Abstract

The spacecraft Hayabusa2 was launched on December 3, 2014, to collect and return samples from a C-type asteroid, 162173 Ryugu (provisional designation, 1999 JU3). It is expected that the samples collected contain organic matter and water-bearing minerals and have key information to elucidate the origin and history of the Solar System and the evolution of bio-related organics prior to delivery to the early Earth. In order to obtain samples with volatile species without terrestrial contamination, based on lessons learned from the Hayabusa mission, the sample catcher and container of Hayabusa2 were refined from those used in Hayabusa. The improvements include (1) a mirror finish of the inner wall surface of the sample catcher and the container, (2) adoption of an aluminum metal sealing system, and (3) addition of a gas-sampling interface for gas collection and evacuation. The former two improvements were made to limit contamination of the samples by terrestrial atmosphere below 1 Pa after the container is sealed. The gas-sampling interface will be used to promptly collect volatile species released from the samples in the sample container after sealing of the container. These improvements maintain the value of the returned samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The spacecraft Hayabusa returned successfully as the first asteroid exploration mission to the S type asteroid, Itokawa in 2010 after a 7-year trip. On December 3, 2014, Hayabusa2 was launched for the second asteroid sample return mission to a C-type asteroid (Tsuda et al. 2013), 162173 Ryugu (the provisional designation was 1999 JU3), of which the reflected spectrum resembles to those of CM chondrites (Binzel et al. 2001; Vilas 2008; Abe et al. 2008; Sugita et al. 2013). Since the physical, chemical, and mineralogical properties of Ryugu are expected to be different from those of Itokawa, the on-board scientific instruments of Hayabusa2 were improved or newly developed to be optimized for the target asteroid. Modifications include (1) improvements of ONC (Optical Navigation Camera), NIRS3 (Near-Infrared Spectrometer), TIR (Thermal Infrared Imager), LIDAR (Light Detection And Ranging), MINERVA II (MIcro/Nano Experimental Robot Vehicle Asteroid), and SMP (Sampler), and (2) addition of new scientific instruments, SCI (Small Carry-on Impactor), DCAM3 (wide-angle Deployable Camera), and MASCOT (Mobile Asteroid Surface Scout). Although Hayabusa returned the Itokawa samples that have provided many valuable information on the evolution of the asteroid Itokawa (e.g., Nakamura et al. 2011; Noguchi et al. 2011, 2014a, 2014b; Nagao et al. 2011; Tsuchiyama et al. 2011; Yurimoto et al. 2011; Nakamura et al. 2012; Harries and Langenhorst 2014; Keller and Berger 2014; Langenhorst et al. 2014; Mikouchi et al. 2014; Thompson et al. 2014; Takeda et al. 2015), it had some malfunctions during the voyage and after its return to the Earth. Recognized failures are troubles in the posture control system of the spacecraft (reaction wheels) and the ion engine systems (Nishiyama et al. 2010; Nishiyama and Kuninaka 2012), unfired sampling bullets during touchdown-sampling (Okada et al. 2015), and invasion of the terrestrial atmosphere to the sample container on the Earth (Okazaki et al. 2011; Yada et al. 2014a). Improvements and modifications were also made on the basic bus equipment of Hayabusa2 to ensure success of the landing and sampling processes (Tsuda et al. 2013).

The improvements of SMP instruments include (1) increase of the number of sample-storage chambers in the sample catcher from two to three for three touchdown samplings from different sites (Tsuda et al. 2013; Tachibana et al. 2014; Sawada et al. 2012), (2) adding a mirror finish of the inner wall surface of the sample catcher and the sample container, (3) change of the catcher-container sealing method to an aluminum metal system from the double fluorocarbon O-rings system of Hayabusa, (4) addition of a thinned-out part at the container base to be used as an interface for collection of volatiles released from the collected samples, (5) a tip lapel structure of the sampler horn to lift up pebbles on the asteroid regolith (Tachibana et al. 2014), and (6) strict and rigorous contamination control (Yada et al. 2014b; Karouji et al. 2014). Here, we, describe (2), (3), and (4) in details that are closely related to maintenance of the scientific quality of the returned samples.

2 Requirements on the Hayabusa2 Sampler from Scientific and Engineering Aspects

2.1 Overall Scientific Goals of Hayabusa2 and Scientific Requirements

Spectroscopic observations made from the ground suggest that Ryugu is covered with materials similar to hydrated and dehydrated CM chondrites that are expected to contain variable amounts of water, organic material, and phyllosilicates (Binzel et al. 2001; Vilas 2008; Abe et al. 2008; Sugita et al. 2013). Hence, it is expected that samples returned from Ryugu will give us information about the evolution of the early Solar System and the origin and evolutionary history of organic materials that could have evolved into the life on the Earth. The overall scientific goals of Hayabusa2 are to interpret (1) diversification of organic matter resulting from interaction between inorganic minerals, water, and organic matter in the early stage of the solar system evolution, (2) the internal structure and the collision dynamics of Ryugu, as an analog body of planetesimals, (3) the whole history of Ryugu including its origin and generation of constituent materials, thermal and aqueous alteration, collision history, orbital evolution, and space weathering processes, and (4) the mechanism and the variation of processes supplying volatile materials, such as water and organic matter, from the asteroid belt to the Earth. These scientific objectives should be performed by combining results from the remote-sensing observations and those from laboratory analyses of the returned samples. In order to accomplish the scientific goals, the minimum of 100 mg is necessary for laboratory analyses. Not only the mass, it is also required that the samples should contain several mm-sized particles for investigation of textural and petrographic information. In addition, samples are expected to be collected from multiple locations of Ryugu with different geological features, and to be stored separately in different chambers of the sample catcher. The sampling of the surface materials of the asteroid must be performed with the minimal thermal effects to avoid decomposition of dehydration of hydrated minerals and loss of volatile species.

There are some meteorites enriched in volatile elements and organic materials, such as CI and CM chondrites, and the Tagish Lake chondrite, the study of which have given some significant progresses for understanding of the origin and history of primitive Solar-System materials. However, the number of meteorites containing a copious amount of organics is limited. Moreover, meteorites fallen or found on the Earth are inevitably exposed to the terrestrial atmosphere containing oxygen and water, and hence should suffer terrestrial weathering to various degrees, such as changes of morphologies of rocks and minerals, decomposition of some unstable and reactive materials (e.g., Noguchi et al. 2014a, 2014b; Dukes et al. 1999; Loeffler et al. 2009), and production of secondary alteration materials (e.g., Tyra et al. 2007). These processes result in alteration of the original and intrinsic characteristics of some of these extraterrestrial materials, such as the physicochemical factor of rocks (e.g., porosity and strength), mineral compositions, elemental compositions, and isotopic compositions. Contamination of meteorites by terrestrial organic and inorganic materials, and man-made inorganics is also problematic. Therefore, it is important to preserve the samples returned by Hayabusa2 in as pristine a state as possible. In order to minimize the possible alteration and contamination of the collected samples, special attention was paid in the planning of the structure and mechanisms of the sample container and catcher (Karouji et al. 2014; Yada et al. 2014b). In addition, potential contamination has been controlled at the clean rooms used for construction and performance testing, and at the launch site, Tanegashima Space Center (TNSC) (Tachibana et al. 2014). Results of analyses of the category 3 samples of Hayabusa (Uesugi et al. 2014) and explosion products (Takano et al. 2014, 2015) will provide us important information for assessing the origin of carbonaceous materials (Sect. 3.4).

In designing the sample catcher and container, we have put a quantitative requirement on the maximum leak rate allowed for terrestrial atmosphere into the sample container (\({\sim}200~\mbox{cm}^{3}\): Okazaki et al. 2011) to keep pressure in the container less than 1 Pa for 100 hours after sealing of the sample container. The limit was established to allow detection of 1 % of solar wind (SW) 4He and 20Ne (\(10^{-4}\) and \(10^{-6}~\mbox{cm}^{3}\) standard temperature and pressure (STP), respectively) released from the returned samples and stored in the sample container, with an assumption that the samples are 100 mg in weight and contain solar gases at the average concentration in lunar samples (\({\sim}10^{-1}\) and \(10^{-3}~\mbox{cm}^{3}\) STP/g for 4He and 20Ne, respectively; Fegley and Swindle 1993).

