Abstract

The purpose of the currents study was to enhance bioavailability of rivaroxaban (RXB) and reduce the food effect. RXB loaded PLGA nanoparticles (RXB-PLGA-NPs) were prepared by emulsion solvent evaporation method and optimized using central composite design (CDD). The optimized RXB-PLGA-NPs (F8) with composition, PLGA (125 mg), PVA (0.5%w/w) and RXB (20 mg) was found optimum with particle size (496 ± 8.5 nm), PDI (0.607), ZP (− 18.41 ± 3.14 mV), %EE (87.9 ± 8.6) and %DL (9.5 ± 1.6). The optimized NPs (F8) was further evaluated in vitro for DSC, FTIR, SEM and in vitro release studies. A comparative pharmacokinetic studies with commercial tablet (XARELTO®) were conducted on fasted and fed state rats. Compared to commercial tablet (XARELTO®), the RXB-PLGA-NPs (F8) exhibited a significant enhancement of bioavailability in both fasted and fed state. In addition, the bioavailability of RXB from NPs (F8) was found unaffected in the presence of food.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Highlights

-

Development of sustained release of Rivaroxaban loaded PLGA nanoparticles (RXB-PLGA-NPs).

-

Development of various RXB-PLGA-NPs (F1-F13) were prepared and optimized by a central composite design (CCD) using design expert.

-

The optimized NPs (F8) was further evaluated in vitro for DSC, FTIR, SEM and in vitro release studies.

-

Comparative pharmacokinetic studies with commercial tablet (XARELTO®) were conducted on fasted and fed state rats.

-

The RXB-PLGA-NPs (F8) exhibited a significant enhancement of bioavailability in both fasted and fed state. In addition, the bioavailability of RXB from NPs (F8) was found to be unaffected in the presence of food.

Introduction

Rivaroxaban (RXB) is a first potent oral anticoagulant extensively used as prophylactic of deep vein thrombosis (DVT), lung embolism and to diminution threat of systemic embolism followed by stroke due to nonvalvular arterial fibrillation. Traditional anticoagulant drugs such as vitamin K, unfractionated heparin, and fawarin are not widely used due to unsatisfactory effectiveness of treatment and toxic effect [1,2,3,4]. RXB competitively inhibits factor Xa responsible for activation of factor- IIa(thrombin) from factor II (prothrombin) [5]. The potency of factor Xa is more profound could generate thousands of thrombin molecules and its network, thus selective binding of RXB terminates thrombin formation and clotting. RXB considered to be safe and doesn’t required therapeutic drug monitoring as compared to other anticoagulant drug for instance vitamin K antagonists (warfarin) adversely effects of perfuse internal bleeding leading to lethal disability, brain death or death. RXB was proved to be superior to warfarin in the disease management of strokes and embolism, avoiding major bleedings [2]. RXB exhibits low solubility and high permeability, hence classified as BCS II class drug [6,7,8,9]. RXB is available in the market in tablet dosage strength of 10, 15 and 20 mg. USFDA recommends to administer lower dose (10 mg) with or without food, and higher dose (15, 20 mg) with food. The bioavailability of lower dose (10 mg) is unaffected with food. However, higher dose (15, 20 mg) bioavailability increases when take with food [10, 11].

‘Poly(D,L-lactide-co-glycolide) (PLGA)’ is an excellent polymer which is used to sustain the release, improve the stability, enhance the oral bioavailability and therapeutic efficacy of poorly soluble drugs. PLGA has been extensively used as an excellent carrier to deliver low bioavailable drugs [12,13,14,15]. PLGA polymer was successfully loaded the drugs and enhanced the dispersibility, solubility, and release in vitro, sustain the plasma concentration for longer period of time [12, 16].

The purpose of this study to enhance the in vitro release, bioavailability and sustained the release of RXB in the fasted state. Based on the through literature search, RXB loaded PLGA polymeric nanoparticles/microparticles have not yet been studied in order to sustained the release of RXB. The objective of this study is to prepare RXB loaded PLGA nanoparticles that could potentially sustained the release of drug that might reduce the frequency of dose in fasted state.

