metabolism of nodal segments

In this research we studied the enzymatic activity of POX, CAT, APX, SOD, GR, DHAR, MDHAR and GST enzymes, as well as lipid peroxidation (an oxidative stress parameter), in neem nodal segments after incubation for 4 weeks at 23 °C with ASA (0, 25 or 100 µM, T1) or after the pretreatment, the encapsulation of the nodal segments and cold storage of them at 12 °C for 4 additional weeks (T2). The ANOVA found significant differences between treatments (T1, T2) and ASA concentrations as well as significant interactions between T and ASA for all enzymatic activities determined. Therefore, a separate analysis of ASA levels within each treatment was done. The nodal segments untreated with ASA but stored at 12 °C for 4 weeks (Controls, T2), showed higher activity levels of the SOD, CAT, DHAR and GR enzymes, and lower activity levels of POX and MDHAR than the untreated nodal segments placed in culture room conditions at 23 °C (Controls, T1) (Fig. 3). In the presence of ASA, the enzymatic activity was higher than in the T1 untreated controls, especially SOD, APX, POX, GR and MDHAR whereas a trend of decreasing in the DHAR and GST activity was observed (Fig. 3). When the treated nodal segments were kept in cold at 12 °C (T2), the activity of CAT, GST, DHAR and GR enzymes increased compared with the treated nodal segments maintained in standard conditions; APX, and MDHAR activity decreased while SOD activity only increased at 25 mM ASA (Fig. 3). Additionally, the presence of ASA significantly reduced the oxidative damage to neem nodal segments. Thus, when ASA was added, a decrease on the lipid peroxidation values was noticed regardless on the storage temperature, although the values were somewhat lower in samples stored at 23 °C for 4 weeks (T1) than in samples stored at 12 °C for 4 additional weeks (Table 3).

Enzymatic activities in neem nodal segments after incubation for 4 weeks with ASA at 23 °C (T1) and subsequently encapsulated and preserved at 12 °C for 4 weeks (T2). For each enzyme and T, different letters represent significant differences between ASA concentrations according to Student–Newman–Keul’s test (p < 0.05). For each enzyme and for 0 µM ASA, controls, an asterisk (*) indicates significant differences between values of T1 and T2 treatments according to contrast test (p < 0.05)

This data, taken together, may indicate that incubation in the presence of ASA prior to encapsulation and refrigeration of the neem nodal segments stimulated the antioxidative defenses of the plant, especially APX, CAT, POX, DHAR and GR, and reduced the oxidative damage that could in turn improve viability of the nodal segments. Plants usually respond to various environmental conditions, such as cold stress, by triggering various defense mechanisms; one of them is the antioxidant defense system, including antioxidant enzymes (Asada 1999; Noctor and Foyer 1998). Antioxidant enzymes allow the elimination of reactive oxygen species, such as superoxide radicals (O2.−) or hydrogen peroxide (H2O2), converting or reducing them to water. Rapid detoxification of both elements is essential for preventing oxidative damage. The impact of salicylic acid on the antioxidant enzymatic system in different species under chilling stress has been studied. Zhang et al. (2011) demonstrated that a chilling-tolerant cucumber cultivar displays a higher SA level than a chilling-sensitive one, and that exogenous SA can enhance the chilling tolerance ability, which might be achieved through modulation of the antioxidant system. Sedghi et al. (2013) showed that sunflower leaves sprayed with salicylic acid increased the activity of CAT, SOD and POX enzymes compared to control. In pea plants subjected to salt stress, SA treatments increased the activity levels of GST, CAT and SOD, and induced the gene expression of PR-1b suggesting that SA treatment could enhance the resistance of salt stressed plants to possible opportunistic pathogen attack (Barba-Espín et al. 2011).

In summary, in this research we developed a sodium alginate encapsulation protocol for neem nodal segment as an easy, cheap and practical method for neem to preserve in vitro culture material and collections of this species for laboratory exchange but also for the short-term storage. We confirm the sensitivity of neem in vitro nodal segments/buds to chilling temperature, which makes in vitro cold conservation difficult. However, a previous work with growth retardants led us to consider an ASA pretreatment at low concentration for neem in vitro nodal segments, hoping to induce a certain degree of protection to the buds from the cold during storage. In this research we proved that ASA, specially at 25 µM, applied as a pretreatment to the nodal segments of neem improved their survival to cold and that this survival could be due to an increase in the activity of several antioxidant enzymes.