In summary, the following scientific requirements are called for the design of the Hayabusa2 sample catcher and container: (1) To obtain the minimum of 100 mg including several mm-sized particles. (2) To store the samples collected from multiple locations separately in the sample catcher. (3) To prevent thermal effects during sampling from decomposing or dehydrating hydrous minerals and losing volatile components contained in the surface materials of the asteroid. (4) To minimize contamination of terrestrial or mam-made matters including substances of the spacecraft, terrestrial organics, inorganic minerals, and terrestrial (atmospheric) volatiles.

2.2 Engineering Requirements from the Design, Assemblage, and Launch of Hayabusa2

The basic design of Hayabusa2 inherited that of Hayabusa in many respects (Tsuda et al. 2013), which enable rapid development of the spacecraft with higher reliability relative to Hayabusa. This primal requirement sets limitations on the design of the sample catcher and container, including (1) the dimension and weight of the sample catcher and container must not be changed largely from those of Hayabusa, and (2) addition of any electric device on the sample catcher and container is not allowed. Subsequently, the sampling operation of Hayabusa2 must be done within a short duration (\({\sim}1~\mbox{sec}\)) at the touchdown under microgravity on the asteroid, in the same way as Hayabusa. Within these limitations, we have designed and developed the sample catcher and container, as described in Sect. 4.

3 Evaluation of the Scientific Requirements for the Sample Catcher and Container

We here discuss the requirements for the Hayabusa2 sample catcher and container from scientific points of view.

3.1 Noble Gas Isotopes

Abundances and isotopic compositions of noble gases, and their release temperatures are important to elucidate the origin and history of the planetary materials. For example, isotopic compositions of Ne and Xe can be used to constrain the origin of extraterrestrial materials such as presolar grains (e.g., Wieler 2002a; Ott 2002), and the release temperatures of solar He in micrometeorites and IDPs (interplanetary dust particles) obtained by stepwise heating can be used to estimate their temperature increase during atmospheric entry (e.g., Love and Brownlee 1991, 1994; Okazaki et al. 2015). A fraction of the noble gases in presolar grains is released at low temperature (from \({\sim}200~{}^{\circ}\mbox{C}\); Huss and Lewis 1994). Since adsorbed atmospheric noble gases are also mainly released from meteorites at such a low temperature (Okazaki et al. 2010), it is important to minimize adsorbed gases to discuss the origin of low-temperature released noble gases in extraterrestrial samples. Solar noble gases are common in extraterrestrial materials derived from the surface regolith layer of air-less bodies, and could contain information on the evolutionary history of the regolith layer. Solar He is contained mainly in the very thin (\({<}1~\upmu \mbox{m}\)) space-weathering rims, which are friable to terrestrial weathering (see below).

Abundances of isotopes produced by radionuclide decays or cosmic-ray exposures are used for dating of specific events and processes, such as K–Ar dating for shock-heated meteorites or galactic cosmic-ray exposure ages for meteorites (Swindle 2002; Wieler 2002b).

However, the exposure to atmospheric gases can cause other problems. For example, phosphate-bearing sulfides, one of the host minerals of potassium in CM chondrites (e.g., Nazarov et al. 2009), are easily oxidized. Therefore, contamination and adsorption of atmospheric gases must be eliminated as much as possible. In the next subsection, we discuss the risk of oxidization of highly reactive phases in detail.

In addition to the inward leakage of the atmospheric gases, volatiles emanating from the materials of the sample catcher and container must be kept as low as possible. These volatiles are mainly of atmospheric gases adsorbed on surfaces of the sample catcher and container, and also on contaminants or themselves. Adsorption of atmospheric gases onto the returned samples leads to contamination of noble gases indigenous to the samples collected by heavy noble gases such as Ar, Kr, and Xe. In order to minimize the amounts of adsorbed atmospheric gases on the surface of the sample catcher and container on the ground before the launch, the sample container must be tightly sealed and most of the parts were polished to form a mirror-finished surface (see Sect. 4.3). Moreover, the sample catcher and container were cleaned by an ultrasonic cleaner before the construction (Tachibana et al. 2014; Yada et al. 2014b) to minimize the contamination as much as possible.

3.2 Reactive Minerals and Phases

Some minerals contained in chondrites can be used to constrain the conditions under which they were formed. Noguchi et al. (2014a, 2014b) found space-weathered rims, sylvite, and halite on the surface of dust particles returned by Hayabusa. These findings are important to understand the processes and condition of space weathering and the regolith evolution. However, the rims and these minerals are chemically reactive and are easily decomposed by reaction with oxygen and water in the atmosphere. For example, although sylvite and amorphous materials have been observed in the ultra-thin sections through the initial analysis of the Itokawa particles (Noguchi et al. 2014b) after exposure to the terrestrial atmosphere of 5000 Pa for 8 days (∼200 hours) (Okazaki et al. 2011; Yada et al. 2014a), it was found that they had decomposed after \({\sim}1\)-year storage (Noguchi et al. 2014b) in the clean chamber No. 2 of the PMSCF (Planetary Material Sample Curation Facility)/JAXA, even though this chamber was filled with ultra-pure \(\mathrm{N}_{2}\) (Yada et al. 2014a). Similar problems were also seen for space weathered rims: Space weathered rims were observed in FIB and ultramicrotommed sections in the initial analysis of Itokawa particles (Noguchi et al. 2011), but the rims were seen to alter over time even though the samples were kept in vacuum desiccator storage (Noguchi et al. 2014a). Although it is difficult to estimate the decomposition rates quantitatively, it was reported that metallic iron nano-particles on the surface of olivine grains experimentally irradiated by helium and hydrogen ions are readily oxidized and decomposed in the atmosphere within 1 min (Dukes et al. 1999; Loeffler et al. 2009).

Alteration and decomposition of host minerals of radionuclides, such as phosphates and sulfides (e.g., Nazarov et al. 2009), must be avoided to study the timing of geological events occurred on Ryugu. Secondary-produced minerals during the terrestrial weathering (e.g., Tyra et al. 2007) is also problematic to discuss the condition through which the asteroid have formed and evolved.

The exposure to the terrestrial atmosphere of 1 Pa for 100 hours corresponds to several seconds of exposure to the atmosphere by assuming the linear correlation between the reaction rate and the oxygen pressure, and will reduce the risk of oxidation of reactive phases. We note that the sample container should be evacuated as soon as possible after the return to the Earth to minimize sample alteration.

3.3 Organic Compounds and Inorganic Volatile Molecules

Some chemical groups of carbonaceous chondrites (Krot et al. 2003) have a carbon-rich matrix (organic carbon <6 wt%; e.g., Pearson et al. 2006). The abundances and compositions of organic compounds and volatile inorganic molecules in meteorites (e.g., Cronin and Chang 1993) are one of the indicators of exogenous primordial delivery of organics to the Earth. Sephton (2002) and Gilmour (2003) compiled compound classes found in meteorites, including aliphatic hydrocarbons, aromatic hydrocarbons, amino acids, carboxylic acids, sulfonic acids, phosphonic acids, alcohols, aldehydes, ketones, sugars, amines, amides, nitrogen heterocycles, sulfur heterocycles, and high molecular weight complex organics. The organic molecules in carbonaceous chondrites can be subdivided operationally into three components: (1) free organic matter (FOM), which is an extractable fraction; (2) labile organic matter (LOM), which has a diverse range of organic molecular weight, and (3) refractory organic matter (ROM), which is also macromolecular but is unaffected by hydrous pyrolysis and chemical treatments (cf. Sephton et al. 2003). Compound-specific isotopic compositions of organic compounds and inorganic volatiles including \(\mathrm{H}_{2}\mathrm{O}\), \(\mathrm{CO}_{2}\), and \(\mathrm{NH}_{3}\) are important information to elucidate their origins prior to or during the early evolution of Solar System (cf. Becker and Epstein 1982; Kerridge 1985). For example, nitrogen, ammonia, which is the most abundant chemical species, showed 15N-enriched profile (i.e., \(\delta^{15}\mathrm{N} < +223~\mbox{\textperthousand}\) vs. Air standard) as volatile compounds (in the Grave Nunataks 95229 CR chondrite; Pizzarello et al. 2011). Potentially, the chemically-labile component plays an important role of chemical evolution relevant to nitrogen compounds. It is thus important to minimize the potential risk of contamination and sample alteration (especially, for the FOM and LOM fractions above mentioned) for the description of evolution history of exogenous organic compounds. For instance, the potential effect of terrestrial contaminations of water on the hydrogen isotopic composition of water vapor released from the samples can be expressed as follows,