Materials and methods

Material

Rivaroxaban (RXB) was received from “Mesochem Technology (Beijing, China)”. “Poly (D, L-lactide-co-glycolide) lactide:glycolide (50:50) (PLGA) mol. wt 4000–15000” and ‘Polyvinyl alcohol (PVA)’ were procured from “Sigma-Aldrich, St. Louis, USA”. The solvents used in the experiments were purchased from “Sigma-Aldrich, USA”. The chemical and solvents used during this work was of pure and analytical grade.

Preparation of RXB loaded PLGA NPs

Emulsification and solvent evaporation method was adopted for the preparation of RXB loaded PLGA nanoparticles [13]. Briefly, accurately weighed amount of RXB (20 mg) was dissolved in 4 mL of PLGA polymeric solution in dichloromethane (DCM). Separately, aqueous phases were prepared by dissolving the required amount of PVA (0.5–2%w/v) in distilled water (8 mL). Furthermore, the prepared organic phase was emulsified with the aqueous phase dropwise under probe sonication for 3 min at 60% voltage efficiency (“Fisher Scientific; Made in USA”) with 10 s on–off pulse. The dispersion is subsequently placed over a magnetic stirrer (“Labtec; Made in Korea”) for 24 h at 700 rpm to evaporate the organic phase. After complete evaporation, the dispersion was centrifuged (“HermleLabortechnik; Made in Germany”) at 14,000×g for 15 min. To remove the adsorbed drug as well as the excessive surfactant, the sediment was washed thrice with Milli-Q water; both the supernatant and filtrate were preserved for drug content estimations. The concentrated NPs were lyophilized and preserved for further analysis.

Experimental design for RXB loaded PLGA NPs

Various RXB loaded PLGA NPs were prepared by a central composite design (CCD) utilizing the design expert “(version 12, state-Ease Inc., Minnepolis, MN)” [17, 18]. Thirteen (13) experimental runs were planned for the optimization of the formulation by selecting three independent variables such as PLGA (X1) and PVA (X2) as polymer and surfactant respectively. The dependent variables (responses) were particle size (Y1), PDI (Y2), zeta potential (Y3), %EE (Y4) and %DL (Y5) with constrains applied on the RXB loaded PLGA NPs. The two-level concentrations of independent variables in the study were selected along with high and low levels (Tables 1, 2).

Particle characterization

The mean size and PDI of the RXB loaded PLGA NPs were measured with the help of a “Malvern particle size analyzer (Zetasizer Nano ZS; Holtsville, NY)” at temperature of 25 ± 1 °C. The light scattering angle of measurement was set at 90° to incident laser light or they record back scattering (173°–177°), this angle works best depends on scattering intensity and concentration of the sample [15]. The required amount of NPs was reconstituted in distilled water with suitable dilution (1:200) in order to get a transparent aqueous dispersion. The aqueous dispersion was sonicated for 10 min and transferred in a disposable transparent plastic cuvette for the measurement of particle size and PDI. The same technique was adopted for the measurement of zeta potential (ZP), except the aqueous dispersion was transferred into a glass electrode sample holder [19].

Drug encapsulation efficiency

The percent drug entrapment efficiency (%EE) and percent drug loading (%DL) were measured by centrifuging a freshly prepared NPs suspension (F1–F13) at 15,000 rpm for 10 min. The un-entrapped drug in the supernatant was measured by UV spectroscopy at 250 nm [20] “(Jasco V-630; Made in Japan)”. The %EE and %DL were calculated using following Eq:

Evaluation of optimized NPs

Differential scanning calorimetry (DSC)

Thermal spectra of the samples were recorded by using DSC “(Metler 822 DSC).” The samples under study were sealed in an aluminum pan (test) and an empty pan (reference) and were subjected to a heating rate of 10 °C min−1 at a temperature range of approximately 50–400 °C under inert nitrogen gas environment.

Fourier transform infrared (FTIR)

FTIR spectra of RXB and RXB loaded PLGA NPs were recorded from 400 to 4000 cm−1 using KBr pellet technique “(Jasco FTIR Spectrophotometer; Made in Japan)” and the spectra was interpreted by predicting different types of vibrational and functional peaks with the help of software.