References

Ahmad N, Anis M (2010) Direct plant regeneration from encapsulated nodal segments of Vitex negundo. Biol Plant 54(4):748–752. https://doi.org/10.1007/s10535-010-0134-8

Allan EJ, Stuchbury T, Mordue AJ (1999) Azadirachta indica A juss. (Neem tree): in vitro culture, micropropagation, and the production of Azadirachtin and other secondary metabolites. In: Bajaj YPS (ed) Biotechnology in agriculture and forestry, 43. Medicinal and aromatic plants XI. Springer-Verlag, Berlin, pp 11–41

Arora K, Sharma M, Srivastava J, Ranade SA, Sharma AK (2010) Rapid in vitro cloning of a 40-year-old tree of Azadirachta indica A. Juss (Neem) employing nodal stem segments. Agrofor Syst 78(1):53–63. https://doi.org/10.1007/s10457-009-9230-1

Asada K (1999) The water-water cycle in chloroplasts: Scavenging of active oxygens and dissipation of excess photons. Ann Rev Plant Biol 50:601–639. https://doi.org/10.1146/annurev.arpplant.50.1.601

Barba-Espín G, Clemente-Moreno MJ, Álvarez S, García-Legaz MF, Hernández JA, Díaz-Vivancos P (2011) Salicylic acid negatively affects the response to salt stress in pea plants: effects on PR1b and MAPK expression. Plant Biol 13:909–917. https://doi.org/10.1111/j.1438-8677.2011.00461.x

Bhushan A, Gupta RK (2017) In vitro shoot regeneration and heterosis studies in tomato (Solanum lycopersicon Mill.). Int J Plant Res 30:359–364. https://doi.org/10.5958/2229-4473.2017.00097.0

Block W (2003) Water status and thermal analysis of alginate beads used in cryopreservation of plant germplasm. Cryobiology 47:59–72. https://doi.org/10.1016/S0011-2240(03)00069-5

Chand S, Singh AK (2004) Plant regeneration from encapsulated nodal segments of Dalbergia sissoo Roxb., a timber-yielding leguminous tree species. J Plant Physiol 161(2):237–243. https://doi.org/10.1078/0176-1617-01036

Chaturvedi R, Razdan MK, Bhojwani SS (2004) In vitro morphogenesis in zygotic embryo cultures of neem (Azadirachta indica A. Juss.). Plant Cell Rep 22(11):801–809. https://doi.org/10.1007/s00299-004-0768-0

Clemente-Moreno MJ, Díaz-Vivancos P, Barba-Espín G, Hernández JA (2010) Benzothiadiazole and L-2-oxothiazolidine- 4-carboxylic acid reduced the severity of Sharka symptoms in pea leaves: effect on the antioxidative metabolism at subcellular level. Plant Biol 12:88–97. https://doi.org/10.1111/j.1438-8677.2009.00204.x

Danso KE, Ford-Lloyd BV (2003) Encapsulation of nodal cuttings and shoot tips for storage and exchange of cassava germplasm. Plant Cell Rep 21(8):718–725. https://doi.org/10.1007/s00299-003-0594-9

Driver JA, Kuniyuki AH (1984) In vitro propagation of Paradox walnut rootstock. HortScience 19:507–509. https://doi.org/10.7235/Hort.2012.12009

Fujita M, Fujita Y, Noutoshi Y, Takahashi F, Narusaka Y, Yamaguchi-Shinozaki K, Shinozaki K (2006) Crosstalk between abiotic and biotic stress responses: a current view from the points of convergence in the stress signaling networks. Curr Opin Plant Biol 9(4):436–442. https://doi.org/10.1016/J.Pbi.2006.05.014

Gairi A, Rashid A (2005) Direct differentiation of somatic embryos on cotyledons of Azadirachta indica. Biol Plant 49(2):169–173. https://doi.org/10.1007/s10535-005-0173-8