where \(f\) represents the molar fraction of contaminated water vapor and \(\delta D_{\mathrm{asteroid}}\), \(\delta D_{\mathrm{terrestrrial}}\), \(\delta D_{\mathrm{water}\ \mathrm{vapor}}\) are the hydrogen isotopic compositions of water vapor from the asteroid samples, contaminated water vapor, and their mixture, respectively.

Concentrations of \(\mathrm{H}_{2}\mathrm{O}\) in CM chondrites range from 2 to 18 wt% (Yanai and Kojima 1995). Assuming that the sample container (\({\sim }200~\mbox{cm}^{3}\)) is filled with the terrestrial atmosphere of 1 Pa with the saturated water vapor at 300 K, the \(\mathrm{H}_{2}\mathrm{O}\) abundance in the container will be \(5\times10^{- 5}~\mbox{mg}\), which corresponds to <0.0025 % of \(\mathrm{H}_{2}\mathrm{O}\) in the 100 mg sample.

The abundance of \(\mathrm{NH}_{3}\) in Murchison CM chondrite is \(19~\upmu \mbox{g}/\mbox{g}\) (Pizzarello et al. 1994). The \(\mathrm{NH}_{3}\) abundance in the terrestrial troposphere is 0.1–3 ppb (volume content: Warneck 1988), corresponding to \(0.15\mbox{--}4.5 \times10^{-9}~\upmu \mbox{g}\) in the \(1~\mbox{Pa}\times 200~\mbox{cm}^{3}\) STP atmosphere. Even if additional contamination comes from evaporated gas from atmospheric aerosol particles (the particle concentration of \(17~\upmu \mbox{g}/\mbox{m}^{3}\) and the \(\mathrm{NH}_{4}^{+}\) concentration of 8 %: Chowdhury et al. 2001; Lelieveld et al. 2001; Ramanathan et al. 2001), the contaminated \(\mathrm{NH}_{3}\) is expected to be \(2.7\times10^{-9}~\upmu \mbox{g}\). Hence, the contamination of \(\mathrm{H}_{2}\mathrm{O}\) and \(\mathrm{NH}_{3}\) from the terrestrial atmosphere of 1 Pa is negligibly small compared to those in the 100 mg sample.

Amounts of organic materials contained in Murchison are \(106~\upmu \mbox{g}/\mbox{g}\) of carbon dioxide (Yuen et al. 1984), \(332~\upmu \mbox{g}/\mbox{g}\) of monocarboxylic acids (Lawless and Yuen 1979; Yuen et al. 1984), \(12\mbox{--}35~\upmu \mbox{g}/\mbox{g}\) of aliphatic hydrocarbons (Kvenvolden et al. 1970), \(15\mbox{--}28~\upmu \mbox{g}/\mbox{g}\) of aromatic hydrocarbon (benzene: Pering and Ponnamperuma 1971), and \(8~\upmu \mbox{g}/\mbox{g}\) of amines (Jungclaus et al. 1976). If the pressure of the sample container remains to be less than 1 Pa after the return to the Earth due to the atmosphere leakage, about \(0.00135~\upmu \mbox{g}\) of contaminant carbon dioxide will be inside the sample container (350 ppm \(\mathrm{CO}_{2}\) in the terrestrial atmosphere: Keeling et al. 1984). As for the contamination of FOM and LOM, if the contaminates are the evaporated gas molecules from atmospheric particles (the organic matter concentration of 26 %: Lelieveld et al. 2001), the amount of FOM- and ROM-contaminations from the 1-Pa terrestrial atmosphere will be \(10^{-8}~\upmu \mbox{g}\), which is also negligibly small compared to those contained in the samples.

3.4 Quality Assurance by Assessing the Origin of Unseen Particles: Lessons from Hayabusa

In addition to the contamination of volatiles and inorganic materials in the returned samples by terrestrial atmosphere and atmospheric particles (aerosols), organic matter has the potential risk to be contaminated by artifact materials, such as explosion products (Takano et al. 2014, 2015: cf. Hayabusa2 operation from Tachibana et al. 2014) and unseen particles, such as carbonaceous Category 3 particles found during the Hayabusa curation works (Uesugi et al. 2014). Considerable effort has been made to perform a comprehensive assessment of the Category 3 particles. The initial assessment was made using multi-isotope imaging with hydrogen, carbon, and nitrogen and hydrogen by a nanoSIMS ion microprobe, which requires a minimum morphological size ranging from \(1\mbox{--}5~\upmu \mbox{m}\) (Ito et al. 2014). Scanning transmission X-ray microscope (STXM) and X-ray absorption near edge structure (XANES) were performed for functional group analysis of organic molecules using a similar morphological scale samples, as do micro-Raman, infrared, and Transmission Electron Microscope TEM studies (ca. \(1\mbox{--}5~\upmu \mbox{m}\): Yabuta et al. 2014; Kitajima et al. 2015). In addition to these analyses, time of flight-secondary ion mass spectrometry (ToF-SIMS) was performed to study diagnosis ions for the surface organic molecules (Naraoka et al. 2015). When we focus on some important organic molecules, e.g., amino acids, the minimum amount for sub femto mole (i.e., 0.1–1.0 femto mole) orders are required for identification (e.g., Elsila et al. 2009; Naraoka et al. 2012) and determination of their enantiomer ratio (D/L ratio) using appropriate derivatization (Hamase et al. 2014). The results of these analyses will be important to assess the degree of contamination, and to discuss the origin of the carbonaceous matters that would be contained in the sample catcher of Hayabusa2. The summary of contamination management has been archived including explosion-specific products (Takano et al. 2014; 2015) during the sampling operation (Saiki et al. 2013; Tachibana et al. 2014) and comprehensive curation systems within entire laboratory workflows (Abe et al. 2015).

4 Mechanism of the Sealing System and the Design of the Sample Catcher and Container

4.1 Transfer of the Sample Catcher and Activation of the Sealing Mechanism

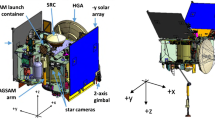

A schematic diagram (Figs. 1a–c) and a picture (Fig. 1d) of the sample catcher and container of Hayabusa2 are shown in Fig. 1. Figure 1a shows the sampling system after three touchdown operations and pulling out of the sampling reflector attached to the sample horn (Sawada et al. 2012). The sample catcher will then be transferred to the sample container mounted in the Earth-reentry capsule (Fig. 1a). The transfer force comes from spring-load that is controlled by an NEA (Non-explosive Actuator) and the pressing load after the transfer is 29 N. The transfer length is about 160 mm and the overall accuracy of the centering of the transfer mechanism is 0.63 mm. After the transfer, the sample catcher is put inside the container, and the catcher and container are combined each other in place (Fig. 1b). At this stage, the curved-surface lid composed of nearly pure aluminum alloy (A-1070) does not contact with the container edge made of aluminum alloy (A-6061) (Fig. 1b). After the combination, the other NEA that is mounted in the sample catcher is activated to release the spring tension. The pressing load of 2683 N (about twice of the Hayabusa) compresses the curved-surface lid onto the container edge (Fig. 1c). The metal sealing system consist only of aluminum alloys (A-1070 and A-6061), which reduces the potential contamination from the sample catcher and container themselves. In the Hayabusa mission, the sealing mechanism used fluorocarbon O-rings. However, the fluorocarbon sealing system was not used in Hayabusa2 because fluorocarbon easily absorbs (or adsorbs) and occludes organic and inorganic volatiles that are originated both from the samples in the container and from the terrestrial atmosphere.