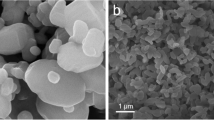

Scanning electron microscopy (SEM)

The images of the optimized RXB-PLGA NPs (F8) were viewed under the SEM “JSM-6360LV Scanning Microscope, Jeol, Tokyo, Japan”. The NPs (F8) were vortexed for 2 min, and a drop of suspended nanoparticles was spreaded on a glass slide dried in in a desiccators. The dried NPs sample was put on carbon tape and sputter-covered utilizing a thin gold palladium layer under an argon climate utilizing a gold sputter module in a high-vacuum evaporator and coated sample was then scanned for imaging using software (SMILE VIEW™ Map, Tokyo, Japan) [21].

In vitro release study

Release studies of RXB loaded PLGA NPs in comparison to XARELTO® tablet (20 mg) were performed in phosphate buffer (pH 6.8). Accurately weighed XARELTO® tablet (20 mg) and RXB loaded PLGA NPs (F8) was dispersed in 900 mL in phosphate buffer under continuous stirring at a speed of 100 rpm at temperature 37 ± 2 °C and the release profile was monitored for 48 h. At a different time points (0.5, 1, 2, 3, 6, 12, 24 and 48 h), 1 mL of aliquots was withdrawn and analyzed for the drug content after suitable dilution by UV method at 250 nm [20, 22].

Bio-analytical methods

Briefly, an ultra performance liquid chromatography (UPLC) coupled with mass spectrometry (UPLC MS/MS) was used for the analysis of RXB in rat plasma (“Micromass® Quattro micro Waters Corp, Milford, MA, USA”). Our previous studies has been reported in rat plasma [23]. To increase the sensitivity of the assay, the electrospray ionization was operated in positive mode and the calibration range was between 1 and 1000 ng/mL with lower limit of quantification (LOQ) 1 ng/mL in plasma samples. The analyte (RXB) and the internal standard (IS) were detected at ion transition of m/z 436.00 ˃ 1.44.87 for RXB and m/z 411.18 ˃ 191.07 for IS with dwell time of 0.061 in the multiple reaction monitoring (MRM) mode.

Pharmacokinetic studies in rats

Male Wistar rats weighing 220–230 gm (n = 6) were utilized for the pharmacokinetic studies of RXB. Rats were issued from “Animal Care Unit, College of Pharmacy, Prince Sattam Bin Abdulaziz University” and studied were preformed as per “International standard guidelines of the animal care and use”. Prior to the test, the animals were kept on overnight fasting in plastic enclosures under standard research center conditions, and the pellet diet was given with water ad libitum. The in vivo pharmacokinetic study of RXB loaded PLGA NPs (F8) and reference formulation of XARELTO® (both of them containing 20 mg RXB) were tested under fasted and fed conditions in a parallel study with two groups of rats (n = 6), each group has six rats [10]. Animals were randomly divided into four groups (n = 6) which served as RXB loaded PLGA NPs (F8) (fed and fasted state) and XARELTO® tablet (Fed and fasted state) suspension in PEG400 to treatment groups, respectively. RXB (equivalent to 1 mg/kg, oral) was administered to the respective group and blood samples (0.5 mL) were withdrawn in heparinized tubes from the retro-orbital plexus of rats at different time intervals (predose, 0.25, 0.5, 1, 2, 4, 8, 24, and 48 h). The blood sample were centrifuged at 4500×g for 8 min to collect plasma and were stored frozen at 80 ± 10 °C till further analysis. The obtained pharmacokinetic parameters were calculated and analyzed with the help of “WinNonlinsoftware (Pharsight Co, Mountain View CA)”. The parameters Cmax, Tmax, AUClast, AUCtot, kel, half life (T1/2) and Mean residence time (MRT).

Results and discussion

Preparation and optimization of RXB loaded PLGA NPs using central composite design (CDD)

The optimization of RXB loaded PLGA NPs was selected based on five responses like particle size, PDI, ZP, entrapment efficiency and drug loading by applying point prediction method of Design-Expert 12 software. Based on the 13 developed formulations by Expert Design® software, particle size, PDI, ZP, %EE and %DL with a range from 470 to 1329 nm, 0.476–1.00, − 0.607 to − 18.41 mV, 35.08–87.91% and 2.7–9.5% were prepared respectively (Table 2). Among these nanoparticles, Formulation (F8) with composition, PLGA (125 mg), PVA (0.5% w/v) and 20 mg of RXB was found to be optimum with particle size (496 nm), PDI (0.607), ZP (18.41 mV), EE (87.91%) and DL (9.5%).The response surface 3D graph generated by Expert-Design software showing influence of independent variables on particle size, PDI, ZP, %EE and %DL (Fig. 1). These graphs were used to study the effect of one independent variables on the responses while the second variables at a constant level. The optimized formulation (F8) was further subjected for morphology, spectroscopic characterization and pharmacokinetic studies in animal.