Gangopadhyay G, Bandyopadhyay T, Poddar R, Gangopadhyay S, Mukherjee KK (2005) Encapsulation of pineapple micro shoots in alginate beads for temporary storage. Curr Sci 88(6):972–977

Grossman K (1990) Plantgrowth retardants as tools in physiological research. Physiol Plant 78(4):640–648. https://doi.org/10.1111/j.1399-3054.1990.tb05254.x

Gupta SD, Kumar A, Agarwal A (2019) Impact of light-emitting diodes (LEDs) on the growth and morphogenesis of encapsulated shoot buds of Curculigo orchioides Gaertn., an endangered medicinal herb. Acta Physiol Plant 41(4):50. https://doi.org/10.1007/s11738-019-2840-y

Habing WH, Jakoby WB (1981) Assays for differentiation of glutathione S-transferases. Methods Enzymol 77:398–405. https://doi.org/10.1016/S0076-6879(81)77053-8

Hung CD, Trueman SJ (2012) Alginate encapsulation of shoot tips and nodal segments for short-term storage and distribution of the eucalypt Corymbia torelliana x C. citriodora. ACTA Physiol Plant 34(1):117–128. https://doi.org/10.1007/s11738-011-0810-0

Jarret RL (1997) Effects of chemical growth retardants on growth and development of sweetpotato (Ipomoea Batatas (L.) Lam) in vitro. J Plant Growth Regul 16(4):227–231. https://doi.org/10.1007/Pl00007001

Joshi MS, Thengane SR (1996) In vitro propagation of Azadirachta indica A. Juss (neem) by shoot proliferation. Ind J Exp Biol 5:480–482

Karpinski S, Wingsle G, Karpinska B, Hallgren JE (2002) Low-temperature stress and antioxidant defense mechanism in higher plants. In: Inze D, van Montagu M (eds) Oxidative stress in plants. Taylor and Francis Publishers, London, pp 69–103

Katouzi SSS, Majd A, Fallahian F, Bernard F (2011) Encapsulation of shoot tips in alginate beads containing salicylic acid for cold preservation and plant regeneration in sunflower (Helianthus annuus L.). Aust J Crop Sci 5(11):1469–1474

Khan MI, Ahmad N, Anis M, Alatar AA, Faisal M (2018) In vitro conservation strategies for the Indian willow (Salix tetrasperma Roxb.), a vulnerable tree species via propagation through synthetic seeds. Biocatal Agric Biotechnol 16:17–21. https://doi.org/10.1016/j.bcab.2018.07.002

Korsukova AV, Borovik OA, Grabelnych OI, Voinikov VK (2015) The tebuconazole-based protectant of seeds “bunker” induces the synthesis of dehydrins during cold hardening and increases the frost resistance of wheat seedlings. J Stress Physiol Biochem 11(4):118–127

Kulus D, Zalewska M (2014) In vitro plant recovery from alginate encapsulated Chrysanthemum × grandiflorum /Ramat./ Kitam shoot tips. Propag Ornam Plants 14(1):3–12

Kulus D (2018) Genetic resources and selected conservation methods of tomato. J Appl Bot Food Qual 91:135–144. https://doi.org/10.5073/JABFQ.2018.091.00X

Kulus D (2019) Application of synthetic seeds in propagation, storage and cryopreservation of Asteraceae plant species. In: Faisal A, Alatar A (eds) Synthetic seeds germplasm regeneration, preservation and prospects. Springer Science & Business Media, Dordrecht, pp 155–179

Kumar D, Mishra DS, Chakraborty B, Kumar P (2013) Pericarp browning and quality management of litchi fruit by antioxidants and salicylic acid during ambient storage. J Food Sci Technol 50(4):797–802. https://doi.org/10.1007/s13197-011-0384-2

Kumar D, Mishra DK (2014) Variability in permeability and integrity of cell membrane and depletion of food reserves in neem (Azadirachta indica) seeds from trees of different age classes. J For Res 25(1):147–153. https://doi.org/10.1007/s11676-014-0440-7

Littell RC, Stroup WW, Freund RJ (2002) SAS for linear models, 4th edn. SAS Institute Inc, Cary, p 466