Schematic diagram (a)–(c) and pictures (d) of the sample catcher and container of Hayabusa2. (a) The sample catcher is transferred forward to the sample container and the re-entry capsule. (b) The sample catcher is combined with the sample container in place. (c) The curved-surface lid is thrusted on the edge of the sample container by release of the spring tension. (d) Pictures of the flight models of the sample catcher and the sample container

4.2 Aluminum Foils for Sweeping Dust Particles on the Sealing Part

There could be a possibility that collected dust particles waft from the sample catcher and land on the container sealing part before sealing. As shown in the Figs. 1 and 2, aluminum foils were inserted and positioned in the sample catcher to sweep dust particles of the sealing surface during the transfer of the sample catcher into the container (Figs. 1a, b, and 2). A performance test showed that the aluminum foils can remove dust particles without scratching the surface of the sealing part. This is owing to the incline on the edge of the container (Figs. 1b and 2). After the sweeping motion, the foils will be bent and they have no influence on sealing or other subsequent processes and following operations (Figs. 1b and 1c).

Dust-sweeping Al foils of the metal sealing system. (a) Aluminum foils are placed in the sample catcher to sweep dust particles of the sealing surface. (b) The Al foils can remove dust particles during the transfer of the sample catcher from the sealing surface. The edge of the sample container is cut to have incline, which leads to successful removing of dust particles

4.3 Mirror-finished Surface

Surfaces of the sample catcher and container (except for sliding surfaces processed for specific surface treatments) were mechanically polished to be mirror-finished surfaces. The surface roughness measured at the mirror finished parts is about 6 nm expressed by using the arithmetic mean value (\(\mathrm{R}_{\mathrm{a}}\)), which is about \(1/250\) or less of that of the original machine-grinding surface (\(1.6~\upmu \mbox{m}\)). Hirohata et al. (1992) compared surface roughness factors (SRFs) determined by surface profilometry and xenon adsorption methods for samples treated with different surface-finish processes. The SRF of the machine cutting sample determined by gas adsorption is larger than that determined by surface profilometry, whereas the SRFs for the mechanical polished sample are similar between the measurement methods (Hirohata et al. 1992). This indicates that surface profilometry is representative only of the macroscopic structure and underestimates the actual surface area acting as gas adsorption. Hence, the amount of adsorbed gases on the mirror-finished surface is much smaller than \(1/250\) of the machine-grinding surface. Thus, the polishing of surfaces of the sample catcher and container should help minimize the adsorbed contaminant gases.

4.4 Thinned-out Gas-sampling Interface

In order to perform prompt evacuation and collection of the sample container after recovery of the re-entry capsule, a thinned-out gas-sampling interface has been placed at the container base so it can be used as a port for gas collection and evacuation (Sawada et al. 2012). After cleaning of the surface of this gas-sampling interface, the container can be connected to a gas collection system through a hole made on the thinned-out part by a tungsten-carbide needle attached on a linear motion feed-through. A sintered metal filter with \(0.5~\upmu \mbox{m}\) pore size is equipped at the inner side of the gas-sampling interface (shown in Fig. 1c) to prevent sample particles from scattering out from the sample container after it is punctured. In addition, the sintered metal filter can keep off contamination Al particles produced by piercing. The container will be kept statically in vacuum until it is connected to the container opening chamber at the sample curation facility at ISAS/JAXA, which was not the case for the Hayabusa sample container.

5 Performance Tests of the Metal Sealing System

The configuration of performance evaluation tests for the metal sealing system is shown in Fig. 3. The trial sample catcher and container for the evaluation (hereafter trial container) were combined together, and then the latching and sealing tests were performed in a manner similar to those mentioned above (Sect. 4.1). The trial container was connected to the vacuum system through the gas-sampling interface, and wrapped with flexible tape heaters to degas atmospheric gases adsorbed on the inner surface of the trial container and the vacuum system by heating at 150 °C. Baking duration ranged from several hours to 12 hours. A part of the trial container was then covered with a bag filled with helium gas of atmospheric pressure (Fig. 3). The degree of the leakage through the sealing surface (Fig. 3b) was determined based on a He peak height monitored with QMS (Quadrupole Mass Spectrometer), of which sensitivity was calibrated using a He permeation leak standard (Fig. 3a). The trial container was separated off from the vacuum system (by closing MV-4 in Fig. 3a) to evaluate the static-vacuum performance after the leakage check. The pressure in the trial container was measured with a vacuum gauge, by batching off the gas in the container to the flexible tube (Fig. 3a).

Configuration of the performance evaluation test of the metal sealing system. The trial container was connected to the vacuum system and evacuated (a). A part of the trial container including the sealing surface was put in a bag filled with 1 atm-He gas (b). The He leak was monitored by QMS (Quadrupole Mass Spectrometer) (a). The absolute leak rate was calibrated by the He permeation leak standard, by replacing the trial container (a). TMP: Turbo Molecular Pump. MV: Metal Valve

There are several factors lowering the performance of the metal sealing system: (1) eccentric transfer of the sample catcher into the sample container (Sect. 5.2), (2) shocks due to gunpowder explosions for the parachute opening and detachment, landing, and so on (Sect. 5.3), and (3) dust particles on the sealing area (Sect. 5.4). Each of these potential problems is evaluated in Sect. 5.2–5.4, and considered all together as the worst case (Sect. 5.5).

5.1 Static-Vacuum Performance Against Leakage Through the Metal Sealing and Outgas from the Container Surface

Figure 4 shows the result of the ideal evaluation test. The increase of 4He due to the leakage of the terrestrial atmosphere into the trial container through the metal sealing surface was not observed (Fig. 4a). Considering the fluctuation of the background signal, the leak rate of 4He leak is thought to be \({<}5\times10^{-14}~\mbox{A}\). The absolute leak rate was calibrated by using a He permeation leak standard as \(1\times10^{-10}~\mbox{A}\) of 4He detection sensitivity of the QMS used in the test runs to be \(2.3\times10^{-6}~\mbox{cm}^{3}\) STP/sec (denoting a leak rate against helium of atmospheric pressure). The 4He increase (\({<}5\times10^{-1 4}~\mbox{A}\): Fig. 4a) in the ideal evaluation test corresponds to a leak rate of \({<}1\times10^{-9}~\mbox{cm}^{3}\) STP/sec. Hence, the elevation of the inner pressure is calculated to be <0.2 Pa for the sample container with an about 200 cm3 internal volume (Okazaki et al. 2011; Yada et al. 2014a) after 100 hours under atmospheric pressure.

Results of the evaluation test for the leakage and outgas rates. (a) He peak monitored by QMS during the performance test on the ideal condition. The peak height was not changed before and after He supply into the bag surrounding the trial container. (b) The inner pressure of the container against the static hold time. The test runs in which the container was baked for a longer time (\({\sim}12~\mbox{h}\)) plot below the regression line defined by those with shorter baking time (1–2 h)

Increase rates of the pressure in the trial containers measured in several test runs are plotted against the retention time (Fig. 4b). The linear fitting calculation of the results (Fig. 4b) gives about 0.15 Pa of the inner pressure after 100 hours. Data obtained after a longer baking time (∼12 hours) plot slightly below those for shorter baking time (1–2 hours) (Fig. 4b), which suggests that some part of the gases in the trial container were adsorbed atmospheric molecules. In the case of the actual flight container, the adsorbed atmospheric species will have escaped before sealing the container in space. By assuming the adsorption energy of water molecule to be 76 kJ/mol (Fernández et al. 2007), the water vapor pressure in the sample container after the sealing will be negligibly small. Even if we assume the adsorption energy of 100 kJ/mol as a worse case, the internal pressure will be 0.24 Pa. Therefore, the inner vacuum pressure increase due to the leakage of atmosphere and the degassing of volatiles from the container is likely to be <0.4 Pa for the ideal sealing condition and satisfy the scientific requirements.