DSC studies

A comparative DSC spectra of pure RXB and optimized RXB loaded PLGA-NPs (F8) are shown in the Fig. 2. The DSC spectra of pure RXB showed a sharp endothermic melting peak at 234.72 °C followed by abroad decomposition exothermic peaks at 337.09 °C, which is characteristics of pure drug as reported in literature [24]. However, endothermic peak of RXB completely disappeared in DSC spectra of RXB loaded PLGA-NPs (F8), indicating its complete entrapment inside the PLGA polymer.

FTIR studies

A comparative FTIR spectra were recorded for pure RXB and RXB loaded PLGA NPs (F8) to know the interaction between RXB and PLGA polymer (Fig. 3). The FTIR spectrum of pure drug (RXB) showed all the peaks in range of 400–4000 cm−1. The major peaks of pure RXB was assigned corresponding to functional groups, –N–H– stretching (3351.68 cm−1), lactone carbonyl stretching (1736.58 cm−1), –C–O– stretching (1119.48 cm−1), aromatic C–H– bending (827.31 cm−1) and –C–Cl– stretching (756.92 cm−1) confirmed drug sample purity [25]. The major peaks of RXB was significantly shifted or reduced in intensity in the spectrum of RXB loaded PLGA NPs (F8), confirmed RXB successful encapsulation inside PLGA polymer.

SEM analysis

SEM images of RXB loaded optimized PLGA NPs (F8) formulation are shown in Fig. 4. The images of SEM confirmed a spherical in shape having smooth surface nanoparticles. It was observed that the PLGA polymer has been properly coated over the drug moiety had led to better adhesion and smooth surface of nanoparticles, hence maintained the particle morphology. The particle size observed from SEM image close enough to the size measured by the particle size analyzer.

In vitro release studies

In vitro release studies were performed to check the pattern of drug release from polymeric nanoparticles that would be useful scientific steps in the formulation development. The release of RXB from commercial tablet (XARELTO®) and RXB-PLGA-NPs (F8) are shown in the Fig. 5. A enhanced with sustained release of RXB from RXB-PLGA-NPs (F8) was recorded (97.64%) as compared to marketed tablet XARELTO® (68.45%) after 48 h. The sustained release of RXB perhaps due the presence of PLGA polymer matrix over NPs, hence PLGA promoted the sustained release pattern of the drug. The sustained release of RXB from the RXB-PLGA-NPs (F8) might be helpful in reducing the frequency and dose of dosage form [16].

Pharmacokinetic studies

The concentration of RXB in rat blood sample was measured by extrapolating the plasma calibration curve (1–1000 ng mL−1) prepared in blank plasma. The measured pharmacokinetic parameters after oral administration of RXB are documented in Table 3. The extent of absorption (AUC0–48 and AUC0–inf) of F8 NPs in fed and fasted state was found significantly (P < 0.5) higher in comparison to XARELTO® tablet. The maximum extent of absorption was observed in F8 NPs in fasted state as compared to fed state, it clearly indicates no food effect on absorption of RXB. The obtained values of Cmax and AUClast of XARELTO® tablet under fasted state (148 ± 33 ng/ml, 1638 ± 183 ng h/ml) were found lower in comparison to fed state (291 ± 51 ng/ml, 2704 ± 753 ng h/ml), this confirmed food enhances the absorption of commercial XARELTO® tablet. However, in the case of RXB loaded PLGA NPs (F8) under fasted and fed state were found almost similar as (553 ± 157 ng/ml, 4196 ± 546 ng h/ml and 566 ± 40 ng/ml, 3589 ± 138 ng h/ml) respectively. This results revealed that RXB loaded PLGA NPs successfully enhanced the bioavailability of RXB with no food effect. The main reason to increase the bioavailability of RXB due to PLGA polymer and nano size particles [26, 27]. Based on statistics analysis, Cmax, AUClast, and AUClast of RXB loaded PLGA NPs (F8) in both fasted and fed state showed an extremely significant (***P ˂ 0.001) difference when compared with XARELTO® in fasted state. The relative bioavailability of NPs (F8) was found very close in fasted (256%) and fed state (216%) when compared to XARELTO® tablet in fasted and fed state respectively. The mean plasma concentration profile of RXB after oral administration of NPs (F8) and RXB, in fasted and fed state are presented in Fig. 6. The representative chromatogram of RXB are presented in Fig. 7.

