Magnetically separable bimetallic Ag@Ni particles were obtained by the reduction of silver ions on the surface of nickel nanoparticles. Such particles were shown to catalyze the liquid-phase oxidation of cumene by oxygen. A kinetic equation describing this process was proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Metal nanoparticles are finding increasing use in catalysis [1, 2]. In particular, nanoparticles of noble metals are used as catalysts in various reactions due to their unique physical and chemical properties [3].

Catalysis by metals (M) in theM0 state has great potential in liquid-phase oxidation by molecular oxygen, which is an important industrial process [4]. Homogeneous catalysts consisting of salts of transition metals employed in these reactions provide for sufficient selectivity but their separation and regeneration are complicated [5]. Metallic heterogeneous catalysts do not have these disadvantages.

Advances in nanochemistry open prospects for new catalytic systems for liquid-phase oxidation [6], in which nanocatalysts can have the advantages of both homogeneous and heterogeneous catalysts. Nanoparticles (NP) of gold, one of the most passive metals, and of silver display catalytic properties in the oxidation of organic substrates by molecular oxygen under mild conditions [7, 8]. In particular, graphene oxide composites AgNP-graphene display catalytic activity in the oxidation of benzyl alcohol [9] and electrocatalytic activity in the oxidation of methanol and formaldehyde [10]. Silver nanoparticles on Al2O3 catalyze the oxidation of alcohols [11, 12], while these nanoparticles on SnO2 catalyze the photochemical oxidation of organic substrates in the aqueous phase [13].

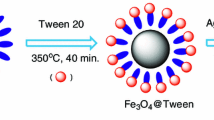

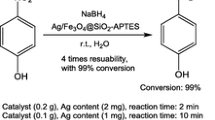

In using nanocatalysts, we still have the problem of improving the methods for their separation and regeneration. The use of magnetic nanoparticles provides the possibility of combining known procedures in heterogeneous catalysis with methods of magnetic separation [14]. The magnetic separation of a catalyst is economically advantageous because it permits less energy required for filtration and centrifugation of the mixture after the reaction. Thus, a current problem is the development of methods for the efficient immobilization of metal nanocatalysts on the surface of magnetic supports. This requires the study of ferromagnetics [15] such as AuNP on the surface of Fe3O4@SiO2 nanoparticles as the support and/or active substance [16].

In the present work, we obtained bimetallic silver–nickel nanoparticles (Ag@Ni) with magnetic properties and studied their catalytic action in oxidation reactions maintaining mild green chemistry conditions using molecular oxygen as the oxidizing agent, no solvent, and a readily separable catalyst.

Experimental

Bimetallic Ag@Ni nanoparticles were obtained by the reduction of silver ions on the surface of nickel nanoparticles (NiNP) in an aqueous medium without surfactants at 25 °C according to the following procedure. A sample of 1.5 g dry NiNP powder with particle diameter 140 ± 30 nm (synthesized as described in our previous work [17]) was dispersed in 150 mL 0.025 M aqueous AgNO3 and stirred for 6 h. The consumption of Ag+ ions was monitored potentiometrically using an ion-selective ELIS-131 (Ag) electrode [18]. The silver conversion over this time was 60% and subsequently, the Ag+ concentration decreased very slowly. The reaction kinetics was not first-order relative to Ag+ as is characteristic for the contact precipitation of metals [19, 20]. This finding probably indicates blockage of the nickel surface by silver nanoparticles.

The Ag@Ni nanocatalyst was separated from the mother liquor using a magnet, washed five times with distilled water, and dried in a desiccator at 25 °C and 10 mm Hg. The resultant particles were studied by scanning electron microscopy (SEM) on a Carl Zeiss EVO-40XVP electron microscope with an INCA Energy 350 energy dispersive X-ray microanalysis system and powder diffraction on a DRON-3.0 powder diffractometer using CuKα radiation.

The reaction kinetics for the oxidation of cumene by molecular oxygen at 70 °C and oxygen pressure 730 mm Hg was studied in the absence of solvent using an apparatus analogous to the system described by Kasperczyk et al. [21]. A sample of 1 mL of the solution studied with added 10-100 mg NiNP or Ag@Ni powder was added to a 5-mL thermostatted reactor equipped with a magnetic stirrer and connected to a gas burette filled with oxygen. The volume of absorbed oxygen was measured. In order to construct the kinetic curve, the volume of oxygen was converted to standard conditions (760 mm Hg, 273 K). Azobisdiisobutyronitrile (AIBN) (0.05 mol/L) was used as the initiator of the cumene oxidation reaction.

Results and Discussion

The data given in Fig. 1a show that the mean diameter of the Ag@Ni nanoparticles was almost the same as the diameter of the starting NiNP (140 ± 50 nm). The elemental chart of the product given in Fig. 1b shows homogeneous distribution of deposited silver on the surface of the nickel particles. The X-ray diffraction data given in Fig. 1c indicated that the product consists of a nickel phase and a silver phase but has no oxides. The silver content in Ag@Ni was 17 mass %, which is in good accord with the value calculated from the potentiometric data (14.5 mass %).