5.2 Vacuum Performance with Eccentric Transfer of the Sample Catcher

The sample catcher will be transferred to the sample container mounted on the re-entry capsule (Fig. 1a: Sect. 4.1) after three touchdown operations with an eccentricity of <0.63 mm against the center of the sample container. Our evaluation tests showed that the sealing performance is not affected by the amount of eccentricity <0.6 mm, although the leakage was observed in the tests with the eccentricity of 0.7–1.0 mm.

5.3 Vacuum Performance Against Shocks Experienced During Flight and Recovery

The re-entry capsule will experience several shocks induced by gunpowder explosions (parachute opening at midair and on ground), landing, and other unexpected causes. The most intense shock during the Earth-return sequence is generated by the parachute deployment at midair between 5 and 10 km (Yamada et al. 2015). In the tests, shocks like those expected from the parachute deployment were simulated. These covered the range from 141 G at 100 Hz to 4930 G at 2400–4000 Hz, with stepped increases of 12 dB/octave (Fig. 5a). A short time leakage (<10 sec) was occasionally observed due to shocks (Fig. 5b). By multiplying the largest leak rate of \(1\times10^{-6}~\mbox{cm}^{3}\) STP/sec (\(5\times10^{-11}~\mbox{A}\); Fig. 5b) by the leak duration of 10 sec, the amount of the intruding He is estimated to be less than \(1\times10^{-5}~\mbox{cm}^{3}\) STP, which corresponds to 0.005 Pa in the sample container. Hence, the explosive shock is highly unlikely to affect the internal pressure of the sample container after the Earth-return.

Results of the shock-resistance performance test. (a) The wave form of simulated impact. The solid yellow line is the wave form expected from parachute deployment, and the red line is the actual form generated in the experiments. (b) The QMS data of the shock-resistance test. A momentary He leak was seen due to the shock, but the total amount of He intruding into the container is negligibly small

5.4 Sealing with Dust Particles Present on the Sealing Surfaces

It is expected that dust particles could drift and float within the sample catcher and container in space due to static electricity under micro-gravity (e.g., Lee 1996). Particle drift could also be induced by spacecraft motions in flight. We conducted two kinds of tests to evaluate the effects of dust particles located at the sealing surface on the sealing performance. One was to see how efficiently particles can be removed from the sealing area by the dust sweeping foils (Sect. 4.2). In this test, 36 silicate particles (crushed andesite) with \({\sim}300~\upmu \mbox{m}\) diameter were distributed evenly on the inner edge of the container. The test showed that the dust-sweeping foils can flap away all of the silicate particles from the sealing part. The other test was to evaluate the vacuum performance with interleaving particles (powdered Murchison, with \({\sim}10~\upmu \mbox{m}\) diameter) on the sealing surface. In this test, no sign of leakage was observed as in the case of the ideal condition test (Sect. 5.1; Fig. 4a), except for the test with particles larger than 300 μm in diameter.

5.5 Performance Evaluation in the Worst Possible Case

We conducted evaluation tests of sealing with all of the potential problems mentioned above at the same time as the situation of the worst possible case; the configuration of the catcher and container with the 0.6 eccentricity, placement of \({\sim}10~\upmu \mbox{m}\) dust particles on the sealing surface, and simulation of explosive impact. Although the degree of leakage of this test is slightly larger than those for individual situations, the most obvious leakage occurred only after shock. The leak rates in the worst case were \({\sim}5\times10^{-1 3}~\mbox{A}\) with a short duration leakage of \({<}1\times10^{-9}~\mbox{A}\) for \({<}{\sim}10~\mbox{sec}\) due to the simulated impact. Figure 6 shows that the internal pressures of the trial containers in all cases were <0.4 Pa after 100 hours. Therefore, the metal sealing system will satisfy the scientific requirements even in the worst case and work effectively to store fresh samples returned from Ryugu by the Hayabusa2 spacecraft.

6 Conclusion

The Hayabusa2 spacecraft was launched to return samples from a C-type asteroid, Ryugu. The sample catcher and container were modified from the designs of Hayabusa in some respects to raise the scientific value of the returned samples. The improvements we made are: (1) applying mirror finish of the inner wall surface of the sample catcher and the sample container, (2) changing to an aluminum metal sealing system, and (3) addition of a gas-sampling interface at the container base for gas collection and evacuation. These improvements enable storage of the samples in the sample container in vacuo. The sample container should be capable of maintaining an internal pressure of <1 Pa after 100 hours from the Earth return against the air leak. This performance satisfies the requirements determined from the scientific points of view, especially for the analysis of volatile components of the returned samples.

References

M. Abe, K. Kawakami, S. Hasegawa, D. Kuroda, M. Yoshikawa, T. Kasuga, K. Kitazato, Y. Sarugaku, D. Kinoshita, S. Miyasaka, S. Urakawa, S. Okumura, Y. Takagi, N. Takato, T. Fujiyoshi, H. Terada, T. Wada, Y. Ita, F. Vilas, P.R. Weissman, Y.-J. Choi, S. Larson, S.J. Bus, A. Tokunaga, T.G. Muller, Ground-based observational campaign for asteroid 162173 1999 JU3. Lunar Planet. Sci. Conf. 39, 1594 (2008)

M. Abe, T. Yada, M. Uesugi, Y. Karouji, A. Nakato, M. Hashiguchi, T. Matsumoto, K. Kumagai, M. Nishimura, T. Okada, Current status of JAXA’s Astromaterials Science Research Group, in Hayabusa 2015: 3rd Symp. Solar System Materials, O-09 (2015)

R.H. Becker, S. Epstein, Carbon, hydrogen and nitrogen isotopes in solvent-extractable organic matter from carbonaceous chondrites. Geochim. Cosmochim. Acta 46, 97–103 (1982)

R.P. Binzel, A.W. Harris, S.J. Bus, T.H. Burbine, Spectral properties of near-Earth objects: palomar and IRTF results for 48 objects including spacecraft targets (9969) Braille and (10302) 1989 ML. Icarus 151, 139–149 (2001)

Z. Chowdhury, L.S. Hughes, L.G. Salmon, G.R. Cass, Atmospheric particle size and composition measurements to support light extinction calculations over the Indian Ocean. J. Geophys. Res. 106(D22), 28,597–28,605 (2001)

C.A. Dukes, R.A. Baragiola, L.A. McFadden, Surface modification of olivine by \(\mathrm{H}^{+}\) and \(\mathrm{He}^{+}\) bombardment. J. Geophys. Res. 104(E1), 1,865–1,872 (1999)

J.R. Cronin, S. Chang, Organic matter in meteorites: molecular and isotopic analyses of the Murchison meteorite, in The Chemistry of Life’s Origins, ed. by J.M. Greenberg et al.(Kluwer Academic, Dordrecht, 1993), pp. 209–258

J.E. Elsila, D.P. Glavin, J.P. Dworkin, Cometary glycine detected in samples returned by Stardust. Meteorit. Planet. Sci. 44, 1323–1330 (2009)

B. Fegley Jr., T.D. Swindle, Lunar volatiles: implications for lunar resource utilization, in Resources of Near-Earth Space, ed. by J. Lewis, M.S. Matthews, M.L. Guerrieri (Univ. Arizona Press, Tucson, 1993), pp. 367–426

E.M. Fernández, R.I. Eglitis, G. Borstel, L.C. Balbás, Ab initio calculations of \(\mathrm{H}_{2}\mathrm{O}\) and \(\mathrm{O}_{2}\) adsorption on \(\mathrm{Al}_{2}\mathrm{O}_{3}\) substrates. Comput. Mater. Sci. 39, 587–592 (2007)

I. Gilmour, Structural and isotopic analysis of organic matter in carbonaceous chondrites, in Treatise on Geochemistry, Vol. 1 (2003), pp. 269–290