Conclusion

An improved formulation of rivaroxaban with enhanced bioavailability with no effect was successfully prepared. Thirteen formulations of the rivaroxaban were designed by using central composite design. The optimized rivaroxaban loaded PLGA nanoparticles (F8) had a suitable particle size, PDI, zeta potential, drug entrapment and drug loading, which was truly confirmed by in vitro release and in vivo pharmacokinetic studies. Comparative pharmacokinetic studies of NPs (F8) with commercial tablet (XARELTO®), following oral administration in fasted and fed state to rats confirmed an enhance in bioavailability with no food effect. Hence, it is concluded that the developed nanoparticles benefits from the nano size and promise better therapeutic efficacy with no food effect.

References

Bellin A, Berto P, Themistoclakis S, Chandak A, Giusti P, Cavalli G, Bakshi S, Tessarin M, Deambrosis P, Chinellato A (2019) New oral anti-coagulants versus vitamin K antagonists in highthromboembolic risk patients. PLoS ONE 14:e0222762

Kalani C, Awudi E, Alexander T, Udeani G, Surani S (2019) Evaluation of the efficacy of direct oral anticoagulants (DOACs) in comparison to warfarin in morbidly obese patients. Hosp Pract (1995) 47(4):181–185

Minematsu K, Ikeda T, Ogawa S, Kitazono T, Nakagawara J, Miyamoto S, Murakawa Y, Takeichi M, Kidani Y, Okayama Y, Sunaya T, Sato S, Yamanaka S (2019) Real-world outcomes of rivaroxaban treatment in patients with both nonvalvular atrial fibrillation and a history of ischemic stroke/transient ischemic attack. Cerebrovasc Dis 2:1–8

Vanassche T, Verhamme P (2013) Rivaroxaban for the treatment of pulmonary embolism. Adv Ther 30:589–606

Coleman CI, Baker WL, Meinecke AK, Eriksson D, Martinez BK, Bunz TJ, Alberts MJ (2019) Effectiveness and safety of rivaroxaban vs. warfarin in patients with non-valvular atrial fibrillation and coronary or peripheral artery disease. Eur Heart J CardiovascPharmacother. https://doi.org/10.1093/ehjcvp/pvz047

Sherje AP, Jadhav M (2018) β-Cyclodextrin-based inclusion complexes and nanocomposites of rivaroxaban for solubility enhancement. J Mater Sci Mater Med 29(12):186

Metre S, Mukesh S, Samal SK, Chand M, Sangamwar AT (2018) Enhanced biopharmaceutical performance of rivaroxaban through polymeric amorphous solid dispersion. Mol Pharm 15:652–668

Abouhussein DMN, El Din Bahaa, Mahmoud D, Mohammad FE (2019) Design of a liquid nano-sized drug delivery system with enhanced solubility of rivaroxaban for venous thromboembolism management in paediatric patients and emergency cases. J Liposome Res 1:1–14

Ganesh M (2016) Design and optimization of rivaroxaban lipid solid dispersion for dissolution enhancement using statistical experimental design. Asian J Pharm 10:1–6

Xue X, Cao M, Ren L, Qian Y, Chen G (2018) Preparation and optimization of rivaroxaban by self-nanoemulsifying drug delivery system (SNEDDS) for enhanced oral bioavailability and no food effect. AAPS PharmSciTech 19:1847–1859

US Food and Drug Administration. Centre for Drug Evaluation and Research. Highlights of prescribing information of XARELTO® (Rivaroxaban). tablets. https://www.accessdata.fda.gov/drugsatfda_docs/label/2014/022406s015lbl.pdf. Accessed Jan 2014

Anwer MK, Mohammad M, Ezzeldin E, Fatima F, Alalaiwe A, Iqbal M (2019) Preparation of sustained release apremilast-loaded PLGA nanoparticles: in vitro characterization and in vivo pharmacokinetic study in rats. Int J Nanomed 14:1587–1595