The oxygen absorption kinetics under different reaction conditions is presented in Fig. 2. Pure nickel nanoparticles (NiNP) were found not to affect the cumene oxidation rate (Fig. 2a, curves 1 and 2). On the other hand, the addition of Ag@Ni nanoparticles to the reaction mixture (100 mg/mL, Fig. 2a, curve 3) leads to an increase in the reaction rate by a factor of 3.3.

a) Kinetic curves for oxygen absorption by cumene at 70 °C in the presence of AIBN (1), AIBN and 10 mg/mL NiNP (2), AIBN and 100 mg/mL Ag@Ni (3) ([AIBN] = 0.05 mol/L), b) dependence of the squared rate of oxygen absorption ((d[O]2/dt)2) in the oxidation of cumene on the concentration of Ag@Ni nanoparticles at 70 °C.

Thus, the nickel nanoparticles in this system may be seen as an inert ferromagnetic support for the catalyst consisting of silver nanoparticles.

The square of the rate of oxygen absorption (d[O2]/dt)2 increases with increasing concentration of Ag@Ni nanoparticles in the reaction medium. The data given in Fig. 2b show that the square of the reaction rate is directly proportional to the concentration of Ag@Ni.

The classical mechanism for the oxidation of cumene by molecular oxygen at temperatures up to 90-100 °C is a radical chain scheme without branching [22]. The participation of radicals in the heterogeneous catalysis of the liquid-phase oxidation was shown by Gorokhovatskii et al. [23] and the participation of radicals in the case of nanoparticles has been demonstrated by various workers [24,25,26,27].

Taking account of the data of Crites et al. [28] and our previous results [29] on the oxidation of cumene by molecular oxygen in the presence of AgNP, for which radical chain nature was demonstrated and there is no effect of the nanoparticles on the decomposition of AIBN (In), the reaction mechanism may be represented as follows:

The rate of initiation (Wi) in the presence of AIBN and Ag@Ni nanoparticles participating in the initiation may be represented by the following equation:

In the steady state approximation considering Eqs. (1)-(5), the oxidation rate (d[O2]/dt) is described by the following equation:

The form of Eq. (6) linear relative to [Ag@Ni] is written as

In this case,

Supporting the proposal of the participation of Ag@Ni in the initiation reaction, the relationship shown in Fig. 2b is described in satisfactory agreement by Eq. (7) with aAgNi = 1.37∙10–10 and bAgNi = 11.52∙10–10 (determination coefficient R2 = 0.989).

Special interest here is found in the value of coefficient a. The dependence of the reaction rate on the nanoparticle content obtained under the same conditions for the oxidation of cumene in the presence of silver metal nanoparticles AgNP presented in our previous work [29] is also satisfactorily described by Eq. (7). In this case, the value of aAg is 28.89∙10–10. Considering Eq. (8) and the corresponding values of a, we obtain

Such a relationship between the initiation constants is partially related to the circumstance that the silver content in the Ag@Ni catalyst studied is only 17% of the total mass. Furthermore, we may assume that metallic nickel, which is inert in the oxidation reaction, has a hindering effect on the catalytic activity in the initiation reaction of the silver nanoparticles immobilized on it.

The catalytic action of Ag@Ni may be described by reactions, in which O-centered radicals participate, with the catalyst surface, i.e., with the formation of an ROO•Ag@Ni adduct and radicals on the silver surface according to the reactions

In our case, the reaction of two ROO• radicals with the silver surface to give a nonradical product ROOAgNPOOR with subsequent decomposition of this intermediate through reaction (10) is more likely. However, this assumption requires more rigorous proof and further study of the reaction of the radicals with the nanoparticles.

Hence, the catalytic effect of bimetallic Ag@Ni nanoparticles manifests itself due to the presence of silver homogeneously distributed over the nickel surface. Nickel itself is catalytically inactive in this system but it reduces the rate constant of the initiation reaction of the silver supported on it. On the other hand, we can conclude that Ag@Ni nanoparticles synthesized by the contact reduction method may be used as rather efficient and inexpensive magnetically separable catalysts for the oxidation of cumene by molecular oxygen under mild conditions without solvent.

References

F. Tao (ed.), Metal Nanoparticles for Catalysis: Advances and Applications, Royal Society of Chemistry, Cambridge (2014).

B. Zhou, S. Han, R. Raja, and G. A. Somorjai (eds.), Nanotechnology in Catalysis, Vol. 3, Springer Science + Business Media, New York (2007).

D. M. P. Mingos (ed.), Gold Clusters, Colloids and Nanoparticles I, Springer, New York (2014).

Ya. B. Gorokhovatskii, Heterogeneous–Homogeneous Reactions [in Russian], Tekhnika, Kiev (1972).

Zh. Shi, Ch. Zhang, C. Tanga, and N. Jiao, Chem. Soc. Rev., 41, 3381-3430 (2012).