K. Hamase, Y. Nakauchi, Y. Miyoshi, R. Koga, N. Kusano, H. Onigahara, H. Naraoka, H. Mita, Y. Kadota, Y. Nishio, M. Mita, W. Linder, Enantioselective determination of extraterrestrial amino acids using a two-dimensional chiral high-performance liquid chromatographic system. J. Chromatogr. 35, 103–110 (2014)

D. Harries, F. Langenhorst, The mineralogy and space weathering of a regolith grain from 25143 Itokawa and the possibility of annealed solar wind damage. Earth Planets Space 66, 163 (2014)

Y. Hirohata, M. Hashiba, T. Hino, T. Yamashina, Surface characterization and gas desorption measurements (II): effects of surface treatment for outgassing behavior of type 2017 aluminium alloy. Bull. Fac. Eng., Hokkaido Univ. 159, 19–29 (1992). http://hdl.handle.net/2115/42311

G.R. Huss, R.S. Lewis, Noble gases in presolar diamonds I: three distinct components and their implications for diamond origins. Meteoritics 29, 791–810 (1994)

M. Ito, M. Uesugi, H. Naraoka, H. Yabuta, F. Kitajima, H. Mita, Y. Takano, Y. Karouji, T. Yada, Y. Ishibashi, H, C, and N isotopic compositions of Hayabusa category 3 organic samples. Earth Planets Space 66, 91 (2014)

G. Jungclaus, J.R. Cronin, C.B. Moore, G.U. Yuen, Aliphatic amines in the Murchison meteorite. Nature 261, 126–128 (1976)

Y. Karouji, Y. Ishibashi, M. Uesugi, T. Yada, A. Nakato, K. Kumagai, T. Okada, M. Abe, The handling and contamination control of Hayabusa-returned sample in Extraterrestrial Sample Curation Center of JAXA. Chikyukagaku (Geochemistry) 48, 211–220 (2014). (In Japanese with English abstract)

C.D. Keeling, A.F. Carter, W.G. Mook, Seasonal, latitudinal, and secular variations in the abundance and isotopic ratios of atmospheric \(\mathrm{CO}_{2}\): 2. Results from oceanographic cruises in the tropical Pacific Ocean. J. Geophys. Res. 89(D3), 4,615–4,628 (1984)

L.P. Keller, E.L. Berger, A transmission electron microscope study of Itokawa regolith grains. Earth Planets Space 66, 71 (2014)

J.F. Kerridge, Carbon, hydrogen and nitrogen in carbonaceous chondrites: abundances and isotopic compositions in bulk samples. Geochim. Cosmochim. Acta 49, 1,707–1,714 (1985)

F. Kitajima, M. Uesugi, Y. Karouji, Y. Ishibashi, T. Yada, H. Naraoka, M. Abe, A. Fujimura, M. Ito, H. Yabuta, H. Mita, Y. Takano, T. Okada, A micro-Raman and infrared study of the several Hayabusa category 3 (organic) particles. Earth Planets Space 67, 20 (2015)

A. Krot, K. Keil, C. Goodrich, E. Scott, M. Weisberg, Classification of meteorites, in Meteorites, Comets and Planets. Treatise on Geochemistry, vol. 1 (2003), pp. 83–128

K. Kvenvolden, J. Lawless, K. Pering, E. Peterson, J. Flores, C. Ponnamperuma, I.R. Kaplan, C. Moore, Evidence for extraterrestrial amino-acids and hydrocarbons in the Murchison meteorite. Nature 228, 923–926 (1970)

F. Langenhorst, D. Harries, K. Pollok, P.A. van Aken, Mineralogy and defect microstructure of an olivine-dominated Itokawa dust particle: evidence for shock metamorphism, collisional fragmentation, and LL chondrite origin. Earth Planets Space 66, 118 (2014)

J.G. Lawless, G.U. Yuen, Quantification of monocarboxylic acids in the Murchison carbonaceous meteorite. Nature 282, 396–398 (1979)

P. Lee, Dust levitation on asteroids. Icarus 124, 181–194 (1996)

J. Lelieveld, P.J. Crutzen, V. Ramanathan, M.O. Andreae, C.A.M. Brenninkmeijer, T. Campos, G.R. Cass, R.R. Dickerson, H. Fischer, J.A. de Gouw, A. Hansel, A. Jefferson, D. Kley, A.T.J. de Laat, S. Lal, M.G. Lawrence, J.M. Lobert, O.L. Mayol-Bracero, A.P. Mitra, T. Novakov, S.J. Oltmans, K.A. Prather, T. Reiner, H. Rodhe, H.A. Scheeren, D. Sikka, J. Williams, The Indian Ocean experiment: widespread air pollution from South and Southeast Asia. Science 291, 1,031–1,036 (2001)

M.J. Loeffler, C.A. Dukes, R.A. Baragiola, Irradiation of olivine by 4 keV He+: Simulation of space weathering by the solar wind. J. Geophys. Res. 114, E03003 (2009). doi:10.1029/2008JE003249

S.G. Love, D.E. Brownlee, Heating and thermal transformation of micrometeorites entering the Earth’s atmosphere. Icarus 89, 26–43 (1991)

S.G. Love, D.E. Brownlee, Peak atmospheric entry temperatures of micrometeorites. Meteoritics 29, 69–70 (1994)

T. Mikouchi, M. Komatsu, K. Hagiya, K. Ohsumi, M.E. Zolensky, V. Hoffmann, J. Martinez, R. Hochleitner, M. Kaliwoda, Y. Terada, N. Yagi, M. Takata, W. Satake, Y. Aoyagi, A. Takenouchi, Y. Karouji, M. Uesugi, T. Yada, Mineralogy and crystallography of some Itokawa particles returned by the Hayabusa asteroidal sample return mission. Earth Planets Space 66, 82 (2014)

K. Nagao, R. Okazaki, T. Nakamura, Y.N. Miura, T. Osawa, K. Bajo, S. Matsuda, M. Ebihara, T.R. Ireland, F. Kitajima, H. Naraoka, T. Noguchi, A. Tsuchiyama, H. Yurimoto, M.E. Zolensky, M. Uesugi, K. Shirai, M. Abe, T. Yada, Y. Ishibashi, A. Fujimura, T. Mukai, M. Ueno, T. Okada, M. Yoshikawa, J. Kawaguchi, Irradiation history of Itokawa regolith material deduced from noble gases in the Hayabusa samples. Science 333, 1,128–1,131 (2011)

E. Nakamura, A. Makishima, T. Moriguti, K. Kobayashi, R. Tanaka, T. Kunihiro, T. Tsujimori, C. Sakaguchi, H. Kitagawa, T. Ota, Y. Yachi, T. Yada, M. Abe, A. Fujimura, M. Ueno, T. Mukai, M. Yoshikawa, J. Kawaguchi, Space environment of an asteroid preserved on micrograins returned by the Hayabusa spacecraft. Proc. Natl. Acad. Sci. 109, E624–E629 (2012)

T. Nakamura, T. Noguchi, M. Tanaka, M.E. Zolensky, M. Kimura, A. Tsuchiyama, A. Nakato, T. Ogami, H. Ishida, M. Uesugi, T. Yada, K. Shirai, A. Fujimura, R. Okazaki, S.A. Sandford, Y. Ishibashi, M. Abe, T. Okada, M. Ueno, T. Mukai, M. Yoshikawa, J. Kawaguchi, Itokawa dust particles: a direct link between S-type asteroids and ordinary chondrites. Science 333, 1,113–1,116 (2011)

H. Naraoka, H. Mita, K. Hamase, M. Mita, H. Yabuta, K. Saito, K. Fukushima, F. Kitajima, S.A. Sandford, T. Nakamura, T. Noguchi, R. Okazaki, K. Nagao, M. Ebihara, H. Yurimoto, A. Tsuchiyama, M. Abe, K. Shirai, M. Ueno, T. Yada, Y. Ishibashi, T. Okada, A. Fujimura, T. Mukai, M. Yoshikawa, J. Kawaguchi, Preliminary organic compound analysis of microparticles returned from Asteroid 25143 Itokawa by the Hayabusa mission. Geochem. J. 46, 61–72 (2012)