López-Delgado HA, Scott IM (1997) Induction of in vitro tuberization of potato microplants by acetylsalicylic acid. J Plant Physiol 151(1):74–78. https://doi.org/10.1016/S0176-1617(97)80039-9

López-Delgado HA, Jimenez-Casas M, Scott IM (1998) Storage of potato microplants in vitro in the presence of acetylsalicylic acid. Plant Cell Tiss Org Cult 54(3):145–152. https://doi.org/10.1023/A:1006110118669

Lukatkin AS, Brazaityte A, Bobinas C, Duchovskis P (2012) Chilling injury in chilling-sensitive plants: a review. Zemdirbyste 99(2):111–124

Lyons JM (1973) Chilling injury in plants. Annu Rev Plant Physiol 24(1):445–466. https://doi.org/10.1146/annurev.pp.24.060173.002305

Marino G, Negri P, Cellini A, Masia A (2010) Effect of carbohydrates on in vitro low temperature storage of shoot cultures of apricot. Sci Hortic 126:434–440. https://doi.org/10.1016/j.scienta.2010.08.008

Moradi S, Baninasab B, Gholami M, Ghobadi C (2017) Paclobutrazol application enhances antioxidant enzyme activities in pomegranate plants affected by cold stress. J Hortic Sci Biotechnol 92(1):65–71. https://doi.org/10.1080/14620316.2016.1224605

Murashige T, Skoog F (1962) A revised medium for rapid growth and bioassays with tobacco tissue culture. Physiol Plant 15:473–497. https://doi.org/10.1111/j.1399-3054.1962.tb08052.x

Muslihatin W, Jadid N, Safitri CE, Kuncoro EP (2018) In vitro germination of Moringa oleifera synthetic seed on different composition of medium. Biosci Res 15(3):1982–1991

Mutlu S, Karadagoglu O, Atici O, Nalbantoglu B (2013) Protective role of salicylic acid applied before cold stress on antioxidative system and protein patterns in barley apoplast. Biol Plant 57(3):507–513. https://doi.org/10.1007/s10535-013-0322-4

Naik SK, Chand PK (2006) Nutrient-alginate encapsulation of in vitro nodal segments of pomegranate (Punica granatum L.) for germplasm distribution and exchange. Sci Horti 108:247–252. https://doi.org/10.1016/j.scienta.2006.01.030

Nair DS, Reghunath BR, Soni KB, Alex S (2019) Cryopreservation of encapsulated axillary buds of Clitoria ternatea (L). Cryoletters 40(1):28–35

Noctor G, Foyer CH (1998) Ascorbate and glutathione: keeping active oxygen under control. Ann Rev Plant Physiol Plant Mol Biol 49:249–279. https://doi.org/10.1146/annurev.arplant.49.1.249

Ojaghian MR, Almoneafy AA, Zq C, Xie G-L, Zhang J (2013) Application of acetyl salicylic acid and chemically different chitosans against storage carrot rot. Post Biol Tech 84:51–60. https://doi.org/10.1016/j.postharvbio.2013.04.006

Padilla IMG, Fernández-García N, Olmos E, Burgos L, Piqueras A (2015) Effects of growth retardants on sprouting and development of apricot (Prunus armeniaca L.) and neem (Azarchta indica A. Juss.) nodal buds. Plant Cell Tiss Org Cult 122(2):285–297. https://doi.org/10.1007/s11240-015-0765-8

Quraishi A, Koche V, Sharma P, Mishra SK (2004) In vitro clonal propagation of neem (Azadirachta indica). Plant Cell Tiss Org Cult 78(3):281–284. https://doi.org/10.1023/B:TICU.0000025647.58548.3d

Rai MK, Jaiswal VS, Jaiswal U (2008) Alginate-encapsulation of nodal segments of guava (Psidium guajava L.) for germplasm exchange and distribution. J Hort Sci Biotechnol 83(5):569–573. https://doi.org/10.1080/14620316.2008.11512425

Rout GR (2005) In vitro somatic embryogenesis in callus cultures of Azadirachta indica A. Juss.: a multipurpose tree. J For Res 10(4):263–267. https://doi.org/10.1007/s10310-004-0130-y