I. V. Melikhov, Ross. Khim. Zh., 46, No. 5, 7-14 (2002).

H. Salari, H. Robatjazi, M. R. Hormozi-Nezhad, et al., Catal. Lett., 144, No. 7, 1219-1222 (2014).

A. M. Eremenko, N. P. Smirnova, I. P. Mukha, and H. R. Yashan, Teor. Éksp. Khim., 46, No. 2, 67-86 (2010). [Theor. Exp. Chem., 46, No. 2, 65-88 (2010) (English translation).]

B. Zahed and H. Hosseini-Monfared, Appl. Surf. Sci., 328, 536-547 (2015).

N. S. Andryushina, A. L. Stroyuk, O. O. Ustavytska, et al., Teor. Éksp. Khim., 50, No. 3, 152-159 (2014). [Theor. Exp. Chem., 50, No. 3, 155-161 (2014) (English translation).]

S. N. Orlyk, Teor. Éksp. Khim., 53, No. 5, 296-305 (2017). [Theor. Exp. Chem., 53, No. 5, 315-326 (2017) (English translation).]

N. O. Popovych, S. O. Soloviev, and S. M. Orlyk, Teor. Éksp. Khim., 52, No. 3, 133-151 (2016). [Theor. Exp. Chem., 52, No. 3, 133-151 (2016) (English translation).]

S. V. Khalameida, M. N. Samsonenko, V. V. Sydorchuk, et al., Teor. Éksp. Khim., 53, No. 1, 39-45 (2017). [Theor. Exp. Chem., 53, No. 1, 40-46 (2017) (English translation).]

S. Shylesh, V. Schunemann, and W. R. Thiel, Angew. Chem. Int. Ed., 49, No. 20, 3428-3459 (2010).

M. J. Jacinto, F. P. Silva, P. K. Kiyohara, et al., ChemCatChem, 4, No. 5, 698-703 (2012).

R. L. Oliveira, P. K. Kiyohara, and L. M. Rossi, Green Chem., 12, No. 1, 144-149 (2010).

O. Pobigun, L. Bazylyak, and A. Kytsya, Visn. L’viv. Univ., Ser. Khim., 57, Part 2, 527-533 (2016).

A. Kytsya, L. Bazylyak, Y. Hrynda, et al., Int. J. Chem. Kinet., 47, No. 6, 351-360 (2015).

G. D. Sulka and M. Jaskula, Hydrometallurgy, 64, No. 1, 13-33 (2002).

J. A. Sędzimir, Hydrometallurgy, 64, No. 3, 161-167 (2002).

K. Kasperczyk, B. Orlinska, and J. Zawadiak, Open Chemistry, 12, No. 11, 1176-1182 (2014).

R. V. Kucher and I. A. Opeida, Cooxidation of Organic Compounds in the Liquid Phase [in Russian], Naukova Dumka, Kiev (1989).

Y. B. Gorokhovatskii, N. P. Eremenko, M. V. Kost’, and V. A. Khizhnyi, Teor. Éksp. Khim., 9, No. 3, 373-375 (1973). [Theor. Exp. Chem., 9, No. 3, 292-293 (1973) (English translation).]

S. E. Davis, M. S. Ide, and R. J. David, Green Chem., 15, 17-45 (2013).

K. Yamaguchi and N. Mizuno, Angew. Chem. Ind. Ed., 41, 4538-4541 (2002).

Ye. Yu. Kalishyn, I. B. Bychko, T. M. Kameneva, et al., Teor. Éksp. Khim., 50, No. 5, 299-304 (2014). [Theor. Exp. Chem., 50, No. 5, 304-310 (2014) (English translation).]

X. J. Yang, L. Ouyang, J. Xu, and Y. F. Han, Heterogeneous Gold Catalysts and Catalysis, Royal Society of Chemistry (2014), pp. 229-287.

C. O. L. Crites, G. L. Hallett-Tapley, M. Frenette, et al., ACS Catal., 3, No. 9, 2062-2071 (2013).

I. A. Opeida, A. R. Kytsya, L. I. Bazylyak, and O. I. Pobigun, Teor. Éksp. Khim., 52, No. 6, 367-372 (2016). [Theor. Exp. Chem., 52, No. 6, 369-374 (2017) (English translation).]

This work was carried out with the partial financial support of the State Basic Research Fund (Competition Project No. 20440). The authors thank V. A. Vynar and S. A. Kornii at the G. E. Karpenko Physicomechanical Institute of the National Academy of Sciences of Ukraine for assistance in carrying out the microstructural investigations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Teoreticheskaya i Éksperimental’naya Khimiya, Vol. 54, No. 4, pp. 223-226, July-August, 2018.

Rights and permissions

About this article

Cite this article

Opeida, I.A., Kytsya, A.R., Bazylyak, L.I. et al. Magnetically Separable Nanocatalyst Ag@Ni for the Liquid-Phase Oxidation of Cumene. Theor Exp Chem 54, 242–246 (2018). https://doi.org/10.1007/s11237-018-9569-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11237-018-9569-3