H. Naraoka, D. Aoki, K. Fukushima, M. Uesugi, M. Ito, F. Kitajima, H. Mita, H. Yabuta, Y. Takano, T. Yada, Y. Ishibashi, Y. Karouji, T. Okada, M. Abe, ToF-SIMS analysis of carbonaceous particles in the sample catcher of the Hayabusa spacecraft. Earth Planets Space 67, 67 (2015)

M.A. Nazarov, G. Kurat, F. Brandstaetter, T. Ntaflos, M. Chaussidon, P. Hoppe, Phosphorus-bearing sulfides and their associations in CM Chondrites. Petrology 17, 101–123 (2009)

K. Nishiyama, S. Hosoda, H. Koizumi, Y. Shimizu, I. Funaki, H. Kuninaka, M. Bodendorfer, J. Kawaguchi, Hayabusa’s way back to Earth by microwave discharge ion engines, in Proc. 46th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, AIAA 2010-6862 (2010)

K. Nishiyama, H. Kuninaka, Discussion on performance history and operations of Hayabusa ion engines, in Trans. Jpn. Soc. Aeronaut. Space Sci., Aerospace Tech. Jpn., vol. 10 (2012), Tb_1–Tb_8

T. Noguchi, T. Nakamura, M. Kimura, M.E. Zolensky, M. Tanaka, T. Hashimoto, M. Konno, A. Nakato, T. Ogami, A. Fujimura, M. Abe, T. Yada, T. Mukai, M. Ueno, T. Okada, K. Shirai, Y. Ishibashi, R. Okazaki, Incipient space weathering observed on the surface of Itokawa dust particles. Science 333, 1,121–1,125 (2011)

T. Noguchi, M. Kimura, T. Hashimoto, M. Konno, T. Nakamura, M.E. Zolensky, R. Okazaki, M. Tanaka, A. Tsuchiyama, A. Nakato, T. Ogami, H. Ishida, R. Sagae, S. Tsujimoto, T. Matsumoto, J. Matsuno, A. Fujimura, M. Abe, T. Yada, T. Mukai, M. Ueno, T. Okada, K. Shirai, Y. Ishibashi, Space weathered rims found on the surfaces of the Itokawa dust particles. Meteorit. Planet. Sci. 49, 188–214 (2014a)

T. Noguchi, M. Kimura, T. Hashimoto, M. Konno, T. Nakamura, M.E. Zolensky, A. Tsuchiyama, T. Matsumoto, J. Matsuno, R. Okazaki, M. Uesugi, Y. Karouji, T. Yada, Y. Ishibashi, K. Shirai, M. Abe, T. Okada, Sylvite and halite on particles recovered from 25143 Itokawa: a preliminary report. Meteorit. Planet. Sci. 49, 1305–1314 (2014b)

T. Okada, M.E. Zolensky, T. Ireland, T. Yada, Science of solar system materials examined from Hayabusa and future missions. Earth Planets Space 67, 116 (2015)

R. Okazaki, N. Takaoka, K. Nagao, T. Nakamura, Noble gases in enstatite chondrites released by stepped crushing and heating. Meteorit. Planet. Sci. 45, 339–360 (2010)

R. Okazaki, K. Nagao, Y.N. Miura, T. Osawa, K. Bajo, S. Matsuda, T. Nakamura, K. Shirai, M. Abe, T. Yada, T. Noguchi, Y. Ishibashi, A. Fujimura, T. Mukai, M. Ueno, T. Okada, M. Yoshikawa, J. Kawaguchi, Noble gases recovered from the Hayabusa sample container. Lunar Planet. Sci. XXXXII, 1653 (2011)

R. Okazaki, T. Noguchi, S. Tsujimoto, Y. Tobimatsu, T. Nakamura, M. Ebihara, S. Itoh, H. Nagahara, S. Tachibana, K. Terada, H. Yabuta, Mineralogy and noble gas isotopes of micrometeorites collected from Antarctic snow. Earth Planets Space 67, 90 (2015)

U. Ott, Noble gases in meteorites—trapped components, in Noble Gases in Geochemistry and Cosmochemistry, ed. by D. Porceli, C.J. Ballentine, R. Wieler. Reviews in Mineralogy and Geochemistry, vol. 47 (2002), pp. 71–96

V.K. Pearson, M.A. Sephton, I.A. Franchi, J.M. Gibson, I. Gilmour, Carbon and nitrogen in carbonaceous chondrites: elemental abundances and stable isotopic compositions. Meteorit. Planet. Sci. 41, 1,899–1,918 (2006)

K.L. Pering, C. Ponnamperuma, Aromatic hydrocarbons in the Murchison meteorite. Science 173, 237–239 (1971)

S. Pizzarello, X. Feng, S. Epstein, J.R. Cronin, Isotopic analyses of nitrogenous compounds from the Murchison meteorite: ammonia, amines, amino acids, and polar hydrocarbons. Geochim. Cosmochim. Acta 58, 5,579–5,587 (1994)

S. Pizzarello, L.B. Williams, J. Lehman, G.P. Holland, J.L. Yarger, Abundant ammonia in primitive asteroids and the case for a possible exobiology. Proc. Natl. Acad. Sci. 108, 4,303–4,306 (2011)

V. Ramanathan, P.J. Crutzen, J. Lelieveld, A.P. Mitra, D. Althausen, J. Anderson, M.O. Andreae, W. Cantrell, G.R. Cass, C.E. Chung, A.D. Clarke, J.A. Coakley, W.D. Collins, W.C. Conant, F. Dulac, J. Heintzenberg, A.J. Heymsfield, B. Holben, S. Howell, J. Hudson, A. Jayaraman, J.T. Kiehl, T.N. Krishnamurti, D. Lubin, G. McFarquhar, T. Novakov, J.A. Ogren, I.A. Podgorny, K. Prather, K. Priestley, J.M. Prospero, P.K. Quinn, K. Rajeev, P. Rasch, S. Rupert, R. Sadourny, S.K. Satheesh, G.E. Shaw, P. Sheridan, F.P.J. Valero, Indian Ocean experiment: an integrated analysis of the climate forcing and effects of the great Indo–Asian haze. J. Geophys. Res. 106(D22), 28,371–28,398 (2001)

T. Saiki, H. Sawada, C. Okamoto, H. Yano, Y. Takagi, Y. Akahoshi, M. Yoshikawa, Small carry-on impactor of Hayabusa2 mission. Acta Astronaut. 84, 227–236 (2013)

H. Sawada, R. Okazaki, C. Okamoto, H. Yano, Y. Miura, The sampling system of Hayabusa2 missions (abstract), in 63rd Int. Astronaut. Cong. IAC-12-A3.4.6 (2012)

M.A. Sephton, Organic compounds in carbonaceous meteorites. Natl. Prod. Rep. 19, 292–311 (2002)

M.A. Sephton, A.B. Vershovsky, P.A. Bland, I. Gilmour, M.M. Grady, I.P. Wright, Investigating the variations in carbon and nitrogen isotopes in carbonaceous chondrites. Geochim. Cosmochim. Acta 67, 2,093–2,108 (2003)

S. Sugita, D. Kuroda, S. Kameda, S. Hasegawa, S. Kamata, T. Hiroi, M. Abe, M. Ishiguro, N. Takato, M. Yoshikawa, Visible spectroscopic observations of asteroid 162173 (1999JU3) with the GEMINI-S telescope. Lunar Planet. Sci. Conf. 44, 2591 (2013)

T.D. Swindle, Noble gases in the moon and meteorites: radiogenic components and early volatile chronologies, in Noble Gases in Geochemistry and Cosmochemistry, ed. by D. Porceli, C.J. Ballentine, R. Wieler. Reviews in Mineralogy and Geochemistry, vol. 47 (2002), pp. 101–124