Jamil A, Mirza MA, Anwer MK, Thakur PS, Alshahrani SM, Alshetaili AS et al (2019) Co-delivery of gemcitabine and simvastatin through PLGA polymeric nanoparticles for the treatment of pancreatic cancer: in vitro characterization, cellular uptake, and pharmacokinetic studies. Drug Dev Ind Pharm 45:745–753

Anwer MK, Al-Shdefat R, Ezzeldin E, Alshahrani SM, Alshetaili AS, Iqbal M (2017) Preparation, evaluation and bioavailability studies of eudragit coated PLGA nanoparticles for sustained release of eluxadoline for the treatment of irritable bowel syndrome. Front Pharmacol 8:844

Anwer MK, Al-Mansoor MA, Jamil S, Al-Shdefat R, Ansari MN, Shakeel F (2016) Development and evaluation of PLGA polymer based nanoparticles of quercetin. Int J BiolMacromol 92:213–219

Sapna K, Sudhakar G, Kumar RS (2012) A review article to develop sustain release rivaroxaban formulation. J Atoms Mol 2:14–16

Ahmed N, Hasan I, Saifuddin M, Chowdhury JA, Reza MS (2016) Formulation and optimization of carbamazepine microspheres by 2 factor 2 level central composite design. Bangladesh Pharm J 19:152–160

Singh S, Verma D, Mirza MA, Das AK, Dudeja M, Anwer MK, Talegaonkar S, Iqbal Z (2017) Development and optimization of ketoconazole loaded nano-transfersomal gel for vaginal delivery using Box-Behnken design: in vitro, ex vivo characterization and antimicrobial evaluation. J Drug Deliv Sci Technol 39:95–103

Alshahrani SM, Alshetaili AS, Alalaiwe A, Alsulays BB, Anwer MK, Al-Shdefat R et al (2017) Anticancer efficacy of self-nanoemulsifying drug delivery system of sunitinib malate. AAPS PharmSciTech 19:123–133

Çelebier M, Kaynak MS, Altınöz S, Sahin S (2014) UV spectrophotometric method for determination of the dissolution profile of rivaroxaban. Dissolution Technol 21(4):56–59

Altamimi MA, Elzayat EM, Qamar W, Alshehri SM, Sherif AY, Haq N et al (2019) Evaluation of the bioavailability of hydrocortisone when prepared as solid dispersion. Saudi Pharm J 27:629–636

Alsulays BB, Anwer MK, Aldawsari MF, Aodah A, Adam E, Alshehri S et al (2019) Preparation and evaluation of a stable and sustained release of lansoprazole-loaded poly(d, l-lactide-co-glycolide) polymeric nanoparticles. J Polym Eng 39:822–829

Iqbal M, Khalil NY, Imam F, Anwer MK (2014) A validated high-throughput UHPLC-MS/MS assay for accurate determination of rivaroxaban in plasma sample. J Thromb Thrombol 39:79–88

Ding T, Chen L, Zhai L-H, Fu Y, Sun B-W (2017) Compatibility study of rivaroxaban and its pharmaceutical excipients. J Therm Anal Calorim 130:1569–1573

Patel P (2017) Formulation, development and evaluation of rivaroxaban tablets by using solubility enhancement technique. Int J Pharm Sci Sci Res 3:51–55

Miao Y, Sun J, Chen G, Lili R, Ouyang P (2015) Enhanced oral bioavailability of lurasidone by self-nanoemulsifying drug delivery system in fasted state. Drug Dev Ind Pharm 42:1234–1240

Anwer MK, Jamil S, Ansari MJ, Iqbal M, Imam F, Shakeel F (2016) Development and evaluation of olmesartanmedoxomil loaded PLGA nanoparticles. Mat Res Innov 20:193–197

Acknowledgements

This project was supported by the Deanship of Scientific Research at Prince Sattam Bin Abdulaziz University under the research Project No. 2019/03/10912.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest is associated with this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anwer, M.K., Mohammad, M., Iqbal, M. et al. Sustained release and enhanced oral bioavailability of rivaroxaban by PLGA nanoparticles with no food effect. J Thromb Thrombolysis 49, 404–412 (2020). https://doi.org/10.1007/s11239-019-02022-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11239-019-02022-5