Rihan HZ, Kareem F, El-Mahrouk ME, Fuller MP (2017) Artificial seeds (principle, aspects and applications). Agron-Basel 7(4):71. https://doi.org/10.3390/agronomy7040071

Sacandé M, Buitink J, Hoekstra FA (2000) A study of water relations in neem (Azadirachta indica) seed that is characterized by complex storage behaviour. J Exp Bot 51(344):635–643. https://doi.org/10.1093/jexbot/51.344.635

Sedghi M, Basiri HK, Sharifi RS (2013) Effects of salicylic acid on the antioxidant enzymes activity in sunflower. Ann West Univ Timişoara 16(2):67–72

Shahin-Uz-Zaman M, Ashrafuzzaman M, Haque MS, Luna LN (2009) In vitro clonal propagation of the neem tree (Azadirachta indica A. Juss.). Afr J Biotechnol 7(4):386–391

Sharma S, Shahzad A, Mahmood S, Saeed T (2015) High-frequency clonal propagation, encapsulation of nodal segments for short-term storage and germplasm exchange of Ficus carica L. Trees 29:345–353. https://doi.org/10.1007/s00468-014-1114-y

Singh AK, Sharma M, Varshney R, Agarwal SS, Bansal KC (2006) Plant regeneration from alginate-encapsulated shoot tips of Phyllanthus amarus Schum and Thonn, a medicinally important plant species. In Vitro Cell Dev Biol Plant 42:109–113. https://doi.org/10.1079/IVP2005735

Soliman MH, Alayafi AAM, El Kelish AA, Abu-Elsaoud A (2018) Acetylsalicylic acid enhance tolerance of Phaseolus vulgaris L. to chilling stress, improving photosynthesis, antioxidants and expression of cold stress responsive genes. Bot Stud 59:6. https://doi.org/10.1186/s40529-018-0222-1

Srivastava P, Singh M, Mathur P, Chaturvedi R (2009) In vitro organogenesis and plant regeneration from unpollinated ovary cultures of Azadirachta indica. Biol Plant 53(2):360–364. https://doi.org/10.1007/s10535-009-0067-2

Varshey A, Anis M (2014) Synseed conception for short-term storage, germplasm exchange and potentialities of regeneration genetically stable plantlets of desert date tree (Balanites aegyptiaca Del.). Agrofor Syst 88(2):321–329. https://doi.org/10.1007/s10457-014-9685-6

You J, Chan Z (2015) ROS regulation during abiotic stress responses in crop plants. Front Plant Sci 6:1092. https://doi.org/10.3389/fpls.2015.01092

Zhang WP, Jiang B, Lou NL, Lu MH, Yang M, Chen JF (2011) Impact of salicylic acid on the antioxidant enzyme system hydrogen peroxide production in Cucumis sativus under chilling stress. Z Naturforsch C J Biosci 66(7–8):413–422

Zhang Y, Jiang J, Yang YL (2013) Acetyl salicylic acid induces stress tolerance in tomato plants grown at a low night-time temperature. J Hort Sci Biotech 88(4):490–496. https://doi.org/10.1080/14620316.2013.11512996

Zhao JJ, Feng NF, Wang XX, Cai GR, Cao MY, Zheng DF, Zhu HD (2019) Uniconazole confers chilling stress tolerance in soybean (Glycine max L.) by modulating photosynthesis, photoinhibition, and activating oxygen metabolism system. Photosynthetica 57(2):446–457. https://doi.org/10.32615/ps.2019.059

Acknowledgements

IMGP thanks The Spanish National Research Council-European Social Fund I3P program for a postdoctoral contract.

Funding

This work was funded by the Spanish Ministry of Education and Science with European Social Funds.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Maurizio Lambardi.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Padilla, I.M.G., Barba-Espín, G., Hernández, J.A. et al. Acetylsalicylic acid improved antioxidative status and cold storage of encapsulated nodal segments of neem (Azadirachta indica A. Juss.). Plant Cell Tiss Organ Cult 144, 261–270 (2021). https://doi.org/10.1007/s11240-020-01828-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11240-020-01828-z