S. Tachibana, M. Abe, M. Arakawa, M. Fujimoto, Y. Iijima, M. Ishiguro, K. Kitazato, N. Kobayashi, N. Namiki, T. Okada, R. Okazaki, H. Sawada, S. Sugita, Y. Takano, S. Tanaka, S. Watanabe, M. Yoshikawa, H. Kuninaka, The Hayabusa2 project team, Hayabusa2: scientific importance of samples returned from C-type near-Earth asteroid (162173) 1999 \(\mathrm{JU}_{3}\). Geochem. J. 48, 571–587 (2014)

Y. Takano, K. Yamada, T. Saiki, M. Hayakawa, H. Imamura, M. Abe, K. Tanaka, M. Arakawa, T. Nakamura, H. Sugahara, R. Okazaki, T. Sawada, S. Tachibana, Abiotic formation of amorphous carbonaceous particles by a HMX (cyclotetramethylenetetranitramine) explosion experiment: implication from organic matter and the quench effect, in Hayabusa 2014: 2nd Symp. Solar System Materials, P03 (2014)

Y. Takano, K. Yamada, C. Okamoto, K. Sakamoto, T. Sawada, R. Okazaki, S. Tachibana, Assessing organic molecules during a deflagration process with quenching effect, in Hayabusa 2015: 3rd Symp. Solar System Materials, P07 (2015)

H. Takeda, H. Nagaoka, A. Yamaguchi, Y. Karouji, Y. Yazawa, Mineralogy of some evolved LL chondrites with reference to asteroid materials and solar system evolution. Earth Planets Space 67, 5 (2015)

M.S. Thompson, R. Christoffersen, T.J. Zega, L.P. Keller, Microchemical and structural evidence for space weathering in soils from asteroid Itokawa. Earth Planets Space 66, 89 (2014)

A. Tsuchiyama, M. Uesugi, T. Matsushima, T. Michikami, T. Kadono, T. Nakamura, K. Uesugi, T. Nakano, S.A. Sandford, R. Noguchi, T. Matsumoto, J. Matsuno, T. Nagano, Y. Imai, A. Takeuchi, Y. Suzuki, T. Ogami, J. Katagiri, M. Ebihara, T.R. Ireland, F. Kitajima, K. Nagao, H. Naraoka, T. Noguchi, R. Okazaki, H. Yurimoto, M.E. Zolensky, T. Mukai, M. Abe, T. Yada, A. Fujimura, M. Yoshikawa, J. Kawaguchi, Three-dimensional structure of Hayabusa samples: origin and evolution of Itokawa regolith. Science 333, 1,125–1,128 (2011)

Y. Tsuda, M. Yoshikawa, M. Abe, H. Minamino, S. Nakazawa, System design of the Hayabusa 2—asteroid sample return mission to 1999 \(\mathrm{JU}_{3}\). Acta Astronaut. 91, 356–362 (2013)

M.A. Tyra, J. Farquhar, B.A. Wing, G.K. Benedix, A.J.T. Jull, T. Jackson, M.H. Thiemens, Terrestrial alteration of carbonate in a suite of Antarctic CM chondrites: evidence from oxygen and carbon isotopes. Geochim. Cosmochim. Acta 71, 782–795 (2007)

M. Uesugi, H. Naraoka, M. Ito, H. Yabuta, F. Kitajima, Y. Takano, H. Mita, I. Ohnishi, Y. Kebukawa, T. Yada, Y. Karouji, Y. Ishibashi, T. Okada, M. Abe, Sequential analysis of carbonaceous materials in Hayabusa-returned samples for the determination of their origin. Earth Planets Space 66, 102 (2014)

F. Vilas, Spectral characteristics of Hayabusa 2 near-Earth asteroid targets 162173 1999 JU3 and 2001 QC34. Astron. J. 135, 1,101–1,105 (2008)

P. Warneck, Chemistry of the Natural Atmosphere. International Geophysics Series, vol. 41 (Academic Press, New York, 1988), p. 757

R. Wieler, Noble gases in the solar system, in Noble Gases in Geochemistry and Cosmochemistry, ed. by D. Porceli, C.J. Ballentine, R. Wieler. Reviews in Mineralogy and Geochemistry, vol. 47 (2002a), pp. 21–70

R. Wieler, Cosmic-ray-produced noble gases in meteorites, in Noble Gases in Geochemistry and Cosmochemistry, ed. by D. Porceli, C.J. Ballentine, R. Wieler. Reviews in Mineralogy and Geochemistry, vol. 47 (2002b), pp. 125–170

H. Yabuta, M. Uesugi, H. Naraoka, M. Ito, A.L.D. Kilcoyne, S.A. Sandford, F. Kitajima, H. Mita, Y. Takano, T. Yada, Y. Karouji, Y. Ishibashi, T. Okada, M. Abe, X-ray absorption near edge structure spectroscopic study of Hayabusa category 3 carbonaceous particles. Earth, Planets Space 66, 156 (2014)

T. Yada, A. Fujimura, M. Abe, T. Nakamura, T. Noguchi, R. Okazaki, K. Nagao, Y. Ishibashi, K. Shirai, M.E. Zolensky, S. Sandford, T. Okada, M. Uesugi, Y. Karouji, M. Ogawa, S. Yakame, M. Ueno, T. Mukai, M. Yoshikawa, J. Kawaguchi, Hayabusa-returned sample curation in the Planetary Material Sample Curation Facility of JAXA. Meteorit. Planet. Sci. 49, 135–153 (2014a)

T. Yada, M. Abe, M. Uesugi, Y. Karouji, K. Kumagai, W. Satake, Y. Ishibashi, A. Nakato, T. Okada, A nature of particles in the Hayabusa sample catcher and contamination controls for Hayabusa 2 sample containers, in 77th Annual Meteoritical Society Meeting, (2014b), p. 5239

T. Yamada, K. Yoshihara, K. Yamada, Development of a Hayabusa-2 sample return capsule, in 30th ISTS, ISTS-2015-K-62 (2015)

K. Yanai, H. Kojima, Catalog of the Antarctic Meteorites Collected from December 1969 to December 1994 with Special Reference to Those Represented in the Collections of the National Institute of Polar Research (National Institute of Polar Research, Tokyo, 1995), p. 230

G. Yuen, N. Blair, D.J. DesMarias, S. Chang, Carbon isotope composition of low molecular weight hydrocarbons and monocarboxylic acids from Murchison meteorite. Nature 307, 252–254 (1984)

H. Yurimoto, K. Abe, M. Abe, M. Ebihara, A. Fujimura, M. Hashiguchi, K. Hashizume, T.R. Ireland, S. Itoh, J. Katayama, C. Kato, J. Kawaguchi, N. Kawasaki, F. Kitajima, S. Kobayashi, T. Meike, T. Mukai, K. Nagao, T. Nakamura, H. Naraoka, T. Noguchi, R. Okazaki, C. Park, N. Sakamoto, Y. Seto, M. Takei, A. Tsuchiyama, M. Uesugi, S. Wakaki, T. Yada, K. Yamamoto, M. Yoshikawa, M.E. Zolensky, Oxygen isotopic compositions of asteroidal materials returned from Itokawa by the Hayabusa mission. Science 333, 1,116–1,119 (2011)

Acknowledgment

We thank the two anonymous reviewers for their helpful comments which improved the clarity of the paper. K. N. acknowledges the Ministry of Science, ICT and Planning (MSIP) of Korea, for supporting preparation of the paper.

Author information

Authors and Affiliations

Consortia

Corresponding author

Rights and permissions

About this article

Cite this article

Okazaki, R., Sawada, H., Yamanouchi, S. et al. Hayabusa2 Sample Catcher and Container: Metal-Seal System for Vacuum Encapsulation of Returned Samples with Volatiles and Organic Compounds Recovered from C-Type Asteroid Ryugu. Space Sci Rev 208, 107–124 (2017). https://doi.org/10.1007/s11214-016-0289-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11214-016-0289-5